Bend-Pak RBJ25000 User manual

BendPak, Inc. Corporate Oce

1645 Lemonwood Drive

Santa Paula, CA 93060 USA

Toll Free US/Canada: 1-800-253-2363

Fax: 1-805-933-9160

Customer Service Desk / Warranty

Customer Service Representatives

Oce Tel: 1-805-933-9970

Toll Free US/Canada: 1-800-253-2363

Fax: 1-805-933-9160

customerservic[email protected]

Parts Orders

Customer Service Representatives

Oce Tel: 1-805-933-9970

Toll Free US/Canada: 1-800-253-2363

Fax: 1-805-933-9160

Domestic Sales & Service

USA Sales Representatives

Oce Tel: 1-805-933-9970

Toll Free US/Canada: 1-800-253-2363

Fax: 1-805-933-9160

International Sales & Service

Oce Tel: 1-805-933-9970

Exports Dept: 1-805-933-9970 EXT. 192

Ext. Toll Free US/Canada: 1-800-253-2363

Fax: 1-805-933-9160

bpkex[email protected]om

Service Manual

SERVICE PARTS & DIAGRAMS

This guide is a troubleshooting reference used for maintaining and

servicing your Bend Pak product. It provides comprehensive information

on identifying serviceable parts and components and assists in

troubleshooting problems and performing assembly /disassembly

procedures.

BENDPAK

RBJ25000

PRODUCT SKU

5175033

DRAWING Nº

5260544

CATEGORY

Rolling Bridge Jack

REV

Version V

DATE

12.15.2022

DIMENSIONS ARE IN MM

☺

1

2

ITEM NO

PART NUMBER

DESCRIPTION

QTY

REV

1 5205006

RBJ18000/25000 LIFT SUPERSTRUCTURE

1

M

2 5250117

RBJ18000/25000 PARTS BOX

1

G

-

5900004

RBJ SERIES MANUAL

1

--

REVISION

REV

DESCRIPTION

DATE

EDITED BY

ECO#

T

UPDATED BOM REVISION

11/06/2020

CA

01230

U

ADDED 5905775 AND 5906044

09/03/2021

CA

01322

V

REPLACED LABELS WITH COLORS & GRAPHICS

NOTE, REPLACED 5940056 WITH PACKAGING

INSTRUCTION NOTE

09/29/2021

CA

01348

SHEET 1 OF 2

REV

DWG. NO.

A

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

V

1645 LEMONWOOD DR.

SANTA PAULA, CA 93060

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS

THE SOLE PROPERTY OF

BENDPAK INC.

ANY

REPRODUCTION IN PART OR AS A WHOLE WITHOUT

THE WRITTEN PERMISSION OF

BENDPAK INC.

IS

PROHIBITED.

NOTE: UNLESS OTHERWISE SPECIFIED

.

TM

5260544

RBJ25000 PRODUCTION

LIFT VER C

01/18/2016

DO NOT SCALE DRAWING

1:10

SCALE:

THIRD ANGLE PROJECTION

OR

10/01/2021

REFER TO MODEL FOR ADDITIONAL INFORMATION

1.

SEE SHIPPING INSTRUCTIONS FOR FINAL PACKAGING

2.

SEE COLORS & GRAPHICS FOR LABEL PLACEMENT

3.

APPLY LIQUID THREAD SEALANT TO FITTINGS PRIOR TO ASSEMBLY.

4.

SEE BP SPECIFICATION FORM 5580012

DIMENSIONS ARE IN MM

☺

WHERE USED

RBJ18000

RBJ25000

ITEM

NO.

