bemodern PRYZM 5D 1000L Guide

1

Instructions for installation

Patent pending

UK Registered Design

R1 Aug 2019 200789_1

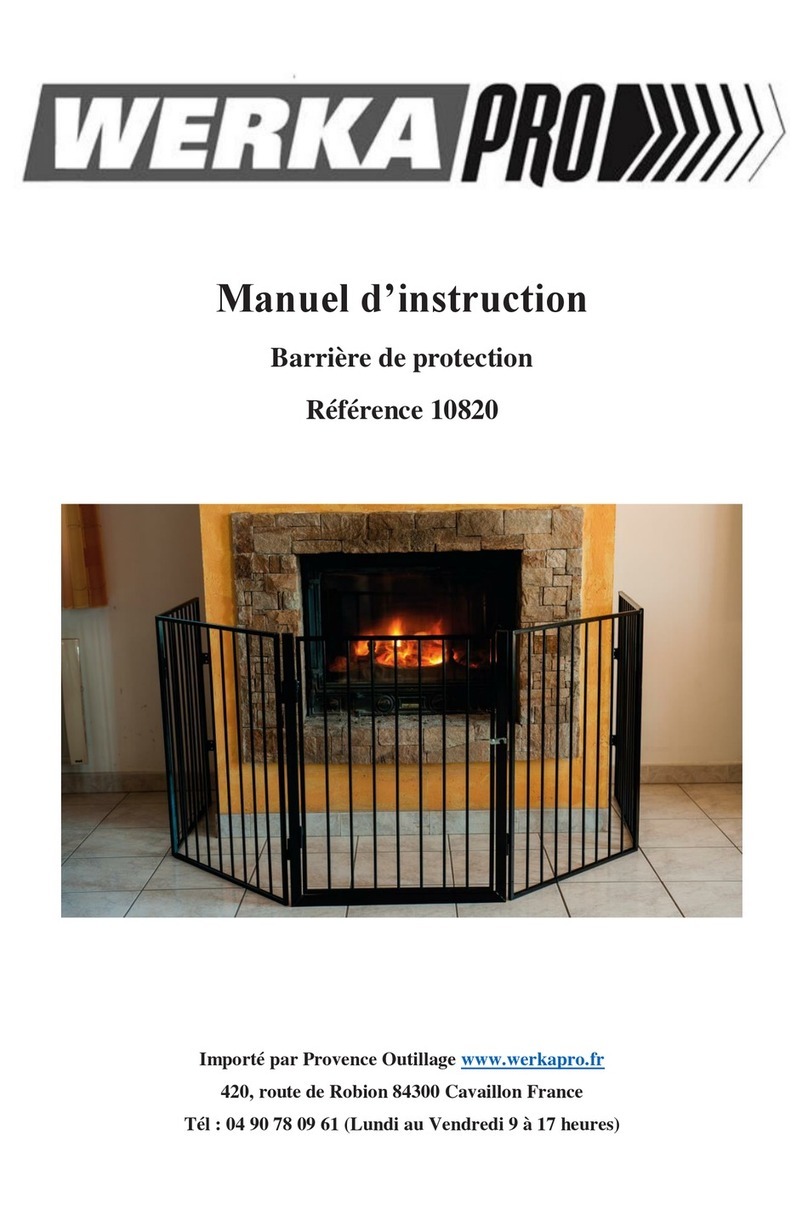

Camino- Chimney Breast

Plinth/ No Plinth Options

2

Contents

Technical Specification 3

What is in the Boxes 4 –5

Installation- Introduction 5

Installation- Including Optional Plinth 6

Installation- Excluding Optional Plinth 7

Assembly- Hanging System 8

Assembly- Decorative Panel 9-11

Assembly- Framework 12-13

Assembly- Hearth 13

Assembly- Hearth & Framework 14

Installation- Fixing To The Wall 15-16

Installation- Fixing The Fire 17

Installation- Fitting The Decorative Panels 18

Maintenance / Troubleshooting 19

200789_1

Excluding

Plinth

Including

Plinth

Ceiling

(Without

Coving)

Ceiling (Without Coving)

Floor

3

Technical Specification

200789_1

Fire Description Logs

Dimensions

A B C D E

53” CAMINO

CHIMNEY BREAST

PRYZM 5D 1000L

Timber

Wall mounted:

Excluding Plinth

4 LRG

1220mm 2009mm

290mm 1350mm 212mm

53” CAMINO

CHIMNEY BREAST

PRYZM 5D 1000L

Timber

Floor standing:

Including

Removable

Plinth

4 LRG

1220mm 2253mm

290mm 1350mm 212mm

Note: All dimensions stated above are the minimum requirements for installation in rooms without coving

installed. The chimney breast can be installed in rooms with ceiling heights greater than these dimensions.

For installation excluding the plinth adjust the installation dimensions on Page 7 accordingly and for

installation including the plinth follow the installation dimensions on Page 6.

4

200789_1

What Is In The Boxes?

