Bench Dog Tools Pro-Builder Series User manual

Read and understand the entire contents

of this manual before attempting assembly

or operation of this tool! Inspect contents

for shipping damage and shortages. Report

problems directly to Bench Dog, Inc.

Be sure to check out our web site for all the

latest and greatest accessories and tools.

www.benchdog.com

1-800-786-8902

QUESTIONS? Tools Required

1/8" hex wrench (supplied)

5/32" hex wrench (supplied)

3/16" hex wrench (supplied)

7/16" wrench

7/16" socket wrench

Phillips screwdriver

Thank you for purchasing our ProTop

Contractor router table! We are certain this

made in USA router table, with its many

exclusive features, will become one of your

favorite tools.

Bench Dog offers a full line of tools and

accessories that continue Bench Dog's

commitment to solve common problems

and ensure safe operation of a variety of

woodworking and other tools.

If you have questions, please feel free to

contact us at any time. Your comments are

always welcome.

612.782.8205 main

612.788.2518 fax

800.786.8902 toll free

benchdog.com

Bench Dog, Inc.

3310 5th St. NE

Minneapolis, MN 55418

82-0036-08 1204

2004 Bench Dog, Inc.

Stock No. 40-001

Keep this manual handy for

quick reference

Owner's Manual

LIMITED TWO-YEAR WARRANTY

We make every effort to assure that our products meet quality and durability standards, and warrant to the original retail purchaser that this

product is free from defects in materials and workmanship for two years. Remedy shall be limited to Bench Dog’s choice of repair,

replacement or refund. This warranty does not provide remedy for consequential economic loss.

This is a limited two year warranty. It requires the purchaser to contact Bench Dog in writing within 30 days of discovering the defect.

Warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or accidents, repairs or alterations, or due to lack

of maintenance. It excludes components and parts not manufactured by Bench Dog, defects caused by failure to provide a suitable

installation environment, and damage caused by use for purposes other than those for which the product was designed. Bench Dog, Inc.

reserves the right to make product changes without notice and without obligation to make these changes on products previously sold. It

excludes warranties of fitness for a particular purpose.

If the product is defective, we reserve the right to fix it, replace it, or refund the cost of the product to you. Typically, this results in a refund.

All claims are limited to the two-year claims period. We must receive the product before a credit or refund will be issued. The warranty

language on the product or in the product’s manual may contain additional limitations, which govern.

If you wish to return something, call the dealer where you purchased the product. If you wish to return something purchased from Bench

Dog directly, call 1-800-786-8902 to receive an RMA number. Upon receipt and inspection of the goods, a credit or replacement will be

issued for defective products. Return of nondefective items to Bench Dog are subject to a 7% restocking charge. This is necessary due to

the cost of checking, repackaging, and inventorying the stock.

BENCH DOG DISCLAIMS AND BUYER EXPRESSLY WAIVES ANY AND ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO, IMPLIED CONDITIONS OF FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR ANY OTHER

MATTER.

Page 2

General Conditions / Limited Two Year Warranty

Important Safety Points

Before operating your router table please read this manual thoroughly. Safety and use tips are contained in the manual.

This page is not the sole source of safety information. Retain the manual for future reference. Refer to your router

owner's manual for safety instructions regarding use of that tool. This manual is not an instruction book on how to do

woodworking with a power tool. We encourage all woodworkers to continually seek improvement in their woodworking skills,

regardless of their craftsmanship or years of experience. The router table, fence and accessories must only be used for their

intended purpose: woodworking via normal routing operations. “Normal operations” means basic shaping of wood in

conditions where grounded electricity, sharp tools, dust, and rapidly spinning parts can be used or encountered safely. The

following instructions elaborate on this concept.

1. Do not use your router table as a step or seat.

2. The top and cabinet must be properly secured, and be level before use. Inspect your table and base for

damage and levelness prior to each use.

3. Keep work area clean, dry and well lit.

4. The hardware affixing the insert to the routertop must be installed for safe use. Tighten insert hold-down

screws before each use.

5. Safe operation requires a router table fence, bit guard, dust collection system, starting pin or fulcrum, and

speed reducer for large diameter bits. We recommend reducing router speed for 1" or larger diameter bits.

Consult your bit manufacturer for the exact speed.

6. Use the right tool for the job. Do not force a tool or attachment to do a job for which it was not designed.

7. Secure your work with a featherboard, clamps, or a vice when appropriate. The use of inappropriate

accessories may cause injury.

8. Wear safety glasses, dust mask, face shield and ear protection. This is not an exhaustive list. Every-day

eye glasses do not substitute for safety glasses.

9. Do not wear gloves or jewelry while using a power tool and ProTop Contractor.

10. Maintain your equipment and its accessories in good working condition. Look for wear, poor alignment of

moving parts, binding of moving parts, breakage, poor mounting, or other conditions that may affect

operation and safety. Repair or replace any damaged parts.

11. Disconnect the power before moving, adjusting, or repairing parts, or otherwise maintaining your router table

and any accessories you may be using.

12. Keep children, pets, and those who may disregard safety away from work area, cords, sockets and tools.

13. Wear snug fitting clothes and keep long hair back to avoid catching in moving parts.

14. Do not overreach. Maintain balanced footing and stance.

15. Stay alert. Use common sense.

Page 3

1

5

4

6

10

11 11

13

12

15 14

18

16 17

19

89

2

3

7

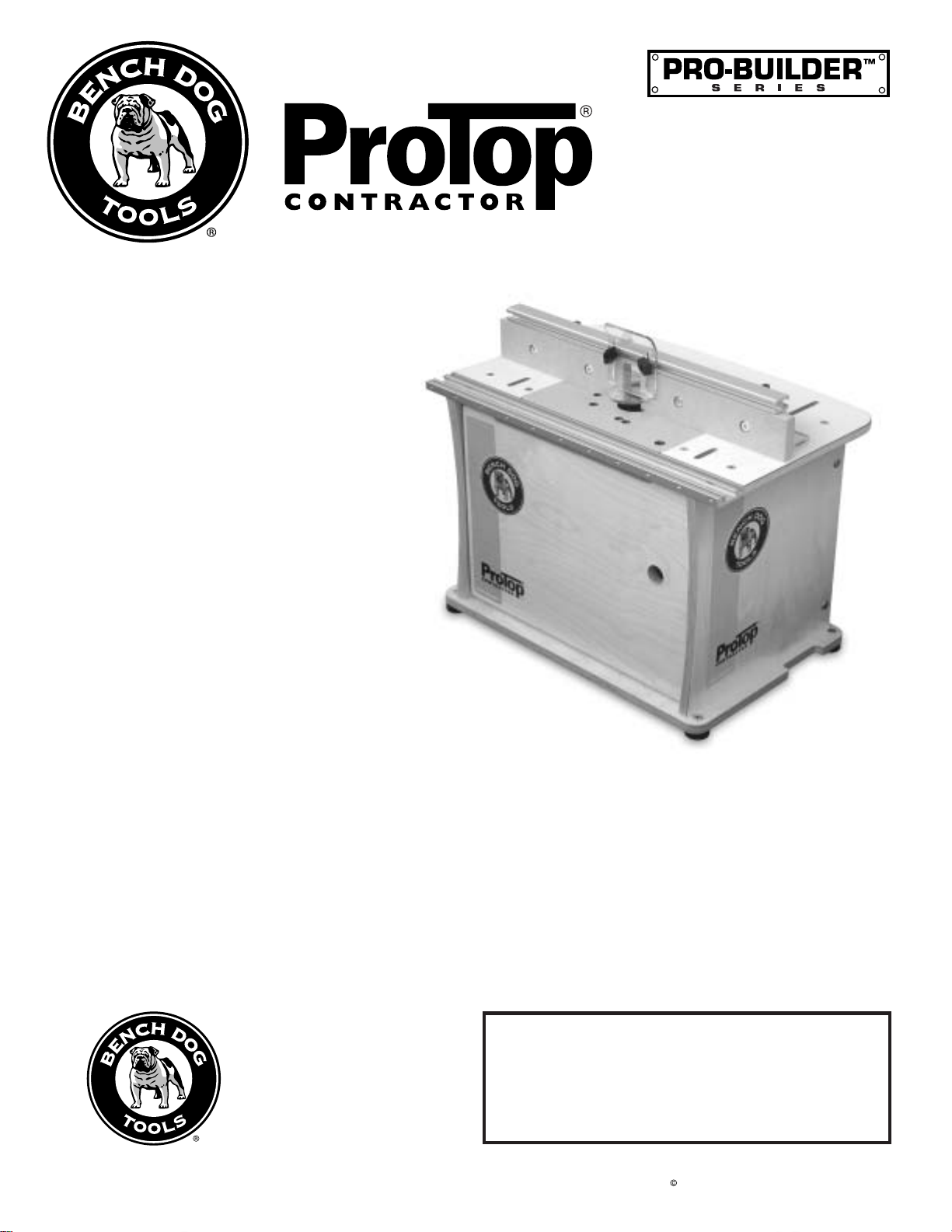

Contents of Box

Fence Hardware/Accessories

Cabinet Panels

Item Quantity Part Number Description

1 1 FP0100-01 Router top

2 1 FP0100-02 Base panel

3 1 FP0100-03 Door

4 1 FP0100-04 Side panel, left

5 1 FP0100-05 Side panel, right

6 1 FP0100-06 Back panel

7 1 FP0133 Router insert plate (Stock No. 40-042)