PART

NUMBER

DESCRIPTION

QTY

REV

1 5600355

RBJ BASE WELDMENT

1

F

2 5215180

RBJ18000/25000 SCISSOR ASSEMBLY

1

J

3 5215456

RBJ18000/25000 UPPER EXTENSION ARM ASSEMBLY

1

C

4 5502167

CYLINDER ASSEMBLY Ø3.0 x 4.5

1

F

5 5745057

RBJ18000/25000 CYLINDER PIVOT PIN

1

B

6 5746628

RJ/RBJ18000/25000 SMALL UPPER PIVOT SHAFT

1

C

7 5746094

RJ/RBJ8000/25000 LONG UPPER PIVOT SHAFT

1

C

8 5755118

RJ/RBJ18000/25000 LONG UPPER TUBE SPACER

1

D

9 5746629

RJ/RBJ18000/25000 SPACER

2

C

10 5746155

RBJ15000/18000/25000 SAFETY PIN

1

B

11 5300913

RBJ15000/18000/25000 SAFETY

2

B

12 5300871

RBJ15000/18000/25000 SAFETY HANDLE

1

C

13 5210219

RBJ45000 BYB/15000/18000/25000 RAIL ROLLER ASSEMBLY

4

D

14 5570806

RJW SERIES HOSE ASSY Ø6.4mm x 600mm DS

1

E

15 5736508

RJ/RBJ18000/25000 RETAINING WASHER

4

C

16 5505106

SPRING PIN M6 x 50

4

-

17 5545130

WASHER 3/8" SL

1

-

18 5530133

HHB 3/8"-16 x 3" GR8/CL 10.9

1

-

19 5530054

SSS M10x1.5x12

5

-

20 5585736

AIR HYDRAULIC PUMP YELLOW RBJ18000/25000 PSI:9700

1

-

21 5550086

FTG ELB -04 NPT x -04 JIC

1

-

22 5550493

FTG RST -04 JIC x -06 NPT x .062 ID

1

-

23 5545347

WASHER, M12 FLAT WASHER

4

-

24 5540027

COMPRESSION SPRING 22 x 50mm

4

A

25 5505006

COTTER PIN Ø3.2 x 20mm

4

-

REVISION

REV

DESCRIPTION

DATE

EDITED BY

ECO#

K

UPDATED BOM REVISION

01/02/2019

TS

01038

L

UPDATED BOM REVISION

08/06/2019

CA

01112

M

UPDATED BOM REVISION

11/06/2020

CA

01230

NEXT ASSEMBLY

5260279

5260544

SHEET 1 OF 2

REV

DWG. NO.

A

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

M

1645 LEMONWOOD DR.

SANTA PAULA, CA 93060

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS

THE SOLE PROPERTY OF

BENDPAK INC.

ANY

REPRODUCTION IN PART OR AS A WHOLE WITHOUT

THE WRITTEN PERMISSION OF

BENDPAK INC.

IS

PROHIBITED.

NOTE: UNLESS OTHERWISE SPECIFIED

.

TM

5205006

RBJ18000/25000 LIFT

SUPERSTRUCTURE

11/17/2015

DO NOT SCALE DRAWING

1:12

SCALE:

THIRD ANGLE PROJECTION

OR

11/12/2020

REFER TO MODEL FOR ADDITIONAL INFORMATION

1.

SEE SHIPPING INSTRUCTIONS FOR FINAL PACKAGING

2.

ASSEMBLE ITEMS AS SHOWN

3.

AIR HYDRAULIC PUMP MUST BE INSTALLED USING THE

4.

INCLUDED BOLTS

A

16 15

9

8

6

3

2

18

17

4

21

14

22

20

11

12

1

19

54

10

7

DETAIL A

SCALE 1 : 4

25

23

24

13

SHEET 2 OF 2

REV

DWG. NO.

A

SIZE

TITLE:

M

1645 LEMONWOOD DR.

SANTA PAULA, CA 93060

5205006

RBJ18000/25000 LIFT

SUPERSTRUCTURE

1:12

SCALE:

DIMENSIONS ARE IN MM

☺

3

4

1

2

REVISION

REV

DESCRIPTION

DATE

EDITED BY

ECO#

E

REMOVED 5745054, REPLACED (1) 5210423

WITH 5210186, REPLACED (1) 5210423 WITH

5210187, REPLACED (1) 5210424 WITH 5210188,

REPLACED (1) 5210424 WITH 5210189, UPDATED

TITLE TO REFLECT MARKETING, UPDATEDNEXT

ASSEMBLIES

11/17/2015

TM

00739

F

ADDED 5580012

02/25/2020

CA

01146

G

REMOVED 5580012

09/30/2020

TM

01213

WHERE USED

RBJ18000

RBJ25000

ITEM

NO.

