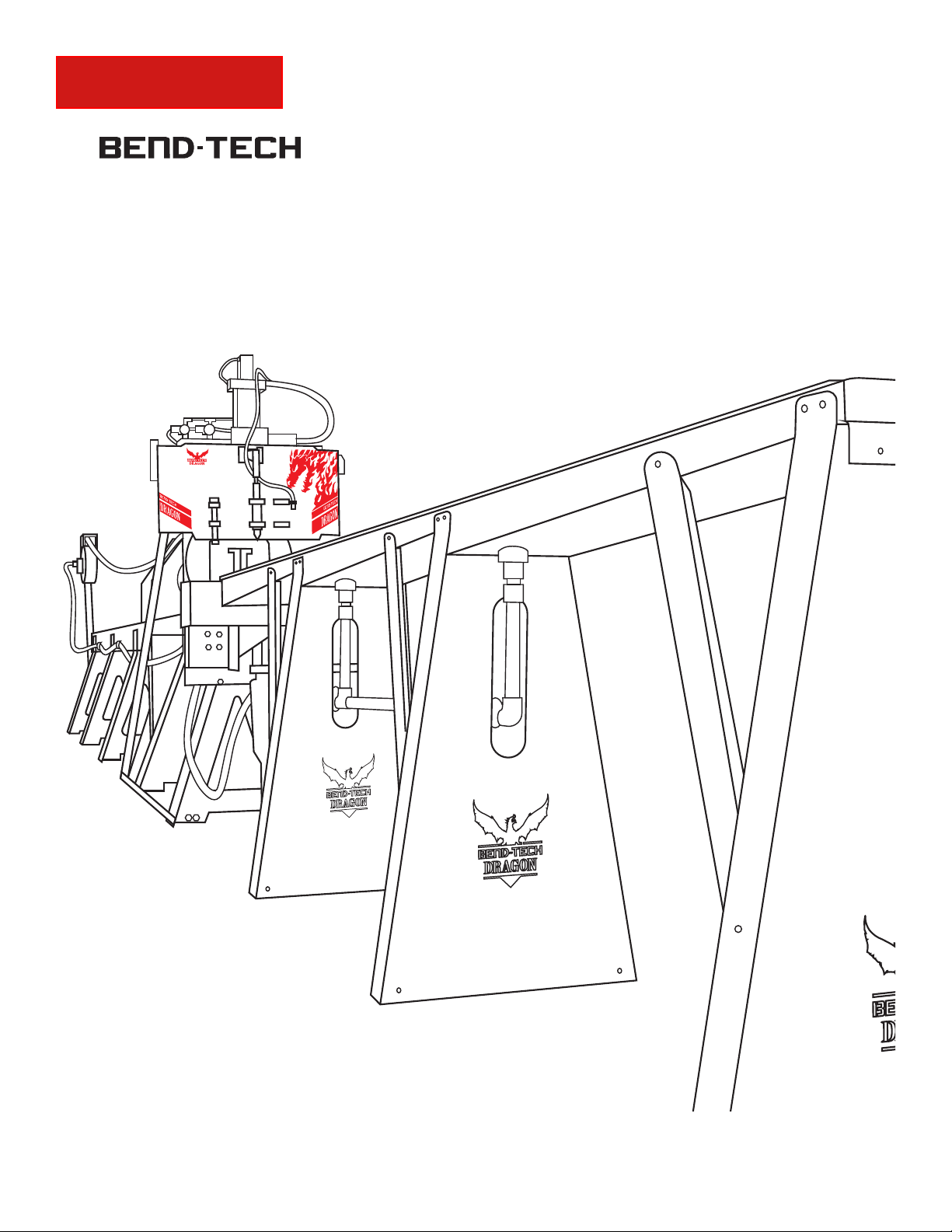

Bend-Tech Dragon mAchines User manual

Part 1 of 1

Material Coolant System

Assembly Manual

Revision 7 | English ©2021 Bend-Tech LLC

Dragon Machines

ii Bend-Tech Dragon

Material Coolant System Assembly Manual

©2021 Bend-Tech LLC

All rights reserved. The information in this manual is subject to change without notice.

Bend-Tech LLC strives to produce the most complete and accurate information regarding

its products. We are constantly working to improve and advance our products to increase

performance, user satisfaction and experience. Bend-Tech LLC assumes no responsibility for

errors or omissions regarding this manual. Bend-Tech LLC assumes no liability for damages

resulting from the use of the information contained in this publication.

iiiBend-Tech Dragon

Material Coolant System Assembly Manual

Dragon Machines

Material Coolant System

Assembly Manual

Revision 7

English

Original Instructions

August 2021

Bend-Tech, LLC

729 Prospect Ave.

Osceola, WI 54020 USA

(651) 257-8715

www.bend-tech.com

iv Bend-Tech Dragon

Contents

Material Coolant System Assembly Manual

Contents

Contents..........................iv

Limited Warranty ...................v

Customer Satisfaction Commitment. . . . . vi

Customer Service. . . . . . . . . . . . . . . . . . . vi

01

Parts and Equipment .............. 7

1.1 Parts List ......................7

1.2 Tools and Equipment .............8

02

Material Coolant System

Assembly ................................. 9

2.1 Overview ......................9

2.1.1 Cooling System Assembly Tools 9

2.2 Coolant Tray Components ........ 10

2.2.1 Parts Catcher and Support Leg

Removal ...................... 10

2.2.2 Support Leg Gusset......... 10

2.2.3 Leveling Feet ...............11

2.2.4 Parts Catcher...............11

2.2.5 Attach Water Tray to Parts

Catcher ....................... 12

2.2.6 Water Tray System Assembly . 13

2.2.7 C-Bracket................. 14

2.2.8 Support Leg Braces......... 14

2.2.9 Finishing the Coolant Tray

Assembly ..................... 15

2.3 Water Tray Drain System ......... 15

2.3.1 Bung Installation ........... 15

2.3.2 PVC Drain Installation ....... 16

2.3.3 Tray System Drain Diagram. . . 16

2.3.4 Placing the Cooling System

Reservoir ..................... 16

2.4 Water Pump ................... 16

2.4.1 Water Pump Requirements ... 17

2.4.2 Recommended Water Pump

.................. 17

2.5 Hose System .................. 17

2.6 Connect the Pump .............. 17

2.7 Install the Water Pump........... 17

2.8 Attaching the Hose to the Rail Beam 18

2.9 Hose Reel Mount ............... 18

2.10 Hose Reel ................... 19

2.11 Trolley Hose Mount ............ 19

2.12 Connect the Hose ............. 20

2.13 Leveling the Coolant Trays. . . . . . . 20

2.14 Sealing the Coolant Trays ....... 20

2.15 Control Box Guard ............. 21

2.16 Fill the Reservoir .............. 21

2.17 Plug Adapter. . . . . . . . . . . . . . . . . . 21

vBend-Tech Dragon

Contents

Material Coolant System Assembly Manual

Limited Warranty

Covering Bend-Tech Dragon

Bend-Tech, LLC provides a limited warranty on all new Dragon machines that are

manufactured directly or under license by Bend-Tech, LLC, and sold by Bend-Tech, LLC or its

approved distributors.

