Focused Technology Solutions SpikeEase FTS20182 User manual

FTS20182 - Battery Operated Spike Puller

FTS20182 Operation Manual

04-21-21

www.FocusedTS.com

973.705.7133

customerservice@focusedts.com

1

TABLE OF CONTENTS

SAFETY SYMBOLS 2

SAFETY PRECAUTIONS 3

TOOLS STICKERS & TAGS 4

OPERATION 5

MAINTENANCE & TROUBLESHOOTING 6

SPECIFICATIONS 7

DRILL TYPE 7

ACCESSORIES 7

WARRANTY 7-8

IMPORTANT

To fill out a Product Warranty Recording form, and for information on your warranty, call FTS at (973) 705-7187

and request the Warranty form or have your Warranty assigned number ready. (NOTE: The warranty recording

form must be submitted to validate the warranty).

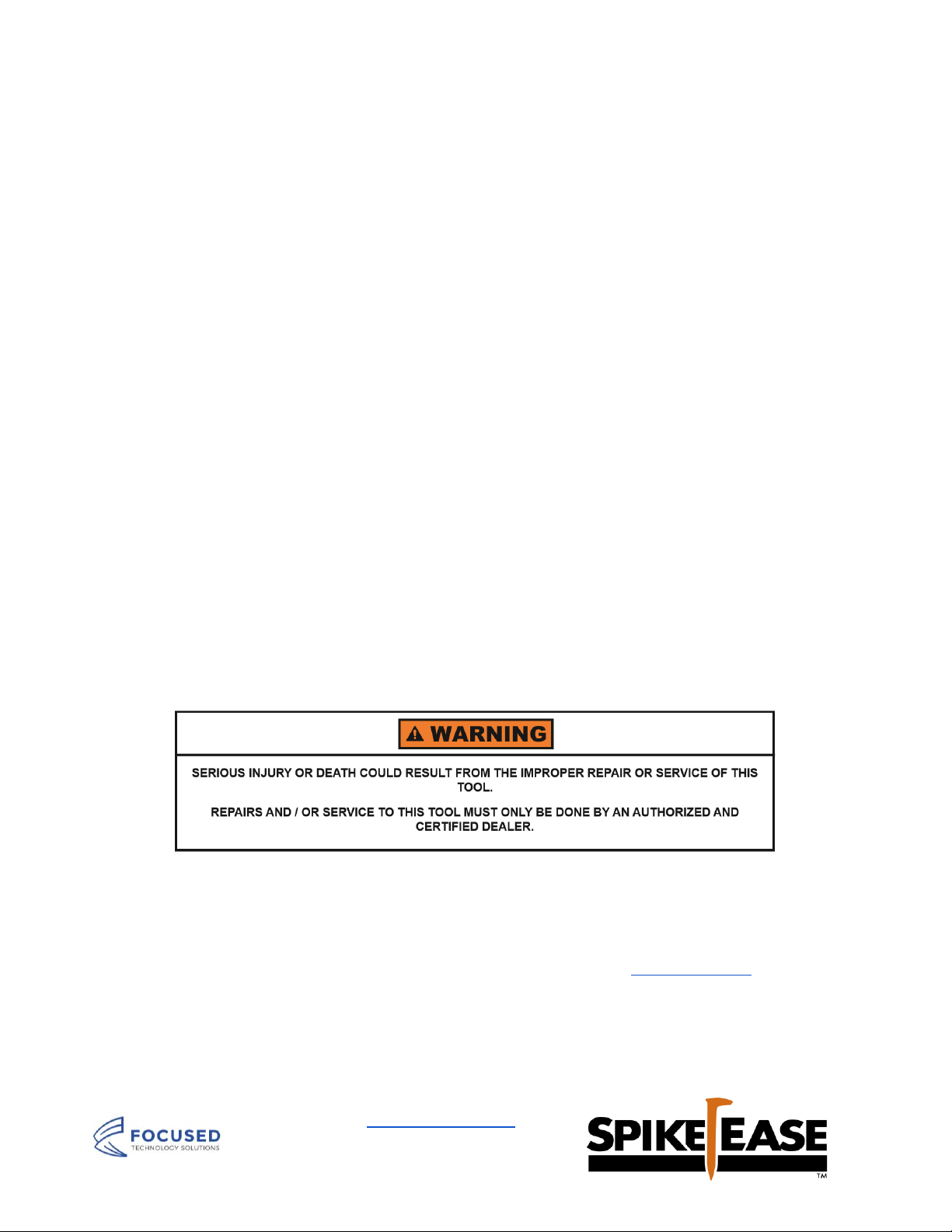

SERVICING: This manual contains safety, operation, and routine maintenance instructions. FTS recommends that

servicing of battery powered tools, other than routine maintenance, must be performed by an authorized and

certified dealer. Please read the following warning.

For the nearest authorized and certified dealer, call FTS at 973-705-7133 and ask for a Customer Service

Representative.

For our Terms and Conditions and any other information, visit our WebPage www.FocusedTS.com.

FTS20182 - Battery Operated Spike Puller

FTS20182 Operation Manual

04-21-21

www.FocusedTS.com

973.705.7133

customerservice@focusedts.com

2

SAFETY SYMBOLS

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair

actions which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to

equipment.

FTS20182 - Battery Operated Spike Puller

FTS20182 Operation Manual

04-21-21

www.FocusedTS.com

973.705.7133

customerservice@focusedts.com

3

SAFETY PRECAUTIONS

Tool operators and maintenance personnel must always comply with the safety precautions given in this manual

and on the stickers and tags attached to the tool. These safety precautions are given for your safety. Review

them carefully before operating the tool and before performing general maintenance or repairs. Supervising

personnel should develop additional precautions relating to the specific work area and local safety regulations. If

so, place the added precautions in the space provided in this manual. This tool will provide dependable service if

operated in accordance with the instructions given in this manual. Read and understand this manual and any