PART

NUMBER

DESCRIPTION

QTY.

REV

1 5210186

RBJ18000/25000 TOP TUBE RAIL SHORT HEIGHT

ADAPTER WELDMENT

2

A

2 5210187

RBJ18000/25000 EXTENSION ARM SHORT HEIGHT

ADAPTER WELDMENT

2

A

3 5210189

RBJ18000/25000 EXTENSION ARM LONG HEIGHT

ADAPTER WELDMENT

2

A

4 5210188

RBJ18000/25000 TOP TUBE RAIL LONG HEIGHT

ADAPTER WELDMENT

2

A

NEXT ASSEMBLY

5260279

5260544

SHEET 1 OF 1

REV

DWG. NO.

A

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

G

1645 LEMONWOOD DR.

SANTA PAULA, CA 93060

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS

THE SOLE PROPERTY OF

BENDPAK INC.

ANY

REPRODUCTION IN PART OR AS A WHOLE WITHOUT

THE WRITTEN PERMISSION OF

BENDPAK INC.

IS

PROHIBITED.

NOTE: UNLESS OTHERWISE SPECIFIED

.

AC

5250117

RBJ18000/25000

PARTS BOX

01/05/2010

DO NOT SCALE DRAWING

1:5

SCALE:

THIRD ANGLE PROJECTION

OR

10/02/2020

SEE SHIPPING INSTRUCTIONS FOR FINAL PACKAGING

1.

2

4

1

7

65

8

9

3

ISOMETRIC VIEW

FOR REFERENCE ONLY

DO NOT SCALE

ITEM

NO

PART

NUMBER

DESCRIPTION

QTY

REV

1 5505199

RJ-18000/25000 CENTER PIVOT PIN

1

A

2 5600356

RBJ18000/25000 INNER SCISSOR WELDMENT

1

E

3 5731010

RBJ18000/25000 OUTER HOSE RETAINER SCISSOR ARM

2

C

4 5736505

RJ-18000/25000 SCISSOR ARM SPACER

2

A

5 5746157

RJ-18000/25000 SCISSOR SPACER

1

A

6 5746156

RJ-18000/25000 BEARING WASHER

2

A

7 5505137

SPRING PIN M6 x 80

2

-

8 5735166

RBJ-18000/25000 PLASTIC SLIDE BLOCK

2

D

9 5550025

FTG GRS M6 x 1.0

1

-

REVISION

REV

DESCRIPTION

DATE

EDITED BY

ECO#

G

UPDATED BOM REVISION

02/10/2017

DB

00812

H

UPDATED BOM REVISION

04/17/2017

TM

00825

J

UPDATED BOM REVISION

07/12/2018

TM

00973

NEXT ASSEMBLY

5205006

SHEET 1 OF 1

REV

DWG. NO.

A

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

J

1645 LEMONWOOD DR.

SANTA PAULA, CA 93060

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS

THE SOLE PROPERTY OF

BENDPAK INC.

ANY

REPRODUCTION IN PART OR AS A WHOLE WITHOUT

THE WRITTEN PERMISSION OF

BENDPAK INC.

IS

PROHIBITED.

NOTE: UNLESS OTHERWISE SPECIFIED.

AC

DIMENSIONS ARE IN MM

TOLERANCES: MACHINE TO

0 = ±1.5

0.0 = ±0.5

0.00 = ±0.13

ANGULAR: MACHINE TO

0. = ±½

°

SURFACE FINISH 1.6 Ra µm

FOR MACHINED SURFACES

UNLESS OTHERWISE SPECIFIED

5215180

RBJ18000/25000

SCISSOR ASSEMBLY

DO NOT SCALE DRAWING

1:8

SCALE:

THIRD ANGLE PROJECTION

CA

07/23/2018

ASSEMBLE ITEMS AS SHOWN

1.