Warranty Coverage

Each Bend-Tech Dragon machine is warrantied by the manufacturer against defects in material

workmanship for 12-months. The warranty period commences upon delivery of the Dragon

machine to the customer’s facility.

Repair or Replacement Only

The Manufacturer’s sole liability, and the Customer’s exclusive remedy under this warranty

shall be limited to repairing or replacing the defective part. Repair or replacement of parts

is at the sole discretion of the manufacturer. The Customer is responsible for warranty parts

installation. Bend-Tech does not provide warranty service labor.

Limits

This warranty does not cover components subject to wear due to normal use of the machine

such as belts, lights, tooling etc. This warranty is void if Bend-Tech, LLC has determined any

failure is the result of mishandling, abuse, misuse, improper installation, improper storage,

become void or limited in the event that hardware changes or adaptations are made to the

machine.

Software

Dragon software is covered by a 2-year maintenance plan from the purchase date of the

Dragon machine. After the 2-year maintenance plan is expired, the Customer can purchase

a maintenance plan. A maintenance plan will ensure the customer always has the newest

version of Dragon software. The maintenance plan is critical to keeping Dragon software

updated with the newest capabilities possible, and is critical to the servicing of the machine.

Bend-Tech, LLC will contact the Customer regarding updates to the maintenance plan within

1-month of expiration. Contact Bend-Tech Support to ensure software is up to date: support@

bend-tech.com.

vi Bend-Tech Dragon

Contents

Material Coolant System Assembly Manual

Customer Satisfaction Commitment

Congratulations on your purchase of the world’s best CNC plasma tube and pipe cutting

machine, the Bend-Tech Dragon. Bend-Tech LLC places great pride in customer satisfaction

our support is a key factor in your success.

Contact Us

Bend-Tech’s hours of operation are Monday - Friday, 8:00 - 5:00 EST. The Bend-Tech support

team and sales team are always available during our hours of operation.

Phone: 651-257-8715

Email: Sales team: [email protected]

Address: Bend-Tech, 729 Prospect Ave., Osceola, WI 54020, U.S.A..

Customer Service

Comments, questions, or concerns regarding the Dragon Machine, this manual, or the Bend-

Tech Software can be directed to Bend-Tech sales and service representatives at the above

contact information. Check out the following links for more information regarding Dragon

Machines and Bend-Tech Software.

Website, Socials, and Online Resources

• http://www.bend-tech.com

• https://www.facebook.com/2020ssi

• https://www.instagram.com/bend_tech

• https://www.youtube.com/bendtech2020

• http://www.bend-tech.com/wiki7

7Bend-Tech Dragon

Parts and Equipment

01

Material Coolant System Assembly Manual

01

Parts and Equipment

1.1 Parts List

Cooling System

• Plug Kit

• Aluminum Trays (3)

• Aluminum Support Legs (3)

• Parts Catcher/Control Box Cover Box

• Reservoir

• Hose Reel

• Hose Reel Mount

Cooling System Hardware

(shipped inside water reservoir)

• Hardware Bag

• Material Rollers (3)

• Clear Silicone (1)

• PVC Cement (1)

• Cushion Clamps (6)

• Leveling Feet (6)

• Disposable Mesh Bags (2)

• 8 in. zip ties (8)

Fastener Bag

• Nuts (54)

• Washers (54)

• ¾ in. Button Head Hex Screws (40)

• 1 in. Button Head Hex Screws (14)

PVC Components

• Coupling (5)

• Union (3)

• Bung (4)

• Tee (2)

• Elbow (2)

• Pipe (11)

8Bend-Tech Dragon

Parts and Equipment

01

Material Coolant System Assembly Manual

1.2 Tools and Equipment

Reel and Hose Hardware

• ¼-20 T-nuts (6)

• ¼-20 ½ in. Hex head screws

• Flanged hex head screws (8)

•

• Small Tube Plug Adapter

• Large Tube Plug Adapter

• ¾ in. Barb x ¾ in. FGHT w/ rubber grommet

• Hose Clamps (2)

Cooling System Tools List

•

• Rubber Mallet

•

•

•

•

•

• ½ in. wrench

• Flat head screwdriver

9Bend-Tech Dragon

Material Coolant System Assembly

02

Material Coolant System Assembly Manual

02

Material Coolant

System Assembly

2.1 Overview

The Dragon Material Coolant System enables the machine to achieve cleaner cuts with less

dross or slag. The material coolant system also reduces plasma dust and toxic gas during

the cutting process. While the material coolant system will help the Dragon machine achieve

steel.

2.1.1 Cooling System Assembly Tools

Before assembling the material coolant system, ensure the required tools are available. The

following tools are required to assemble the material coolant system:

Tools Needed

•

•

•

•

•

•

•

• Slotted or Flat blade

screwdriver

• Punch or small Phillips

screwdriver

• Utility knife

• Rubber mallet or plastic dead

blow hammer

• Large channel lock pliers

10 Bend-Tech Dragon

Material Coolant System Assembly

02

Material Coolant System Assembly Manual

2.2 Coolant Tray Components

The coolant trays are placed at the Head of the machine. The coolant trays serve as both parts

catcher and coolant drainback system for the coolant system. Before beginning assembly,

ensure that all components for the coolant trays are present. The coolant Trays consists of:

• Aluminum Trays (3)

• Aluminum Support Legs (3)

• Parts Catcher (1)

• Support Leg Braces (6)

• Parts Rollers (3)

• Leveling Feet (6)

• C Bracket (1)