stickers and tags attached to the tool before operation. Failure to do so could result in personal injury or

equipment damage.

•Inspect work area prior to operation of tool and ensure safe distances maintained with tool and any spectators.

• Only thoroughly trained workers may operate the tool. Exception is for operators under the guidance of a

trainer. All operators must follow its own company’s established training program to ensure safe operation.

• Always wear the following safety equipment when operating the tool: ear protection, gloves, safety

goggles, head protection, and safety shoes.

• The operator must avoid operation of the tool in treacherous situations, such as steep slopes, dangerous

terrain and other prohibited conditions.

• Maintain proper footing and balance at all times. Do not overextend.

• Disconnect battery source from tool prior to inspection or cleaning. Accidental engagement of the tool may

cause serious injury.

• Do not operate a damaged, improperly adjusted, or incompletely assembled tool.

• Never wear loose clothing that can get entangled in the working parts of the tool.

• Do not weld or cut the chute, handle or jaws of the tool.

• Only use accessories that conform to the specifications given in the OPERATION section of this manual.

• All tool repair, maintenance and service must only be performed by authorized and properly trained personnel

to avoid personal injury or equipment damage.

• Place the end of the chute squarely against the tie plate, tilting as required to avoid the sudden realignment

that may occur as the tool begins to pull.

• Always hold the tool firmly with both hands on the handles when the unit is running.

FTS20182 - Battery Operated Spike Puller

FTS20182 Operation Manual

04-21-21

www.FocusedTS.com

973.705.7133

customerservice@focusedts.com

4

TOOLS STICKERS & TAGS

Focused Technology -SpikeEase - Pinch Point Warning Decal –FTS20182-CP02

Focused Technology SpikeEase - Arrow Decal - FTS20182-CP03

Focused Technology - SpikeEase - Eco Friendly Decal - FTS20182-UP01

Focused Technology Logo Decal –FTS SpikeEase Product Label - FTS20182-CP01

NOTE: THE INFORMATION LISTED ON THE STICKERS SHOWN, MUST BE LEGIBLE AT ALL TIMES. REPLACE DECALS

IF THEY BECOME WORN OR DAMAGED. REPLACEMENTS ARE AVAILABLE FROM YOUR LOCAL FTS DISTRIBUTOR.