12/09/2009

DIMENSIONS ARE IN MM

☺

1

2

3

ITEM

NO

PART

NUMBER

DESCRIPTION

QTY

REV

1 5601066

RBJ18000/25000 UPPER ARM RECEIVER TUBE WELDMENT

1

B

2 5530789

BHSK M8 x 1.25 x 14

2

--

3 5601067

RBJ18000/25000 UPPER ARM WELDMENT

2

B

NEXT ASSEMBLY

5205006

REVISION

REV

DESCRIPTION

DATE

EDITED BY

ECO#

A

PRODUCTION RELEASE,DERIVED FROM 5215334

11/17/2015

TM

00739

B

REPLACED 5530284 WITH 5530789

12/01/2016

TM

00791

C

UPDATED BOM REVISION

04/17/2017

TM

00825

SHEET 1 OF 1

REV

DWG. NO.

A

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

C

1645 LEMONWOOD DR.

SANTA PAULA, CA 93060

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS

THE SOLE PROPERTY OF

BENDPAK INC.

ANY

REPRODUCTION IN PART OR AS A WHOLE WITHOUT

THE WRITTEN PERMISSION OF

BENDPAK INC.

IS

PROHIBITED.

NOTE: UNLESS OTHERWISE SPECIFIED

.

TM

5215456

RBJ18000/25000 UPPER

EXTENSION ARM ASSEMBLY

11/17/2015

DO NOT SCALE DRAWING

1:8

SCALE:

THIRD ANGLE PROJECTION

DB

05/03/2017

ASSEMBLE ITEMS AS SHOWN

1.

600

2 3 1

ITEM NO

PART NUMBER

DESCRIPTION

QTY

REV

1 5570171

HOSE; Ø6.35 RJ SERIES HYDRAULIC HOSE

534mm*

-

2 5550325

FTG NPL Ø1/4 CRIMP x -04 JIC

2

-

3 5570037

HOSE BEND RESTRICTOR

2

-

NEXT ASSEMBLY

5205005

5205006

5205007

5205008

5205009

5205010

5205011

5205012

5205013

WHERE USED

RJ-45LP

RJ45W

RJ7W

RJ9W

RBJ7000A

RBJ4500 BYB

RBJ15000

RBJ18000

RBJ25000

REVISION

REV

DESCRIPTION

DATE

EDITED BY

ECO#

C

C-001

UPDATED 5570171 TO SHOW ROUTING

UPDATED NEXT ASSEMBLIES

03/17/2015

08/21/2015

TM

TM

00692

00719

D

UPDATED TITLE AND NEXT ASSEMBLIES

02/29/2016

CA

00739

E

UPDATED TITLE TO REFLECT MARKETING,

UPDATED NEXT ASSEMBLIES

12/28/2018

TS

01038

SHEET 1 OF 1

REV

DWG. NO.

A

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

E

1645 LEMONWOOD DR.

SANTA PAULA, CA 93060

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS

THE SOLE PROPERTY OF

BENDPAK INC.

ANY

REPRODUCTION IN PART OR AS A WHOLE WITHOUT

THE WRITTEN PERMISSION OF

BENDPAK INC.

IS

PROHIBITED.

AC

5570806

RJW SERIES HOSE ASSY

Ø6.4mm x 600mm DS

01/16/2010

DO NOT SCALE DRAWING

1:2

SCALE:

THIRD ANGLE PROJECTION

CA

04/24/2019

DIMENSIONS ARE IN MM

TOLERANCES:

0. = ±1.5

0.0 = ±0.5

SURFACE FINISH 1.6 ISO Ra µm

FOR MACHINED SURFACES

UNLESS OTHERWISE

SPECIFIED

NOTE: UNLESS OTHERWISE SPECIFIED

.

FOR ITEM 1 SPECIFICATIONS REFER TO PART SPECIFICATION FORM

1.

LENGTH SHOWN IS AFTER SWAGING

2.

ITEM 1 QTY FOR REFERENCE ONLY

3.

10,000 PSI / 700 BAR WORKING PRESSURE

4.

40,000 PSI / 2800 BAR MIN. BURST PRESSURE

5.