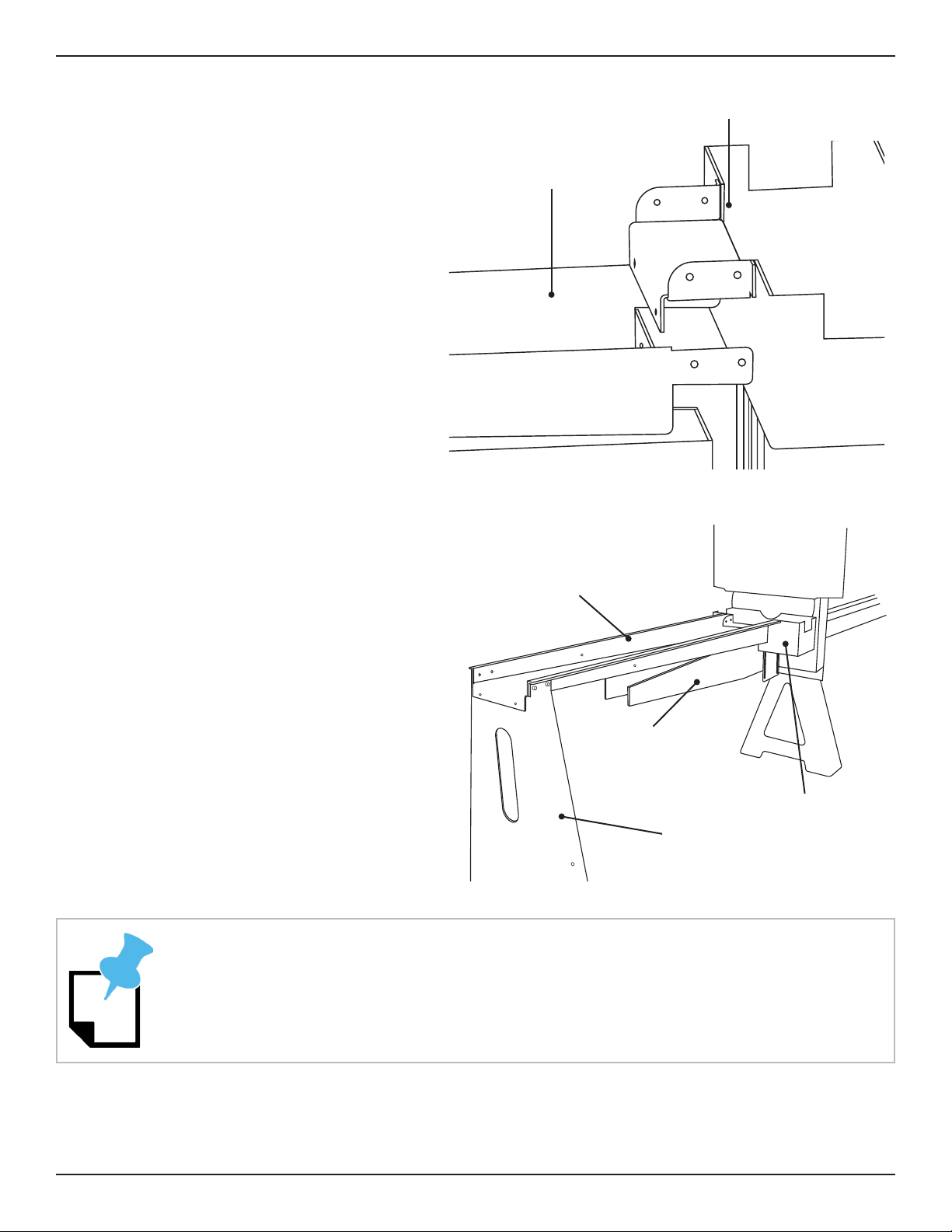

2.2.1 Parts Catcher and Support Leg Removal

It will be necessary to remove the parts catcher, parts tray, and support leg from the Beak

remove the four screws that hold the parts catcher at the front and back end of the Beak.

Remove the eight screws that hold the parts tray where the Beak mounts to the Head of the

2.2.2 Support Leg Gusset

The bottom of each support leg is constructed with an integrated gusset design. In each

corner, secure the gusset using a 1 in. Button Head Hex Screw, washers and nut. Place a

washer on the 1 in. Button Head Cap Screw and insert into the hole in the Support Leg and

gusset. Place a washer on the inside and thread a nut onto the Button Head Cap Screw. Use

and ratchet to tighten

the nut, securing the

gusset. 1 in. Button Head

Cap Screw

11Bend-Tech Dragon

Material Coolant System Assembly

02

Material Coolant System Assembly Manual

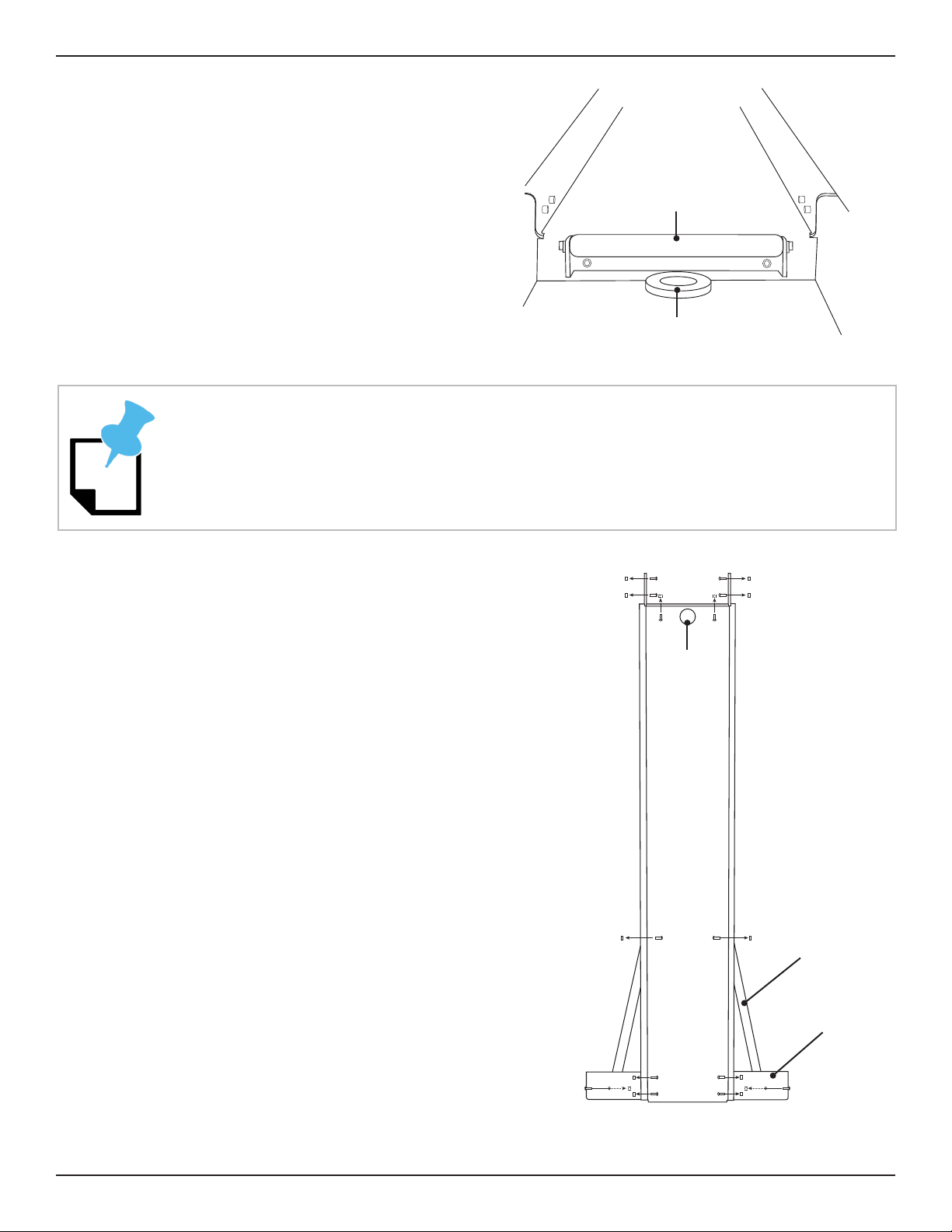

2.2.3 Leveling Feet

Locate the Leveling Feet in the hardware bag. Thread a nut onto each leveling foot, leaving

about an inch between the base of the foot and the nut. Insert a Leveling Foot into the hole at

the bottom of each Aluminum Support Leg.

Thread a second nut

onto the Leveling

Foot after inserting it

in the mounting hole

on the bottom of the

Aluminum Support

Leg. Do not tighten.

Leave space for

adjustment of the

support legs.

2.2.4 Parts Catcher

Place the parts catcher on the Beak at

the Head of the machine, just in front

of and under the Gate opening.

