Bend-Pak RBJ Series User manual

1645 Lemonwood Dr.

Santa Paula, CA, 93060 USA

Toll Free: 1 (800) 253-2363

Tel: 1 (805) 933-9970

bendpak.com

RBJ Series of Rolling Bridge Jacks

Installation and Operation Manual

Manual Revision A — Released May 2017 — Manual P/N 5900004

Models:

•RBJ4500

•RBJ6000

•RBJ7000

•RBJ9000

•RBJ15000

•RBJ18000

•RBJ25000

Designed and engineered by BendPak Inc. in Southern California, USA. Made in China.

⚠DANGER

Always operate this equipment as directed; failure to do so may

cause injury or death. Read the entire contents of this manual prior

to installation or operation. Make sure all other operators also read

this manual. By proceeding with setup and operation, you agree

that you fully understand the contents of this manual.

Manual. RBJ Series of Rolling Bridge Jacks, Installation and Operation Manual, Manual Part Number 5900004,

Manual Revision A, Released May 2017.

Copyright. Copyright © 2017 by BendPak Inc. All rights reserved. No part of this manual can be reproduced,

adapted, translated, or transmitted by any means, electronic or mechanical, for any purpose or in any form,

without prior written permission of BendPak Inc.

Trademarks. BendPak and the BendPak logo are registered trademarks of BendPak Inc. All other company,

product, and service names are used for identification only. All trademarks and registered trademarks mentioned

in this manual are the property of their respective owners.

Limitations. Every effort has been made to ensure complete and accurate instructions are included in this

manual. However, product updates, revisions, and/or changes may have occurred since this manual was

published. BendPak reserves the right to change any information in this manual without incurring any obligation for

equipment previously or subsequently sold. BendPak is not responsible for typographical errors in this manual.

Warranty. The BendPak warranty is more than a commitment to you: it is also a commitment to the value of

your new product. For full warranty details and to register your new product, contact your nearest BendPak dealer

or visit bendpak.com/support/warranty.

Safety.Your new product was designed and manufactured with safety in mind. Your safety also depends on

proper training and thoughtful operation. Do not set up, operate, maintain, or repair the unit without reading and

understanding this manual and the labels on the unit.

Owner Responsibility. In order to maintain your product properly and to ensure operator safety, it is the

responsibility of the product owner to read and follow these instructions:

• Follow all setup, operation, and maintenance instructions.

• Make sure product setup conforms to all applicable local, state, and federal codes, rules, and regulations,

such as state and federal OSHA regulations and electrical codes.

• Read and follow all safety instructions. Keep them readily available for operators.

• Make sure all operators are properly trained, know how to safely operate the unit, and are properly supervised.

• Do not operate the product until you are certain all parts are in place and operating correctly.

• Carefully inspect the product on a regular basis and perform all maintenance as required.

• Service and maintain the unit only with approved replacement parts.

• Keep all instructions permanently with the product and make sure all labels are clean and visible.

Unit Information. Enter the Model Number, Serial

Number, and the Manufactured On date from the label

on your unit. This information is required for part or

warranty issues.

Model:

Serial:

Manufactured On:

RBJ Series of Rolling Bridge Jacks 3P/N 5900004 — May 2017 — Rev. A

Table of Contents

Introduction 3 Maintenance 21

Shipping Information 4 Troubleshooting 22

Safety Considerations 4 Warranty 22

System Components 6 Accessories 23

Specifications 7 Labels 25

Setup 8 Parts Sheets 27

Operation 19 Maintenance Log 51

Introduction

This manual covers the RBJ series of rolling bridge jacks, which are used with four-post lifts to raise

two or four wheels off the runway, thus making automotive service such as brake jobs and suspension

work easier to accomplish.

This manual covers the following RBJ models:

•RBJ4500: Can lift up to 4,500 lbs or 2,041 kg; ALI certified

•RBJ6000: Can lift up to 6,000 lbs or 2,721 kg; ALI certified

•RBJ7000: Can lift up to 7,000 lbs or 3,175 kg; ALI certified

•RBJ9000: Can lift up to 9,000 lbs or 4,082 kg; ALI certified

•RBJ15000: Can lift up to 15,000 lbs or 6,804 kg

•RBJ18000: Can lift up to 18,000 lbs or 8,165 kg

•RBJ25000: Can lift up to 25,000 lbs or 11,340 kg

ALI is the Automotive Lift Institute, an independent organization whose

mission is to promote the safe design, construction, installation,

inspection, and use of automotive lifts.

When a lift is ALI certified, it means that it has been tested by a third-

party, independent organization (ALI) and proven to meet the safety and

performance requirements outlined in the safety standard ANSI/ALI

ALCTV (current edition) “Safety Requirements for the Construction,

Testing and Validation of Automotive Lifts”.

Note that the RBJ15000, RBJ18000, and RBJ25000 were not

submitted for ALI certification.

This manual is mandatory reading for all users of these jacks, including anyone who installs, operates,

maintains, or repairs them.

RBJ Series of Rolling Bridge Jacks 4P/N 5900004 — May 2017 — Rev. A

⚠DANGER Be very careful when installing, operating, maintaining, or repairing your unit; failure

to do so could result in property damage, product damage, injury, or (in very rare

cases) death. Make sure only authorized personnel operate the unit. All repairs

must be performed by an authorized technician. Do not make modifications to the

unit; this voids the warranty and increases the chances of injury or property

damage. Make sure to read and follow the instructions on the labels on the unit.

Keep this manual on or near your jack so that it can be ready by anyone who operates or services it.

Technical support for your unit is available directly from your distributor or you can contact BendPak

Customer Service at (800) 253-2363. You can also ask for parts replacement (be sure to have the

serial and model numbers of your unit available).

Shipping Information

Your unit was carefully checked before shipping. Nevertheless, you should thoroughly inspect the

shipment before you sign to acknowledge that you received it.

When you sign the bill of lading, it tells the carrier that the items on the invoice were received in good

condition. To protect yourself, do not sign the bill of lading until after you have inspected the shipment.

If any of the items listed on the bill of lading are missing or are damaged, do not accept the shipment

until the carrier makes a notation on the bill of lading that lists the missing and/or damaged goods.

If you discover missing or damaged goods after you receive the shipment and have signed the bill of

lading, notify the carrier at once and request the carrier to make an inspection. If the carrier will not

make an inspection, prepare a signed statement to the effect that you have notified the carrier (on a

specific date) and that the carrier has failed to comply with your request.

It is difficult to collect for loss or damage after you have given the carrier a signed bill of lading. If this

happens to you, file a claim with the carrier promptly. Support your claim with copies of the bill of

lading, freight bill, invoice, and photographs, if available. Our willingness to assist in helping you

process your claim does not make us responsible for collection of claims or replacement of lost or

damaged materials.

Safety Considerations

Read this manual carefully before using your new product.

Do not set up or operate

the product until you are familiar with all operating instructions and warnings. Do not allow anyone else

to operate the product until they are also familiar with all operating instructions and warnings.

Rolling Bridge Jack Safety Information

Please note the following:

•The product is a rolling bridge jack. Use it only for its intended purpose.

•The product should only be operated by authorized personnel.