4 X

Locating Clips

2 X

Fire Mounting Brackets

Box- 024287 1000L PRYZM Fire Engine x 1, Logs x 4, Fire Remote x1

Box -031658 Optional Plinth x 1

Box- 029920

Component “A” Wall Fixing Panel x 1

Component “B” Light Bleed Cover x 1

Component “C” Large Decorative Panel x 1

Components “D” & “E” Small Decorative Panel x 2

Component “F” Panel Top Fixing Rail x 1

Component “G” Panel Bottom Fixing Rail x 1

Component “H” Heat Deflector x 1

Box- 029890

Components “J” & “K” Assembled Column Front and Sides x 2

BOX –029882

Component “L” Front Top Fixing Rail x 1

Component “M” Rear Fixing Rail x 1

Component “N” Front Bottom Fixing Rail x 1

Component “P” Assembled Floating Hearth with Pre-installed LED Lights x1

Also included in Box 029882 are two smaller boxes with all the hardware (pins and dowels

etc.), the plug and remote for the pre-installed under hearth lighting and the two wall

hanging brackets for hanging the fire. See below and overleaf.

1 X

Remote For Under

Hearth Lighting

1 X

Plug For Under

Hearth Lighting

1 X

CR2025 3V Battery For

Remote

5

200789_1

4x

3.5mm X 9.5mm

Pozi Flange Head Screws

12 X

No.8 x 30mm

C/Sunk Screws

30 X

No.8 x15mm

Domed-Head

Screws

18 X

6 x 34mm

Pins

12 X

8 x 30mm

Dowels

What Is In The Boxes Continued…

Installation –Introduction

Note: The chimney breast is a two adult person lift. A second person will be required to lift and

support the chimney breast during installation.

Before the chimney breast can be installed, consideration will need to be given to routing the

power supply to the fire. This will affect the stages of the installation process. We advise a qualified

electrician conduct any electrical parts of the installation.

Note: A double wall socket is required for the operation of the chimney breast.

Unpack your new chimney breast and locate the Wall Fixing Panel- Component “A”- Box 029920.

The Wall Fixing Panel- is to be used so the weight of the components can be distributed across a

larger area and enable the installer to achieve a good solid fix to the wall in various points across

the panel as detailed in the following instructions.

The first step to installation will be the fitment of the Wall Fixing Panel- Component “A”, in the

desired position in the room. The installation procedure will be dependant on the variation of

chimney breast purchased.

Installation including an optional plinth- Minimum ceiling height required is 2300mm.

Follow Diagram 1- Page 6, then continue to Page 8

Installation excluding an optional plinth- Minimum ceiling height required is 2160mm.

Follow Diagram 2- Page 7, then continue to Page 8

Please ensure all fixings are present before commencing installation. If anything is missing please

If fixing into a stud wall, locate the studs and consider positioning the Wall Fixing Panel over as many studs

as possible.

Minimum of 2 studs recommended, as well as the 13 additional fixings points ,as detailed in Diagram 1.

Please note suitable fixings for the wall medium should be used. See important notes Page 15.

200789_1 6

Installation –Including Optional Plinth

Minimum Ceiling Height Required- 2300mm (As shown on Page 3)

Mark a centre line on Wall Fixing Panel- Component “A”-as shown in Diagram 1.

Decide on the installation location of the chimney breast and fix the Wall Fixing Panel using the

recommended dimensions and fixing points, as shown in Diagram 1.

Position the panel on the wall and mark- Position Z, drill and temporarily fix. Ensuring the panel is level and

plumb, mark and drill the additional fixing points. Finally fix into position, depending on the wall medium

it may be necessary to plug the drilled holes. See important notes Page 15.

Note: The accuracy and fixing of this panel is critical to the whole installation process- Ensure the Wall

Fixing Panel- is plumb and level before proceeding further.

Note: All dimensions stated are the minimum requirements for installation including an optional plinth.

Component “A” must be installed from the floor at 265mm, as detailed in Diagram 1, even if the ceiling

height is greater than 2300mm.

Diagram 1

A

If fixing into a stud wall, locate the studs and consider positioning the Wall Fixing Panel over as many studs

as possible.

Minimum of 2 studs recommended, as well as the 13 additional fixings points ,as detailed in Diagram 2.

Please note suitable fixings for the wall medium should be used. See important notes Page 15.

Mark a centre line on Wall Fixing Panel- Component “A”-as shown in Diagram 2.

Decide on the installation location of the chimney breast and fix the Wall Fixing Panel using the

recommended dimensions and fixing points, as shown in Diagram 2.

Position the panel on the wall and mark- Position Z, drill and temporarily fix. Ensuring the panel is level and

plumb, mark and drill the additional fixing points. Finally fix into position, depending on the wall medium

it may be necessary to plug the drilled holes. See important notes Page 15.

Note: The accuracy and fixing of this panel is critical to the whole installation process- Ensure the Wall Fixing

Panel- is plumb and level before proceeding further.