Locate eight ¾ in. button head screws,

nuts and washers from the hardware

bag. Insert the eight fasteners through

the slotted opening in the Parts

Catcher, aligning them with the holes in

the Beak.

Ensure the screw heads are on the

outside of the assembly and the nuts

and washers are on the inside. Thread

the nuts on and snug them down. Do

not tighten the nuts at this time.

Bend-Tech recommends enlisting a helper when assembling the Water Tray System.

Head of Machine

Parts Catcher

4 Bolts

per side

Leveling Feet

12 Bend-Tech Dragon

Material Coolant System Assembly

02

Material Coolant System Assembly Manual

2.2.5 Attach Water Tray to Parts Catcher

When assembling the coolant trays,

the face of the tray is placed behind

the parts catcher in the same fashion.

the parts catcher.

Use one of the support legs to support

the free end of the Water Tray. Use

four ¾ in. button head screws, nuts

and washers to attach the side tabs on

the coolant tray to the parts catcher.

Feed the screws through the side of the

coolant tray so the head of the screw is

inside the coolant tray and the nut and

washer are on the outside.

Use a punch or small Phillips head screwdriver to help align the mounting holes in the

Water Tray system.

Head of Machine

Tray 1

Support Leg

Beak

Parts Catcher

Parts Catcher

Tray 1

13Bend-Tech Dragon

Material Coolant System Assembly

02

Material Coolant System Assembly Manual

Locate one of the rollers from the parts

bag. Using two 1 in. button head screws,

nuts and washers, attach the roller on

the inside face of the coolant tray where

it connects to the parts catcher. Feed the

button head screw through the roller and

through the mounting holes in the Water

Tray and the parts catcher. Ensure the

roller is placed as far up as possible.

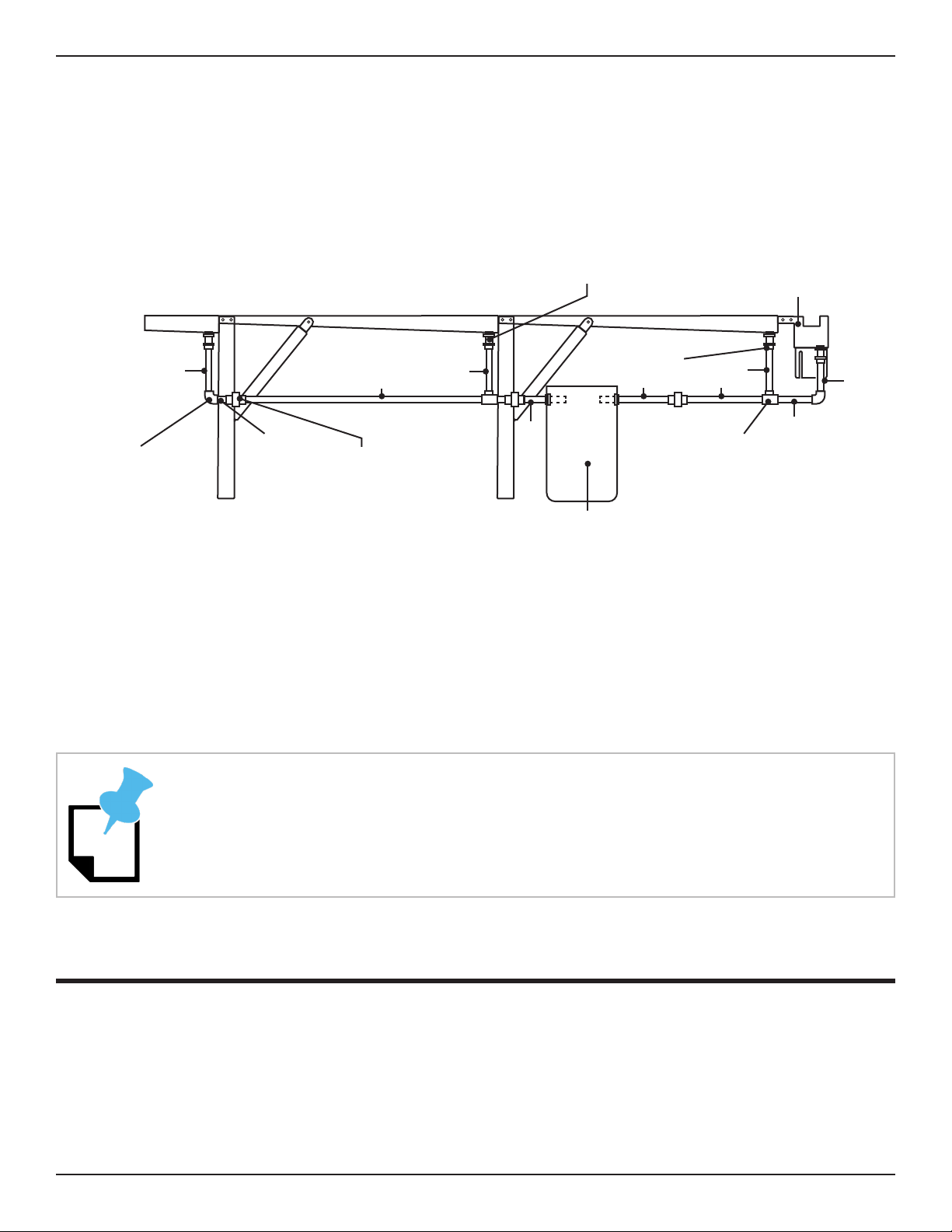

2.2.6 Water Tray System Assembly

Position the second coolant tray behind

second support leg to support the free end

of the second coolant tray.

mounting surface is on the outside of both

water trays. Align the four mounting holes

in the support leg with the holes on the

tabs on the second coolant tray.

Fasten the sides of the coolant trays and

support leg together using four 1 in. button

head screws, nuts and washers. Ensure

the heads of the screws are on the inside

of the water tray and the nuts and washers

are on the outside. Do not tighten.

Top View

Drain

Support Leg Brace

Support Leg

Tray or Parts

Catcher

Drain

Roller

Do not tighten any fasteners on the coolant tray assembly until all of the components

are connected.

14 Bend-Tech Dragon

Material Coolant System Assembly

02

Material Coolant System Assembly Manual

tight.

Repeat this process with the third coolant tray.

