Beltrame S2007 User manual

MANUALE S2007 PRELIMINARE.DOC

PAG.2/21

Contents

Contents ..................................................................................................... 2

Important Notice ........................................................................................ 3

1. SAFETY INSTRUCTIONS ...................................................................... 4

1.1 General .................................................................................................... 4

1.2 Safety Instructions..................................................................................... 5

2. DEVICE DESCRIPTION ........................................................................ 6

2.1 Introduction .............................................................................................. 6

2.2 Hardware.................................................................................................. 6

2.2.1 Control elements and interfaces .......................................................... 7

2.2.2 Device connections CN3 ..................................................................... 9

2.2.3 Device connections CN5 ................................................................... 10

2.2.4 Device connections CN2 ................................................................... 10

2.2.5 Device connections CN4 ................................................................... 11

3. OPERATOR INTERFACE ..................................................................... 12

3.1 Set or change parameters......................................................................... 12

3.2 Navigating the menus .............................................................................. 13

3.3 Menu...................................................................................................... 14

3.3.1 Menu d - Display ............................................................................. 14

3.3.2 Menu P - Parameters........................................................................ 14

4. Running the engine........................................................................... 16

4.1 Running the engine .................................................................................. 16

4.1.1 Starting the engine .......................................................................... 16

4.1.2 Governor Performance ..................................................................... 16

4.2 Additional features................................................................................... 17

4.2.1 Real-Time Display............................................................................ 17

4.2.2 Idle Speed ...................................................................................... 17

4.2.3 Speed Droop Operation .................................................................... 17

4.2.4 Overspeed ...................................................................................... 17

4.2.5 Loss of Magnetic Pickup Sensing........................................................ 18

4.2.6 Variable Speed Inputs ...................................................................... 18

5. System troubleshooting .................................................................... 19

5.1 System inoperative .................................................................................. 19

5.2 Insufficient Magnetic Speed Signal ............................................................. 19

5.3 Electromagnetic Compatibility (EMC)................................................................ 19

5.4 Instability ................................................................................................. 20

6. Specifications ................................................................................... 21

6.1 Performance............................................................................................ 21

6.2 Enviromental........................................................................................... 21

6.3 Compliance/ standards ............................................................................. 21

6.4 Input/output ........................................................................................... 21

6.5 Reliability ............................................................................................... 21

6.6 Physical .................................................................................................. 21

MANUALE S2007 PRELIMINARE.DOC

PAG.3/21

Important Notice

Our experience has shown that, if the information and recommendations contained

in this Operating Instructions are observed, the best possible reliability of our

products is assured.

The data contained herein purports solely to describe the product and is not a

warranty of performance or characteristics. It is with the best interests of our

customers in mind that we constantly strive to improve our products and keep them

abreast of advances in technology. This may, however, lead to discrepancies

between a product and its "Technical Description" or " Operating Instructions".

This document has been carefully prepared and reviewed, however should in spite of

this the reader find an error, he is requested to inform us at his earliest convenience.

It is scarcely possible for the operating instructions for technical equipment to cover

every eventuality, which can occur in practice. We would therefore request you to

notify us or our agent in the case of all unusual behaviour that does not appear to be

covered by these operating instructions.

It is pointed out that all local regulations must be observed when connecting and

commissioning this equipment in addition to these operating instructions.

We cannot accept any responsibility for damage incurred as a result of mishandling

the equipment regardless of whether particular reference is made in these operating

instructions or not.

We lay particular stress on the fact that only genuine spare parts should be used for

replacements.

All rights with respect to this document, including applications for patent and

registration of other industrial property rights, are reserved. Unauthorized use, in

particular reproduction or making available to third parties, is prohibited.

Manufacturer’s address

MANUALE S2007 PRELIMINARE.DOC

PAG.4/21

1. SAFETY INSTRUCTIONS

1.1 General

The safety instructions shall be followed during installation, commissioning, operation and

maintenance. Read all instructions carefully before operating the device and keep this

manual for future reference.

Required Qualification

Personnel involved in installation work and commissioning of the S2007 must be

familiar, specially instructed and informed about the residual danger areas according

to the regulations currently in force.

Operating personnel is not permitted to work at the control system.

Specially instructed personnel must only carry out maintenance and repair work.

The maintenance personnel must be informed about the emergency shutdown

measures and must be capable of turning off the system in case of emergency.

