10/14TONNE INDUSTRIAL TOE JACK

MODEL NO: ITJ10

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

9Regularly inspect and lubricate the jack to ensure it is in good working order and condition. DO NOT use the jack if damaged or a fault is

suspected - check Section 6 Troubleshooting. If necessary, immediately repair or replace damaged parts.

9Use recommended parts only, the use of unauthorised parts may be dangerous and will invalidate your warranty.

9Ensure the work area is clean, tidy and free from unrelated materials and has adequate lighting.

9Use jack on level and solid ground, preferably concrete. Avoid tarmacadam since jack may sink in.

9If being used to lift a vehicle, park the vehicle and apply hand brake. Switch off the engine and place chocks under the wheels.

9Ensure a minimum distance of 0.5m between load and static objects such as doors, walls, etc. to allow for tilting during jacking.

9Check lifting point is centred and stable on jack saddle (off centre loads can slip). Position jack so as to avoid operating it from

under the load.

▲DANGER! Use the jack for lifting only, NOT for supporting the lifted load. Always use adequately rated mechanical supports.

9Keep hands etc. clear of moving parts during raising and lowering of the load.

9Use a qualified person to lubricate and maintain the jack. Confirm that only recommended hydraulic jack oil (Sealey ref: HJO5LS) is used

during maintenance.

8DO NOT exceed the rated capacity of the jack and DO NOT operate the jack beyond its maximum pump stroke.

WARNING! If lifting a vehicle, DO NOT allow the vehicle to move, or try to start the engine, when the vehicle is jacked up.

8DO NOT jack a vehicle if it may result in the spillage of fuel, battery acid, or other dangerous substances.

8DO NOT place any part of your body under load whilst it is supported by the jack. Wait until adequately rated supports have

been correctly positioned.

8DO NOT use jack to support extensions or cradles. DO NOT modify jack in any way. DO NOT use the jack for any other purpose other

than that for which it was designed.

8DO NOT adjust the safety overload valve (fig.2.D.)

9Ensure there are no persons or obstructions beneath the load before lowering.

9Clean and securely stow the jack with the ram in the down position. DO NOT leave the ram extended. Ensure stowage area is

dry.

WARNING! Remember, it is very dangerous to go under a load supported by a jack even if additional supports are used.

WARNING! The warnings, cautions and instructions referred to in this manual cannot cover all possible conditions and situations that

may occur. It must be understood that common sense and caution are factors which cannot be built into this product, but must be

applied by the operator.