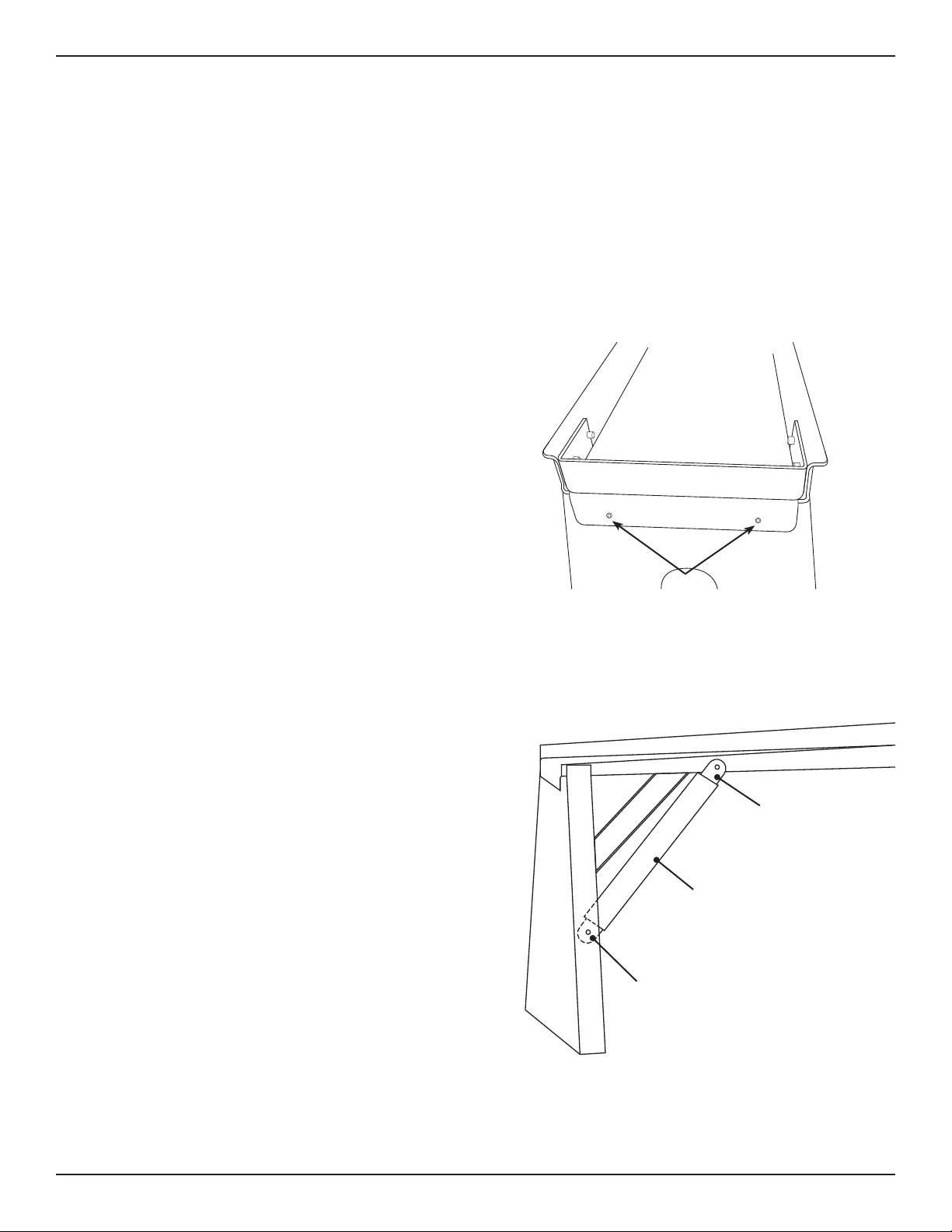

2.2.7 C-Bracket

Place the C-Bracket at the front end of Aluminum Tray No. 3. Align the mounting holes of the

third support leg with the holes in the

Water Tray and C-Bracket.

with the heads on the inside of the Water

Tray and the nuts and washers on the

outside of the support leg.

Below the C-Bracket, insert two ¾ in.

button head fasteners, with the heads on

leg and the nuts on the inside, to secure

leg.