•When the product is in use, keep all body parts away from it.

•Do not make any modifications to the product.

•Make sure all operators read and understand this Installation and Operation Manual. Keep the

manual near the device at all times.

RBJ Series of Rolling Bridge Jacks 5P/N 5900004 — May 2017 — Rev. A

•Make a visual inspection of the product before using it. Check for missing or damaged parts. Do

not use the product if you find any of these issues. Instead, contact an authorized repair facility,

your distributor, or BendPak Customer Service at (800) 253-2363.

•Make a thorough inspection of the product at least once a year. Replace any damaged or severely

worn electrical cables, hydraulic hoses, decals, or warning labels. Do not use the product until

worn or damaged items have been replaced.

•Do not touch hot parts; you could be burned.

•Take care locating cables and hoses; you do not want them driven over or stepped on.

•Always wear heavy-duty footwear and safety glasses when using the product.

•Clear the area if a vehicle is in danger of falling off the jack.

•

Make sure your jack is in a locked position before starting work.

•Operating temperature for all rolling bridge jacks is 41°F to 104°F (5°C to 40°C).

•Make sure the weight of a vehicle being raised by a rolling bridge jack does not exceed the

maximum lifting capacity of the jack.

Symbols

Following are the symbols used in this manual:

⚠DANGER Calls attention to an immediate hazard that

will

result in death or severe injury.

⚠WARNING Calls attention to a hazard or unsafe practice that

could

result in death or severe

personal injury.

⚠CAUTION Calls attention to a hazard or unsafe practice that could result in minor personal

injury, product, or property damage.

Tip Calls attention to information that can help you use your product better.

Liability Information

BendPak assumes no liability for damages resulting from:

• Use of the equipment for purposes other than those described in this manual.

• Modifications to the equipment without prior, written permission from BendPak.

• Damage to the equipment from external influences.

• Incorrect operation of the equipment.

RBJ Series of Rolling Bridge Jacks 6P/N 5900004 — May 2017 — Rev. A

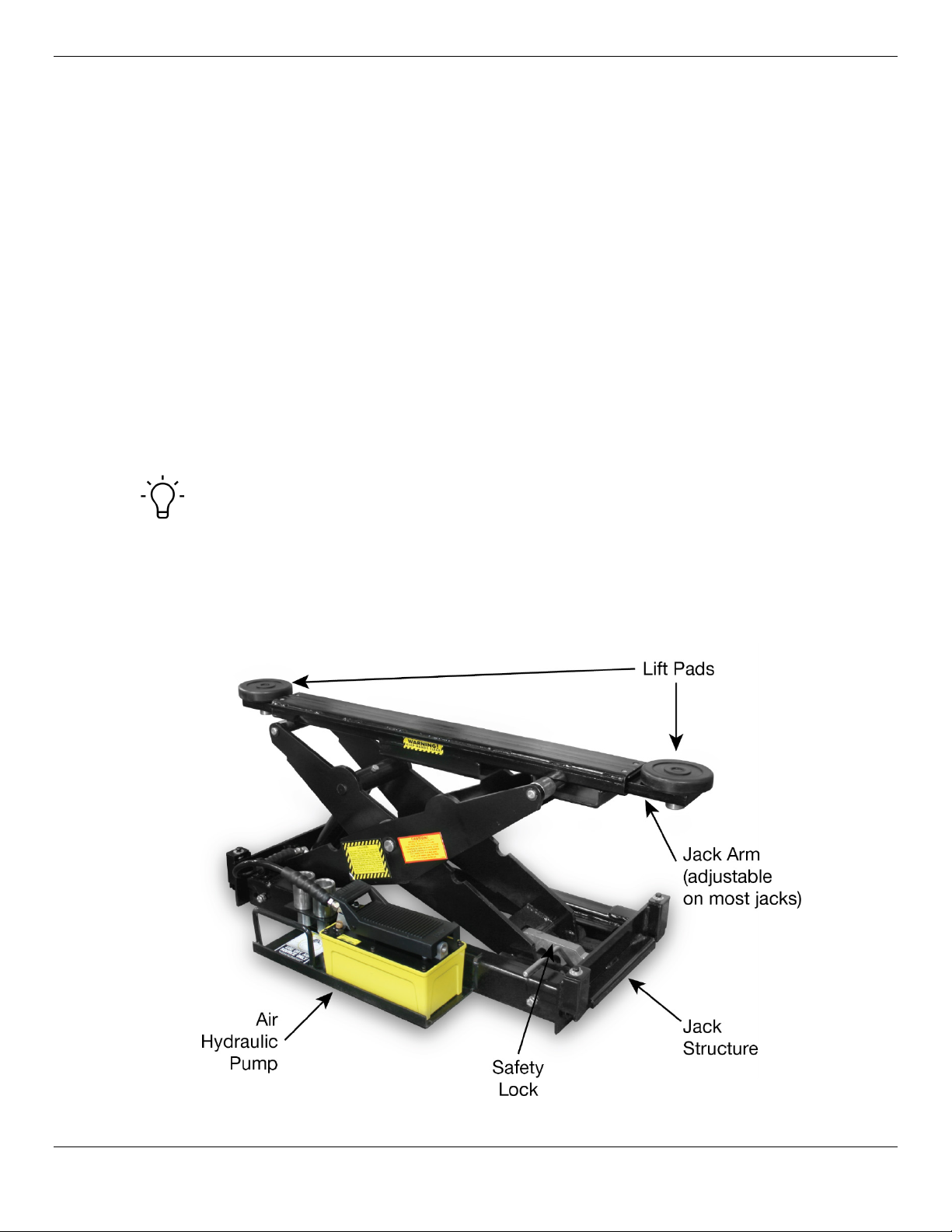

System Components

Rolling bridge jack system components include:

•Lift structure. All rolling bridge jacks are scissor lifts that are powered by air pressure from the

air hydraulic pump, which must be attached to an appropriate air supply.

•Air hydraulic pump. The air hydraulic pump provides power to the lift structure so that it can lift

vehicles. The pump must be attached to an appropriate air supply: 20 CFM (.57 M3/min.) and 100

PSI (7 bar).

•Safety lock. The safety lock holds the lift structure in place once you have raised it to the desired

height. When raising your lift, always put it into a locked position; never leave a jack in an unlocked

position if it is raised.

⚠WARNING Before starting work on a vehicle, make sure the jack is in a locked position and

that all lift pads are in contact with the lifting points on the underside of the vehicle.

•Round lift pad. Lift pads are where the jack connects to the lifting points on the underside of the

vehicle. They fit into the holes on the end of the jack arms. You can also add an included extension

adapter under the round lift pad to give it greater height above the jack arm.

Tip If you have an RBJ4500 and want more control over where the jack contacts the

lifting points on the underside of vehicles, the RBJ4500 Adapter Kit includes two

sliding rubber contact pads and two sliding receivers. See RBJ4500 Adapter

Kit for more information.

•Jack arm. Jack arms slide in and out to accommodate the lifting points of the vehicles you want

to lift. The ends of the jack arm have a hole into which the lift pads and extenders fit.

RBJ4500 shown. Some models are slightly different.