1

3

2

4

5

6

8

7

ISOMETRIC VIEW

FOR REFERENCE ONLY

DO NOT SCALE

REVISION

REV

DESCRIPTION

DATE

EDITED BY

ECO #

A

PRODUCTION RELEASE, DERIVED FROM 5600357

11/16/2015

TM

00739

B

B-001

UPDATED BOM REVISION

ADDED 20% GLOSS PAINT NOTE

12/01/2016

02/21/2020

TM

CA

00791

01146

ITEM NO

PART NUMBER

DESCRIPTION

QTY

REV

1 5766118

RBJ18000/25000 ARM RECEIVER TUBE

1

D

2 5735204

RBJ18000/25000 UPPER TUBE SLIDE PLATE

2

B

3 5700184

RBJ18000/25000 UPPER SCISSOR CHANNEL

1

B

4 5735207

RBJ18000/25000 ARM RECEIVER SUPPORT

2

B

5 5755117

RBJ18000/25000 SHORT UPPER TUBE SPACER

1

B

6 5731219

RBJ18000/25000 ARM RECEIVER EAR

2

B

7 5735206

RBJ18000/25000 UPPER TUBE SUPPORT

2

B

8 5736951

RBJ18000/25000 HEIGHT ADAPTER TUBE RAIL

1

A

WHERE USED

RJ-45LP

NEXT ASSEMBLY

5215456

SHEET 1 OF 2

REV

DWG. NO.

A

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

B

1645 LEMONWOOD DR.

SANTA PAULA, CA 93060

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS

THE SOLE PROPERTY OF

BENDPAK INC.

ANY

REPRODUCTION IN PART OR AS A WHOLE WITHOUT

THE WRITTEN PERMISSION OF

BENDPAK INC.

IS

PROHIBITED.

TM

5601066

RBJ18000/25000 UPPER ARM

RECEIVER TUBE WELDMENT

11/16/2015

DO NOT SCALE DRAWING

1:8

SCALE:

THIRD ANGLE PROJECTION

OR

03/04/2020

DIMENSIONS ARE IN MM

TOLERANCES:

0. = ±1.5

0.0 = ±0.5

SURFACE FINISH 1.6 ISO Ra µm

FOR MACHINED SURFACES

UNLESS OTHERWISE SPECIFIED

REFER TO MODEL FOR ADDITIONAL INFORMATION

1.

BREAK AND DEBURR ALL SHARP EDGES 0.3mm

2.

REMOVE ALL WELD SPLATTER

3.

MASK BORES AND THREADS BEFORE WELDING AND PAINTING

4.

DIMENSIONS SHOWN ARE AFTER PAINTING

5.

PAINT BENDPAK BLACK (RAL-9017) 20% GLOSS

6.

NOTE: UNLESS OTHERWISE SPECIFIED.

1

5

3

2

8

6

7

4

ISOMETRIC VIEW

FOR REFERENCE ONLY

DO NOT SCALE

NEXT ASSEMBLY

5600355

ITEM

NO

PART

NUMBER

DESCRIPTION

QTY

REV

1 5731218

RBJ BASE SIDE COVER

1

C

2 5766117

RBJ18000/25000 BASE SLIDE TUBE

1

B

3 5766114

RBJ18000/25000 BASE ARM TUBE

1

B

4 5731213

RJ-18000/25000 EXTENSION TUBE COVER

2

A

5 5731214

RBJ18000/25000 ARM EXTENSION TUBE GUSSET

2

B

6 5745056

RBJ18000/25000 CENTRALIZER ROLLER PIN

2

B

7 5746625

RBJ18000/25000 CENTRALIZER ROLLER

2

B

8 5620416

RBJ9000/15000/ 18000/25000 RAIL ROLLER CHANNEL

WELDMENT

2

A

REVISION

REV

DESCRIPTION

DATE

EDITED BY

ECO#

B

WAS 73 NOW 82, UPDATED TITLE TO REFLECT

MARKETING, UPDATED BOM REVISIONS

01/15/2016

TM

00739

C

WAS 82 NOW 74.7, REPLACED 5620347 WITH

5620416, UPDATED BOM REVISION

03/24/2016

TM

00756

D

WAS 25 PL NOW 10 PL, WAS 74.7 NOW 60,

UPDATED BOM REVISION

08/06/2019

CA

01112

WHERE USED

RBJ18000

RBJ25000

SHEET 1 OF 3

REV

DWG. NO.

A

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

D

1645 LEMONWOOD DR.

SANTA PAULA, CA 93060

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS

THE SOLE PROPERTY OF

BENDPAK INC.