7

200789_1

Installation –Excluding Optional Plinth

Minimum Ceiling Height Required- 2160mm (As shown on Page 3)

Diagram 2

Note: For ceiling heights between 2160mm and 2300mm we recommended following the installation

dimensions, as detailed in Diagram 2. The critical dimension to adhere to is 2040mm. This will ensure an

approx. 50mm gap between the ceiling and the top of the chimney breast is achieved, which is required

for hanging the decorative panels in a later procedure. Alternatively for ceiling heights greater than

2300mm follow the handy table below or adjust the dimensions accordingly.

A

Req. hearth Top

Height (Y-P3)

Installation

Height(X)

Min Ceiling

Height req.

208mm 120mm 2160mm

350mm 262mm 2300mm

400mm 312mm 2350mm

450mm 362mm 2400mm

8

200789_1

Once the Wall Fixing Panel- Component “A” has been secured to the wall, the next step is the

fitting of the fire mounting brackets -Box 029882.

The Wall Fixing Panel comes with pre drilled holes so the brackets can be attached in the correct

position. Attach the brackets, as shown in Diagram 3, using the supplied screws, 9 x No.8 x15mm

Domed-Head screws per bracket.

Ensure the rear of the bracket sits on the top edge of the panel, as shown in Diagram 4.

Once the brackets have been fitted, the light bleed cover- Component “B”- Box 029920 , needs

to be fastened to the top of the fire mounting brackets- align this up tight against the wall and

secure in place with the 2 x No.8 x15mm Domed-Head screws supplied, as shown in Diagram 5.

Diagram 4

B

A

Fire Mounting

Brackets

B

Diagram 5

Diagram 3

Assembly –Hanging System

X 10

Surplus

Cardboard

Note: Before laying the panels down onto a flat surface, make sure the surface is clear of sharp

objects and other debris that may damage the decorative surface. Consider using the surplus

cardboard packaging to help protect the decorative surface- as shown in Diagram 6.

Locate Component “C”-Box 029920 and position this panel face down. The 10 x Cams have

been pre-installed. Please check that the arrows on the cams are pointing to the outer edge of

the panel to allow the pin to locate correctly.

Locate Components “D” and “E”- Box 029920, screw the pins into the relevant sides of the

panels, 5 X Pins per side, as shown in Diagram 7.

Then position Components “D” and “E” face down either side of Component “C”- as shown in

Diagram 6.

9

200789_1

Assembly –Decorative Panel

Diagram 6

X10

Diagram 7

Diagram 9

X 10

10200789_1

Assembly –Decorative Panel Continued…

Push both Components “D” and “E” into Component “C” ensuring the back surfaces are level

and the ends are flush as shown in Diagram 8. Once in position, lock together by turning the

cams ½ turn clockwise, this will lock the pins into the cams, as shown in Diagram 9.

Once Components “C”, “D” and “E have been locked together, the 4 x locating clips need to

be attached to the sides of Components “D” and “E” as shown in Diagram 10. The holes have

been pre-drilled for ease of assembly. Make sure the locating clips are fixed square to the edge.

Diagram 8

Diagram 10

Position the 4 x locating clips

and align with the screw holes

and screw in place using the

8 x No.8 x15mm Domed-Head

screws provided .

X 4

H

F

11

200789_1

Assembly –Decorative Panel Continued…

Diagram 11

X 7

X 2

X 2

Once Component “F “and “G “are secure, locate Component “H” the heat deflector, remove

the protective film and fix this in position using the 4 x 3.5mmx 9.5mm Pozi Flange Head Screws

supplied, as shown in Diagram 13, the fixing holes have been pre-drilled to ensure correct

location of the heat deflector is achieved, start with the two centre screws and work out

towards the edges. The decorative panel is now complete, store safely to one side for later use.

X5

Components “F” and “G” – Box 029920 , can now be fitted across the rear of the assembled

components, as shown in Diagram 11.

Firstly insert the dowels into Components “D” and “E”, two per panel, the holes have been

pre-drilled.

Once the dowels are in place, push the rails into position over the dowels and secure using the

screws provided. 5 X No.8 x 30mm C/Sunk Screws required for Component “F” and 7 X No.8 x

30mm C/Sunk Screws required for Component “G”.

Note: Be careful not to overtighten the screws, in case they come through the front of the panels.

Note : The bevelled edge of Component “G” needs to face towards the bottom of the panels, as

shown in Diagram 12.

Diagram 12 Diagram 13

G

K

Diagram 14

12

200789_1

Assembly –Framework

Diagram 15

Diagram 16

Note: Once again consider using the surplus cardboard packaging to help protect the painted

surfaces.

Locate Box_029890 - Components “J” and “K” have been pre-assembled.

Locate Box- 029882 - Components “L”, “M” and “N”.

The dowels and pins have been pre-installed on Components “L” and “N” and the Cams have

been pre-installed on Components “J”, “K” and “M”. Please check that the arrows on the cams

are pointing to the outer edges of Components “J”, “K” and “M” to allow the pins to locate

correctly.