RBJ Series of Rolling Bridge Jacks 7P/N 5900004 — May 2017 — Rev. A

Specifications

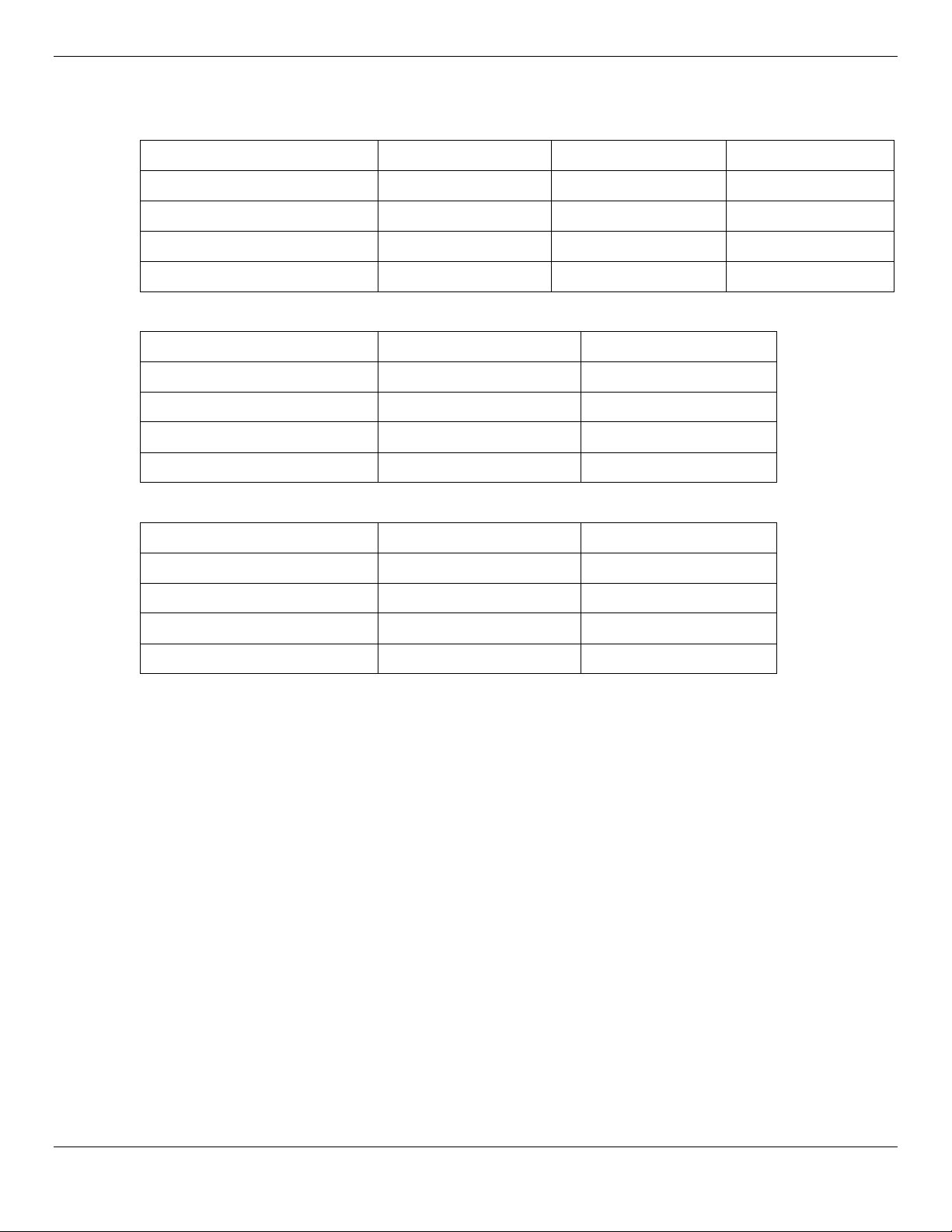

Model RBJ4500 RBJ6000 RBJ7000

Lifting capacity 4,500 lbs / 2,041 kg 6,000 lbs / 2,721 kg 7,000 lbs / 3,175 kg

Minimum arm reach 42" / 1,069 mm 41.8" / 1,062 mm 41.8" / 1,062 mm

Maximum arm reach 57" / 1,449 mm 56.1" / 1,426 mm 56.1" / 1,426 mm

Shipping weight 305 lbs / 139 kg 305 lbs / 139 kg 305 lbs / 139 kg

Model RBJ9000 RBJ15000

Lifting capacity 9,000 lbs / 4,082 kg 15,000 lbs / 6,804 kg

Minimum arm reach 41.8" / 1,062 mm 39.4" / 1,003 mm

Maximum arm reach 56.1" / 1,426 mm 63.7" / 1,618 mm

Shipping weight 305 lbs / 139 kg 570 lbs / 259 kg

Model RBJ18000 RBJ25000

Lifting capacity 18,000 lbs / 8,165 kg 25,000 lbs / 11,340 kg

Minimum arm reach 39.6" / 1,008 mm 39.6" / 1,008 mm

Maximum arm reach 63.4" / 1,612 mm 63.4" / 1,612 mm

Shipping weight 788 lbs / 358 kg 802 lbs / 363 kg

Specifications are subject to change without notice.

RBJ Series of Rolling Bridge Jacks 8P/N 5900004 — May 2017 — Rev. A

Setup

This section describes how to set up your rolling bridge jack.

Tools

You need the following tools:

•Hex key wrench set

•Medium crescent wrench

•Shop crane or other heavy lifting device

•Medium flat screwdriver

•Tape measure, 25 feet or longer

•Air fitting, to connect the rolling bridge jack’s pump to an air supply

Preparing the Lift

Rolling bridge jacks are situated in the open space between the two runways of an appropriate lift.

Keep the following in mind:

•The lift must be installed and operating normally. Only use a rolling bridge jack with an

appropriate lift that has been installed according to manufacturer’s instructions and is operating

normally per those instructions.

⚠WARNING Do not set up or use a rolling bridge jack if the lift is not the model the rolling bridge

jack was designed for or the lift was improperly installed. Instead, contact the

manufacturer of the lift or BendPak Customer Service at (800) 253-2363 for

instructions.

•The lift must be lowered to the ground. Before situating your rolling bridge jack, lower the

lift to the ground or to its lowest position.

Tip If you are going to be using a shop crane to situate your rolling bridge jack, you may need

to lock the lift on the lowest lock position to make room for the legs of the shop crane.

RBJ Series of Rolling Bridge Jacks 9P/N 5900004 — May 2017 — Rev. A

•You can only use the jack in certain locations. You can only use your jack at certain

locations on the lift; basically, the ends but not the middle.