ANY

REPRODUCTION IN PART OR AS A WHOLE WITHOUT

THE WRITTEN PERMISSION OF

BENDPAK INC.

IS

PROHIBITED.

NOTE: UNLESS OTHERWISE SPECIFIED.

AC

5620172

RBJ BASE SLIDE

SUBWELDMENT

01/13/2010

DO NOT SCALE DRAWING

1:5

SCALE:

THIRD ANGLE PROJECTION

CA

08/20/19

BREAK AND DEBURR ALL SHARP EDGES 0.3mm

1.

REMOVE ALL WELD SPLATTER

2.

5746625 MUST TURN FREELY

3.

DIMENSIONS ARE IN MM

TOLERANCES:

0. = ±1.5

0.0 = ±0.5

ANGULAR: 0. =

2

°

SURFACE FINISH 1.6 ISO Ra µm

FOR MACHINED SURFACES

UNLESS OTHERWISE SPECIFIED

PART SPECIFICATION FORM STANDARD

BENDPAK Number:

5900004

MRP Description:

RBJ SERIES MANUAL

Date:

10/27/2020

ECO :

---

1. Engineering Specification

Application:

INSTALLATION MANUAL

Detailed Description:

Print Settings for BendPak Manuals

Unless otherwise specified, use these settings for

printing BendPak manuals:

Color: Black and white.

Size: A4 (210 to 297 mm), 8.5 by 11 inches

(216 to 279 mm), or between

Binding: Saddle stitched

Paper: 100 to 120 gsm (27 to 32 pound),

uncoated

2. Vendor Information (Or for Reference)

Approved Vendor

Vendor Part #

Contact #

PreferredVendor

1)