Insert the pins and dowels, as shown in Diagram 14 , into Components “J” and “K”-2 x dowels

and 1 x pin in each component. Ensure the pins are fully screwed into the board and the dowels

are seated correctly.

Position Components “L” and “N” into the corresponding holes on Components “K”, as shown in

Diagram 15. The bevelled edge of Component “N” needs to facing towards Components “L ”

and “M”, as shown in Diagram 16.

Position Component “M” onto the dowels and pins in Component “K”, as shown in Diagram 15.

N

M

L

L

M

N

J

X 2

Finally position Component “J”, onto Components “L”, “M” and “N”, ensuring the cams, pins and

dowels locate into the correct holes.

K

L

MN

J

13

200789_1

Assembly –Framework Continued…

The final step is to fasten Components “L”, “M” and “N” into position by turning the 6 x cams

clockwise ½ a turn, as shown in Diagram 17.

The framework is now complete, store safely to one side for later use.

Diagram 17

Note: Ensure all cams have locked onto the pins correctly and the framework is secure, before

attempting to move.

P

Assembly –Hearth

Locate Component “P”- BOX 029882, the hearth has been pre- assembled for convenience.

Insert the 3 x Pins and 2 x Dowels into the pre-drilled holes in each side of the hearth, as shown in

Diagram 18.

Diagram 18

Note: Remember to remove the protective cardboard from the underside of the hearth covering

the pre-installed under hearth LED lighting before proceeding further.

Diagram 19

Assembled Framework

P

Diagram 20

14200789_1

Assembly –Hearth and Framework

Ensuring that the pre-installed Cams at the bottom of the framework point to the bottom edge,

as shown in Diagram 20, carefully position the assembled framework onto Component “P”,

ensure the framework is positioned correctly prior to locking the cams onto the pins, as shown in

Diagram 19.

Note: The chimney breast is a two adult person lift. A second person will be required to lift and

support the chimney breast during installation.

Only when you are sure the framework is correctly seated onto the hearth Component “P”, should

you lock the cams into position, this is achieved by turning the cams clockwise ½ a turn. 3 x Cams

per side, , as shown in Diagram 20.

Note: Once assembled please check that the 4 x Fire fixing Screws have been pre-installed, as

these are required to fix the fire at a later stage.

Fire Fixing

Screws

X 3

If fixing into a stud wall, mark the previously located studs used to install the wall fixing panel, on

Component “M”. A minimum 3 fixings points ,as shown in Diagram 22, is recommended .

Please note suitable fixings for the wall medium should be used.

Offer the assembled chimney breast onto the previously installed fire mounting bracket, as

shown in Diagram 21, and push up tight against the wall, ensuring the chimney breast is

centralised on the fire mounting brackets. Be careful not to trap any of the cables for the pre-

installed under hearth LED lighting.

15200789_1

Installation- Fixing To The Wall

Using a spirit level, ensure the assembled chimney breast is plumb, as shown in Diagram 22.

Mark and drill the required fixing positions into Component “M”, and mark the wall behind.

Diagram 21

IMPORTANT NOTE:

Wall fixings (i.e. screws/wall plugs etc.) are not supplied as these are crucially dependent upon

the type of wall and surface the chimney breast is going to be fixed too.

The installer is therefore responsible for ensuring that suitable fittings are used as well as individual

fitting situations and environments. All mechanical fixings, for holding the chimney breast in

position, must be secured to a solid wall or structure.

Diagram 22

Spirit Level

M

Spirit

Level

M

Diagram 24

A

Note: Ensure the assembled chimney breast is pushed tight against the wall and is kept vertical/

plumb during this stage of the installation process.

Once the holes have been drilled and the wall behind marked, remove the assembled chimney

breast from the fire mounting brackets so that the fire can be positioned. Prior to positioning the

fire it may be necessary to plug the drilled holes, depending on the wall medium.

Carefully unpack the fire- Box 024287 and store the logs and remote safely for later use.

Lift the fire onto the internal flanges of the fire mounting brackets and position so the rear of the

fire is against the Wall Fixing Panel - Component “A”, as shown in Diagram 23.

Note: The fire will be fixed in position in a later procedure.

16200789_1

Installation- Fixing To The Wall Continued…

Diagram 23

Internal

Flange

Secure the assembled chimney breast to the wall through Component “M” in the chosen fixing

locations, ensure the correct wall fixings and screws are used for the wall medium.

Once secured to the wall use the 2x No.8 x15mm Domed-Head screws provided, to fasten the

assembled chimney breast to the fire mounting brackets- 1 x screw for each bracket, as shown in

Diagram 24 .

Finally reposition the assembled chimney breast over the fire and onto the fire mounting brackets,

ensuring the cables for the pre-installed under hearth LED lights and the fire are routed in a way so

they are easily accessible for any future maintenance. See separate LED light instructions.

17200789_1

Installation- Fixing The Fire

Once the chimney breast is secured to the wall and brackets, the fire now needs to be secured,

this is done by lifting the fire upwards and pulling forward so that the 4 x keyhole slots on the fire

locate onto the pre-installed screw heads on the rear of the chimney breast front, once over the

screw heads the fire can be lowered in place, as shown in Diagram 25.