A REPLACEMENT FEE MAY BE INCURRED.

FTS20182 - Battery Operated Spike Puller

FTS20182 Operation Manual

04-21-21

www.FocusedTS.com

973.705.7133

customerservice@focusedts.com

5

OPERATION

PRE-OPERATION SAFETY INSPECTION

CHECK BATTERY POWER SOURCE 1. Make sure the battery is fully charged. 2. Remove battery prior to

inspecting the claw or other moving parts of the unit.

CHECK TOOL 1. Make sure all tool accessories are correctly installed. Failure to install tool accessories properly

can result in damage to the tool or personal injury. 2. There should be no signs of damage or missing parts. 3.

The tool should be clean, with no loose or missing parts.

CHECK TRIGGER MECHANISM 1. Check that the trigger operates smoothly and is free to travel between the

"Forward - Up" and "Reverse - Down” positions.

OPERATING PROCEDURES

1. Observe all safety precautions (see page 3).

2. Ensure the battery is installed.

3. Arrows on the sides of the drill cradle indicate the direction of claw travel up or down. Press the drill button

to correspond with the direction in which you want the claw to travel.

4. Set the button to the “Forward - Up” setting. Place the spike puller firmly over the spike to be pulled, making

sure the end of the chute is in full contact with the spike plate.

The spike puller has an automatic pull cycle that engages the spike and sets the tool to the rail then fully

removes the spike. The cycle is automatic and operates by fully depressing the trigger.

5. Just before the top of the stroke, release the trigger, press the button to the “Reverse - Down” setting, engage

the trigger and the spike will automatically be ejected from the puller.

6. Do not use this tool to pull spikes at the joint bar. Doing so, could cause damage to the claw.

7. IMPORTANT: For all day use, every three to four hours, apply two pumps of lubricant (such as Premalube

Extreme Green NLGI #1, H2) through the maintenance port (lower port in upper housing). To apply the lubricant,

slide open the inspection port door, located on the upper housing. Then engage the drill to raise or lower the

carriage plate until the grease fitting is centered in the inspection port opening. Then apply two pumps of

lubricant. Units arrive pre-greased.

8. Ensure that Agency’s safety procedures are followed when working around or near the third rail.

9. Make sure drill is set to #3. Sometimes hands may accidentally reset to a lower setting.

10. Always remove the battery from the tool when not in use. Never access the unit with the battery installed.

COLD WEATHER OPERATION If the spike puller is to be used during cold weather, it may reduce the charge life

of the battery.

FTS20182 - Battery Operated Spike Puller

FTS20182 Operation Manual

04-21-21

www.FocusedTS.com

973.705.7133

customerservice@focusedts.com

6

MAINTENANCE

Daily: Check all accessible screws for tightness. Apply two pumps of provided lubricant every three to four

hours via maintenance port as in item 7 in operating procedures.

Note: Any major repair(s) must be performed by an authorized and certified dealer. Call 973-705-7187.

TROUBLESHOOTING

If symptoms of poor performance develop, the following points can be used as a guide to correct the problem.

When diagnosing faults in operation of the spike puller, always check the battery power source and battery

charge level.

Problem:

Solution:

Spike puller does not cycle properly

Check the power source for proper contact and make

sure the tool is properly lubricated.

Spike puller does not pull effectively

Check power source for damage and check trigger

switch to ensure proper setting for pulling.

Spike puller operates slowly

Check for low battery level and replace the battery. If

a Milwaukee drill is used, make sure it is set to #3.

Jaw does not retract or extend while operating

Check power source for proper contact, low battery,

or remove the battery and look into the chute for an

impedance. Remove impedance and replace the

battery.

*NEVER ACCESS UNIT WITH BATTERY ENGAGED

●Always store the tool in a clean, dry space, safe from damage or pilferage. Also, ensure the battery is

disengaged and not on the tool.

●Do not exceed the rated limits or use of the tool for applications beyond its designed capacity. (see

manual)

●Always keep critical tool markings, such as labels and warning stickers legible.