The maintenance personnel must be familiar with the accident prevention measures

at their workplace and must be instructed in first aid and fire fighting.

It is the owner’s responsibility to ensure that each person involved in the installation

and commissioning of the S2007 has received the appropriate training or instructions

and has thoroughly read and clearly understood the safety instructions in this

chapter.

MANUALE S2007 PRELIMINARE.DOC

PAG.5/21

1.2 Safety Instructions

The safety instructions always appear at the beginning of each chapter and/or

precede any instruction in the context where a potentially dangerous situation may

appear. The safety instructions are divided into five categories and emphasized by

the use of the following layout and safety signs:

DANGER!

This symbol indicates an imminent danger resulting from

mechanical forces or high voltage. A non-observance leads to

life-threatening physical injury or death.

WARNING!

This symbol indicates a dangerous situation. A non-observance

may lead to bad or life-threatening physical injury or death.

CAUTION!

This symbol indicates a dangerous situation. A non-observance

may lead to physical injury or cause damage to the device.

NOTICE!

This symbol emphasizes important information. A non-

observance may cause damage to the device or to objects close

to it.

IMPORTANT!

This symbol indicates useful information. Not to be used to

indicate dangerous situations.

MANUALE S2007 PRELIMINARE.DOC

PAG.6/21

2. DEVICE DESCRIPTION

2.1 Introduction

The S2007 is an electronic device designed to control engine speed with fast and

precise response to transient load changes.

This closed loop control, when connected to a proportional electric actuator and

supplied with a magnetic speed sensor signal, will control a wide variety of engines in

an isochronous or droop mode.

It is designed for high reliability and built ruggedly to withstand the engine

environment.

A practical and simple-to-operate panel on the unit is used for all control operations.

In addition, user-friendly software facilitates commissioning and allows optimization

of operation.

The mechanical construction is compact and robust.

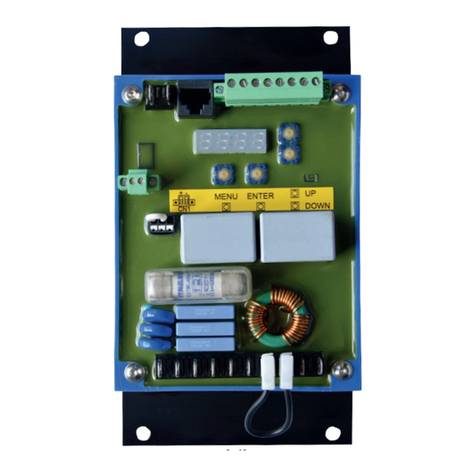

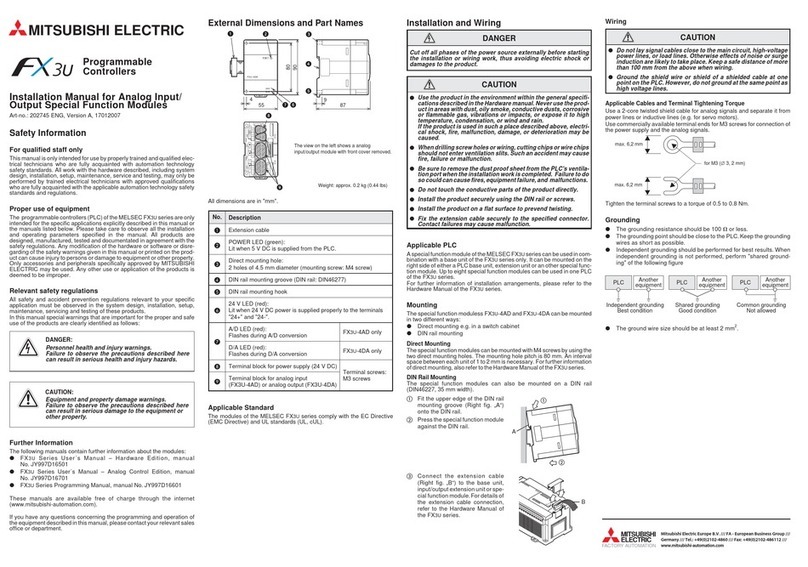

2.2 Hardware

Structure:

The device, placed inside a plastic box, is submerged in resin allowing so the

maximum resistance against engine vibrations and a reliability with time.

