Technical data

Values only apply to closed measuring current transformers.

Insulation coordination acc. to IEC 60664-1/IEC 60664-3

Definitions

Measuring circuit (IC1) ........................................................................

............... primary conductors routed through the current transformer

Secondary (IC2) ...........................terminal block 1 (24 V, GND, S1, S2)

Rated voltage ............................................................................ 300 V

Rated voltage (insulated cables)............................................... 600 V

Overvoltage category....................................................................... III

Area of application ................................................... ≤ 2000 m AMSL

Rated impulse voltage IC1/IC2 .........................................................4 kV

Rated insulation voltage IC1/IC2 ................................................... 300 V

Pollution degree ............................................................................... 2

Basic insulation between IC1/IC2 ............................................. 300 V

Supply voltage

Supply voltage US.................................................................... DC 24 V

Operating range of US.................................................................±5 %

Ripple US................................................................................... ≤ 2 %

Inrush current................................................................10 A for 25 µs

Power consumption .............................. ≤ 0.25 W typ. (2.5 W max.)

Measuring circuit

Measuring current transformer, internal diameter .................25 mm

Characteristics according to IEC 62020 and IEC/TR 60755

........................................................................AC/DC sensitive, type B

Frequency bandwidth..................................................DC … 100 kHz

Measuring range IΔn

DC/AC (< 100 kHz).........................................................10… 500 mA

Technische Daten

Werte gelten nur für geschlossenen Messstromwandler.

Isolationskoordination nach IEC 60664-1/IEC 60664-3

Definitionen

Messkreis (IC1) ................... Durch den Wandler geführte Primärleiter

Sekundär (IC2) ...........................Klemmenblock 1 (24 V, GND, S1, S2)

Bemessungsspannung .............................................................. 300 V

Bemessungsspannung (isolierte Kabel)..................................... 600 V

Überspannungskategorie ................................................................ III

Einsatzhöhe ..........................................................≤ 2000 m über NN

Bemessungs-Stoßspannung IC1/IC2 ...............................................4 kV

Bemessungs-Isolationsspannung IC1/IC2 .....................................300 V

Verschmutzungsgrad ....................................................................... 2

Basisisolierung zwischen IC1/IC2 ............................................. 300 V

Versorgungsspannung

Versorgungsspannung US........................................................ DC 24 V

Arbeitsbereich von US.................................................................±5 %

Ripple US.................................................................................... ≤ 2 %

Einschaltstrom...............................................................10 A für 25 µs

Eigenverbrauch ..................................... ≤ 0,25 W typ. (2,5 W max.)

Messkreis

Messstromwandler Innendurchmesser ...................................25 mm

Charakteristik nach IEC 62020 und IEC/TR 60755

.........................................................................allstromsensitiv, Typ B

Frequenzbandbreite.....................................................DC … 100 kHz

Messbereich IΔn

DC/AC (< 100 kHz).........................................................10… 500 mA

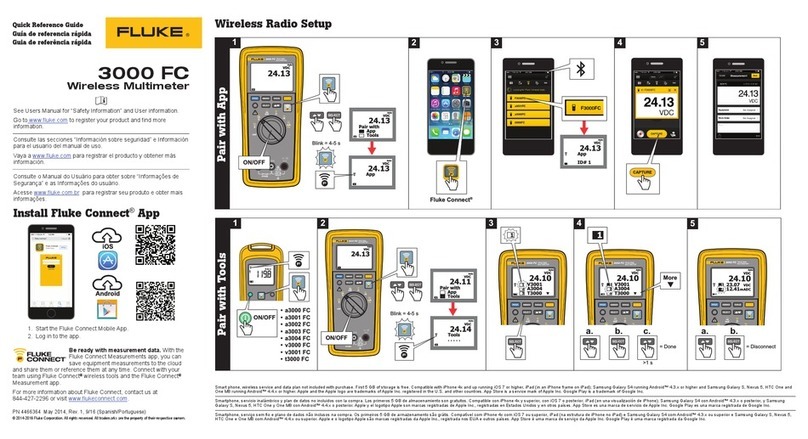

Einbau Messstromwandler Installing measuring current transformer

Alle stromführenden Leitungen/Leiter müssen

durch den Messstromwandler geführt werden.

Keine abgeschirmten Leitungen durch den

Messstromwandler führen!