Diagram 25 Rear View

2

1

The final part of the installation is to hang the previously assembled decorative panels onto the

installed framework.

Note: This is a two adult person lift to avoid injury or damage.

Offer the assembled panels up to the framework, ensuring the locating clips engage over the 4 X

cut outs in Components “K” and “J” and Components “N” and “G” (bevelled rails) engage

together. This can generally be achieved by lifting up, pushing back and lowering into position.

Note: Ensure all of the clips and rails are correctly engaged before releasing the panels, as

shown in Diagram 26.

18200789

Installation- Fitting The Decorative Panels

Once installation is complete please refer to the fire instruction to see how to dress the logs on

your fire and for the full fire operation guide.

Please follow the LED light instruction to operate the pre-installed under hearth lights.

Note: There is a separate remote control for the LED lights.

Please follow a separate instruction for the assembly and installation of the optional plinth.

Diagram 26

G

N

Cut

Outs

Clips

K

J

19

Maintenance

WARNING: Before any maintenance or whilst cleaning the exterior of the fireplace, the

unit should be disconnected from the power supply until it has cooled down.

Cleaning the Fire

Cleaning or polishing products are not recommended. Fingerprints or other marks on

the front glass panel can be removed by a piece of soft, damp, lint-free cloth with a

good quality household glass cleaner. The front glass panel should always be

completely dried with a clean, lint-free cloth or paper towel.

CAUTION: Abrasive cleaners should not be used on the glass panel. Liquids should not

be sprayed directly onto any surface of the unit.

Cleaning the Furniture

Wipe up spills and condensation immediately with a clean damp cloth. When

cleaning the furniture, we also recommend using a clean damp cloth. Avoid using

cleaners or polishes that contain abrasives, solvents, acid and ammonia.

Troubleshooting

Should you have any queries regarding this product please contact Customer Services

on 01914300901 or email us at customerservices@bemodern.co.uk

Recycling

All cardboard packing is recyclable.