8 2 DECALS Decals, side panel (not shown)

Item Quantity Part Number Description

8 1 FP0054 Bit guard

9 1 FP0059 Dust port

10 1 R0001 Aluminum fence

11 2 FP0053 Subfences

12 2 R0009 Jointer bars

13 1 R0049 Miter track, 24"

14 1 FP0106 Insert bracket, right

15 1 FP0105 Insert bracket, left

16 1 150-0020-01 Hardware bag # 1

17 1 150-0020-02 Hardware bag # 2

18 1 150-0001-03 Hardware bag # 3

19 1 150-0020-03 Hardware bag # 4

43

42

47

46 45

40

41

44

38 35 37 36 39

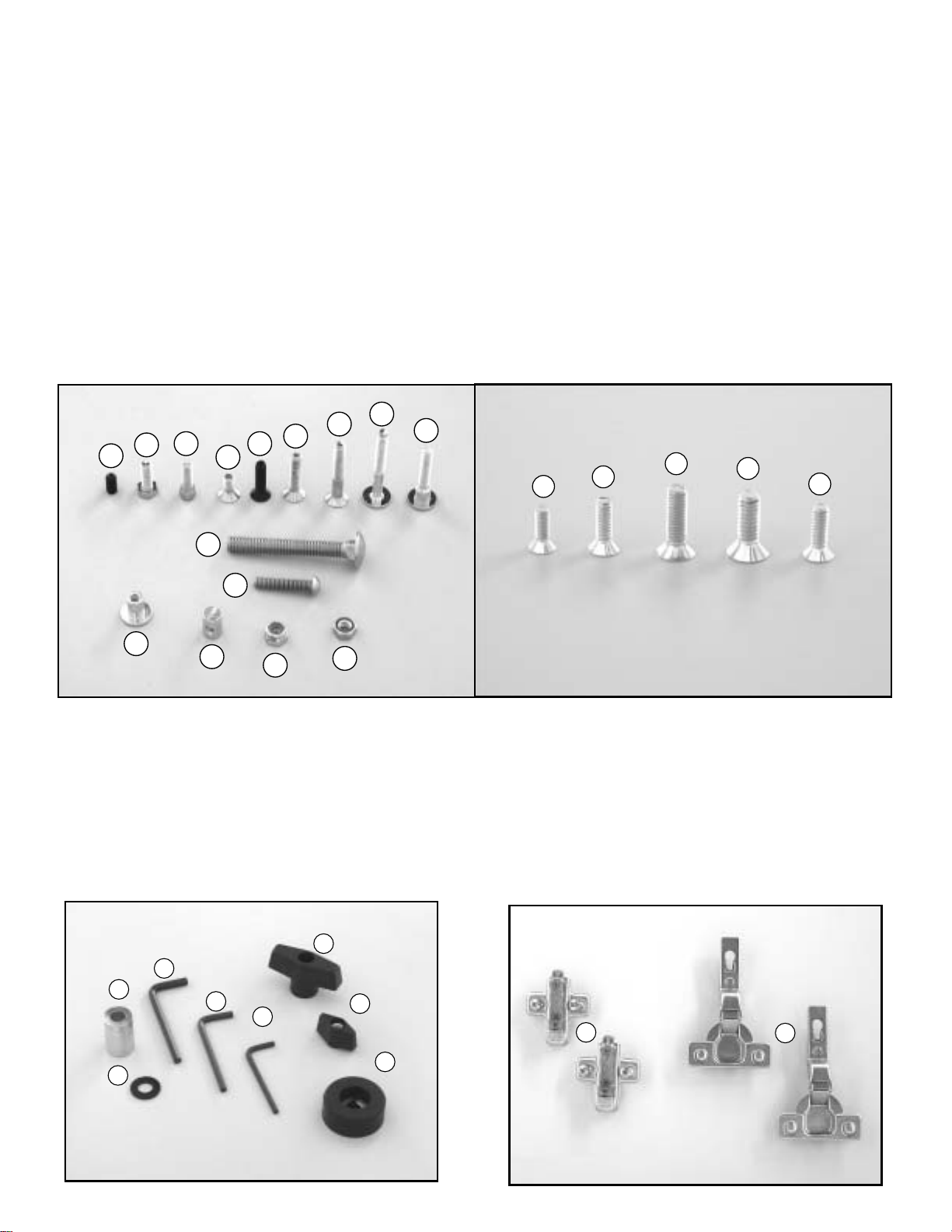

Contents of bag #1

Contents

of Box

Hardware bag #1

Item Quantity Part Number Description

20 2 H0168 Bolt, 3/8-16 x 2-3/4" Carriage

21 6 H0004 Bolt, 1/4-20 x 3/4" Hex head

22 4 H0006 Bolt, 1/4-20 x 50mm (2") Round head

23 4 H0005 Bolt, 1/4-20 x 40mm (1-1/2") Round head shoulder

24 4 H0173 Cap screw, 1/4-20 x 1-1/4" Button head socket

25 18 H0017 Cross Dowel, 1/4-20

26 10 H0103 Nut, 1/4-20 Nylon insert lock

27 8 H0031 Nut, 1/4-20 Hex

28 4 H0174 T-Nut, 1/4-20

29 2 H0171 Screw, 1/4-20 x 5/8" Flat head socket cap

30 6 H0169 Screw, 1/4-20 x 1-1/4" Flat head socket cap

31 12 H0170 Screw, 1/4-20 x 1-3/4" Flat head socket cap

32 11 H0050 Screw, 1/4-28 x 1/2" Set-socket

33 8 H0172 Screw, 1/4-20 x 3/4" Socket head cap

34 2 H0045 Screw, 1/4-20 x 1" Flat head Phillips (black)

35 3 H0037 Screw, 10-24 x 5/8" Flat head Phillips

36 3 H0057 Screw, 5/16-18 x 3/4", Flat head Phillips

37 3 H0060 Screw, 6 x 20 mm, Flat head Phillips

38 3 H0163 Screw, 8-32 x 1/2", Flat head Phillips

39 3 H0198 Screw, 10-32 x 5/8", Flat head Phillips

Hardware bag #2

Contents of bag #2

Item Quantity Part Number Description

40 2 H0014 T-Knob, 3/8-16 x 2"

41 6 H0012 T-Knob, 1/4-20 x 1-1/8"

42 2 H0067 Washer, 3/8" Nylon

43 2 R0010 Spacer, Alum. Knob

44 4 H0175 Rubber feet

45 1 H0019 Wrench, 1/8" hex

46 1 H0128 Wrench, 5/32" hex

47 1 H0129 Wrench, 3/16" hex

Hardware bag #3 (Hinges)

Item Quantity Part Number Description

48 2 H0023 Mounting plate, hinge

49 2 H0027 Hinge, self closing Euro style

32 21 33 29 34 30 31 22 23

20

24

28 25 26 27

Contents of bag #1

(Router insert plate mounting screws)

48 49

Contents of bag #3

Page 4

1/4-20

cross dowel

1/4-20 x 2"

