6

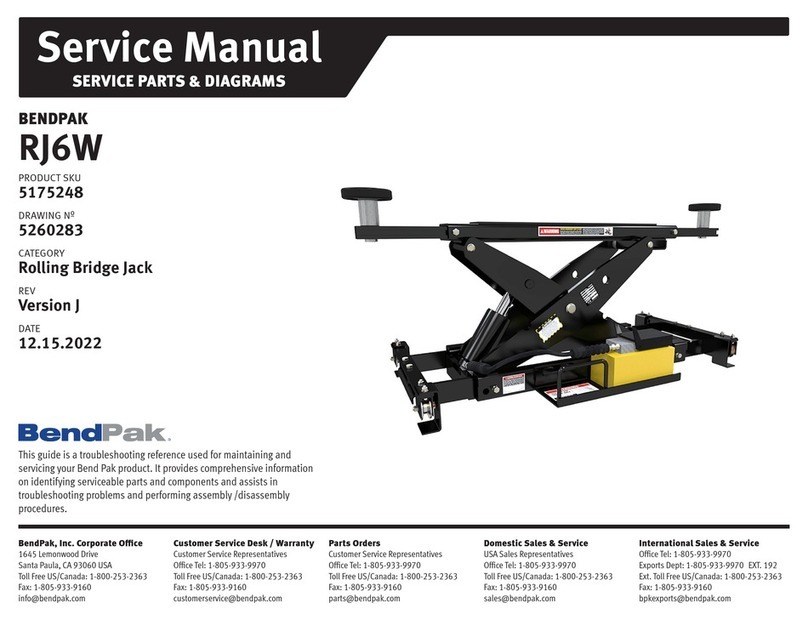

INSTALLER / OPERATOR

PLEASE READ AND FULLY

UNDERSTAND.

BY PROCEEDING YOU AGREE TO /

CERTIFY THE FOLLOWING.

I have visually inspected the lift on which the Rolling

Bridge Jack is to be installed and verified the lift to be

in good condition and free of defects. I understand that

installing a rolling jack on a lift in poor condition could

cause lift failure resulting in personal injury or death.

I understand that this Rolling Bridge Jack is to be

installed ONLY on a lift manufactured by BendPak

Incorporated and that the capacity of the Rolling Bridge

Jack(s) is consistent with the maximum capacity of the lift

that it being installed on.

I understand that a level floor is required for proper

installation and level lifting.

I understand that I am responsible if my floor is of

questionable slope and that I will be responsible for all

charges related to pouring a new level concrete slab if

required and any charges.

I will assume full responsibility for the concrete floor

and condition thereof, now or later, where the above

equipment model(s) are to be installed. Failure to follow

danger, warning, and caution instructions may lead to

serious personal injury or death to operator or bystander

or damage to property.

I understand that BendPak lifts are designed to be

installed in indoor locations only. Failure to follow

installation instructions may lead to serious personal

injury or death to operator or bystander or damage to

property or lift.

Failure to follow danger, warning, and caution

instructions may lead to serious personal injury or death

to operator or bystander or damage to property.

Please read entire manual prior to installation.

Do not operate this machine until you read and

understand all the dangers, warnings and cautions

in this manual. For additional copies

or further information, contact:

BendPak Inc. / Ranger Products

1645 Lemonwood Dr.

Santa Paula, CA. 93060

1-805-933-9970

www.bendpak.com

INSTALLER / OPERATOR

PROTECTIVE EQUIPMENT

Personal protective equipment helps makes installation

and operation safer, however, it does not take the place

of safe operating practices. Always wear durable work

clothing during any installation and/or service activity.

Shop aprons or shop coats may also be worn, however

loose fitting clothing should be avoided. Tight fitting

leather gloves are recommended to protect technician

hands when handling parts. Sturdy leather work shoes

with steel toes and oil resistant soles should be used by

all service personnel to help prevent injury during typical

installation and operation activities.

Eye protection is essential during installation and

operation activities. Safety glasses with side shields,

goggles, or face shields are acceptable.

Back belts provide support during lifting

activities and are also helpful in providing

worker protection. Consideration should

also be given to the use of hearing

protection if service activity is performed

in an enclosed area, or if noise levels are high.