200789_1

Table of contents

Popular Fireplace Accessories manuals by other brands

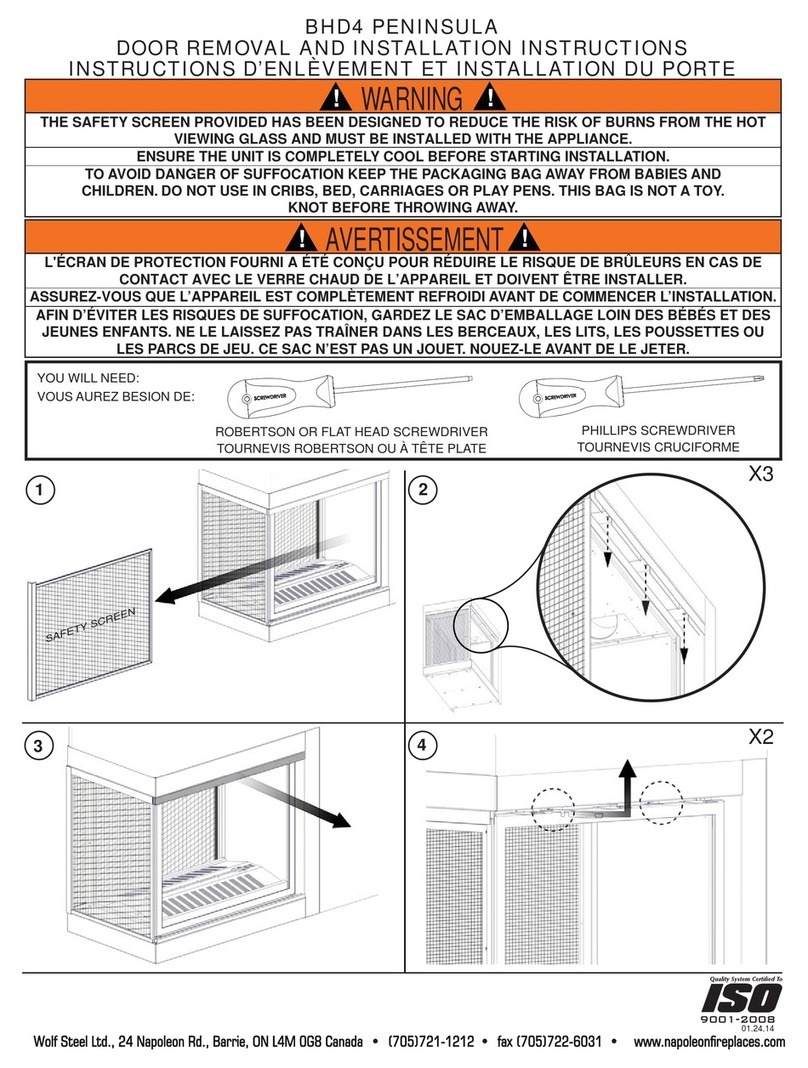

Napoleon

Napoleon BHD4 PENINSULA installation instructions

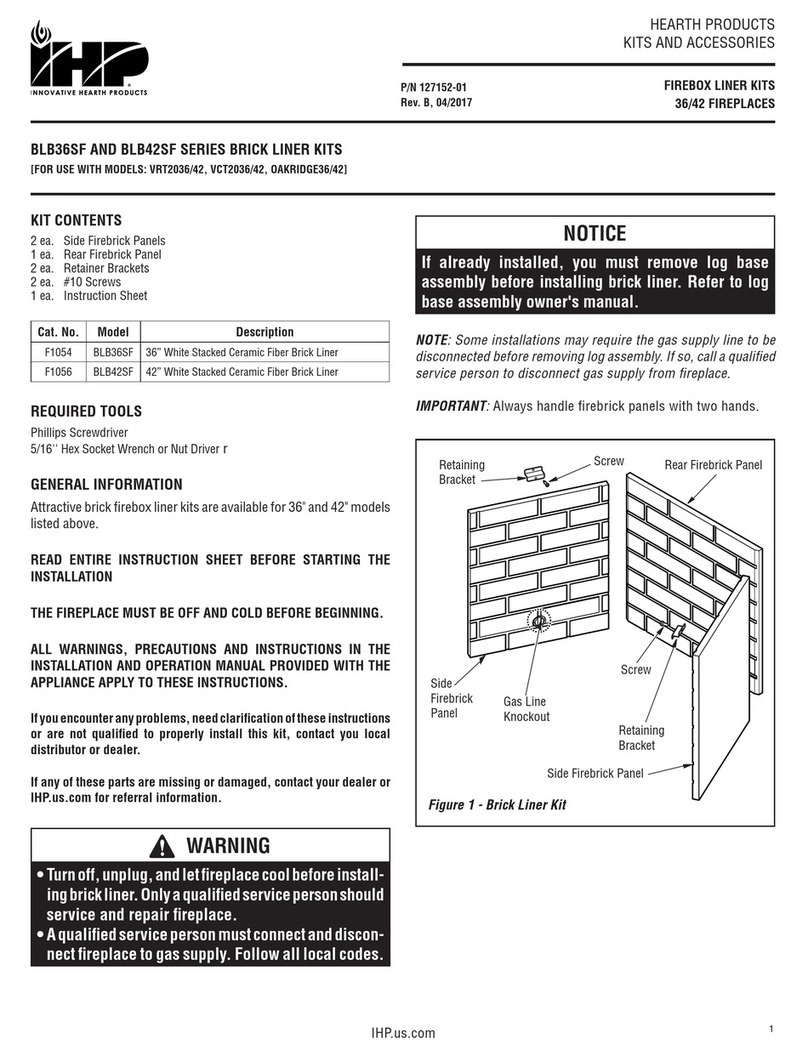

IHP

IHP BLB36SF Series quick start guide

Duluth Forge

Duluth Forge FLT18-1 OWNER'S OPERATION AND INSTALLATION MANUAL