All current-carrying cables must be routed to-

gether through the measuring current transform-

er. Do not route any shielded cables through the

measuring current transformer!

Ein vorhandener Schutzleiter darf grundsätzlich

nicht durch denWandler geführt werden.

L1

L2

L3

N

Never route an existing protective conductor

through the measuring current transformer.

Eine Biegung der Primärleiter darf erst ab dem

angegebenen Mindestabstand erfolgen. Dabei sind

die von den Herstellern vorgeschriebenen

Mindestbiegeradien der verwendeten Leiter

einzuhalten.

* Abstand zum 90°-Winkel = 2 x Außendurchmesser

*

The primary conductors may only be bent from the

specified minimum distance. The minimum

bending radius specified by the manufacturers

must be observed.

* Distance to 90° angle = 2 x external diameter

Die Leitungen/Leiter sind in der Mitte des

Messstromwandlers zu zentrieren. Der

Kabeldurchmesser darf maximal die Hälfte des

Wandlerdurchmessers betragen.

The cables must be aligned with the centre of the

measuring current transformer. The cable diame-

ter may not exceed half the current transformer

diameter.

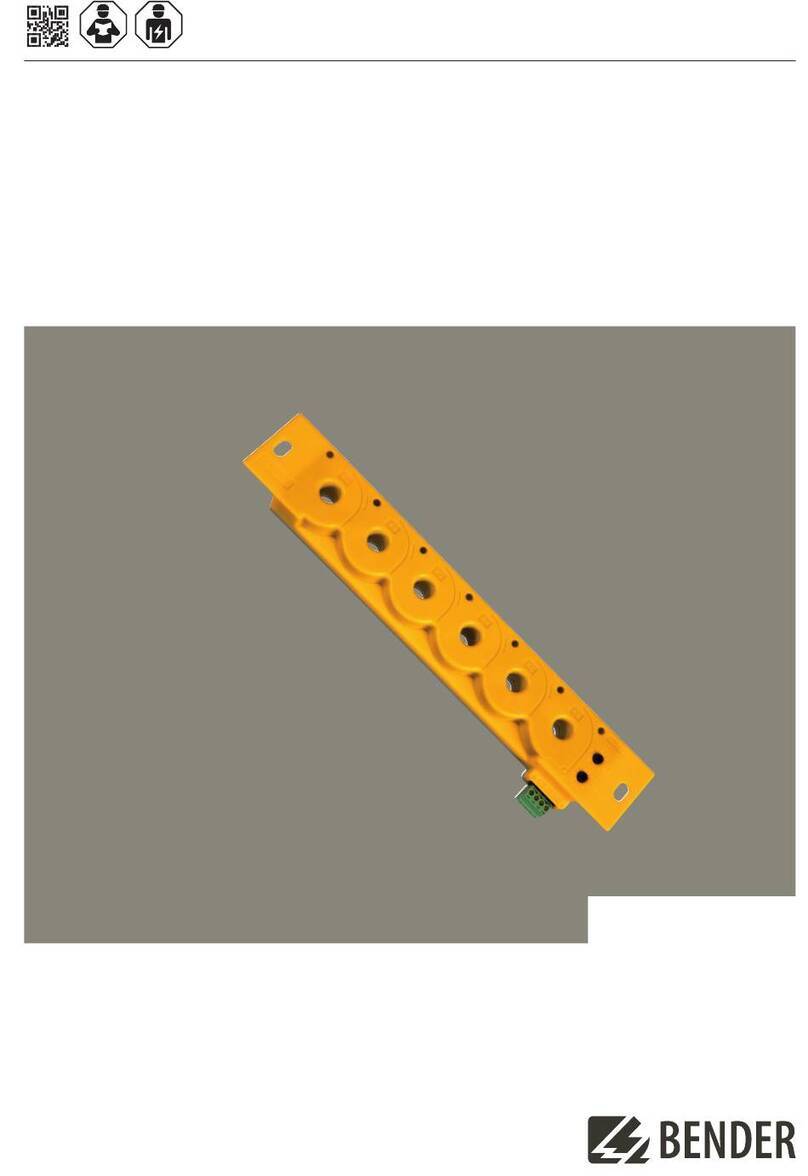

LINETRAXX® CTBS25

CTBS25_D00388_01_M_DEEN/01.2020 3