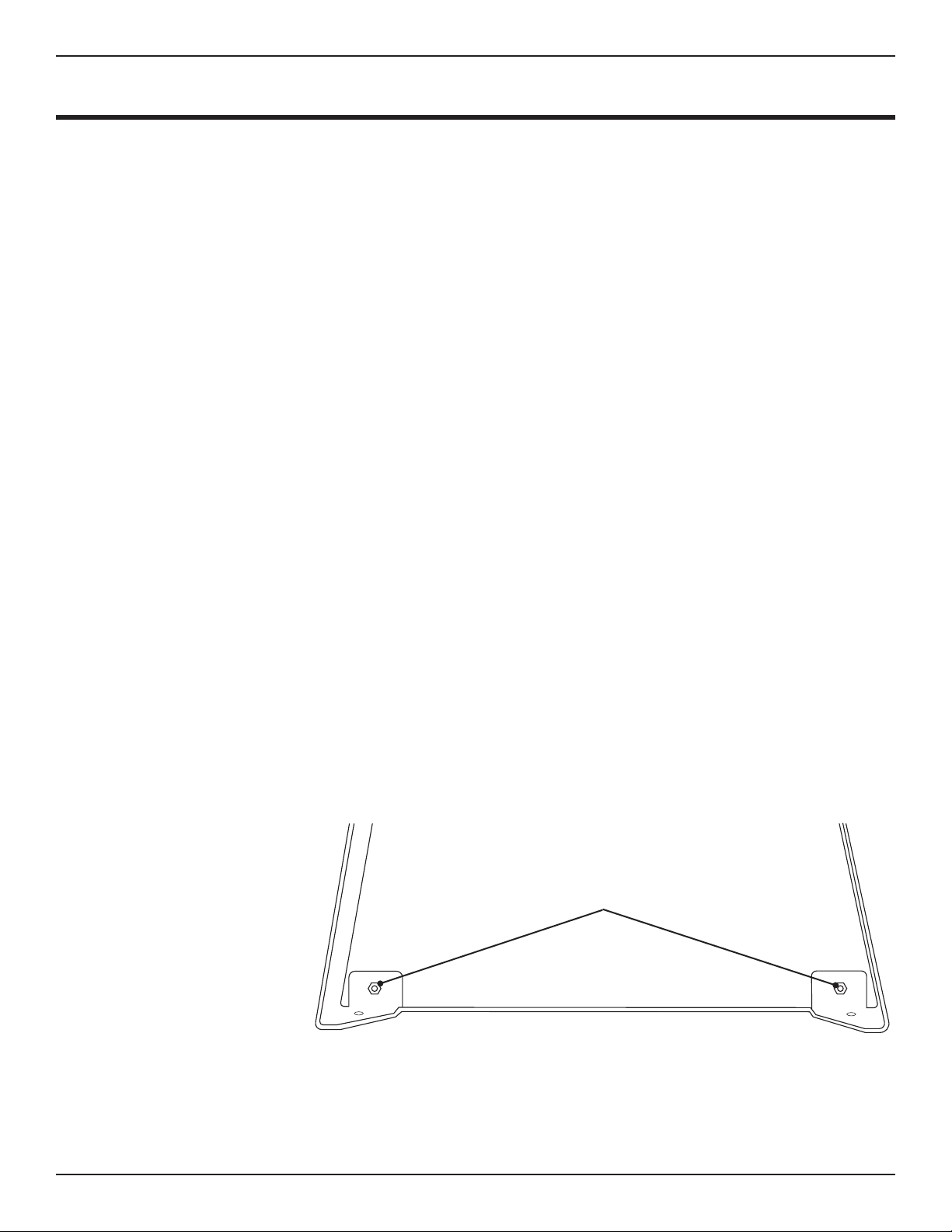

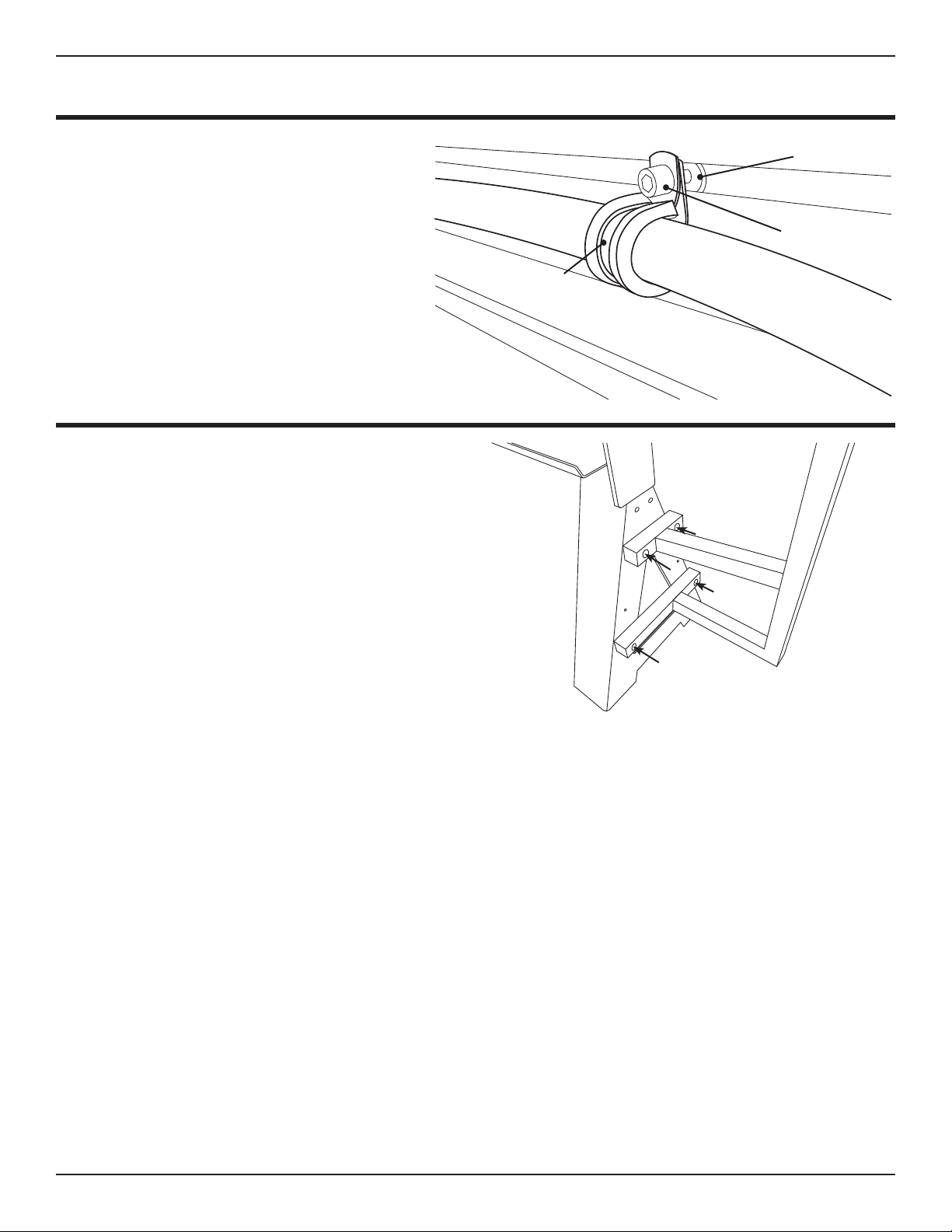

2.2.8 Support Leg Braces

Starting at the front of the system, use (12)

¾ in. button head screws, washers and

nuts to attach the support leg braces to the

support legs and the coolant trays.

brace to the inside the of the support leg,

inserting the button head screws so the

head is on the outside of the support leg

and nut and washer are on the inside.

Attach the bent end of the support leg brace

to the outside of the coolant tray, feeding

the button head screw from the inside of the

coolant tray and the nut and washer are on

the outside.

Outside of Tray

(Bent End)

Support Leg Brace

Inside of Support

Leg (Flat End)

Tray 3

C-Bracket

fasteners

15Bend-Tech Dragon

Material Coolant System Assembly

02

Material Coolant System Assembly Manual

2.2.9 Finishing the Coolant Tray Assembly

braces. Tighten securely. Take care to position the rollers so they sit above the surface of the

coolant trays, adjusted as high as possible.

2.3 Water Tray Drain System

The material coolant system’s drain system collects water from the coolant trays, holds it in the

coolant system reservoir and recirculates

it back through the material.