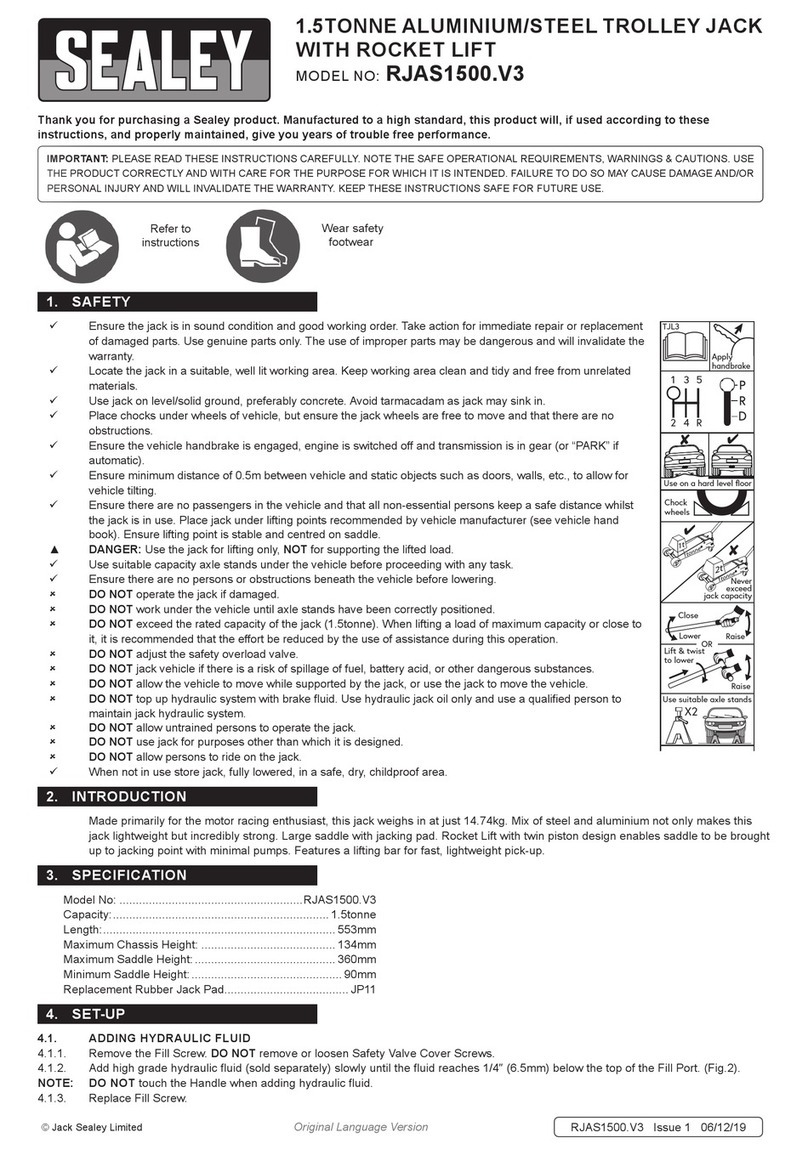

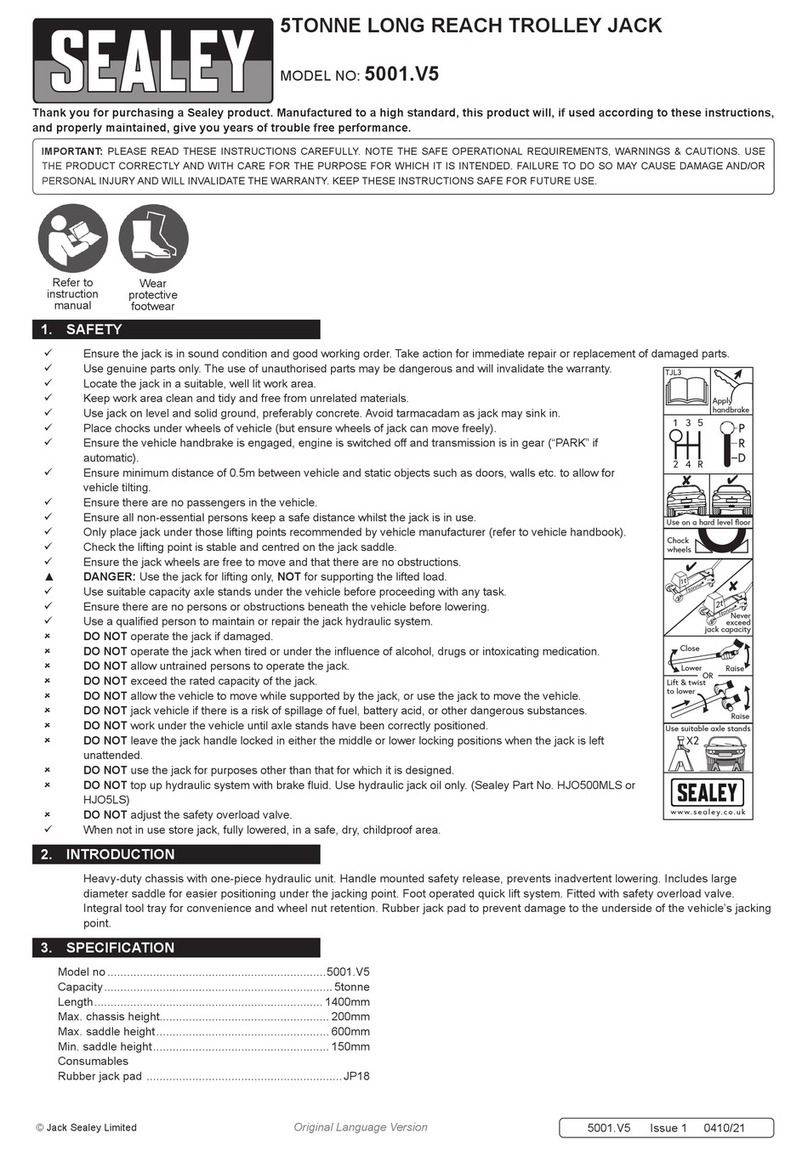

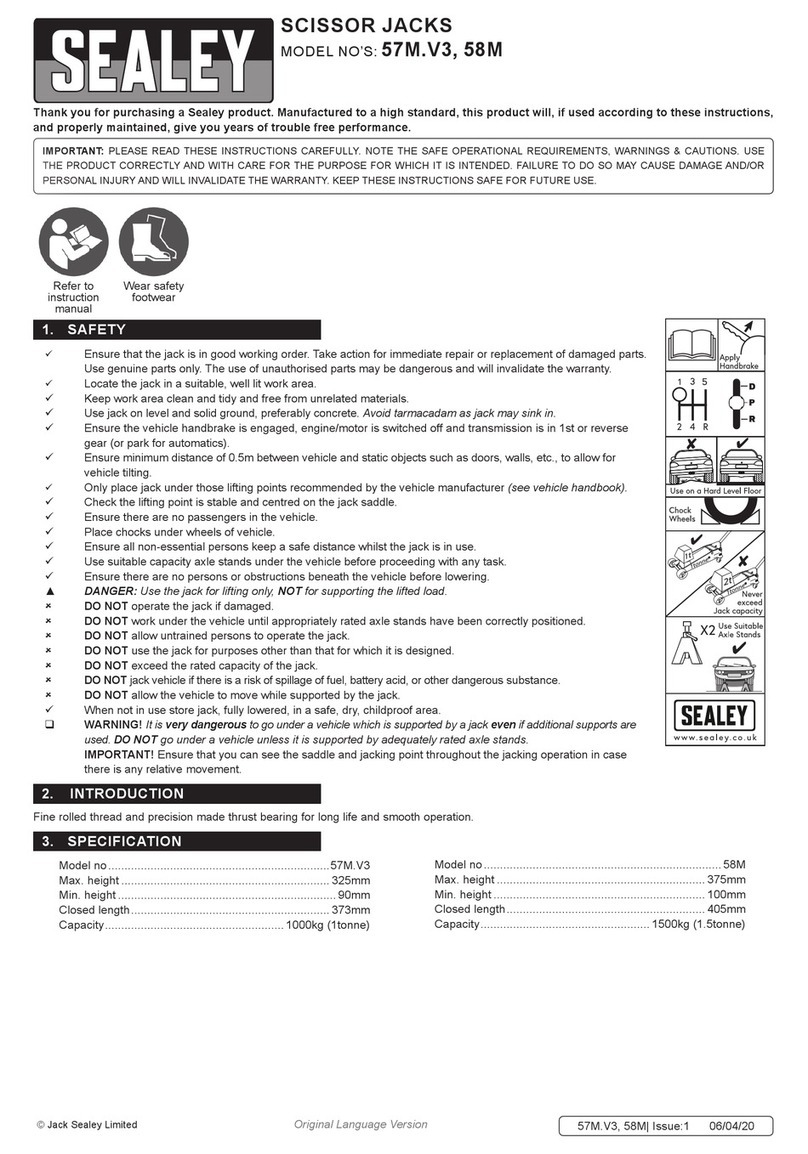

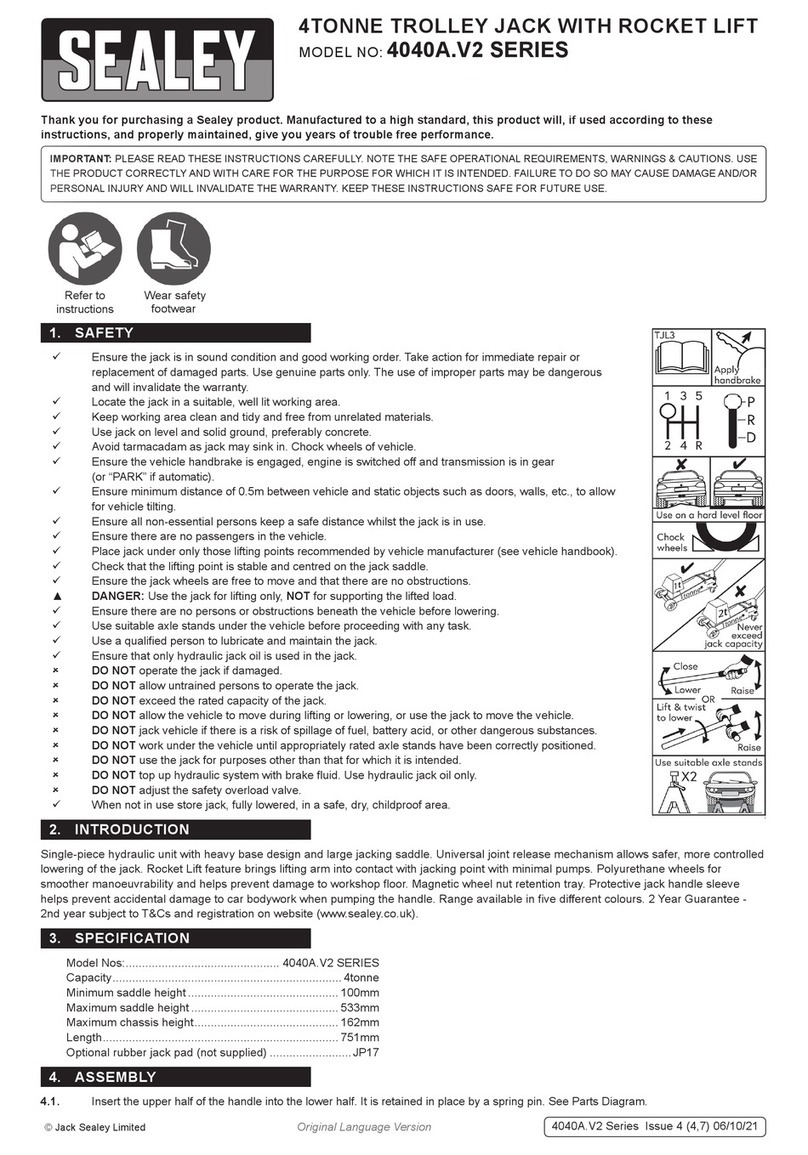

2. i INTRODUCTION

Heavy-duty, industrial quality, dual purpose toe lift bottle jack. Has a lifting capacity of 10tonne on the toe of the jack and 14tonne on the

head. Designed to lift heavy plant or machinery where there is limited ground clearance such as fork lift trucks, machine installation or for

useonconstructionsites.Fittedwitha280°rotatinghandletoenablejackinginconnedspaces.

3. i SPECIFICATION

Model No:.....................................................................ITJ10

Lifting Capacity at Toe:.............................................. 10tonne

Lifting Capacity at Head: ........................................... 14tonne

Minimum Toe Height: ................................................... 30mm

Maximum Toe Height:................................................. 210mm

Minimum Head Height:............................................... 320mm

Maximum Head Height:.............................................. 500mm

4. OPERATION

WARNING! Before lifting ensure Section 1 Safety Instructions are strictly followed.