RBJ Series of Rolling Bridge Jacks 10 P/N 5900004 — May 2017 — Rev. A

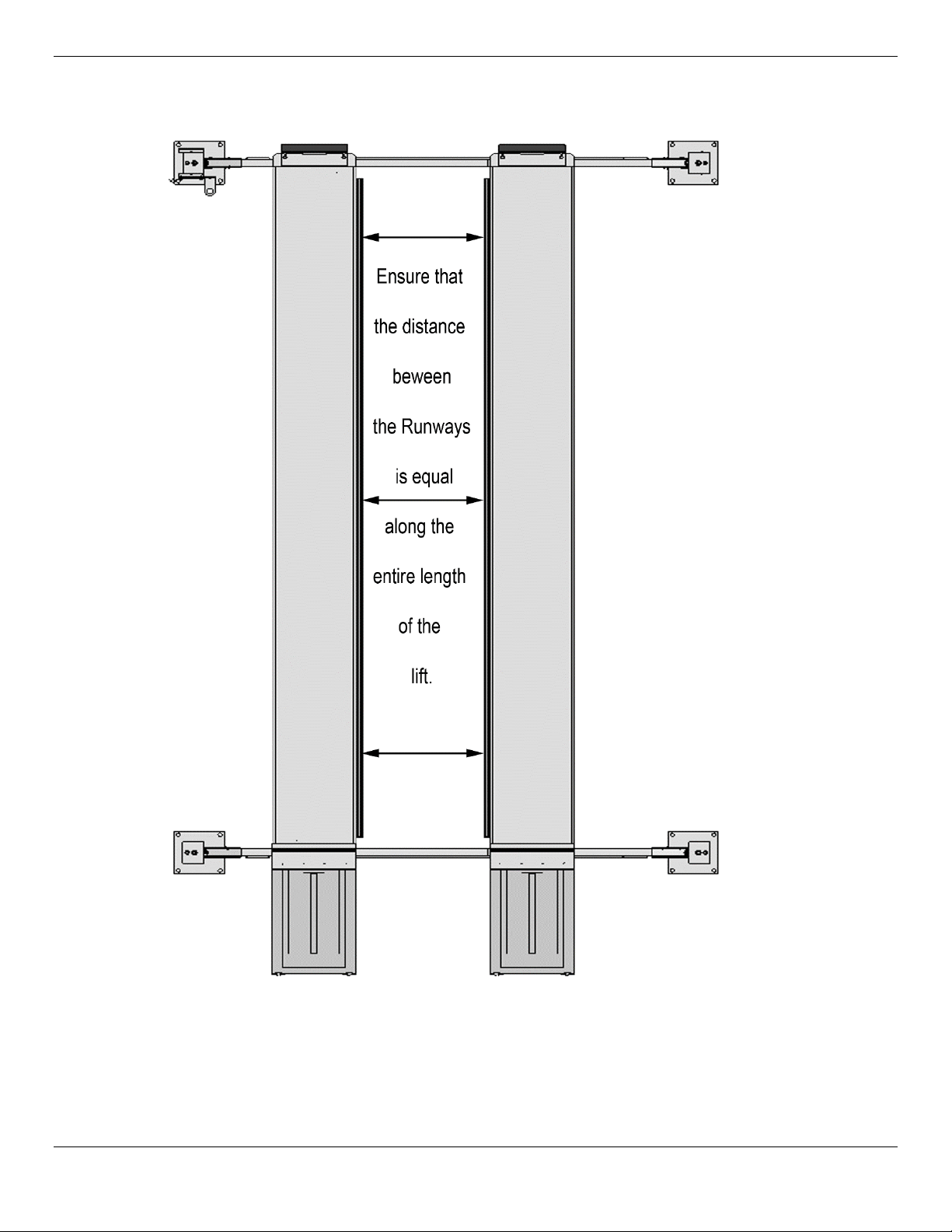

•The lift runways

must

be parallel. Make sure the lift runways were installed parallel to each

other. The distance between the lift runways must be equal along the entire length of the lift.

RBJ Series of Rolling Bridge Jacks 11 P/N 5900004 — May 2017 — Rev. A

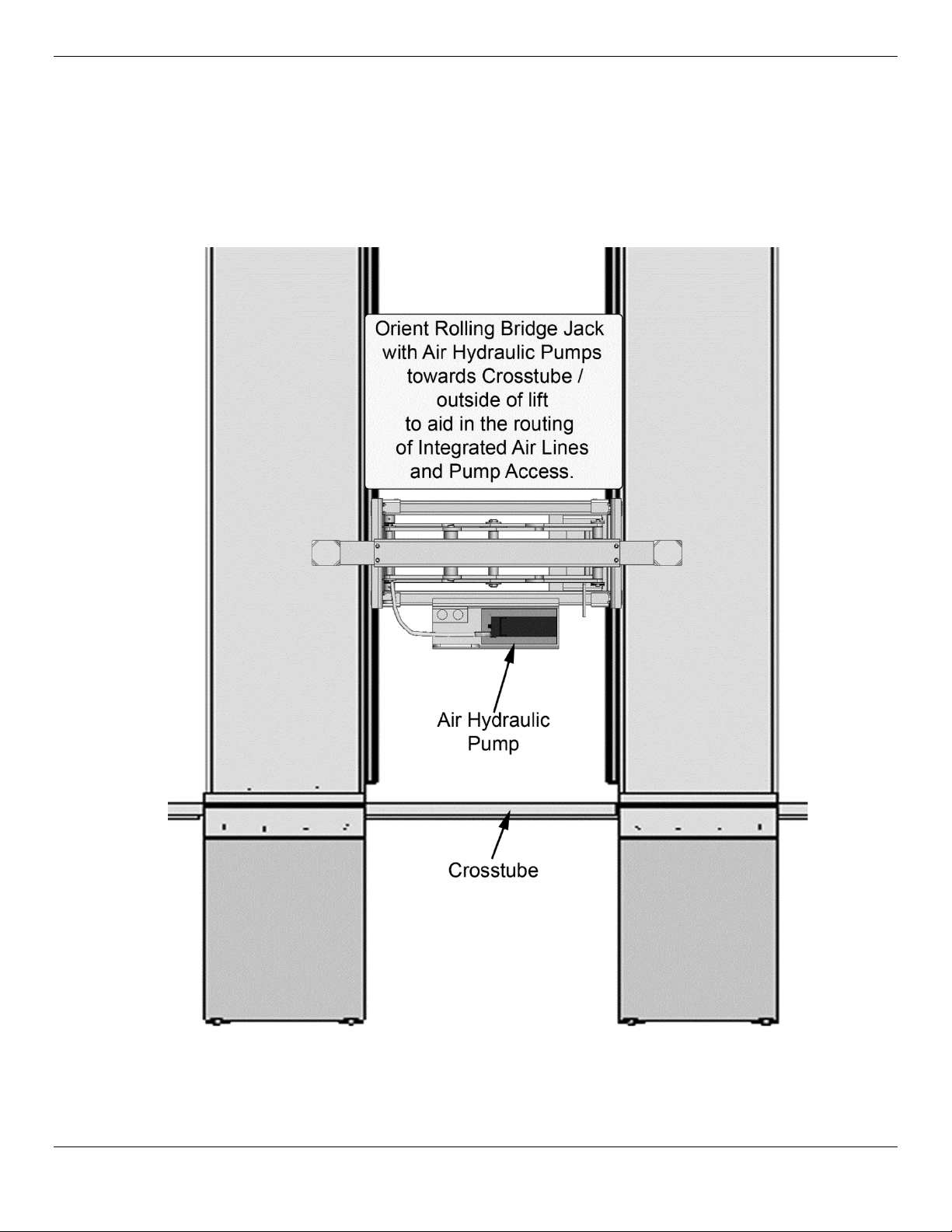

•Orient the Air Hydraulic Pump correctly. You need to orient your rolling bridge jack such

that the air hydraulic pump is facing the lift’s crosstube or the outside of the lift. This makes it

easier to route the integrated air lines and access the pump.