Control elements:

A 4 digit 7-segment display is located on it in order to allow an easy visualization of

parameters. The use of push buttons placed at the side and below the display allows

to scroll the menu of all parameters and to set those of interest.

Installation:

Mounting:

The S2007 is designed for wall mounting on a metal panel.

Mounting on a non-dissipative surface such as a plastic panel may lead to device

overheating and is to be avoided.

For optimal cooling is to keep free a minimum distance of 100 mm all around the

unit.

Connection diagram:

Basic electrical connections are illustrated in the figure below.

MANUALE S2007 PRELIMINARE.DOC

PAG.7/21

2.2.1 Control elements and interfaces

Carrying out settings on the unit

The display and the four keys are sufficient to allow complete operation.

All settings can be carried out directly on the unit without additional equipment

Input/Output configuration

Parameter setting

Display of main measures.

MANUALE S2007 PRELIMINARE.DOC

PAG.8/21

Terminal blocks

Overview of full device connections

CN2 –CAN BUS interface

1. CAN H

2. CAN L

3. GND CAN

4. n.c.

5. n.c.

6. n.c.

7. GND CAN

8. n.c.

CN3 –Inputs/Outputs

1. Actuator -

2. Actuator +

3. Battery –(GND/COM)

CN4 –RS232 interface

1. Reserved (do NOT use!)

2. Tx

3. Rx

4. Reserved (do NOT use!)

5. GND

6. Reserved (do NOT use!)

7. Reserved (do NOT use!)

8. Reserved (do NOT use!)

9. Reserved (do NOT use!)

CN5 –Inputs/Outputs

1. Digital input (COM=GND)

2. Digital input (COM=GND)

MANUALE S2007 PRELIMINARE.DOC

PAG.9/21

4. Battery + (12÷24Vdc)

5. Out aux (Solenoid valve)

6. Pickup +

7. Pickup –

8. UP (COM=GND)

9. DOWN (COM=GND)

10. IDLE (COM=GND)

3. GND/COM

4. Analog input 0÷10V

5. Supply output +10V (max 20mA)

6. Analog input 4÷20mA

7. Analog input -5÷5V

8. GND/COM

n.c. = not connected

2.2.2 Device connections CN3

Terminal designation

Signal

Specifications

Actuator

DC output

12÷24Vdc

0÷12 A (15A for 10s)

Solenoid valve

Digital output

12÷24Vdc

2Amax

Pickup

Passive pickup

Active pickup

or

Up

Digital Input

Down

Digital Input

IDLE

Digital Input

MANUALE S2007 PRELIMINARE.DOC

PAG.10/21

2.2.3 Device connections CN5

Terminal designation

Signal

Specifications

Digital inputs

2 digital inputs

programmable function

Analog inputs

analog input

0÷10Vdc

(Potentiometer

=2k÷ 5k

0,25W)

analog input

4÷20mA

analog input

-5V ÷ +5V

2.2.4 Device connections CN2

Terminal designation

Signal

Specifications

Communication

CAN

selectable termination

MANUALE S2007 PRELIMINARE.DOC

PAG.11/21

CANopen and proprietary

protocols

2.2.5 Device connections CN4

Terminal designation

Signal

Specifications

Communication

RS232

NOTICE!

To connect a device such as a notebook or a personal computer to S2007

Speed Digital Governor,proprietary USB/RS232 adapter or proprietary

RS232/RS232 adapter shall be

MANUALE S2007 PRELIMINARE.DOC

PAG.12/21

3. OPERATOR INTERFACE

In this following charter are described the operations of management parameter

using the integrated display.

3.1 Set or change parameters

Many parameter can be accessed using the integrated display and keys.

SCROL Change menu parameter set (d.xxx and P.xxx)

ENTER Select or save current displayed parameter

UP Increase parameter number or value

DOWN Decrease parameter number or value

MANUALE S2007 PRELIMINARE.DOC

PAG.13/21

3.2 Navigating the menus

When the S2007 is power on, the display automatically shows parameter d.000 (Engine

speed) in the Display menu.

