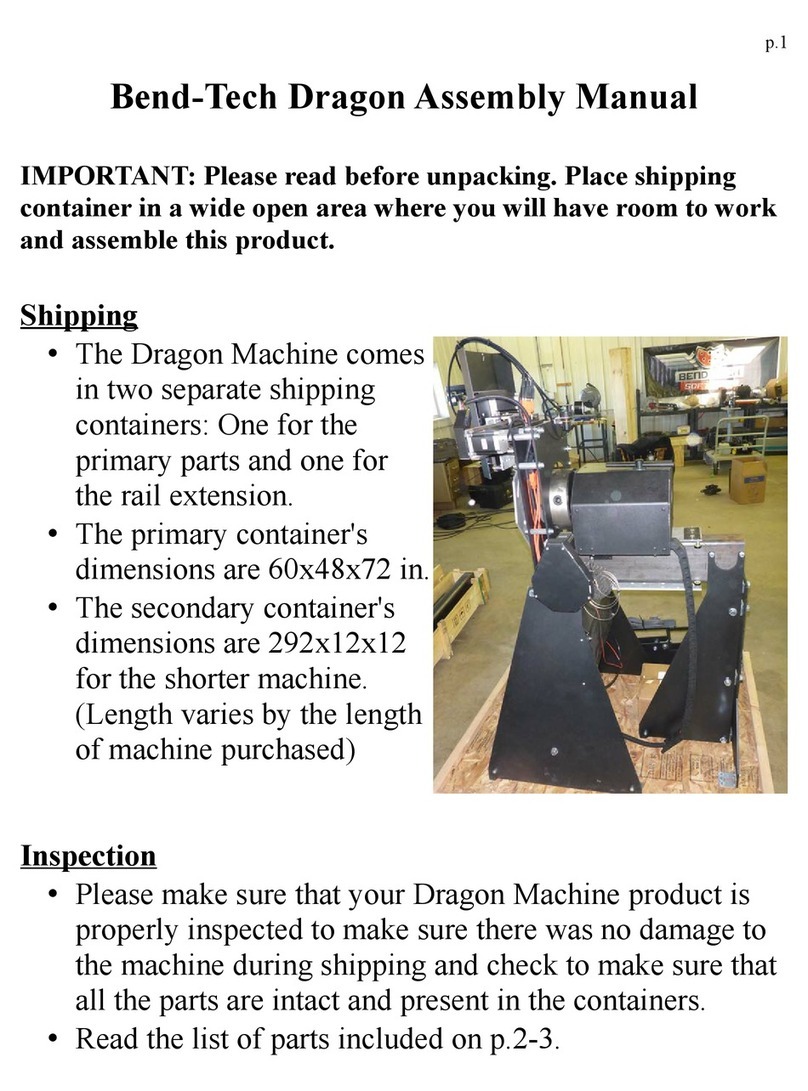

Bend-Tech Dragon A400 User manual

Other manuals for Dragon A400

14

Other Bend-Tech Industrial Equipment manuals

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon mAchines User manual

Bend-Tech

Bend-Tech Dragon A400 Installation and operation manual

Bend-Tech

Bend-Tech Dragon A400 Installation guide

Bend-Tech

Bend-Tech Dragon A400 Installation guide

Bend-Tech

Bend-Tech Dragon User manual

Bend-Tech

Bend-Tech Dragon mAchines User manual

Bend-Tech

Bend-Tech DRAGON A150 User manual

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon A400 User manual

Popular Industrial Equipment manuals by other brands

MICRO-EPSILON

MICRO-EPSILON colorCONTROL MFA operating instructions

SAMCHULLY

SAMCHULLY TS Series instruction manual

Titan

Titan Pulsite Link instruction manual

Danfoss

Danfoss BOCK HRX CO2 T H Translation of the original instructions

Endress+Hauser

Endress+Hauser SmarTec S CLD 132 PROFIBUS-PA operating instructions

Flow

Flow Paser CF900 manual