OR BENDPAK ENGINEERING APPROVED EQUIVALENT

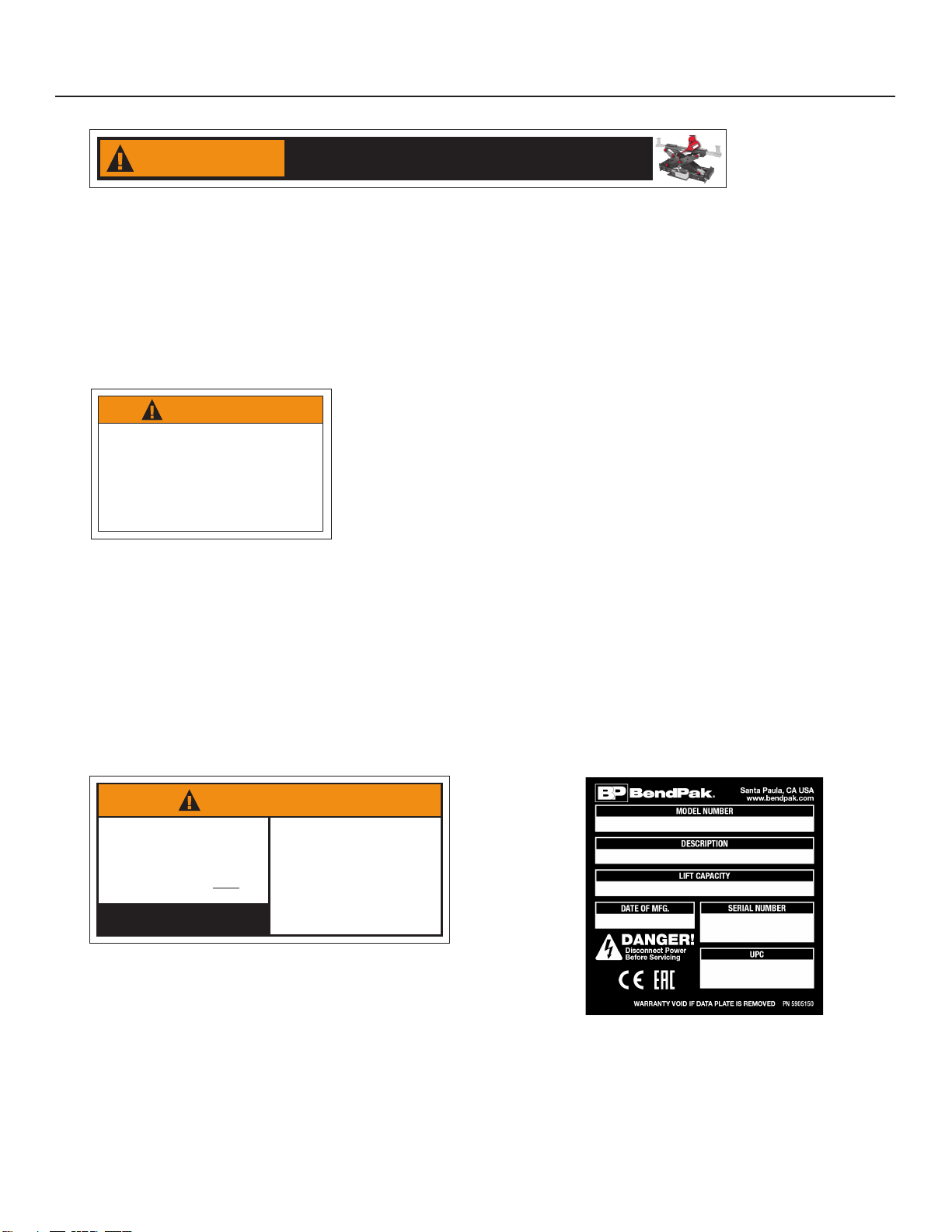

RBJ Series (15, 18, 25) Product Decal Positioning

A

C D

B

Warning_Improper_Use_Label.pdf:

Size: 4”W x 2.5”H

Material: White Vinyl Pressure Sensitive Adhesive

Thickness: 4 Mil

Ink: U.V. protected CMYK 2/C Process

Finish: Polished

Print Process: Offset Lithography - 200 line-screen

or 300 p.p.i. for digital

Lamination: Clear-gloss over-laminate for abrasion,

chemical, and ultra violet protection

Warning_Dry_Air_Label.pdf:

Size: 7”W x 3.5”H

Material: White Vinyl Pressure Sensitive Adhesive

Thickness: 4 Mil

Ink: U.V. protected CMYK 2/C Process

Finish: Polished

Print Process: Offset Lithography - 200 line-screen

or 300 p.p.i. for digital

Lamination: Clear-gloss over-laminate for abrasion,

chemical, and ultra violet protection

2017_Serial_Tag-E-5905150.pdf:

Size: 3”W x 3”H

Material: 2 Mil. Gloss polyester thermal transfer

label with a high performance permanent acrylic

adhesive.

Ink: 1 Color-Black

Rolling_Jack_Service_Warning_Decal.pdf:

Size: 11”W x 1”H

Material: White Vinyl Pressure Sensitive Adhesive

Thickness: 4 Mil

Ink: U.V. protected CMYK 4/C Process

Finish: Polished

Print Process: Offset Lithography - 200 line-screen

or 300 p.p.i. for digital

Lamination: Clear-gloss over-laminate for abrasion,

chemical, and ultra violet protection

PN 5905552

PN 5905190

PN 5905156

PN 5905150

P/N # 5905552

SERVICE REQUIREMENT

EVERY 30-DAYS

Keep entire jack and pump unit clean and free

of debris. Lubricate both sides of all moving

parts and pivot points on jack unit with multi–

purpose lithium based grease, penetrating oil or

90-wt gear oil. Use enough lubrication to prop-

erly maintain all moving parts, but avoid over

application. Apply silicone lubricant to smaller

items such as handles and lock hinges. Always

promptly remove excess grease and debris from

jack unit and pump unit. If you choose to have

this equipment serviced by a service technician,

always perform a personal inspection of all points

to be sure nothing was overlooked. Warranty will

be void on this equipment if service maintenance

is not performed on a regular basis.