round head bolt

Page 5

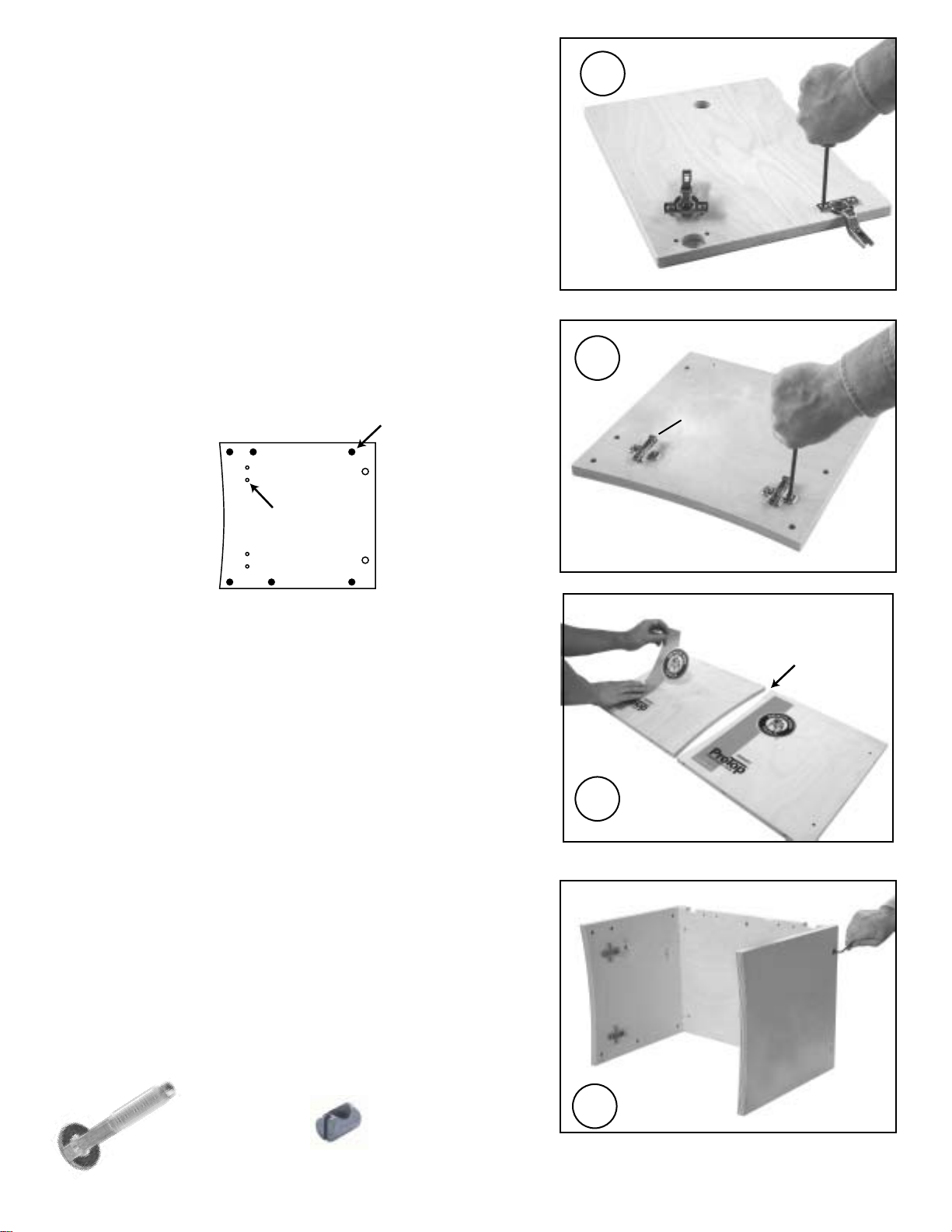

Assembly Instructions

1. Attach the (2) hinges to the door.

Press the hinge "cups" into the large bore in the door. With a

Phillips screwdriver tighten the integral hinge cams clockwise

approximately 1/4 turn. Do not over tighten the cams.

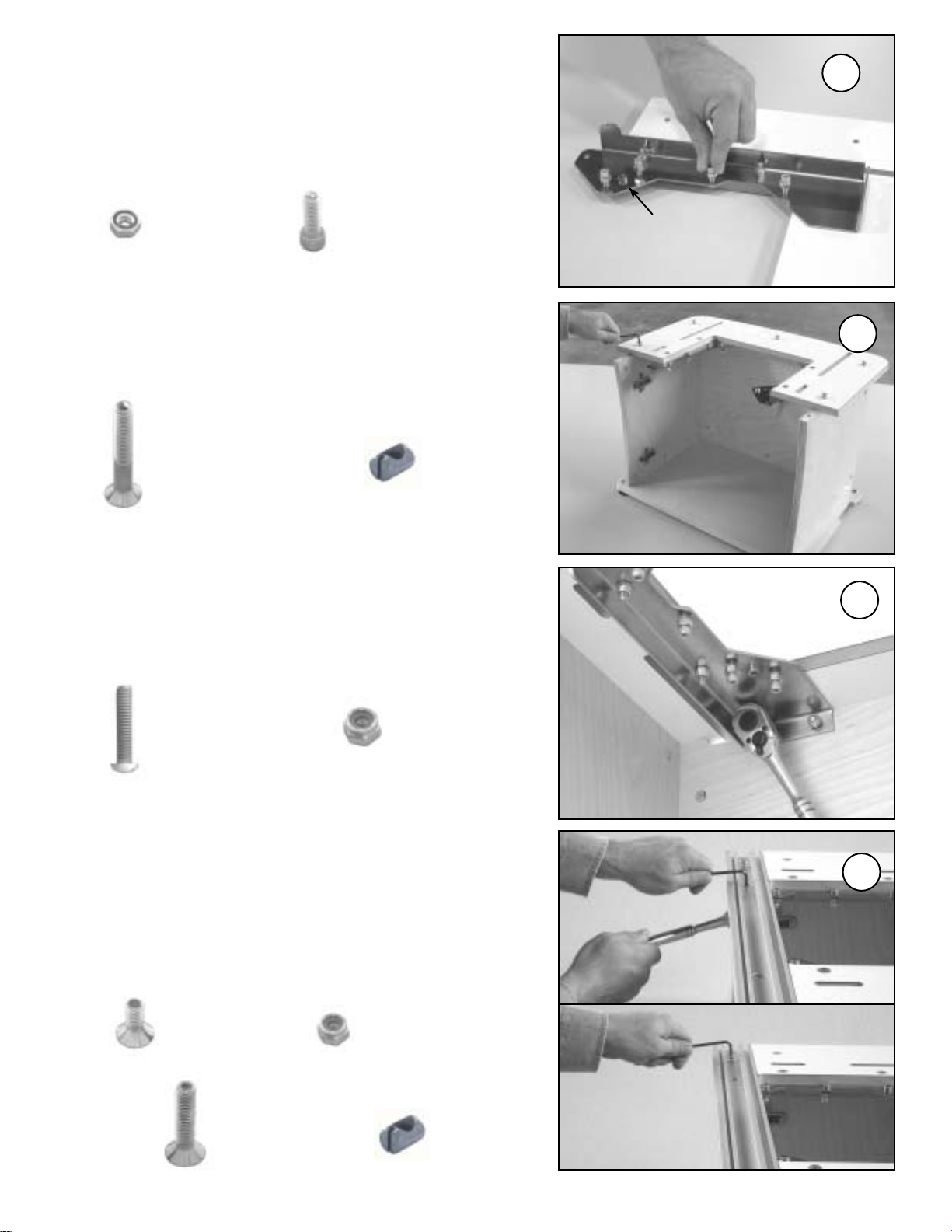

3. Attach side panels to the back panel.

The back panel has two notches that identify the top of the panel,

as shown. The left panel has the hinges. Align the two holes in

side panels with the corresponding holes in the back panel. Use

1/4-20 x 2" round head bolts and 1/4-20 cross dowels. The cross

dowels go in the back panel. Tighten with the included 5/32" hex

wrench. Repeat this step for the right panel. Do not fully tighten the

bolts at this time.

Note: Check that the cross dowel holes are free of debris

prior to inserting the cross dowels.

1

3

2a. Attach the (2) hinge mounting plates to the left side panel.

Carefully study the orientation in Fig. 2. The hinge mounting plates

resemble a cross. Locate the top of the cross nearest the curved

front edge of the left side panel, as shown. On the bottom of the

cross you will find the hinge release lever. All cross dowel holes

are located inside the cabinet.

2a

hinge

plate holes

cross dowel

holes

hinge release

lever here!

2b. Attach the (2) decals to the side panels.

The decals go on the outside of the left and right side panels. The

right side panel decal is positioned near the front curved edge, as

shown. In this photo the person is installing the decal on the left

side panel, about two inches from the back edge. If you find it

easier, attach the decals AFTER your router table is fully

assembled.