If you are using just one rolling bridge jack on a lift, orient the pump toward the lift’s crosstube. If

you are using two rolling bridge jacks on a lift, orient the pump of the first jack toward the lift’s

crosstube and orient the pump of the second jack towards the outside of the lift.

When using two rolling bridge jacks on a lift, orient both pumps towards the outside of the lift.

RBJ Series of Rolling Bridge Jacks 12 P/N 5900004 — May 2017 — Rev. A

Moving the Rolling Bridge Jack into Position

Rolling bridge jacks need to be moved into position using a fork lift or other device appropriate for

lifting heavy loads.

⚠WARNING Pay close attention when moving the rolling bridge jack off its shipping pallet; the

jack could move and can cause injury. Prior to removing the strapping or bolts,

make sure the jack is held securely by a fork lift or other device for lifting heavy

objects.

To move a rolling bridge jack into position on the lift:

1. Make sure the lift is on the ground or in a locked position.

2. Using a shop crane, forklift, or other lifting device, raise the rolling bridge jack and orient it between

the lift’s two runways.

Do not lower it onto the lift yet

.

Remember to orient the air hydraulic pump side appropriately: if you are using just one rolling

bridge jack, orient the pump side towards the crosstube; if using two rolling bridge jacks, orient

both pump sides of the jack towards the outside of the lift (not towards the inside).

3. Lower the rolling bridge jack to just over the utility rails on the inside of the lift’s runways.

Do not

lower it onto the lift yet

.