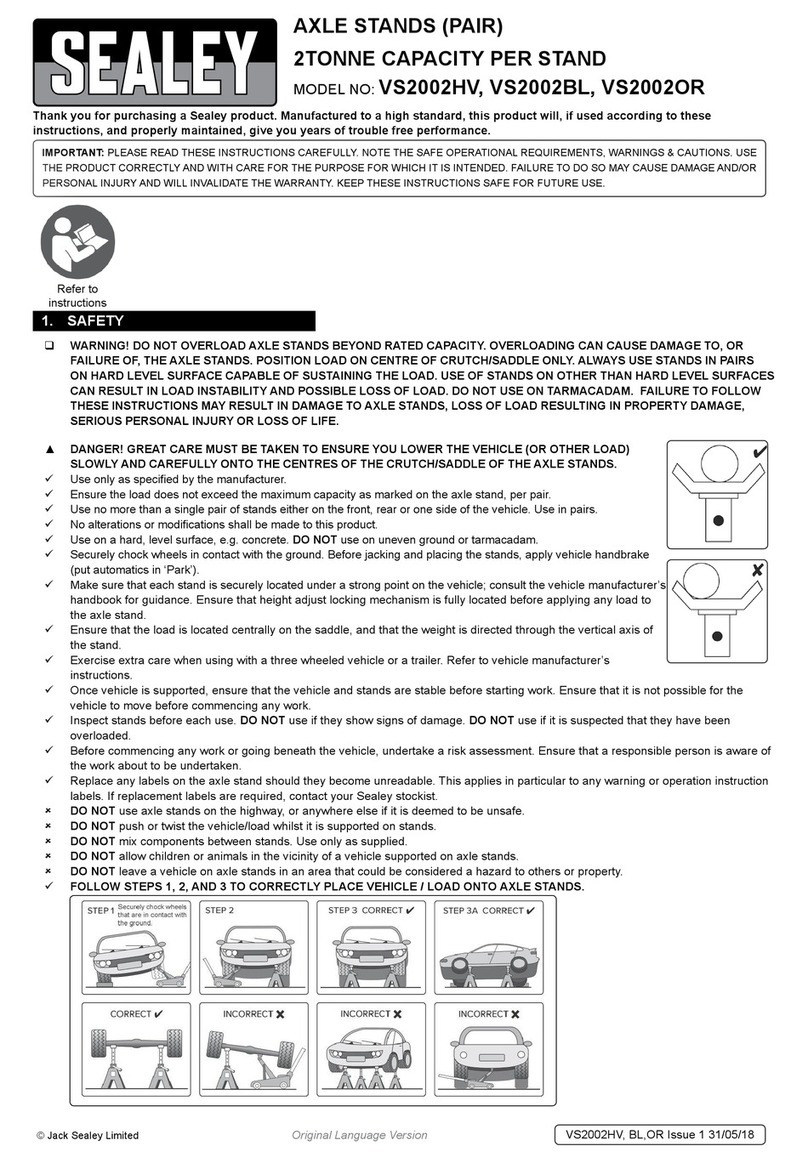

WARNING

PN 5905190

IMPROPER USE OF THIS ROLLING JACK

MAY RESULT IN SERIOUS BODILY HARM!

Always ensure that this rolling jack is positioned

correctly on the runway rail assembly BEFORE

raising the lift or working on or near the vehicle.

KEEP HANDS CLEAR of all pinch points.

NEVER use lift adapters other than those

specifically designed for this jack.

WARNING

WARNING

USE DRY AIR

SOURCE ONLY

Warranty will be void on this equipment if water

SERVICE PARTS AND LABOR NOT

COVERED UNDER WARRANTY IF RUST OR

CORROSION IS PRESENT.

The pump unit on this jack was not designed

to be used as a load holding device, jack must

be raised to a locked position at all times.

The manufacturer recommends installing

an automatic air line oiler in the air inlet line

as close to the pumping unit as possible. Air

pressure must be regulated to 125 P.S.I MAX.

Pump unit must be kept clean to prevent

contamination and pressure loss.

PN 5905156

contamination is found apparent. ALWAYS drain

air compressor tank daily or use in-line dryer.

This manual suits for next models

1

Other Bend-Pak Jack manuals

Popular Jack manuals by other brands

Würth

Würth 1918500050 Instruction and maintenance manual

AC Hydraulic

AC Hydraulic SD20L user guide

OTC Tools

OTC Tools 1507B PARTS LIST & OPERATING INSTRUCTIONS

Omega

Omega 15332 Original instruction

BIG RED JACKS

BIG RED JACKS T90203B owner's manual

Clarke

Clarke strong-arm CBJ30 Operation and maintenance instructions