right panel

front is curved

on both panels

front edge is curved

on both side panels

left panel

top

LEFT

SIDE PANEL

TOP

CURVED

FRONT EDGE

CROSS DOWEL HOLES ARE

LOCATED INSIDE THE CABINET! 2b

Page 6

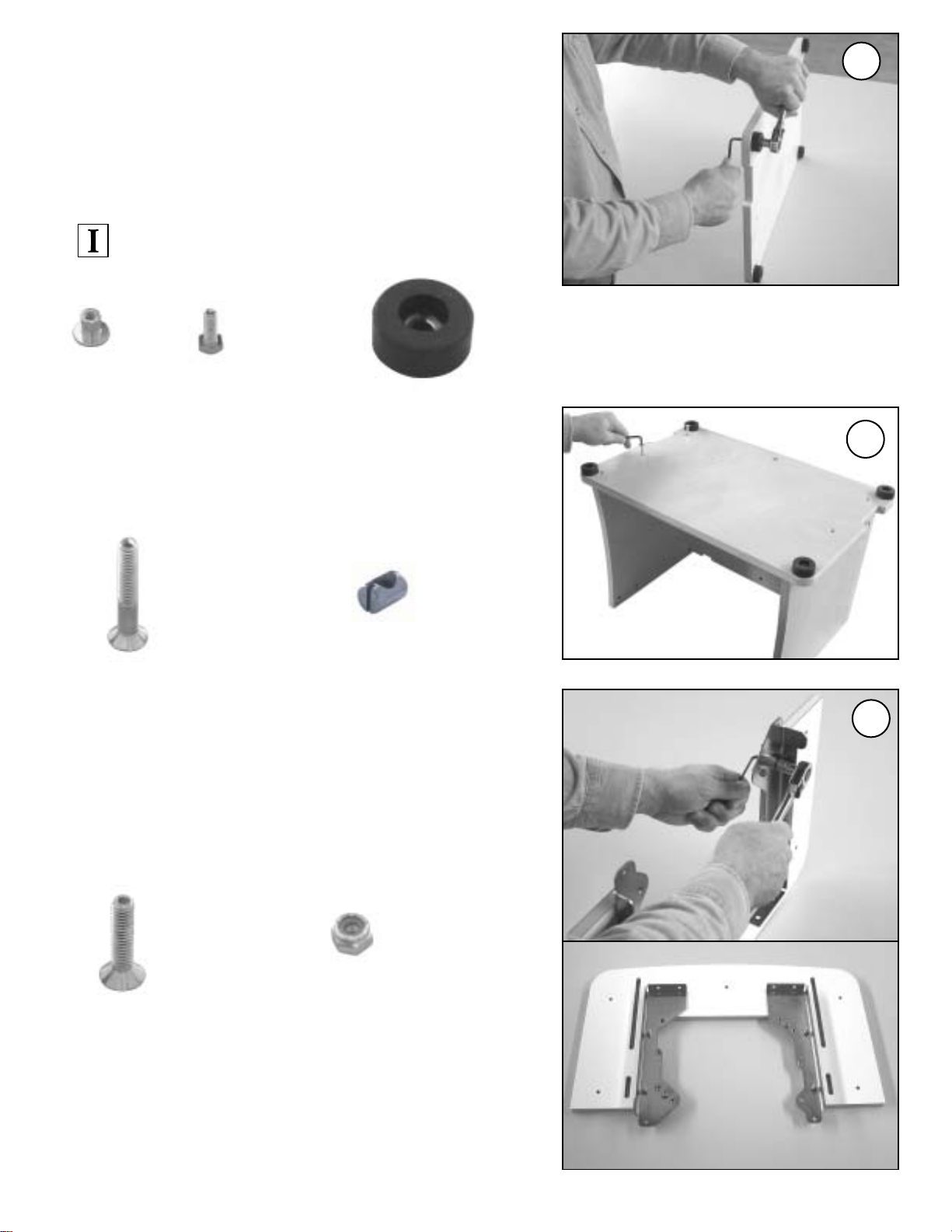

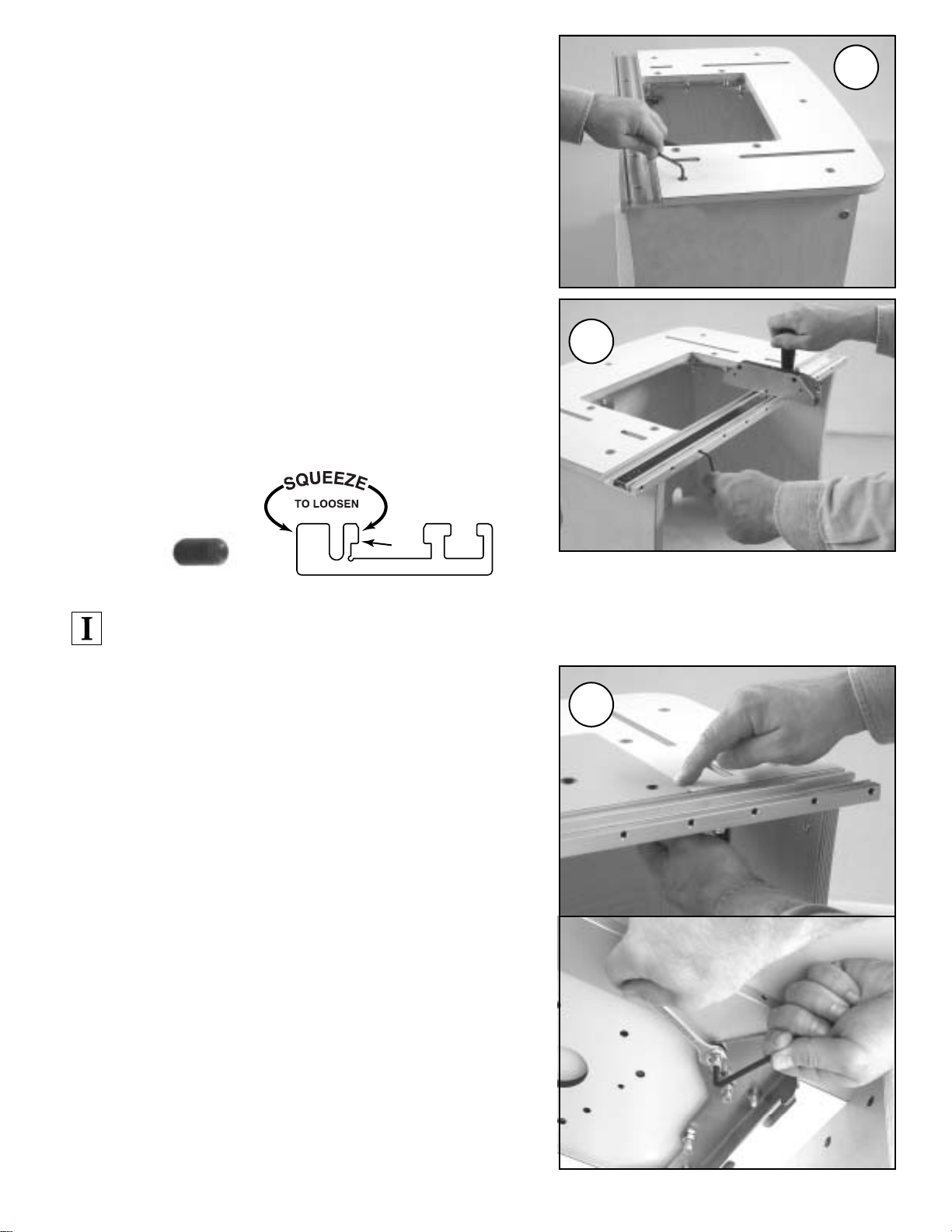

4. Attach the (4) rubber feet to base panel.

Insert the "T" nuts into the four large holes in the base panel.

Locate the head of the "T" nut on the top side of the base panel.

The bottom of the base panel has countersinks, the top does not.

Insert a 1/4-20 x 3/4" hex head bolt through the rubber feet, and

thread into "T" nut, as shown. Tighten using the 3/16" hex wrench

and a 7/16" socket. Do not overtighten.

4

5. Attach base panel to cabinet assembly.

Flip the cabinet assembly upside down, as shown. Use the 1/4-

20 x 1-3/4" flat head socket cap screws and 1/4-20 cross dowels.

Tighten securely. Flip the cabinet assembly right side up when

done.

5

6. Attach insert brackets to routertop.

Position insert brackets as shown. Be sure to mount the brackets

to the underside of the routertop. The routertop surface has

countersinks, the underside does not. Do not fully tighten the

bolts.

6

The bottom side of the base panel has countersunk

holes to accept other fasteners.

T-nut

1/4-20 x 1-3/4"

flat head socket

cap screw

1/4-20 x 3/4"

hex head bolt rubber

foot

1/4-20 x 1-1/4"