Example: how to change a SPEED reference

MANUALE S2007 PRELIMINARE.DOC

PAG.14/21

3.3 Menu

3.3.1 Menu d - Display

Display

Name

Description

[Units]

D.000

Engine speed

Actual engine speed

rpm

D.001

Speed set

Speed set point

rpm

D.002

Actuator current

Current supplied to actuator

A

D.003

Actuator voltage

Voltage supplied to actuator

V

D.004

Input 0-10V

0-10V analog input voltage

V

D.005

Input 4-20mA

4-20mA analog input current

mA

D.006

V Batt

Battery voltage

V

D.007

Firmware version

3.3.2 Menu P - Parameters

Parameter

Name

Description

[Units]

Default

Range

P.000

Speed

Engine speed Set Point

Rpm

1500

1200 - 4000

P.001

Kp

(GAIN)

Proportional (P) gain for

PID control loop

20 - 5000

P.002

Ki

(STABILITY)

Integral (I) gain for PID

control loop

0 - 5000

P.003

Kd

(DEADTIME)

Derivative (D)gain for PID

control loop

0 - 5000

P.004

IDLE

Engine speed in Idle mode

Rpm

1300

1000 - 4000

P.005

Crank

Crank termination

threshold: RPM when the

governor changes from

crank mode to control

mode

Rpm

1200

1000 - 4000

P.006

Over speed

Over speed: RPM when

actuator is shut off for

safety reason

Rpm

1700

1350 - 4750

P.007

Start fuel

Starting fuel: preset utput

voltage to actuator when

crank begins

100%

0,5% - 100%

P.008

Speed ramp

Rate throttle at which is

ramped open during start

10%

0-100%

P.009

Droop

Droop at maximun load

current (based on duty

cycle of the actuator)

1,5 %

0,1% - 8%

P.010

Max current

Max actuator current

A

10

1 - 15

P.011

Overload time

Time before current is

clamped to Max value

(P.010)

10s

0,5s –60s

P.012

Variable speed

control

Maximum speed change

from analog inputs

3%

0% - 100%

P.013

Teeth

Number of teeth on

flywheel

60

10 - 1000

MANUALE S2007 PRELIMINARE.DOC

PAG.15/21

P.014

Rate

Time between calls to PID

control loop

20

1 - 200

P.015

Reset

To reset the device, enter

the number “333” in

parameter P.015

MANUALE S2007 PRELIMINARE.DOC

PAG.16/21

4. RUNNING THE ENGINE

4.1 Running the engine

4.1.1 Starting the engine

Before cranking engine, supply DC power to governor system, then actuator will be pre-set as

defined by START FUEL parameter (P.007, default value is maximum fuel rate).

Starting Ramp (P.007), will then control the rate at which fuel is increased during engine

cranking.

NOTICE!

if engine speed is unstable after start up, adjust GAIN (P.001),

STABILITY (P.002), and DEADTIME COMPENSATION (P.003) until

engine speed is stabilized.

Poor PID settings can affect this response so tune the system at

normal operating speeds before setting the starting parameters (see

below).

4.1.2 Governor Performance

Once the engine is at operating speed and at no load, the following governor performance

adjustment can be made.

A. Increase GAIN parameter until motor speed reachs instability. Gradually decrease the

Gain until stability is recovered. Decrease one count further to insure stable

performance.

B. Increase STABILITY parameter until motor speed reachs instability. Gradually

decrease Stability until stability is recovered. Decrease one count further to insure

stable performance.

C. Increase DEADTIME parameter until motor speed reachs instability. Gradually

decrease Deadtime until stability is recovered. Decrease one count further to insure

stable performance.

D. GAIN, STABILITY and DEADTIME small adjustments may be required after load is

applied to engine. Normally, adjustments made in no load conditions achieve

satisfactory performance.

MANUALE S2007 PRELIMINARE.DOC

PAG.17/21

4.2 Additional features

4.2.1 Real-Time Display

While engine runs, S2007 Digital Speed Governor can display real time measures and other

useful information (see table below). Cycle through the table with UP / DOWN keys.

Display

Parametet

Description

Units

D.000

Engine speed

Actual engine speed

rpm

D.001

Speed set

Speed set point

rpm

D.002

Actuator current

Actual actuator current

A

D.003

Actuator voltage

Actual actuator voltage

V

D.004

Input 0-10V

0-10V input voltage

V

D.005

Input 4-20mA

4-20mA input current

mA

D.006

V Batt

Battery voltage

V

D.007

Firmware version

4.2.2 Idle Speed

To adjust IDLE speed, shut down engine,

place optional external switch in IDLE position

then restart engine. Once started, IDLE speed

set point can be calibrated through IDLE

parameter (P.004).