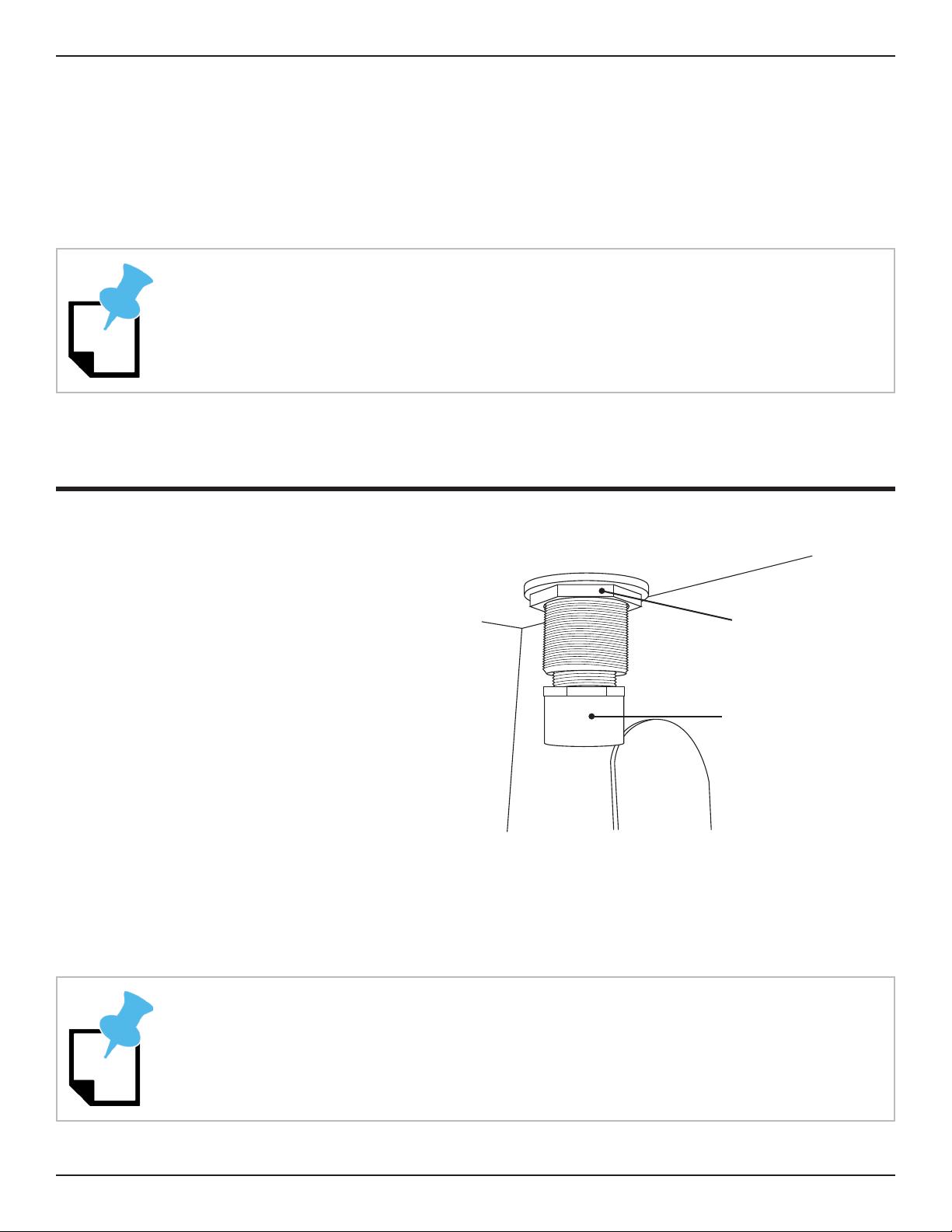

2.3.1 Bung Installation

Locate the four drain bungs in the PVC

parts bag. Remove the coupling nuts from

each drain bung. Insert a bung into the

drain hole in each coolant tray and in the

parts catcher. Thread the nuts back onto

each bung underneath the coolant tray

and tighten securely using a large channel

lock pliers. Locate the male/female

couplers in the PVC parts bag. Thread

one PVC male/female coupler into each

drain bung.

Also thread one PVC coupler into the bung inside the parts catcher. This will allow the parts

catcher to hold water to help cool parts.

Teon tape or plumber’s tape can help seal the male/female coupler in the drain bung.

Drain Bung

Male/Female

Coupler

When in use, the rollers should keep parts from resting on the bottom of the coolant

trays.

16 Bend-Tech Dragon

Material Coolant System Assembly

02

Material Coolant System Assembly Manual

2.3.2 PVC Drain Installation

The PVC drain system is installed beginning at the parts catcher and then working to the end

of the trays. The PVC parts are numbered in order of installation. During this process the

Installer will also place and connect the coolant reservoir. Using PVC cement, install the parts

per diagram 2.3.3.

2.3.3 Tray System Drain Diagram

2.3.4 Placing the Cooling System Reservoir

Place the coolant reservoir according the diagram in section 2.3.3. Install the screens on the

drains feeding into the coolant reservoir. Secure using zip ties.

Fit the No. 5 and No. 6 PVC pieces through the grommets in the reservoir.

2.4 Water Pump

The material coolant system requires a water pump to be operational. Because customer

needs can vary, Bend-Tech does not supply a water pump with the coolant system. The

Customer will be required to supply a water pump to complete the coolant system. Refer to

Drain Bung

Coupler

Parts Catcher

Union Fitting

Elbow Fitting T Fitting

Cooling System

Reservoir

1

2

3

45

8

9

10

11

6

Depending on the size of the the water pump used, the pump may need to be placed

into the reservoir prior to connecting the reservoir to the rest of the PVC drain system.

17Bend-Tech Dragon

Material Coolant System Assembly

02

Material Coolant System Assembly Manual

2.4.1 Water Pump Requirements

2.4.2 Recommended Water Pump Specications

Voltage 120VAC

Running Amps 3.84

Horsepower .5

Volume 2500GPH

2.5 Hose System

The material coolant system uses hoses to transport water from the coolant reservoir back

through the material.

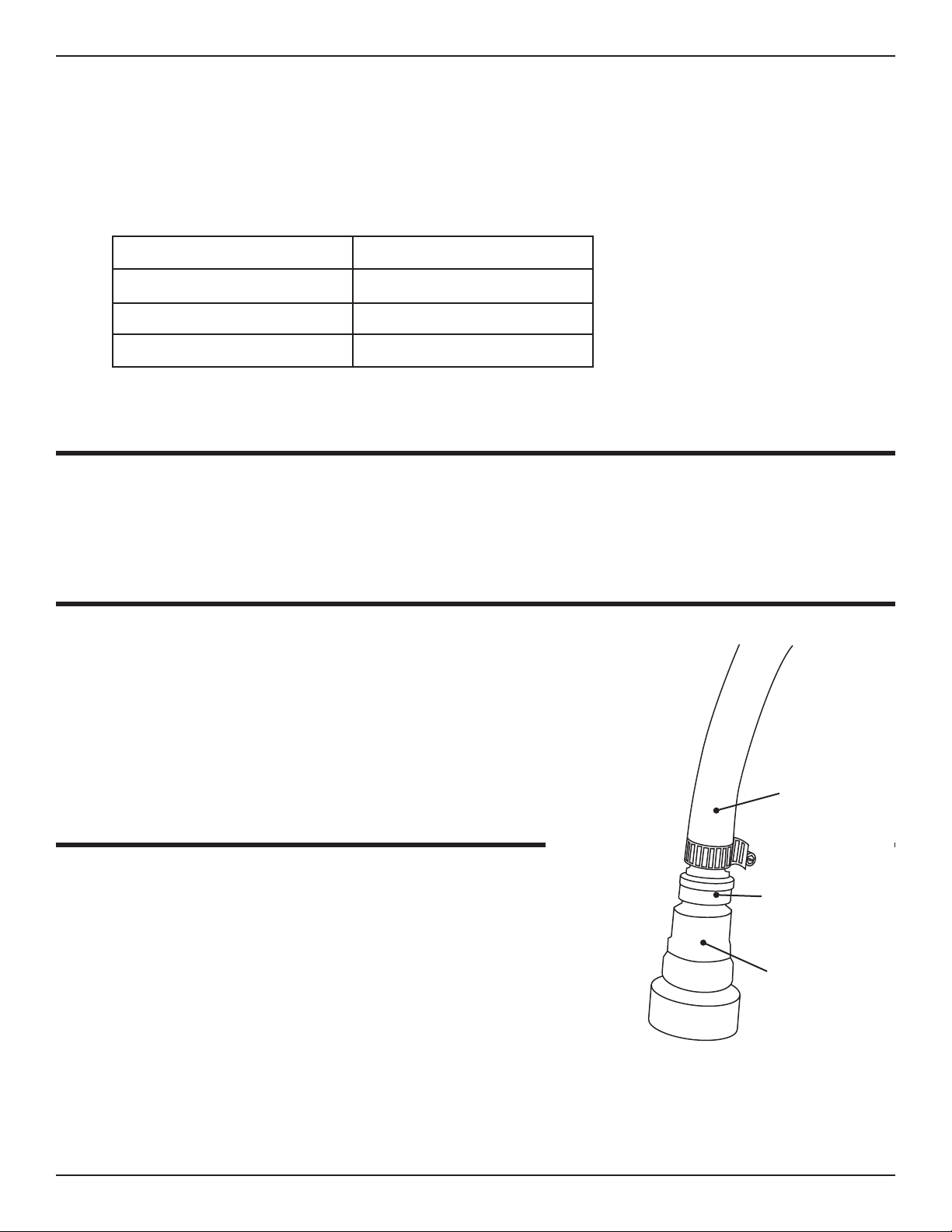

2.6 Connect the Pump

and attach to the water pump. Using a hose clamp

from the hose attachment bag, place the clamp

over the end of the long hose and slip the hose

securely.