flat head socket

cap screw

nylon insert

lock nut

1/4-20

cross dowel

Page 7

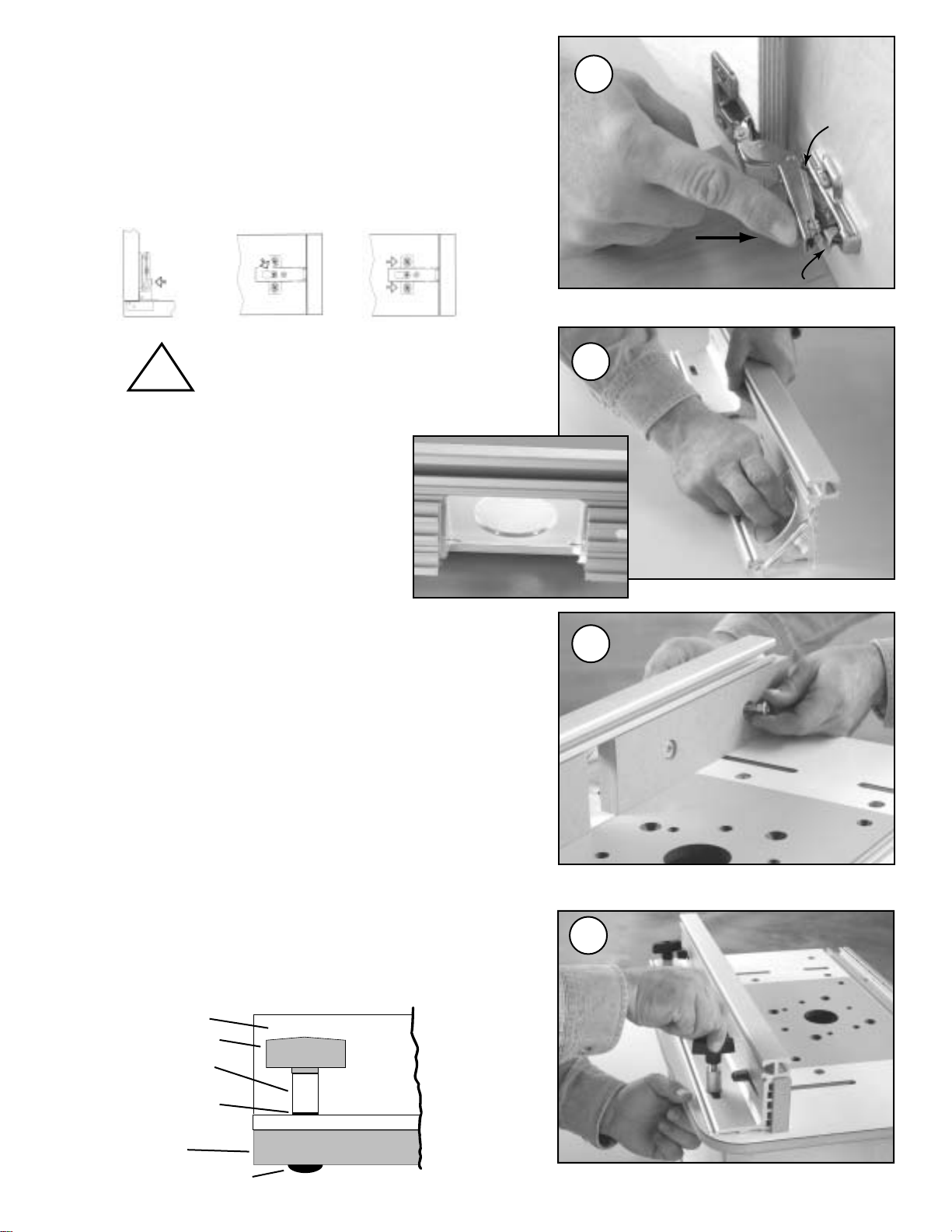

7. Install the (8) leveling screws.

Fully thread a 1/4" hex nut on each of the (8) 1/4-20 x 3/4" socket

head cap screws. Install these bolt assemblies into the (8)

leveling holes in the insert brackets. DO NOT use the two insert

plate attachment holes. These holes have protruding round nuts

on the underside of the insert brackets. You will adjust these

leveling screws in step 13.

8. Attach routertop to cabinet asssembly.

Attach using 1/4-20 x 1-3/4" flat head socket cap screws and

1/4-20 cross dowels. Do not fully tighten at this time.

9. Connect insert brackets to the back panel.

Attach using 1/4-20 x 1-1/4" button head screws and 1/4" nylon

insert lock nuts, as shown. Locate the nuts to the inside of the

cabinet. Do not fully tighten at this time.

10. Attach the miter track to routertop.

Use (2) 1/4-20 x 5/8" flat head socket cap screws and 1/4" nylon

insert lock nuts to fasten the miter track to the insert brackets.

Use (2) 1/4-20 x 1-1/4" flat head socket cap screws and 1/4-20

cross dowels to fasten the miter track to the cabinet side panels.

Eliminate any gap between the miter track and routertop before

tightening the bolts.

7

8

9

10

1/4"

hex nut

1/4-20 x 3/4"

socket head

cap screw

1/4-20 x 1-3/4"

flat head socket

cap screw

1/4-20 x 1-1/4"

button head

socket cap screw

1/4-20 x 5/8"

flat head socket

cap screws

1/4-20

cross dowel

nylon insert

lock nut

nylon insert

lock nut

1/4-20

cross dowel

1/4-20 x 1-1/4"

flat head socket

cap screws.

insert plate

attachment

hole

Page 8

11. Fully tighten all bolts and screws.

Correct any misalignments at this time.

13. Adjust leveling screws until insert plate is flush.

Install the insert plate into the routertop. Adjust leveling screws

until the plate is flush with routertop. To tighten, hold the socket

head cap screw with the 3/16" hex wrench, and use your 7/16"

open end wrench to tighten the nuts, as shown. Note: it may be

necessary to fine tune the adjustment after installing router.

11

12. Adjust miter gauge track to fit your miter gauge.

First test fit your miter gauge into the track. If it's too tight,

squeeze the gib against the front wall of the miter track with a

pair of Channel Locks, use a shop towel to prevent marring.

Next, install the (11) 1/4-28 x 1/2" set screws. Tightening the

screws will deflect the gib into your miter gauge. Tighten all

screws uniformly and gradually until the desired fit is achieved.

12

13

1/4-28 x 1/2"

set screw

This miter track ONLY fits standard 3/8" x 3/4" miter

gauge bars. Wax the slot and bar to reduce wear.

*Miter Gauge NOT INCLUDED!

front

wall gib

Page 9

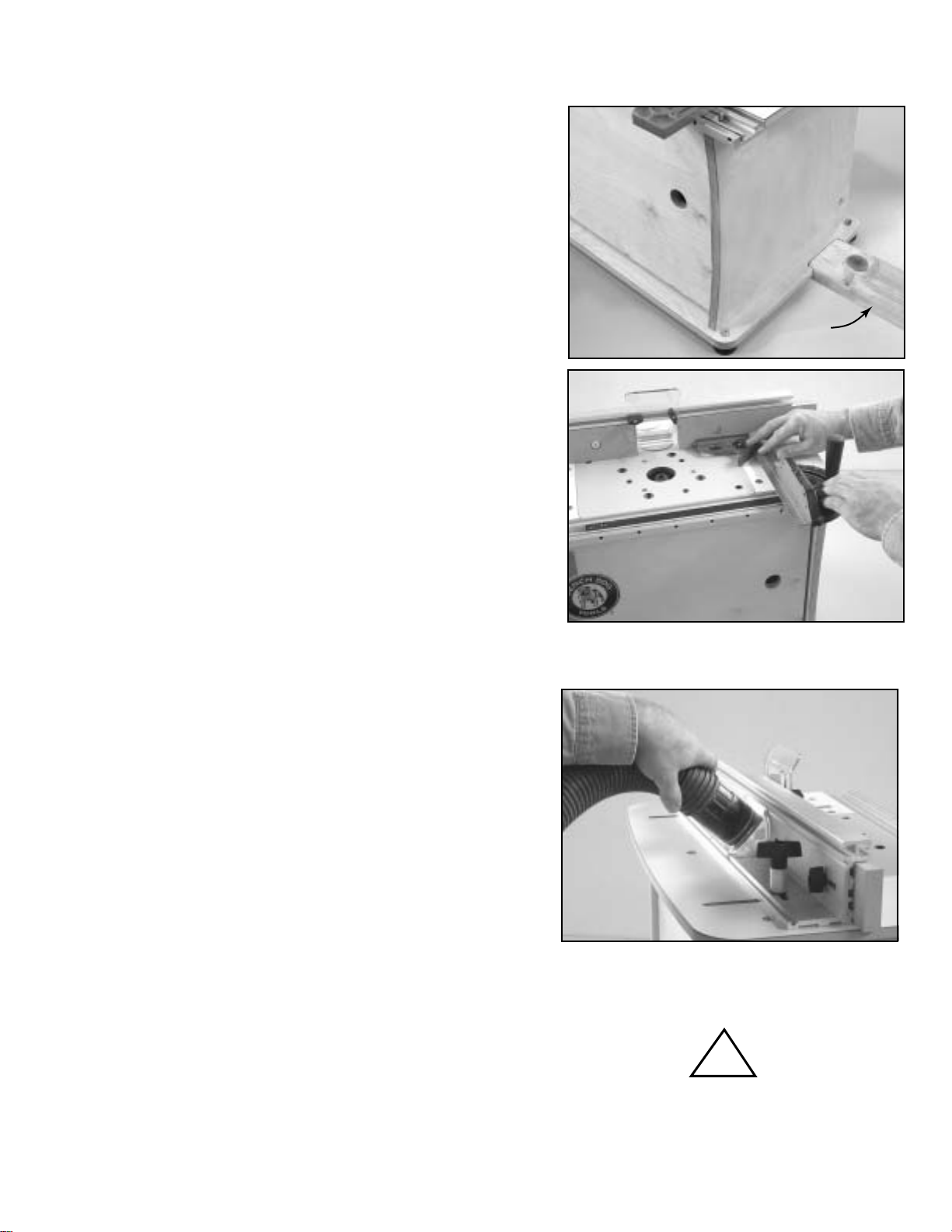

14. Attach door.

Clip on door by "hooking" front of hinge onto hinge mounting

plate first. Then push on back edge of hinge until it locks into

place. If door does not clip on, check hinge mounting plates for

proper installation. To remove door, push down on release

levers.