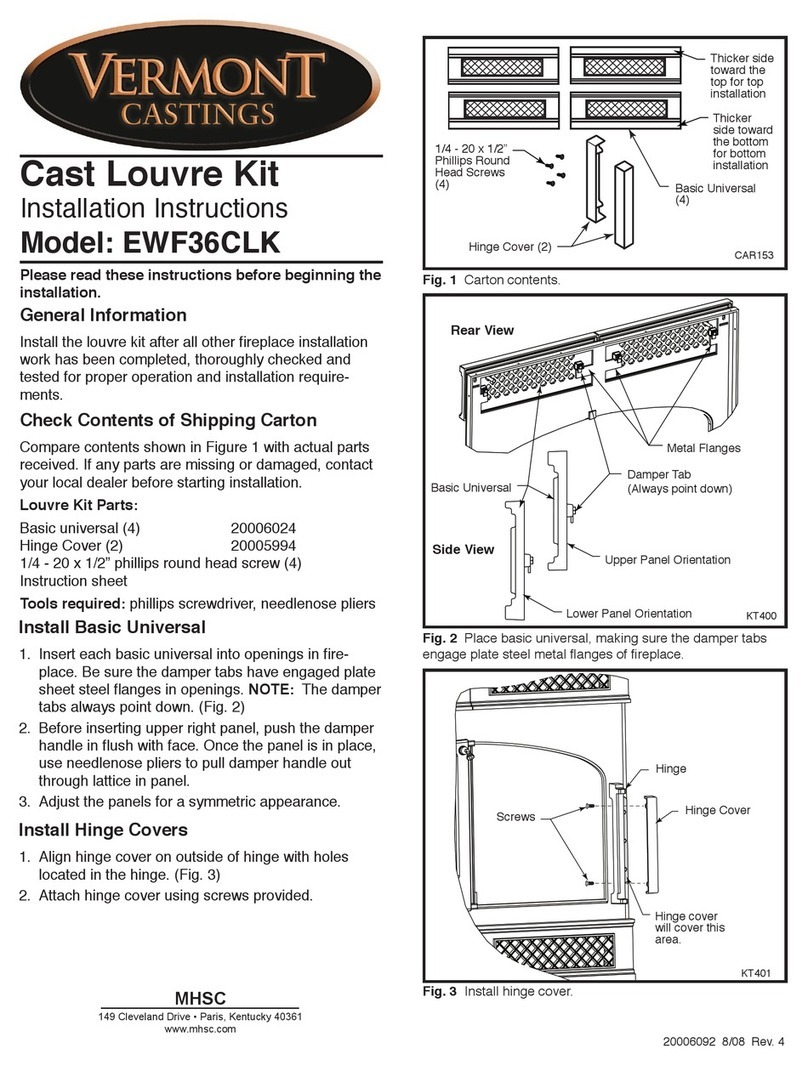

Vermont Castings

Vermont Castings Cast Louvre Kit EWF36CLK installation instructions

Napoleon

Napoleon HDX35 Installation and operation manual

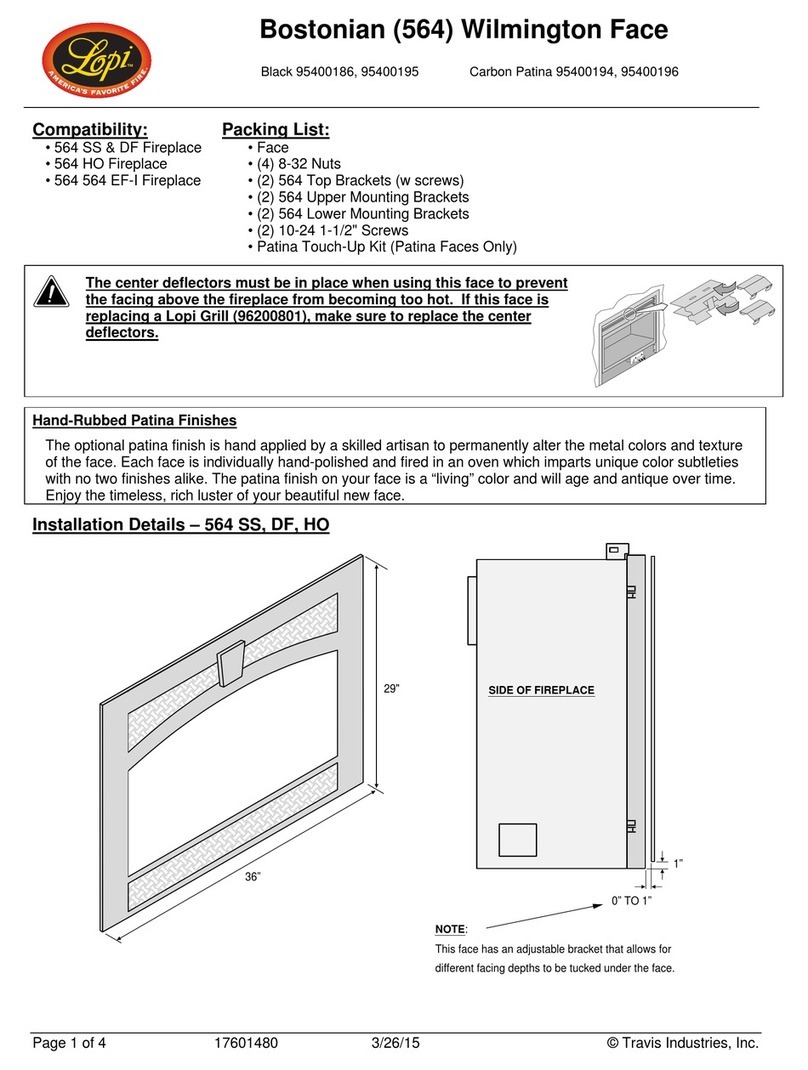

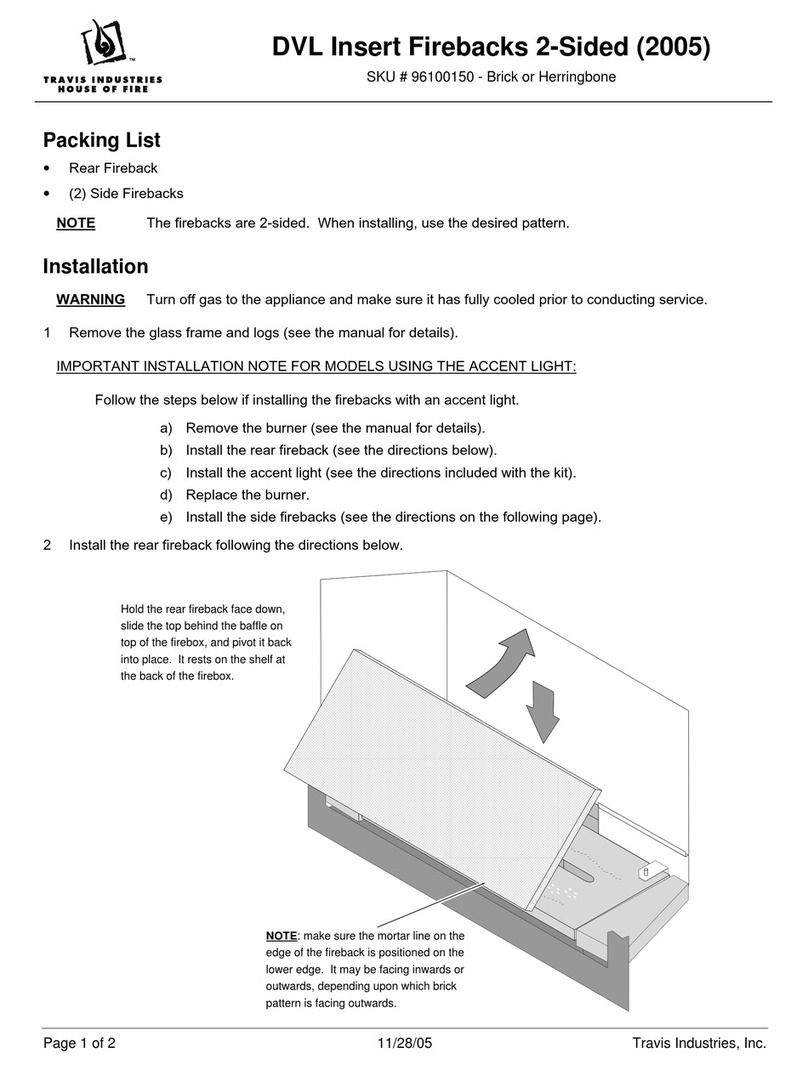

Travis Industries

Travis Industries 96100150 manual

pleasant hearth