4.2.3 Speed Droop Operation

Droop is typically used with parallel of several engine driven generators.

With S2007 governor powered off,

place optional external selector

switch in DROOP position, then start

engine. While engine is running,

DROOP can be adjusted by DROOP

parameter (P.007). In DROOP MODE

engine speed will decrease as engine

load increases. The percentage of

droop is based on the change in

current in the actuator from no load

to full load (DRNG in the Special

Menu).

4.2.4 Overspeed

When the S2007 detects engine has reached the

speed specified by the OVERSPEED parameter

(P.006), the S2007 will force the speed to 0

RPM, will set the actuator output to 0V and, if

enabled, open the solenoid valve. OVERSPEED

is a Menu parameter, and is expressed in RPM.

Notice!

If incorrect tooth count is entered

the OverSpeed setting may not be

what is desired so never rely on

this function as the ultimate

equipment protection.

MANUALE S2007 PRELIMINARE.DOC

PAG.18/21

If the running speed of the engine reaches the OVERSPEED set point, while the

system is in a running state, the S2007 will stop outputting a signal to the actuator

for a zero fuel command and will no longer attempt to control the engine.

After the S2007 has detected an overspeed, the display will flash

the RPM along with the warning and OVERSPEED indicators. No

parameters will be allowed to be changed.

To re-activate the S2007, DC power must be turned off then back

on to reset the control.

4.2.5 Loss of Magnetic Pickup Sensing

If the S2007 is commanding the actuator to move and detects no input from the

magnetic pickup, the S2007 will set the actuator to 0V and command the speed to 0

RPM.

After the S2007 has detected loss of magnetic pickup, the display

will flash the RPM along with the warning indicator.

No parameters will be allowed to be changed.

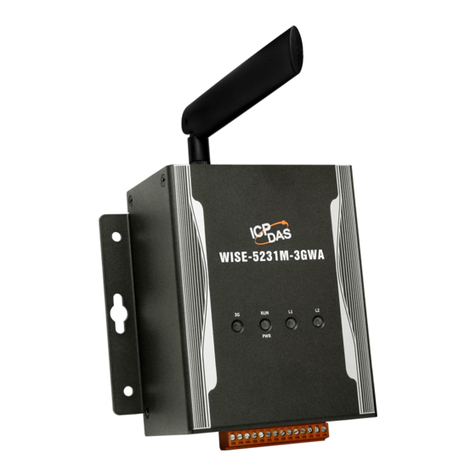

4.2.6 Variable Speed Inputs

The S2007 is equipped with four inputs for variable speed.

1. analog input 0÷10V. This input accepts a 2÷5K potentiometer connected between

terminals 3,4 and 5 of CN5.

2. analog input 4÷20mA. The terminals used are 6 and 8 of CN5.

3. analog input -5V ÷ +5V. The terminals used are 7 and 8 of CN5.

4. digital inputs: terminal 8 for UP and terminal 9 for DOWN of CN3 (closed to ground).

Generally, these inputs are used to perform fine tuning of generator frequency or in

conjunction with other governor system accessories such as load sharing units,

synchronizers, etc. Variable speed function is used to operate over a larger RPM range.

MANUALE S2007 PRELIMINARE.DOC

PAG.19/21

5. SYSTEM TROUBLESHOOTING

5.1 System inoperative

If the engine governing system does not function, the fault may be determined by performing

the voltage tests described in Steps 1 through 3. Positive (+) and negative (-) refer to meter

polarity. Should normal values be indicated during troubleshooting steps, then the fault may

be with the actuator or the wiring to the actuator. Tests are performed with battery power on

and the engine off, except where noted. See actuator publication for testing procedure on the

actuator.

Step

Wires

Normal reading

Probable cause of abnormal reading

1

CN3-3 Battery –(GND)

CN3-4 Battery +

Battery supply voltage

(12 or 24V dc)

1. DC battery power not connected. Check

for blown fuse

2. Low battery voltage

3. Wiring error

2

CN3-6

CN3-7

1Vac RMS minimum

while cranking

1. Gap between speed sensor and gear

teeth too great Check gap

2. Improper or defective wiring to the speed

sensor

3. Resistance between 6 and 7 (CN3) should

be 30 to 1200 ohms. See specific

magnetic pickup data for resistance

4. Defective speed sensor.

5.2 Insufficient Magnetic Speed Signal

A strong magnetic speed sensor signal will eliminate the possibility of missed or extra pulses.