15. Install dust port.

Pull the dust port along the two 45º

grooves in the back of the fence until it

snaps into place (at the center of the open

area). The dust port fits tightly.

16. Install the (2) MDF subfences onto the fence.

Insert (4) 1/4-20 x 40mm shoulder bolts into the counter-bored

recess on the subfences. Light pressure may be required to seat

bolts properly. The bolts are designed to fit snugly to prevent

spinning. Note: the subfences have no specific left/right or

up/down orientation.

14

15

16

Don't force the hinges onto

the mounting plates!

!

Frontal

Adjustment

Screw

Vertical

Adjustment

Screws

Lateral

Adjustment

Screw

first hook

hinge to

plate here

next, push

to clip-on release lever

17. Attach fence to routertop (standard mounting).

Use the (2) 3/8-16 x 3" carriage bolts, (2) aluminum knob

spacers, (2) 3/8" nylon washers and (2) 3/8" (large) T-knobs. For

standard mounting, position fence to "rear" of the routertop, as

shown. The bolts enter from under the routertop. 17

T-knob

routertop

fence

nylon washer

spacer

3/8-16 x 2-3/4" carriage bolt

Page 10

18. Attaching fence to routertop (reverse mounting).

For more workpiece support, the fence can be reversed and

positioned on the "front" of router table, as shown. Install the

bolts from inside the cabinet.

19. Attach the dual position bit guard to fence.

Pre-assemble the guard with the (2) 1/4-20 x 3/4" hex bolts and

(2) knobs. Slide both bolt heads into the fence's T-slot to attach

to fence.

Note: The bit guard is designed for dual positioning. The larger,

curved side is used for general routing of small and medium

sized bits. The smaller angled side is intended for edge jointing

and small diameter bits.

18

19

Always use the bit guard!

!

20. Mount router to the insert plate.

This insert plate is predrilled to fit most popular routers, and

comes with proper mounting screws for these routers. In some

cases, you must drill your own holes and purchase your own

mounting screws. Please refer to the included template to

complete this step.

20

21. Install router and plate into the routertop.

Re-adjust the insert plate flush if necessary (see step 13). Install

the (2) 1/4-20 x 1" flat head phillips screws into the two corners of

the insert plate. These screws prevent side-to-side movement and

keep the insert plate firmly seated, preventing excessive vibration.

Do not overtighten as this could damage the insert plate.

21

Check the tightness of the hold-down

screws before each use!

!*Router not included.

1/4-20 x 1" (black)

flat head phillips

machine screw

Page 11

Securing the router table

The base has rubber feet to reduce vibration and slippage of

the base on a smooth surface. For permanent mounting, the

base can be bolted through the rubber feet to a workstation or

bench. For a secure yet portable mounting, the base is

equipped with two special recesses that accept scrap2x4

dimensional lumber. Fasten the scrap2x4pieces to your

bench using clamps or screws.

Using Your Miter Gauge

*Miter gauge not included.

The miter track has two slots: an accessory T-slot and a T-bar

compatible miter gauge slot. The accessory T-slot is the

narrower of the two. It accepts 1/4" hex bolts for attaching

Feather-Loc featherboards (see Bench Dog accessories) and

other fence accessories like Panel-Loc and Power-Loc. The

miter gauge slot is used in conjunction with a miter gauge, and

fits standard 3/8" x 3/4" miter bars (with or without the T-bar).

The miter gauge is not included.

To adjust fence perpendicular to miter gauge, set miter gauge

to 90º, and place in slot (make sure miter track is adjusted,

see step 12). Loosen the fence's lock knobs and align the

miter gauge to fence using a square, as shown.

2x4

Dust Collection

*Hose not included.

Temperature Regulation

To prevent router overheating periodically open the cabinet

door during use, and never let dust and debris collect inside the

cabinet. Always use a vacuum at the fence mounted dust port.

For extended operation you must install a dust port in the

cabinet or remove the door during operation. Immediately clean the dust and debris

from the inside of your cabinet after

each and every use.

!

Operational Tips

The integral dust collection port is designed to accept a

standard 2-1/2" fitting, typical on most shop vacs. Most of

these fittings actually measure 2-1/4" (outside diameter).

Bench Dog recommends 2-1/2" hose, or larger, because it is

more effective at evacuating dust and chips, and provides

proper air flow over the router motor. Any hose larger or

smaller than 2-1/2" requires an adapter you must provide. If

additional dust collection is needed, a dust port can be

added to your cabinet or motor area. DO NOT USE YOUR

ROUTER TABLE WITHOUT DUST COLLECTION!

Page 12

Fence

b

i

t

r

o

t

a

t

i

o

n

Fence

Fence

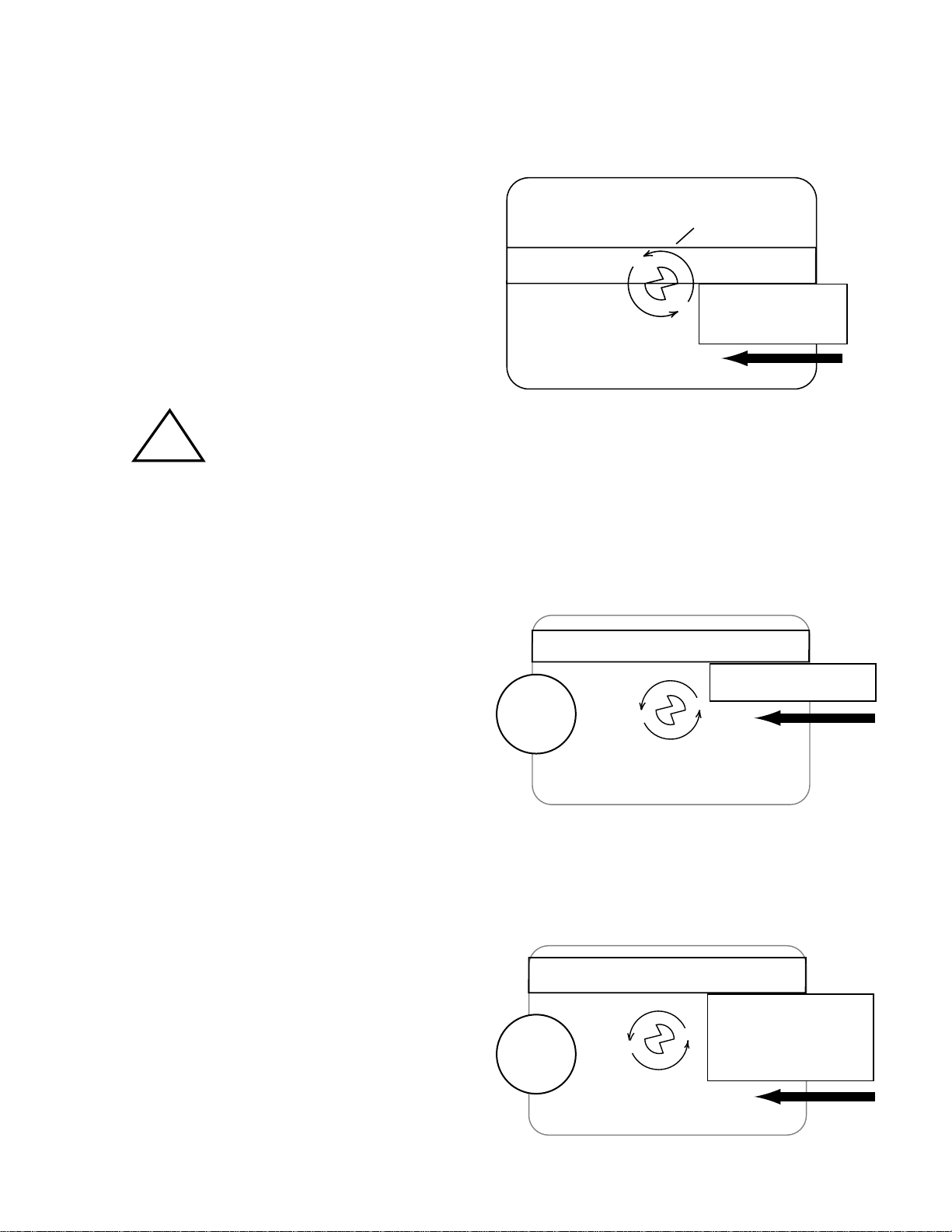

A classic trap resulting in a climb

cut. Always avoid this set-up!

This feed direction will

result in a climb cut because

the stock is trapped between

the fence and the router bit.

NO!