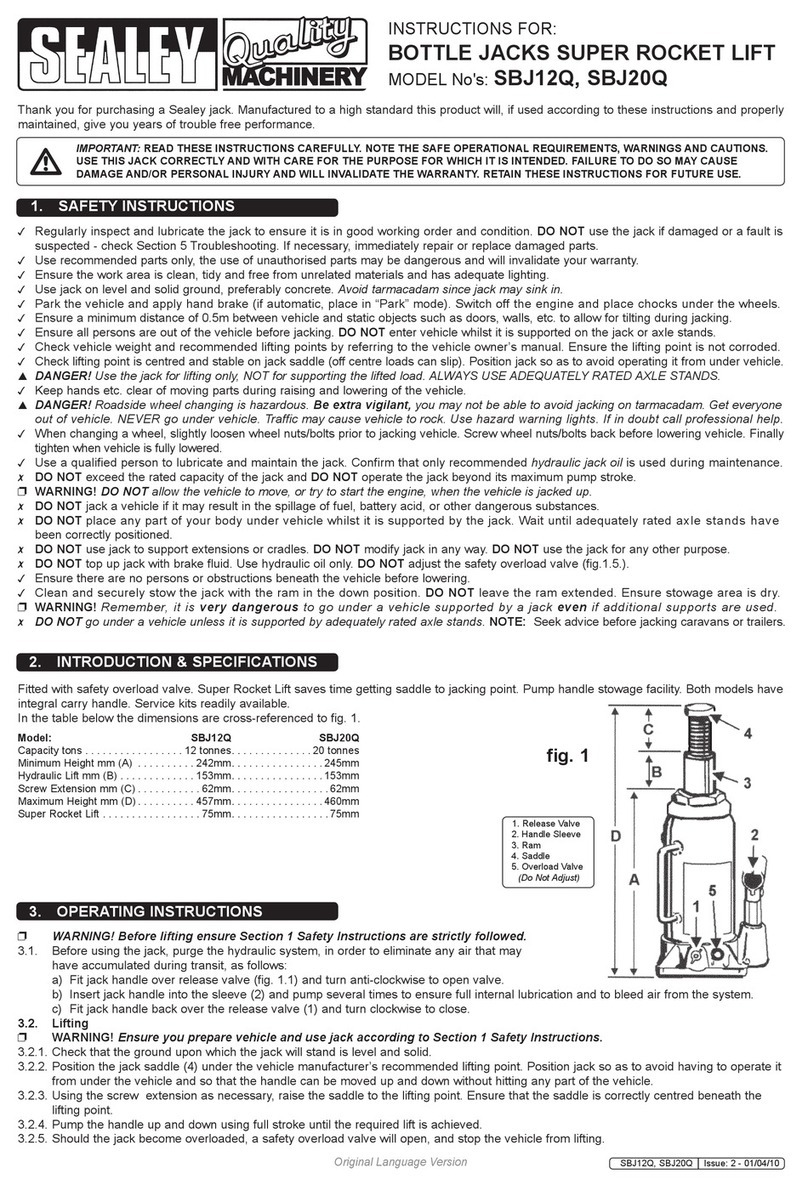

4.1. Before using the jack, purge the hydraulic system, in order to eliminate any air that may have accumulated during transit, as follows:

a) Fit jack handle over release valve (fig.2.B) and turn anti-clockwise to open valve.

b) Insert jack handle into the sleeve (fig.2.A) and pump several times to ensure full internal lubrication and to bleed air from the system.

c) Fit jack handle back over the release valve and turn clockwise to close.

Original Language Version

© Jack Sealey Limited

Refer to

instruction

manual

Wear protective

gloves

Wear

safety footwear

ITJ10T Issue 4 (3, F) 24/07/19