A speed sensor signal of 1VAC RMS or greater at cranking speed is required. Measure the

signal at Terminals 6 and 7 (CN3). Shielding of the pickup wires is recommended.

The amplitude of the speed sensor signal can be raised by reducing the gap between the

speed sensor tip and the engine ring gear. The gap should not be any smaller than 0,45 mm.

When the engine is stopped, back the speed sensor out by 3/4 turn after touching the ring

gear tooth to achieve a satisfactory air gap.

5.3 Electromagnetic Compatibility (EMC)

EMI SUSCEPTIBILITY - The governor system is rated for CE levels per EN50082-1 and

EN50082-2. However, it can be adversely affected by large interfering signals that are

conducted through the cabling or through direct radiation into the control circuits.

Although regulation of emitting devices is better controlled today it is still difficult to predict

levels of interference, applications that include magnetos, solid sate ignition systems, radio

transmitters, voltage regulators or battery chargers and they should be considered as suspect

as possible interfering sources. If it is suspected that external fields, either those that are

radiated or conducted, are or will affect the governor systems operation, it is recommended

to use shielded cable for all external connections to the control Terminals. Be sure that only

one end of the shields, including the speed sensor shield, is connected to a single point on

the case of the speed control unit. Mount the speed control to a grounded metal back plate or

place it in a sealed metal box.

Radiation is when the interfering signal is radiated directly through space to the governing

system. A metal shield or a solid metal container is usually effective for this interference.

Conduction is when the interfering signal is conducted through the interconnecting wiring.

Shielded cables and installing filters are common remedies.

MANUALE S2007 PRELIMINARE.DOC

PAG.20/21

5.4 Instability

Instability in a closed loop speed control system can be categorized into two general types.

PERIODIC appears to be sinusoidal and at a regular rate. NON-PERIODIC is a random

wandering or an occasional deviation from a steady state band for no apparent reason.

The PERIODIC type can be further classified as fast or slow instability. Fast instability is a 3

Hz. or faster irregularity of the speed and is usually a jitter. Slow periodic instability is below

3 Hz., can be very slow, and is sometimes violent.

If fast instability occurs, this is typically the governor responding to engine firings. Raising

the engine speed increases the frequency of instability and vice versa. In this case, readjust

the GAIN and STABILITY for optimum control. In extreme cases, this may not take all the

jitter out of the system. In this case, decrease the DEADTIME parameter.

Slow instability can have many causes. If slow instability exists, verify the SOFT Special

Menu parameter is disabled. If this is unsuccessful, it is possible to decrease the update rate

of the controller. This is done by decreasing the RATE Advanced parameter. This should be

done with extreme caution and in single increments. Each time RATE is changed, the

GAIN, STABILITY, and DEADTIME must be re-adjusted.

If slow instability is unaffected by this procedure, evaluate the fuel system and engine

performance. Check the fuel system linkage for binding, high friction, or poor linkage is the

moist likely cause. Be sure to check linkage during engine operation. Also look at the engine

fuel system. Irregularities with carburetion or fuel injection systems can change engine power

with a constant throttle setting. This can result in speed deviations beyond the control of the

governor system. Adding a small amount of droop can help stabilize the system for

troubleshooting purposes.

NON-PERIODIC instability should respond to the GAIN control. If increasing the Gain

reduces the instability, then the problem is probably with the engine. Higher gain allows the

governor to respond faster and try to correct for disturbance. Look for engine mis-firings, an

erratic fuel system, or load changes on the engine generator set voltage regulator.

If unsuccessful in solving instability, contact Beltrame CSE for assistance.

Other manuals for S2007

1

Table of contents

Other Beltrame Controllers manuals

Popular Controllers manuals by other brands

iNels

iNels RFWB-20/G quick start guide

Marshall Excelsior

Marshall Excelsior MEGR-167CH/751 instruction manual

Moons'

Moons' LIN ENGINEERING Silverpak 17C user manual

Ascon tecnologic

Ascon tecnologic TLZ35 operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley 1512A user manual

ZyXEL Communications

ZyXEL Communications Network Device NXC-8160s quick start guide