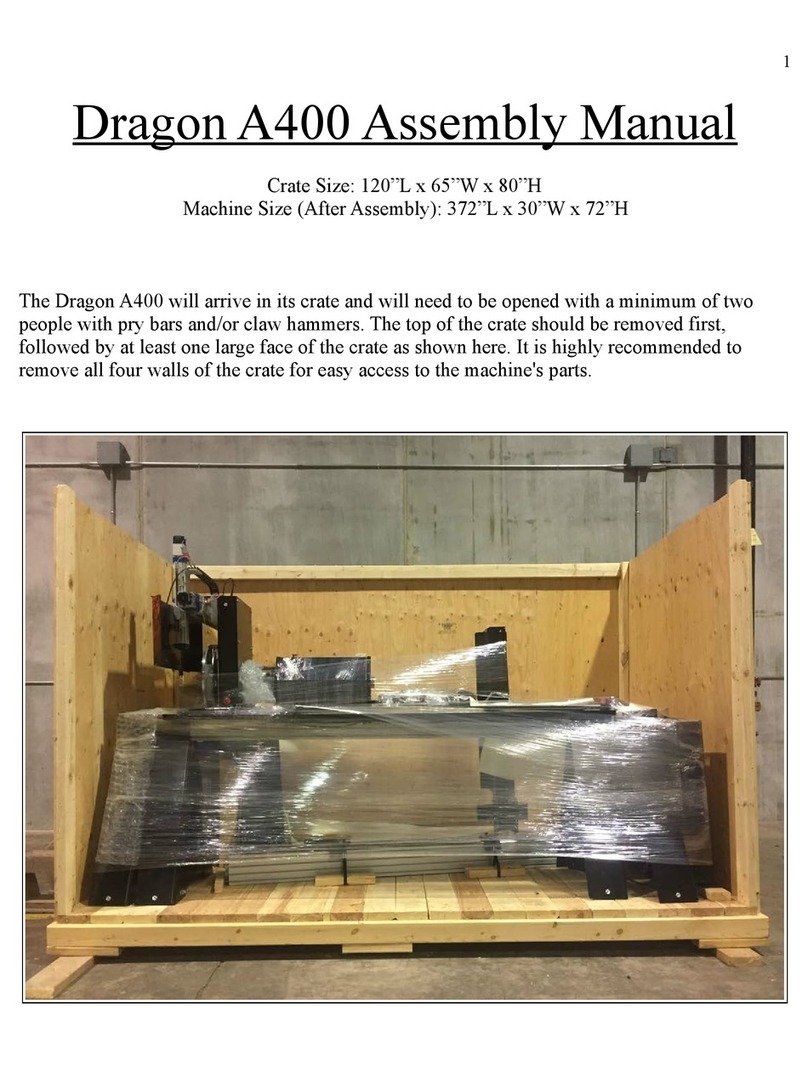

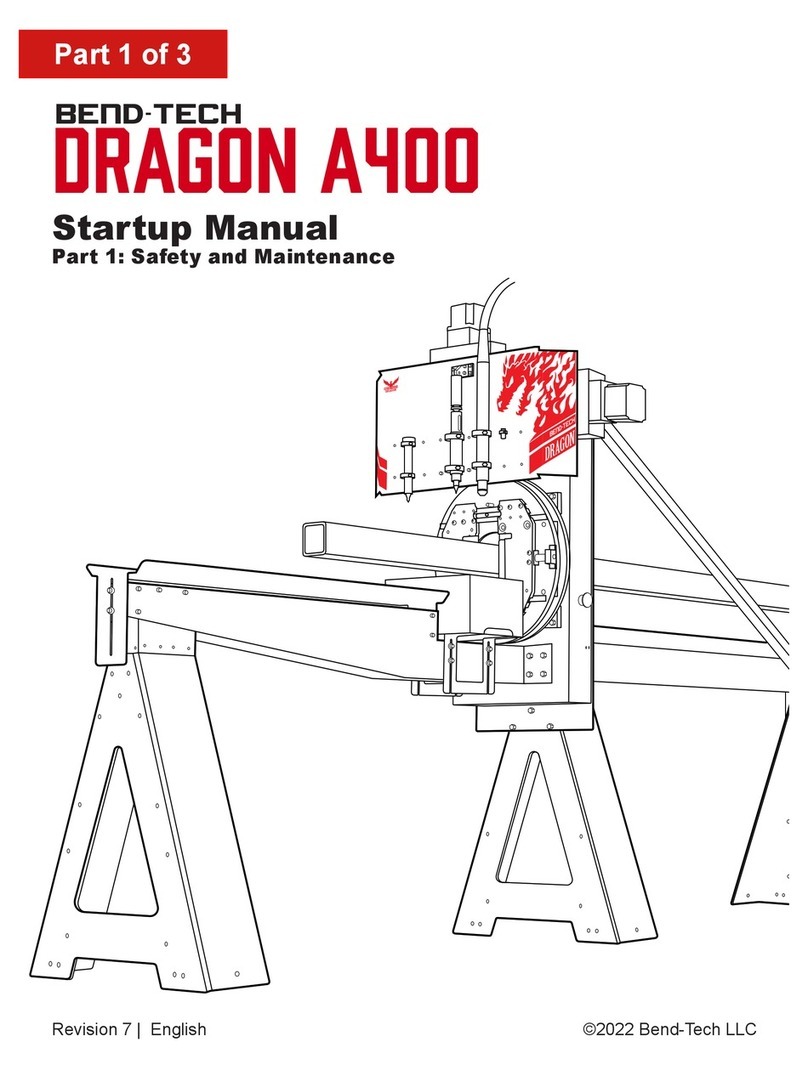

Bend-Tech Dragon A400 User manual

Other manuals for Dragon A400

14

Table of contents

Other Bend-Tech Industrial Equipment manuals

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

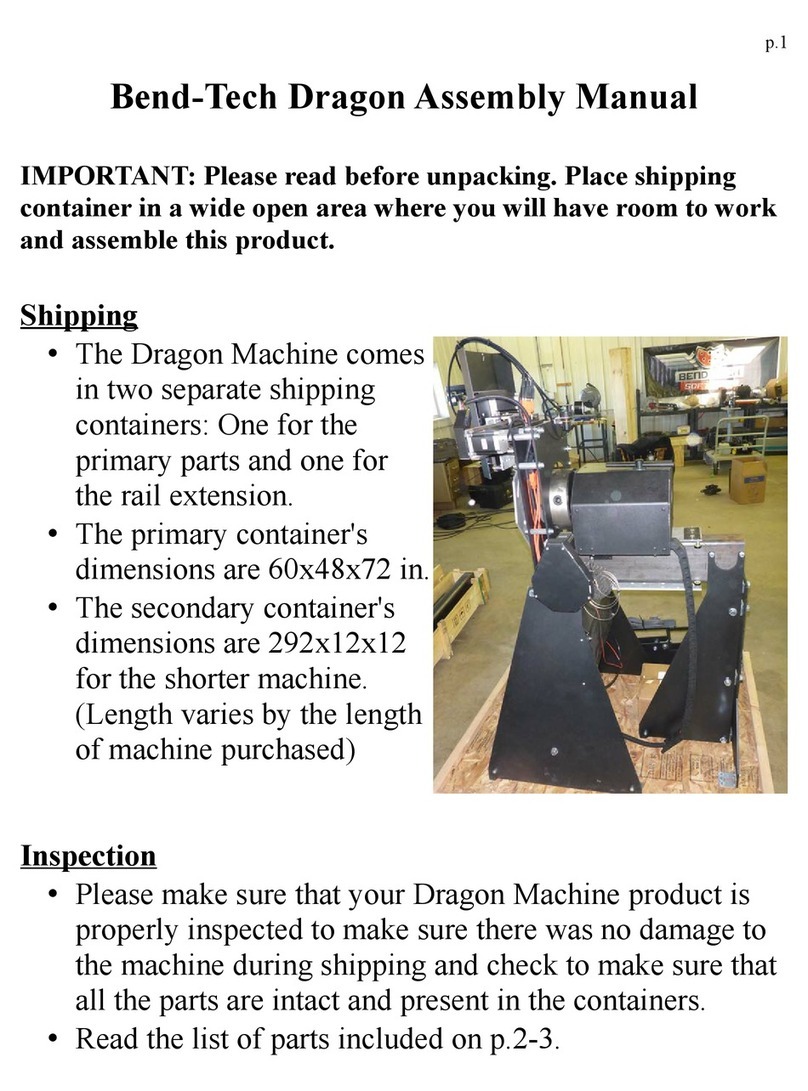

Bend-Tech Dragon mAchines User manual

Bend-Tech