Proper feed direction

b

i

t

r

o

t

a

t

i

o

n

Avoiding Fence Traps

Fence traps occur when the work piece is fully

"trapped" between the router bit and fence. Fence

traps pose two real concerns: the possibility of climb

feeding, and human exposure to the router bit. As

stated earlier, climb cutting should be avoided as loss

of control of the operation is a possibility!

The top drawing shows a classic trap to be avoided.

What appears as a normal feed direction (working

from right to left) is wrong, and will instead produce a

climb cut. Because the work piece is trapped it can

easily be pulled from one's grip and thrown with great

velocity. Feeding the stock from left to right will

eliminate the climb cut but not the danger. It will be

difficult to keep the stock tight against the fence as the

bit's rotation will thrust the stock away from the fence.

Also, your body will be dangerously exposed to the

spinning router bit. The bit guard will not protect you

against flying stock, nor guard against this level of

exposure.

The second drawing is not a trap, as long as the router

bit cuts only partially into the stock. In other words, the

router bit must not completely cut through the

workpiece. In this cut, the bit will grab and push the

stock toward the fence. This is good, as the fence will

control the workpiece better than your hands. Typical

dado cuts resemble this set-up, and are commonly

performed on router tables. If the dado is to be

widened with two (or more) passes, be careful not to

set a classic trap or climb cut.

OK for

dadoes

only

Not a trap as long as the router bit does not

cut all the way through the stock.

Here the feed direction is

correct because the router

bit does not cut all the way

through the stock.

Never Climb Cut!

!

Feed Direction

routertop (top view)

workpiece

workpiece

workpiece

router bit rotation

Always feed the workpiece against the cutter

rotation, as shown. Feeding the workpiece with

the cutter rotation is called "climb cutting". Climb

cutting is very dangerous, because the cutter will

grab the workpiece and thrust it the same direction

as the cutter rotation. Even small router bits will

overpower your ability to hold onto the workpiece

during a climb cut.

Do not use this router table until you understand

proper feed direction and bit rotation. If climb

cutting is still unclear, ask your retailer for help,

give us a call, or reference a book on router table

usage.

A typical set-up. Here, the fence is

partially covering the router bit.

Page 13

Adjusting the Subfences

The (2) MDF (medium density fiberboard) subfences are

designed to slide along the fence approximately 2".

This results in a router bit opening from 0 to 4".

A. "Close" Setting

Many applications require adjusting the subfences close

to the router bit. This accomplishes nearly the same

benefits of a true "zero clearance" setting (see "B")

without cutting the subfences. Before the router is

turned on, and after the fence and router bit height are

properly adjusted, slide the subfences toward the bit to

reduce the gap. Confirm that the router bit can freely

rotate without touching the subfences!

B. "Zero Clearance" Setting

Cutting the subfences into the router bit profile produces

"zero clearance". Zero clearance eliminates the gap

between the fence and router bit. This prevents the

workpiece from getting pulled into the fence just before

the router bit. Moreover, a zero clearance setting

achieves a cleaner cut because the subfence supports

the workpiece fibers. If a true zero clearance setting is

desired, follow these steps:

1. Adjust the bit height and fence position. Note: the

subfences must NOT contact the router bit at this time.

2. Install the bit guard and secure.

4. Start router, and use dust collection. From the back of

the fence, slightly loosen the subfence knobs and

carefully slide the infeed subfence into the spinning

router bit. Hold onto the subfence knobs.

5. After the subfence has reached the guide bearing of

the router bit, fully tighten the knobs on the subfence.

Note: If the bit does not have a guide bearing (i.e.

vertical raised panel bits), slide the subfence half-way

into the bit, then tighten the subfence knobs.

outfeed subfence infeed subfence

outfeed subfence infeed subfence

Router Bit Guide Bearing

The infeed subfence is wide open, and the

outfeed subfence is set to "close".

Here the infeed subfence has been

adjusted to zero clearance.

!

Important Notes:

The outfeed subfence is rarely set to zero clearance,

because doing so has little performance benefit and can

damage the subfence. A "close" setting is more desirable for

most applications. Setting the outfeed subfence to zero

requires great care because the router bit can cause a

portion of the subfence to chip or break. If an outfeed zero

clearance is absolutely necessary, slide the outfeed

subfence very slowly into the bit to minimize the chipping

and tearing.

The subfences can be flipped when changing profiles or bit

heights. New, replacement subfences are available when a

new profile is to be created or if the subfence cannot be

trimmed to provide a fresh edge.

MDF works very well as a subfence because it is softer than

most woods and is much less likely to damage expensive

router bits. MDF also retains the shape of delicate profiles

and thus allows proper support for zero clearance settings.

When adjusting the fence, ensure that no part of the

aluminum fence body could contact the router bit.

Caution: Never adjust or slide the

subfences from the front! Always work

from the back with both hands on the

adjustment knobs.

Jointing

Set-up the Fence

Jointing is the process of making flat, square and straight mating edges.

Jointing is necessary when two boards are edge glued to create a larger

panel. It is also used to "fit" pieces together, as well as to trim stock to

size.

Note: Jointing on a router table is not intended to replace a free-standing

power jointer, especially for stock wider than 1.25". However, jointing with

the router table does have advantages over the jointer. First, small and

short pieces of wood can be safely jointed because the opening of the

fence can be made very small: about 1/2". Second, the quality of the cut

is usually better because the router bit spins much faster than the

jointer's cutter head. A faster cutter speed is especially useful on woods

prone to tear-out, like bird's eye maple and quilted cherry. Be sure not to

move too slowly, as this will leave burn marks in your workpiece.

Your fence has built-in jointing slots to accept the (2) small aluminum

jointer bars that shipped with your router table. Installed in pairs, these

bars "shim out" the out feed subfence either 1/32" or 5/64" (2mm).

Unplug router and install a 1/2" diameter straight or spiral up-cut router

bit.

Caution: Use only 1/2" shank bits for jointing. The bit's cutting

length must not exceed 1.25". Set the bit height to 1.25" or less.

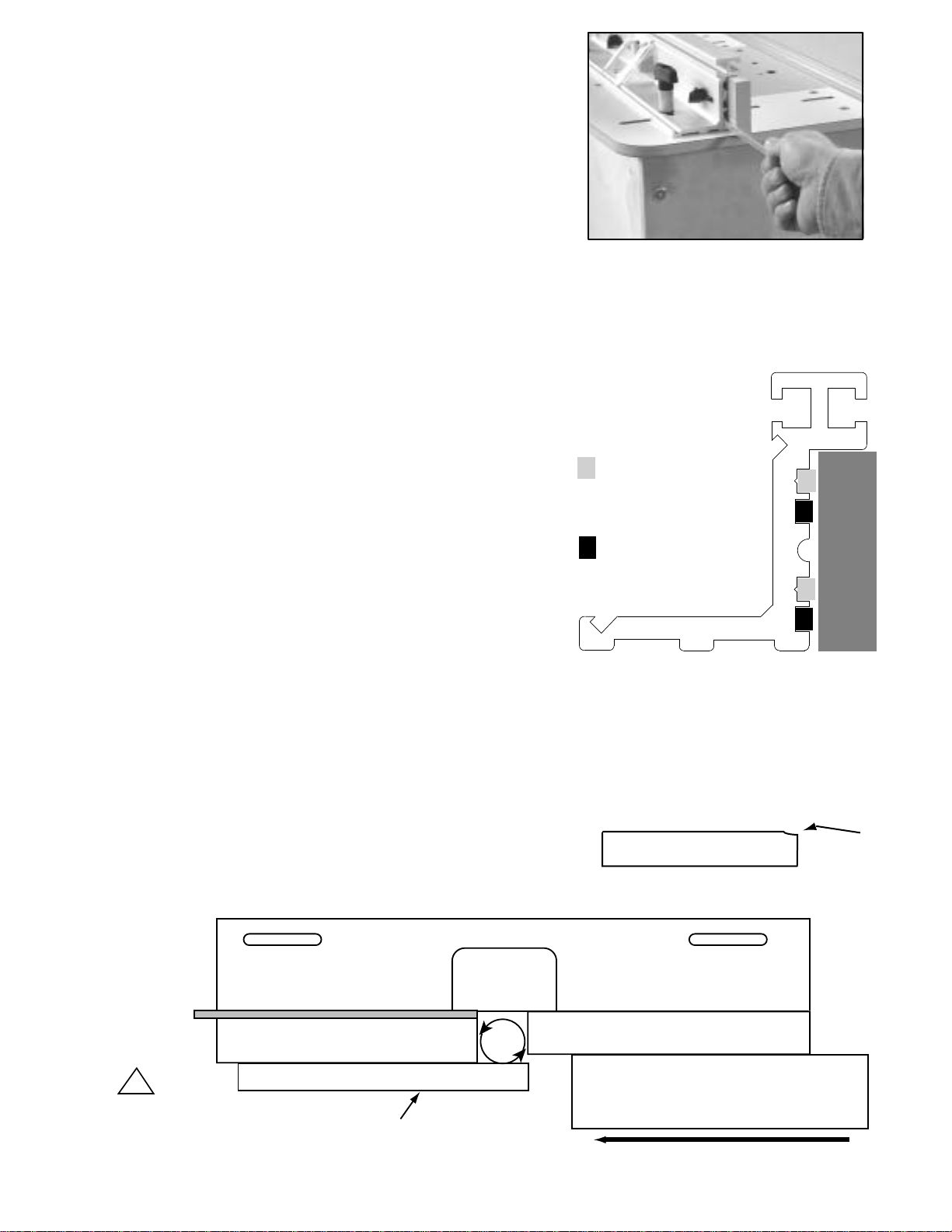

Loosen the outfeed subfence mounting knobs and slide both aluminum

jointer bars (always installed in pairs!) under the outfeed subfence in

either the 2nd and 4th slots, or the 1st and 3rd slots (see illustration).