RBJ Series of Rolling Bridge Jacks 13 P/N 5900004 — May 2017 — Rev. A

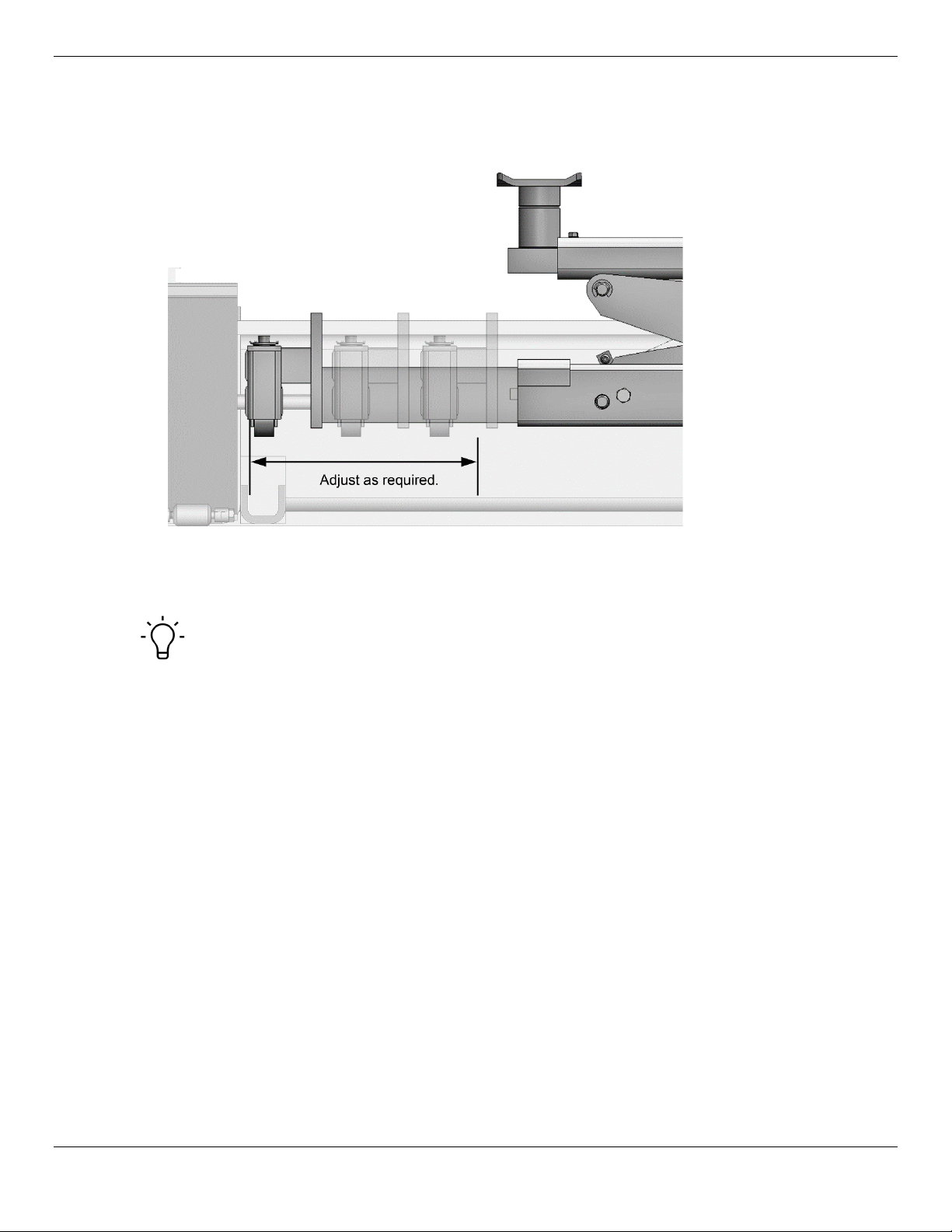

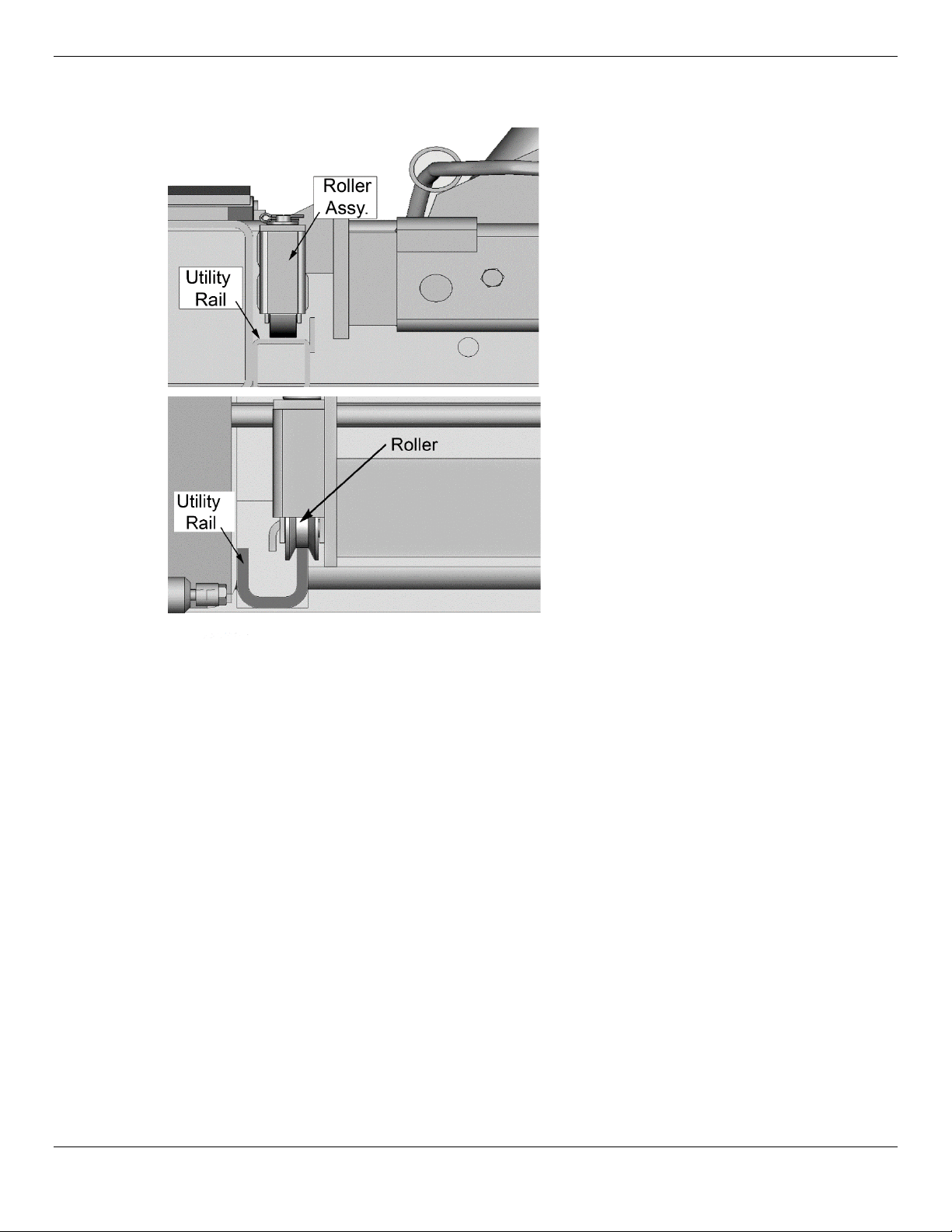

4. Adjust the ends of the rolling bridge jack to the correct width.

The correct width is where the roller assembly is oriented directly over the utility rail channel or the

roller is oriented directly over the utility rail lip.

This image shows the roller assembly on the rolling bridge jack going into the utility rail channel on

the lift.

Note: Models RBJ18000 and RBJ25000 do not have adjustable arms.

Tip In Step 7 below, you will instructed to install safety brackets on your rolling bridge jack.

These safety brackets prevent the jack from moving in certain ways, helping to prevent

accidental injury. Consider putting into place the nuts used to secure the safety brackets

prior to lowering the rolling bridge jack into position on the utility rails, as this will make it

easier to install the safety brackets when you get to Step 7.

RBJ Series of Rolling Bridge Jacks 14 P/N 5900004 — May 2017 — Rev. A

5. Lower the rolling bridge jack onto the utility rail, either into the channel (for jacks with a roller

assembly) or onto the lip (for jacks with a roller).

6. Make sure the utility rail channel is clear of all debris.

RBJ Series of Rolling Bridge Jacks 15 P/N 5900004 — May 2017 — Rev. A

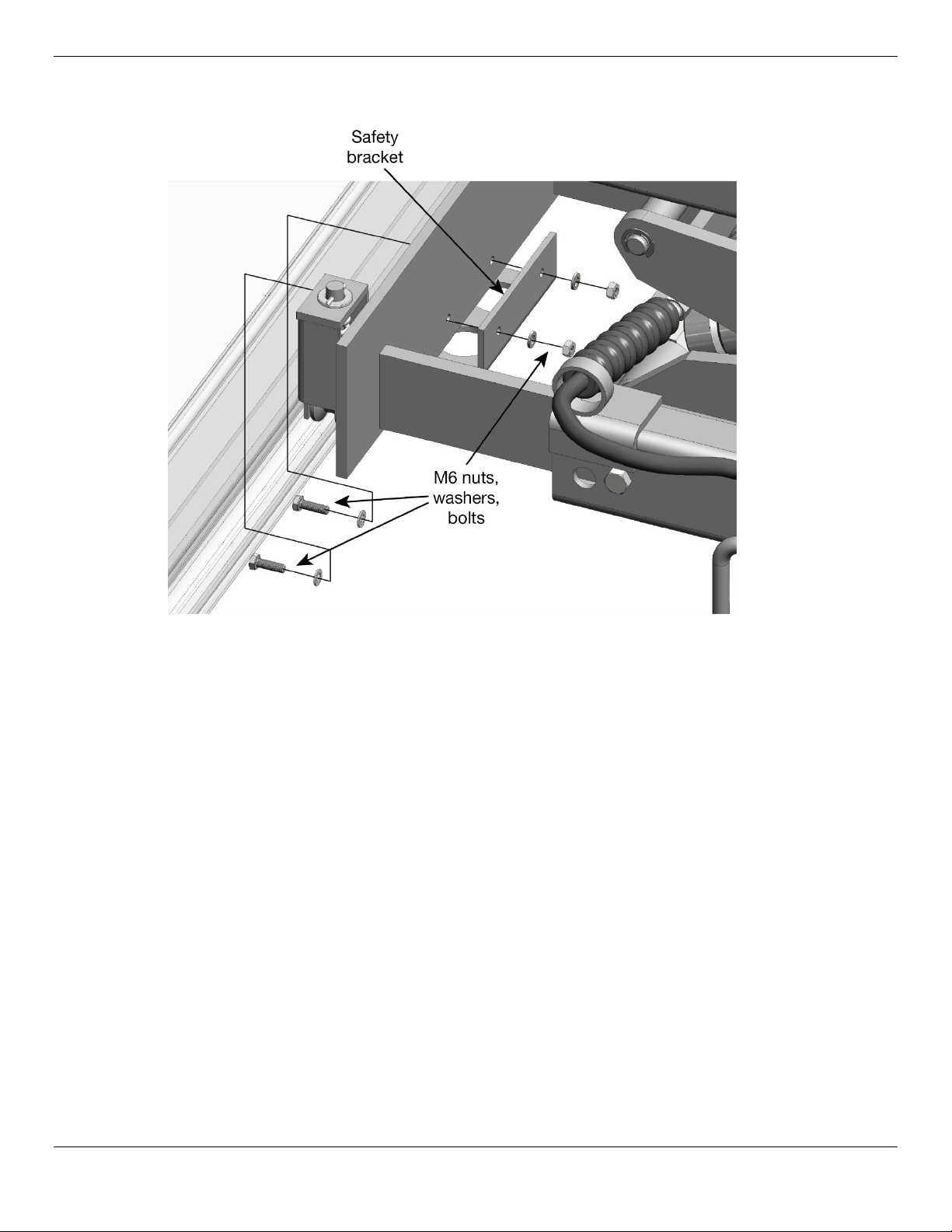

7. Install safety brackets

on both sides of the rolling bridge jacks

using the provided

hardware.