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED

COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OR YOURSELF AND OTHERS

AND CAN CAUSE PERSONAL INJURY OR DEATH. READ AND FOLLOW ALL INSTRUCTIONS IN

THIS MANUAL BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

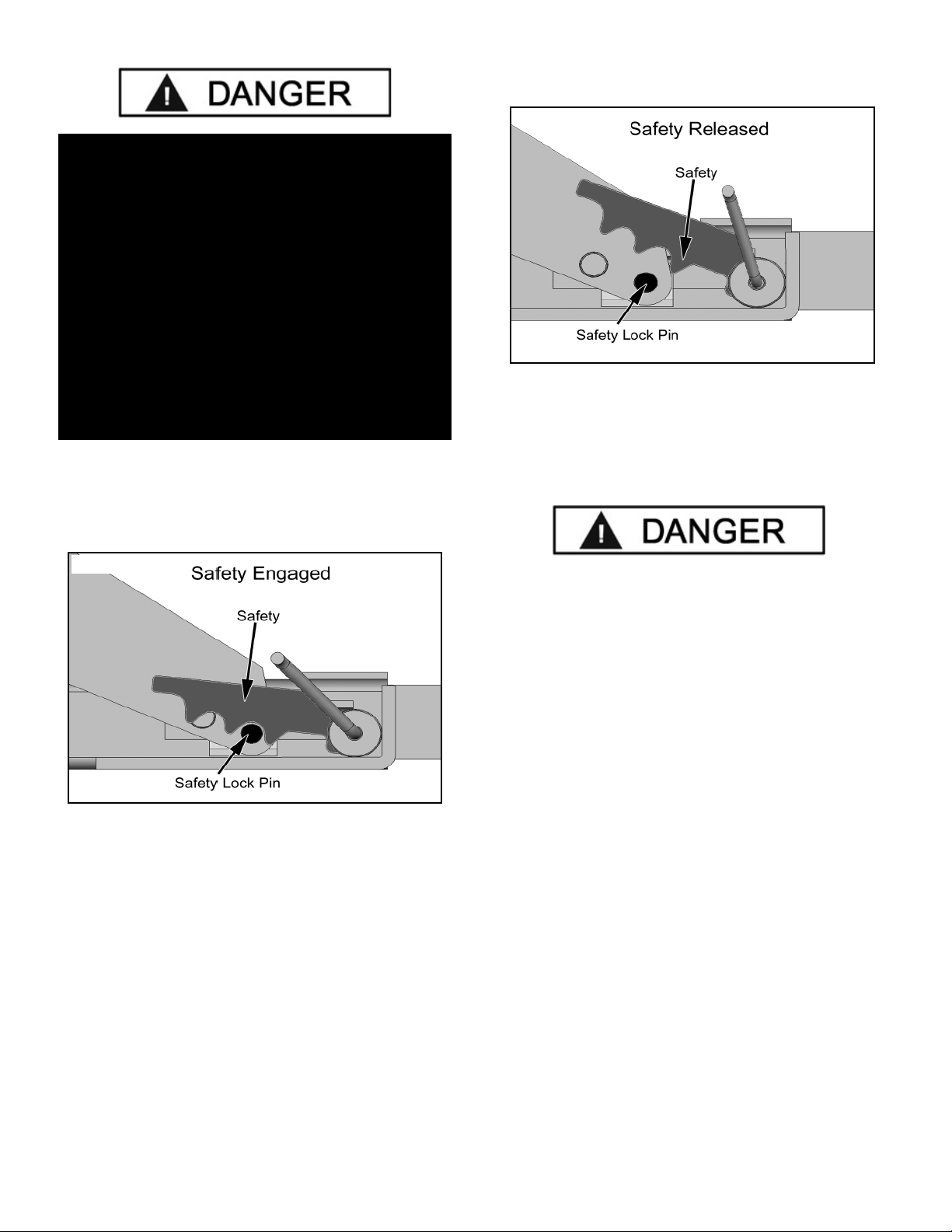

DANGER !

IT IS THE RESPONSIBILITY OF THE OWNER /

INSTALLER OF THIS ROLLING BRIDGE JACK TO

ENSURE THAT THE LIFT UPON WHICH THE ROLLING

BRIDGE JACK IS INSTALLED HAS BEEN PROPERLY

INSTALLED ACCORDING TO THE MANUFACTURER’S

SPECIFICATIONS.