Use a straight edge to adjust the router bit and outfeed subfence to the

same plane (see illustration below). Readjust if necessary. Remove

straight edge when done.

Slide both subfences toward the bit to decrease the amount of gap

around the router bit. Be sure the subfences are not touching the router

bit. Also be sure the router bit is not touching the fence's aluminum body.

Tighten the subfence knobs and place the bit guard in position.

First make a test cut in scrap stock. Readjust if necessary.

outfeed

subfence

Use slots 2 and 4 for

1/32" cuts.

Use slots 1 and 3 for

5/64" (2mm) cuts.

If board "snipe" occurs, realign the out-

feed subfence to the router bit. Don't be

surprised if it takes a few tries to master

this operation.

snipe

jointer bars

Always use a push

stick or push pad.

outfeed subfence infeed subfence

Feed Direction

workpiece

fence (top view)

straight edge - remove before jointing!!!

router

bit

Use a straight edge to set

outfeed subfence and

router bit to same plane.

(Bit guard not shown for clarity, only!)

!

In this photo, the user is sliding the

second bar into position. Be sure to

tighten the subfence knobs when done!

Note the small "v"

grooves. Always install

the bars in pairs.

Page 14

1

2

3

4

This manual suits for next models

2

Other Bench Dog Tools Tools manuals

Popular Tools manuals by other brands

Tohnichi

Tohnichi BQSP operating instructions

Axcaliber

Axcaliber Extra Dovetail Jig user manual

Weidmüller

Weidmüller STRIPAX operating instructions

Astro Pneumatic Tool

Astro Pneumatic Tool 45080 manual

Hilti

Hilti NPU 100-22 Original operating instructions

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN HOB305PRO-SMW2 manual

Dynabrade

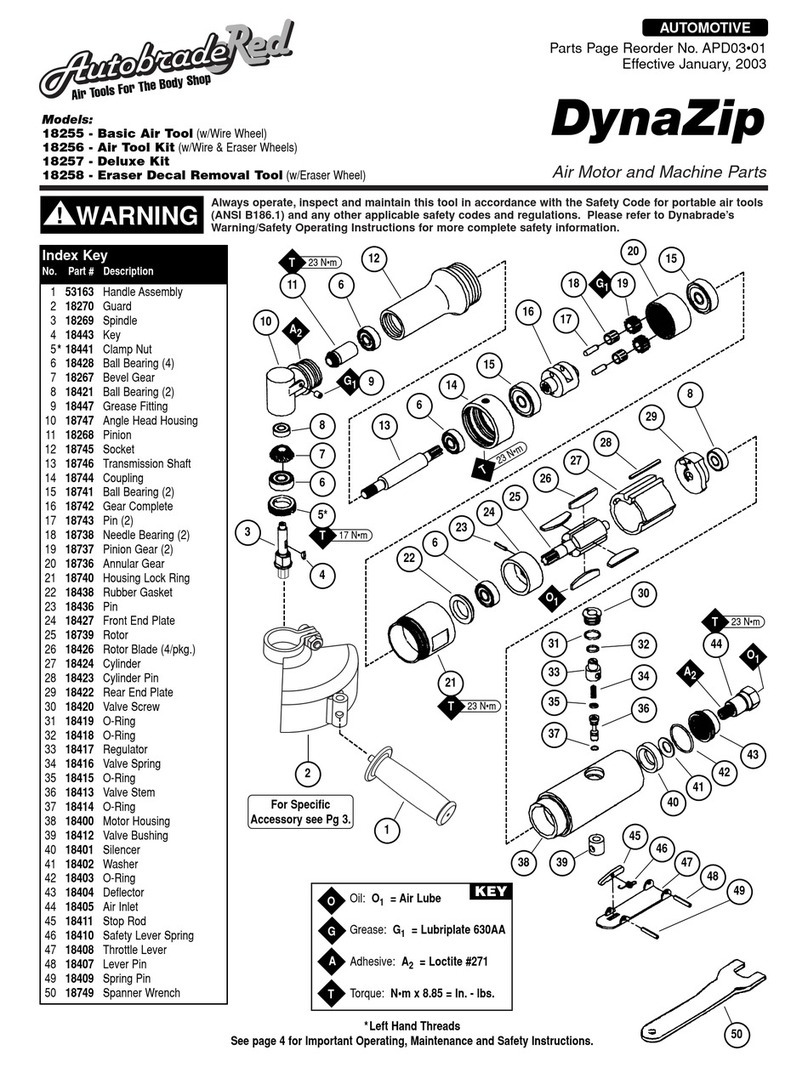

Dynabrade AutobradeRed DynaZip 18255 Operation instructions

Focused Technology Solutions

Focused Technology Solutions SpikeEase FTS20182 Operation manual

Jackco

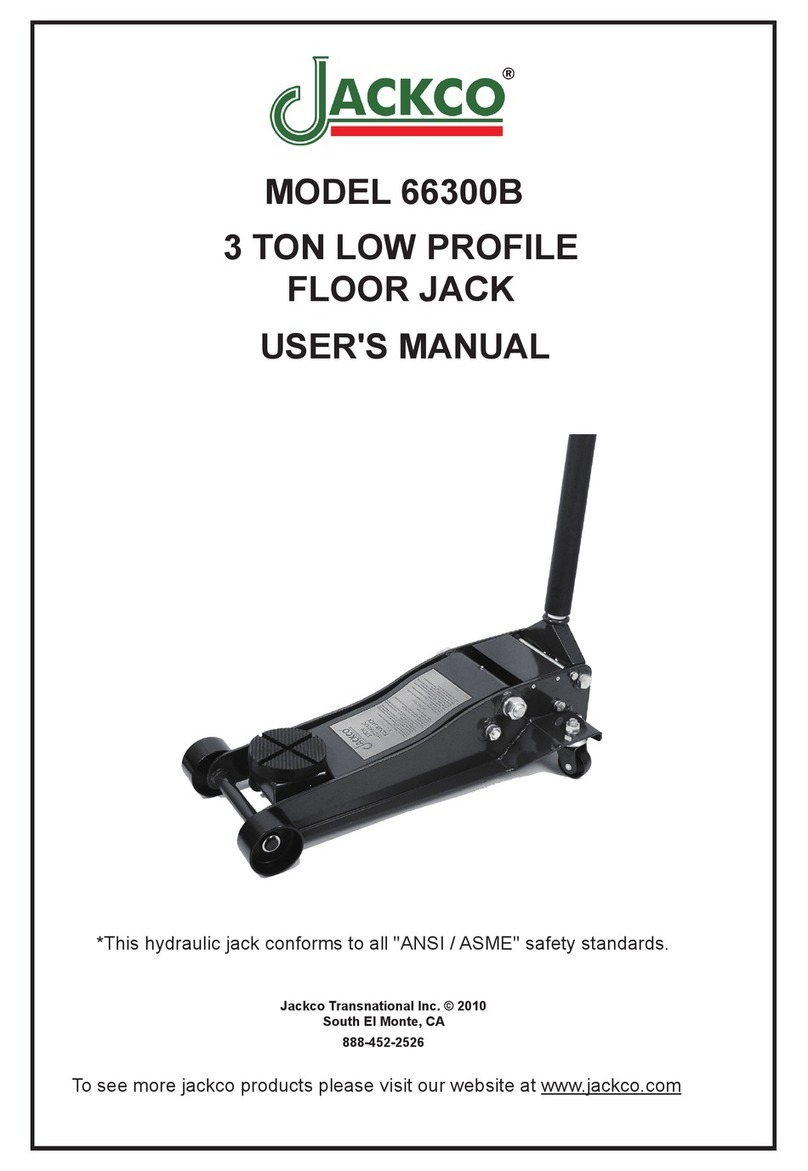

Jackco 66300B user manual

Hitachi

Hitachi H90SE Handling instructions

kincrome

kincrome K15061 manual

Uponor

Uponor 1015764 operating instructions