This image shows the safety bracket being installed on one side of the jack; make sure to install

the safety bracket on both sides.

The nuts to install the safety brackets are put into place from the utility rail side; the washers and

bolts from the jack side.

Note: If you did not put the nuts to install the safety brackets into place earlier, you may need to

raise the rolling bridge jack to get them into place now.

8. If you are using two rolling bridge jacks on the lift, install the safety brackets on the second jack.

9. Raise the lift (so that the rolling bridge jack is off the ground) and lock the lift at the desired locking

position.

If you locked the lift at a locking position in Step 1, you can ignore this step.

⚠WARNING Do not start using the rolling bridge jack until you are certain the lift is correctly

situated on a safety lock.

10. Check the clearance and movement of the rolling bridge jack. Make sure the rollers are centered in

the channel or on the lip at all points along the length of the utility rail.

11. If necessary, make adjustments to the arms of the rolling bridge jack or to the runway to ensure

proper operation of the rolling bridge jack.

RBJ Series of Rolling Bridge Jacks 16 P/N 5900004 — May 2017 — Rev. A

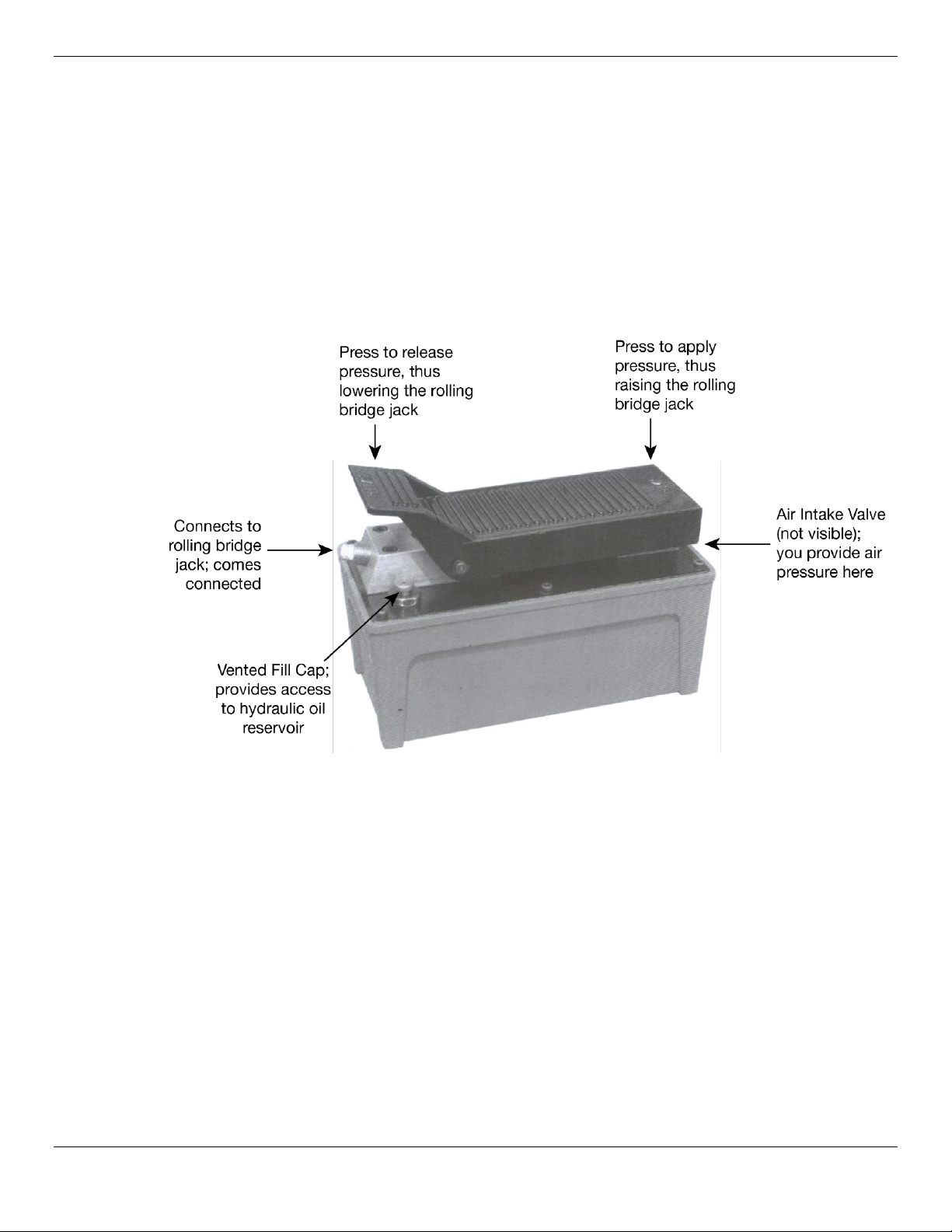

Setting Up the Hydraulic Air Pump

Your rolling bridge jack comes with an hydraulic air pump, which provides air pressure so that you

can raise and lower your jack. It is your responsibility to supply air pressure to the pump.

Air pressure should be set to 20 CFM (.57 M3/min.) and 100 PSI (7 bar; bar is a metric unit of

pressure). Air pressure should also be regulated to a maximum of 125 PSI (8.6 bar).

⚠WARNING Before performing installation or maintenance, release the pressure currently in the

system, then disconnect the hydraulic air pump from its air pressure supply.

To set up your hydraulic air pump:

1. Remove the thread protector from the air intake valve on the pump.

2. Install a threaded fitting (not supplied) that is compatible with your air pressure supply.

3. Connect your air pressure supply to the threaded fitting you just installed on the pump.

An appropriate air line regulator, water separator, and lubricator should be installed on the air

pressure supply line.

Failure to install these items voids the warranty on pneumatic

components.

4. The filler vent cap is overtightened for shipment; loosen it approximately one turn.

RBJ Series of Rolling Bridge Jacks 17 P/N 5900004 — May 2017 — Rev. A

Preparing for Operation

Before the rolling bridge jack is ready for normal operation, you need to make sure the air hydraulic

pump’s oil reservoir is full, then you can do a trial run of raising the jack.

To check the oil reservoir of the air hydraulic pump:

1. Remove the vented fill cap.

2. Insert a dipstick or piece of plastic into the tank until it hits the bottom.

3. Remove the dipstick or piece of plastic and measure the amount of oil.

The hydraulic oil level should be from 3.35 to 3.5 inches deep.

4. If the current level is below 3.35 inches, add hydraulic oil until it is between 3.35 and 3.5 inches.

Approved fluids are any general purpose ISO-32, ISO-46, or ISO-68 hydraulic oil or approved ATF

fluids such as Dexron III, Dexron VI, Mercon V, Mercon LV, or any Synthetic Multi-Vehicle ATF.