Bend-Tech DRAGON A150 User manual

Bend-Tech

Bend-Tech Dragon User manual

Bend-Tech

Bend-Tech Dragon A400 Installation guide

Bend-Tech

Bend-Tech Dragon mAchines User manual

Bend-Tech

Bend-Tech Dragon A400 User manual

Bend-Tech

Bend-Tech Dragon A400 Installation guide

Bend-Tech

Bend-Tech Dragon A400 Installation and operation manual

Popular Industrial Equipment manuals by other brands

Festo

Festo ELGA-BS-KF-70 Repair instructions

Samoa

Samoa NEXU installation manual

MachineryHouse

MachineryHouse TZ Series Operation manual

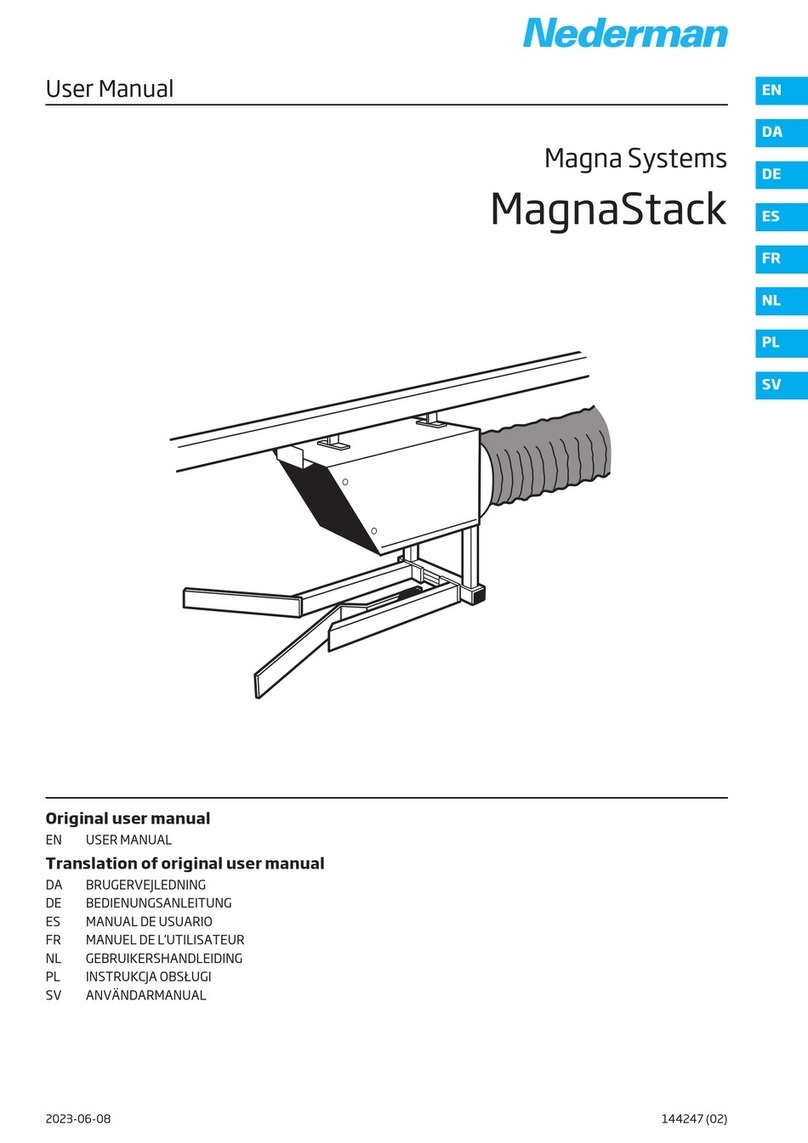

Nederman

Nederman MagnaStack user manual

Lukas

Lukas LX-Strut Translation of the original instructions

Lippert Components

Lippert Components Power Gear 82-L0356 owner's manual