2.7 Install the Water Pump

With the hose attached to the pump, set the pump

inside the coolant reservoir. Install the cover on the

coolant reservoir, routing the water pump power

cord and hose through the opening in the cover.

Attach the wireless remote-control outlet to the

water pump power cord, and then the yellow GFCI

power cable to the remote-control outlet.

Hose Clamp

Brass Barb Fitting

Water Pump Outlet

18 Bend-Tech Dragon

Material Coolant System Assembly

02

Material Coolant System Assembly Manual

2.8 Attaching the Hose to the Rail Beam

Locate six T-nuts and six ½ in. hex

screws from the hardware bag,

along with six cushion clamps. Loop

the cushion clamps around the hose,

spacing evenly at intervals along the

beam. Attach the cushion clamps to

the beam using the T-nuts and hex

screws.

2.9 Hose Reel Mount

Attach the hose reel mount to the Tail

of the machine. The mount bolts to the

outside of the last leg of the machine

in. socket and ratchet.

Hex Screw

Hose

Cushion Clamp

T-Nut

19Bend-Tech Dragon

Material Coolant System Assembly

02

Material Coolant System Assembly Manual

2.10 Hose Reel

four nyloc nuts in the hardware bag.

Position the hose reel in place on the

hose reel mount, aligning the four

hex bolts one at a time, with the head

on the hose reel side. Thread the nyloc

nuts on until they hit the nylon insert.

When all four bolts are in, tighten

socket.

Connect the water hose to the brass

connection on the side of the hose reel

and secure with a hose clamp.

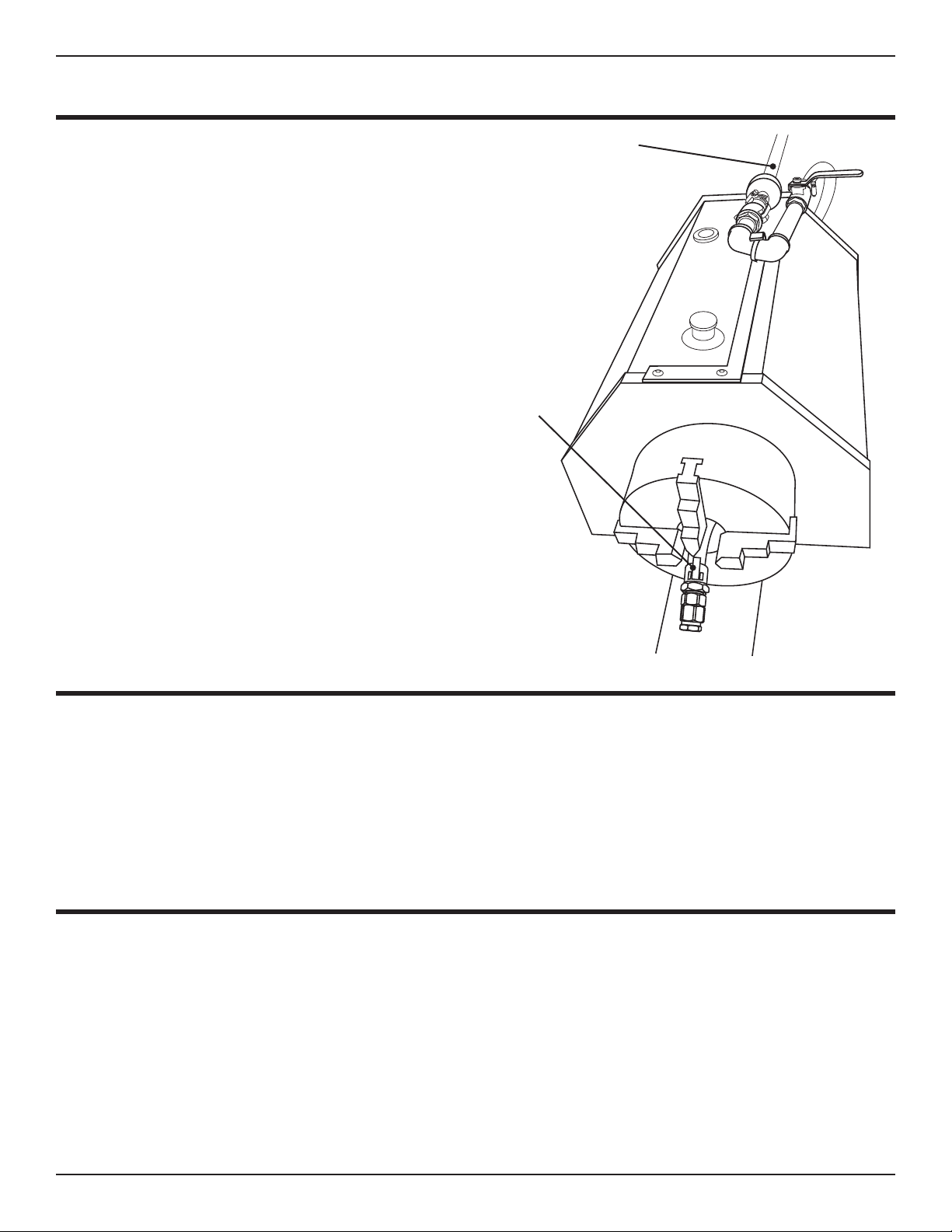

2.11 Trolley Hose Mount

Before attaching the hose mount to the front of

the trolley cover, locate the black rubber mat.

Remove the backing from the rubber mat and

stick it to the side of the trolley cover as shown in

the image. This will reduce physical wear of the

Remove the two screws at the front of the trolley

cover, just above the chuck. Place the trolley

hose mount on the trolley cover. Fasten to the

trolley cover using the two trolley cover screws.

The hose reel is heavy, enlist help during the mounting process.

Hose Mount

Intake Connection

Black Rubber Mat

20 Bend-Tech Dragon

Material Coolant System Assembly

02

Material Coolant System Assembly Manual

2.12 Connect the Hose

Pull the hose from the hose reel and hook the

ball valve assembly on the Hose Mount. Feed

the short section of hose through the back of the

trolley and through the chuck. The Plug Adapters

will be secured with the cam lock.

2.13 Leveling the Coolant Trays

to-side and front to back. Use a bubble level placed on the edges of the coolant trays to

wrench to turn the bottom nut on each leveling foot to adjust. Once level, tighten the top nut on

the leveling foot.

2.14 Sealing the Coolant Trays

Using the silicone sealant, place a bead of silicone around all gaps and seams in the coolant

before using the coolant system.

Feed short end

through the Chuck

Hose from Hose

Reel

Other manuals for Dragon mAchines

1

Table of contents

Other Bend-Tech Industrial Equipment manuals

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon mAchines User manual

Bend-Tech

Bend-Tech Dragon A400 Installation guide

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon User manual

Bend-Tech

Bend-Tech DRAGON A150 User manual

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon A400 Installation guide

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon A400 Installation and operation manual