pleasant hearth IRIS SCROLL quick start guide

Enviro

Enviro C34 instruction manual

Valor

Valor LEGEND G3.5 installation instructions

Regency Fireplace Products

Regency Fireplace Products SIT WiFi Guide instructions

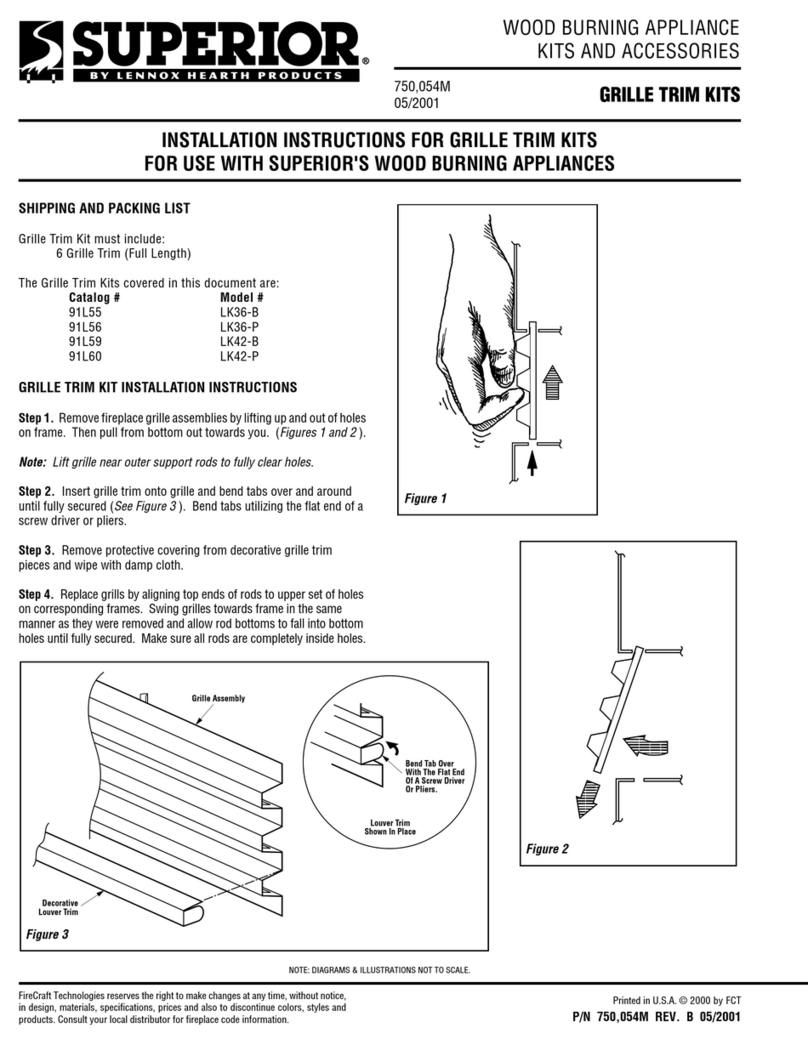

Superior

Superior LK36-B installation instructions

Jøtul

Jøtul 341280 Installation and operating instructions