5. If the current level is already between 3.35 and 3.5 inches, no action needs to be taken.

6. Reinstall the vented fill cap.

To perform a trial run of the rolling bridge jack:

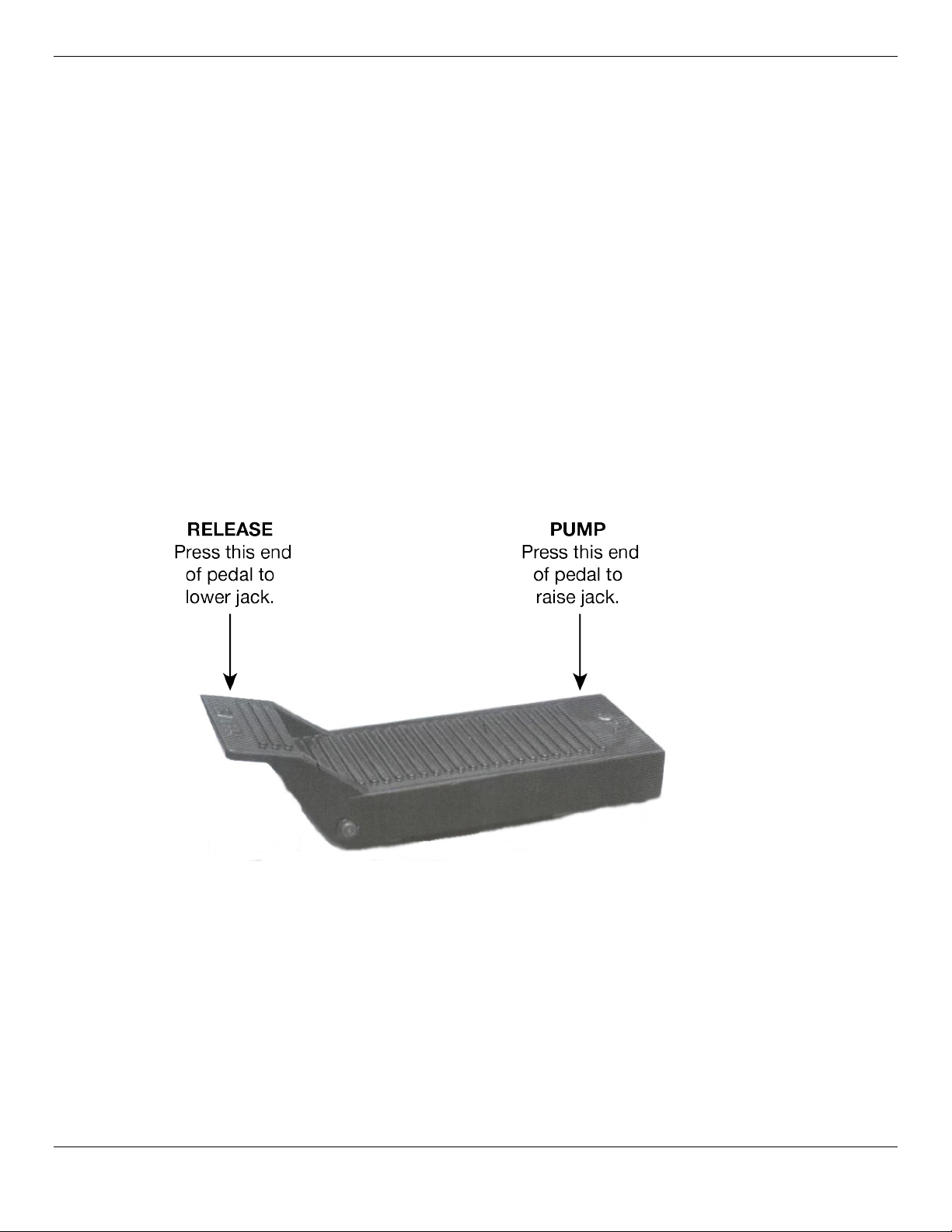

1. Press the PUMP end of the pedal on the top of the air hydraulic pump to begin raising the jack.

If the jack does not raise, refer to the Troubleshooting section.

2. When the jack is at maximum rise, release the PUMP end of the pedal and press the RELEASE

end to begin lowering the jack.

3. Lower the jack onto one of the safety lock positions.

RBJ Series of Rolling Bridge Jacks 18 P/N 5900004 — May 2017 — Rev. A

⚠WARNING Always lower the rolling bride jack onto a safety lock position before performing any

work.

4. To fully lower the jack from a safety lock position, press the PUMP end of the pedal to raise it

enough so that the safety is off the safety stop pin.

5. Flip the safety handle up and off of the safety stop pin.

6. Press the RELEASE end of the pedal to lower the jack.

7. Release the RELEASE end of the pedal when the jack is fully lowered.

Your rolling bridge jack is ready for normal operation.

RBJ Series of Rolling Bridge Jacks 19 P/N 5900004 — May 2017 — Rev. A

Operation

This section describes how to raise and lower your rolling bridge jack.

To raise a load on your rolling bridge jack:

1. Load the vehicle onto the lift following the manufacturer’s instructions.

2. Position the tires of the vehicle in the center of each runway.

3. Set the parking brake on the vehicle or use a wheel chock to hold the vehicle in position.

4. Check the utility rail channels to make sure nothing is in them that could obstruct the movement of

the jack.

5. Check the area to make sure everyone is clear of the lift and of the jack. Also make sure there are

no obstructions above the vehicle you will be lifting with the jack.

6. Adjust the arms of the jack so that the lift pads make contact with the underside of the vehicle at

the lifting points specified by the vehicle manufacturer.

⚠WARNING Make sure to lift the vehicle at the correct lifting points. Lifting at the wrong location

could potentially damage the vehicle and the rolling bridge jack.

7. Press the PUMP end of the pedal on the top of the air hydraulic pump to raise the jack.

8. Raise the vehicle to just past the desired height, then release the PUMP end of the pedal and

press the RELEASE end to lower the jack onto a locking position.

RBJ Series of Rolling Bridge Jacks 20 P/N 5900004 — May 2017 — Rev. A

To lower a load from a safety lock position:

1. Press the PUMP end of the pedal to raise the jack enough so the safety is off the safety stop pin.

2. Flip the safety handle up and off of the safety stop pin.

3. Press the RELEASE end of the pedal to lower the jack.

4. Release the RELEASE end of the pedal when the jack is fully lowered.

Additional Operating Information

Keep the following in mind when operating your rolling bridge jack:

•Check the weight of a vehicle before attempting to lift it. Do not guess. Never exceed the rated

load capacity of the jack.

•Lift pads must always be used; make sure they are correctly positioned on the lifting points of the

vehicle you are raising. Do not raise a load without the lift pads.

•Visually inspect your rolling bridge jack before each use. Do not use it if you find any damage or

severe wear.

•Do not rock the vehicle while it is raised or remove items that could cause excessive weight shift.

•Keep the utility rail channel and lips clean and free from debris.

Hydraulic Power System Warnings

⚠WARNING Failure to observe these precautions can result in serious personal injury, including,

in rare cases, death.

•The air hydraulic pump must be correctly connected to the rolling bridge jack before raising a

vehicle or applying pressure.

•Do not attempt to connect or disconnect hose couplers while a vehicle is raised or while the

hydraulic system is under pressure.

•Use every precaution to guard against dirt getting into the lift or the pump.

This manual suits for next models

7

Table of contents

Other Bend-Pak Jack manuals