●Permit only authorized and certified dealers to perform tool repair.

FTS20182 - Battery Operated Spike Puller

FTS20182 Operation Manual

04-21-21

www.FocusedTS.com

973.705.7133

customerservice@focusedts.com

7

SPECIFICATIONS

Pulling Force - 14,080 lbs. (Milwaukee Drill); 13,500 lbs. (DeWalt Drill)

Weight* - 28 lbs.

Overall Length - 38.76” (with the claw fully extended)

Overall Handle Width - 15.18”

Drill Specification - Milwaukee Impact Drill 2767-20 for FTS20182-09, FTS20182-96 and FTS20182-99; Dewalt

Impact Drill DCF899HB for FTS20182-97, FTS20182-98 and FTS 20182-138

*Does not include drill.

COMPATIBLE DRILL TYPES

Milwaukee Drill 2767-20

DeWalt Drill DCF899HB

ACCESSORIES

FTS20182-70 - ½” Impact Wrench - Milwaukee

FTS20182-84 - Rapid Charger - Milwaukee

FTS20182-75 - 12AH Battery - Milwaukee

FTS20182-152 - 12AH Battery and rapid charger kit -

Milwaukee

SpikeEase Warranty (less drill)

LIMITED WARRANTY

Focused Technology Solutions manufactured products purchased in the U.S., Canada or Europe come with a

limited warranty; if properly used and installed, will be free from defects in material and workmanship for a period

of 90 days after the date of purchase. The warranty period is not extended if we repair or replace a warranted

product or any parts. Said warranty to include the repair or replacement of defective parts or equipment only.

Legislation requires that all protective equipment be tested at least once a year for compliance with Focused

Technology Solutions specifications and to industry standards. Ensuring your safety equipment meets or

exceeds the highest standards reduces the costs of lost-time accidents. Focused Technology Solutions

independent testing facilities used are fully industry compliant.

FTS20182 - Battery Operated Spike Puller

FTS20182 Operation Manual

04-21-21

www.FocusedTS.com

973.705.7133

customerservice@focusedts.com

8

Call 973-705-7133 for “Service and Support” for Service and Maintenance contracts Focused Technology

Solutions offers to the customers. We strongly recommend this service to all our customers.

What is not covered by this limited warranty?

This limited warranty does not cover:

Components manufactured by other parties, damage due to external causes, including accident,

problems with electrical power, and usage not in accordance with product instructions, misuse, neglect,

alteration, repair by unauthorized persons, improper installation, or improper testing and improper

operating procedures.

This limited warranty does not cover batteries or rechargeable batteries.

THIS LIMITED WARRANTY, AND ANY IMPLIED WARRANTIES THAT MAY EXIST UNDER STATE LAW,

APPLY ONLY TO THE ORIGINAL PURCHASER OF THE EQUIPMENT, AND LAST ONLY FOR AS LONG AS

SUCH PURCHASER CONTINUES TO OWN THE EQUIPMENT. THIS WARRANTY REPLACES ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. FOCUSED TECHNOLOGY SOLUTIONS

MAKES NO EXPRESS WARRANTIES BEYOND THOSE STATED HERE. FOCUSED TECHNOLOGY

SOLUTIONS DISCLAIMS WITHOUT LIMITATION, IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. SOME JURISDICTIONS DO NOT ALLOW THE EXCLUSION OF

IMPLIED WARRANTIES, SO THIS LIMITATION MAY NOT APPLY TO YOU.

TO OBTAIN WARRANTY SERVICE, CONTACT FOCUSED TECHNOLOGY SOLUTIONS FOR A RETURN

MATERIAL AUTHORIZATION. WHEN RETURNING EQUIPMENT TO FOCUSED TECHNOLOGY SOLUTIONS,

THE CUSTOMER ASSUMES THE RISK OF DAMAGE OR LOSS DURING SHIPPING AND IS RESPONSIBLE

FOR THE SHIPPING COSTS INCURRED.

Drill Warranty:

See drill manufacturer’s standard warranty.