Bennett Marine SLT6 Operating instructions

This manual suits for next models

1

Table of contents

Other Bennett Marine Marine Equipment manuals

Bennett Marine

Bennett Marine BOLT129 Operation manual

Bennett Marine

Bennett Marine AutoTrimPro Operation manual

Bennett Marine

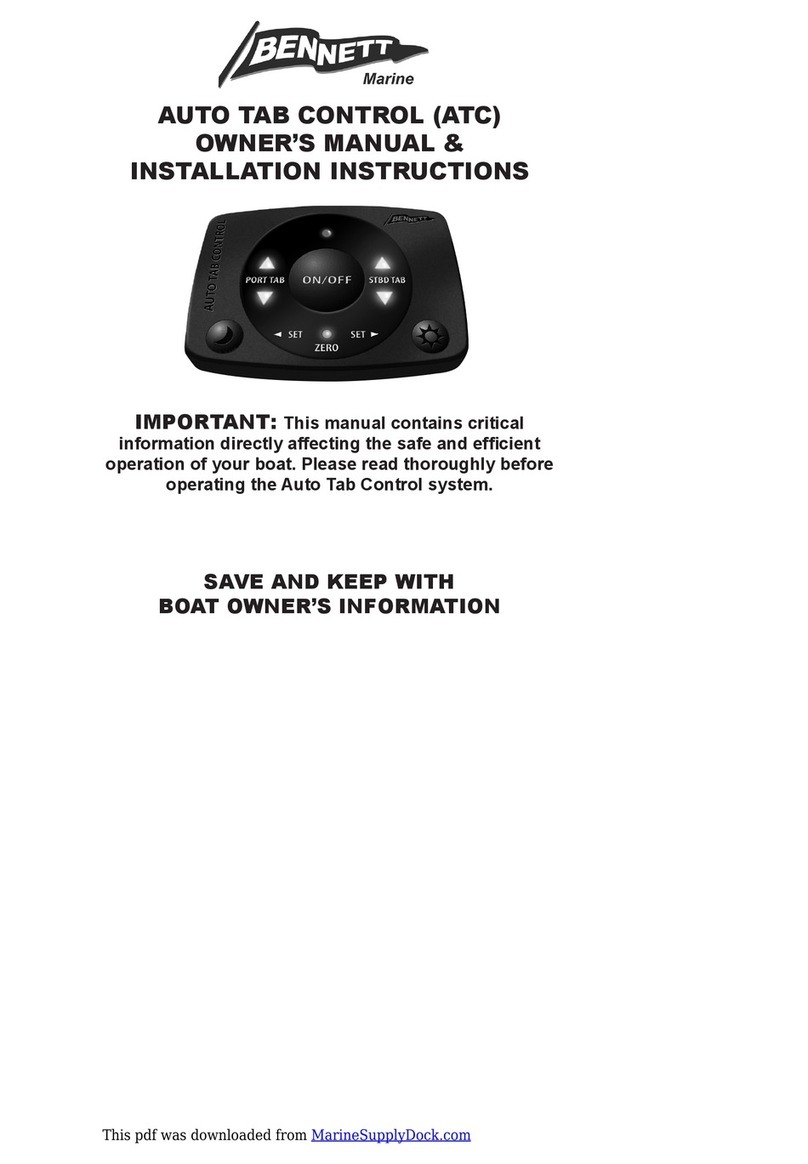

Bennett Marine AUTO TAB CONTROL Original instructions

Bennett Marine

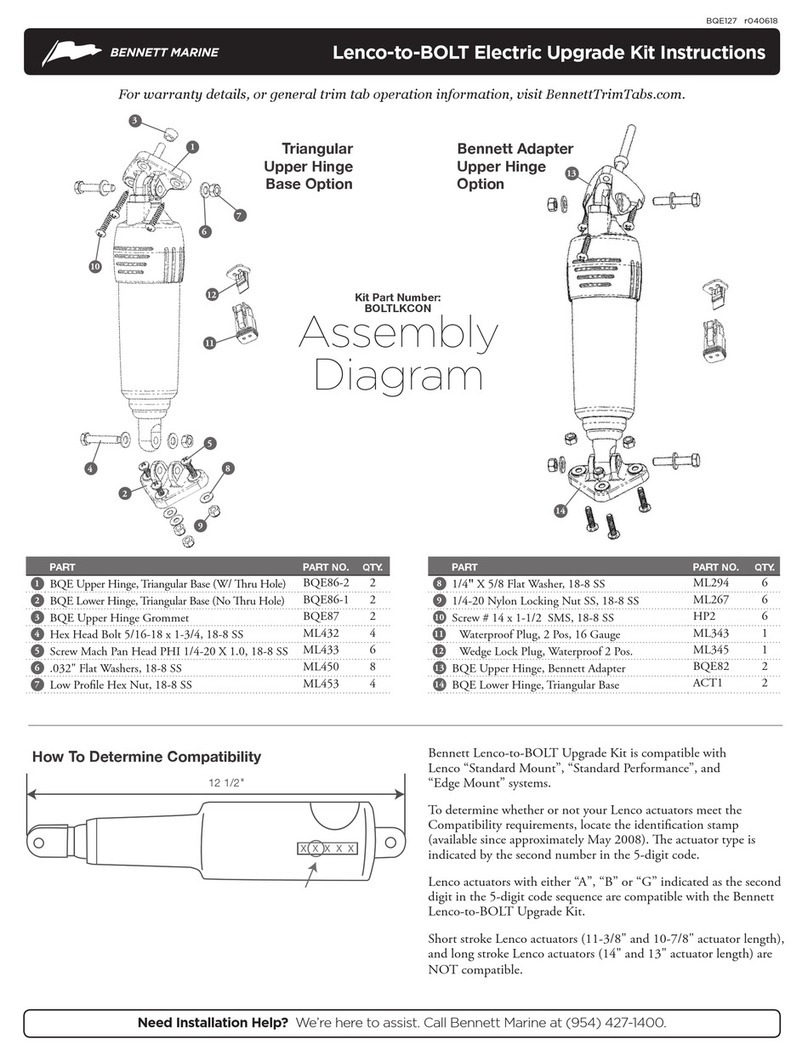

Bennett Marine Lenco-to-BOLT User manual

Bennett Marine

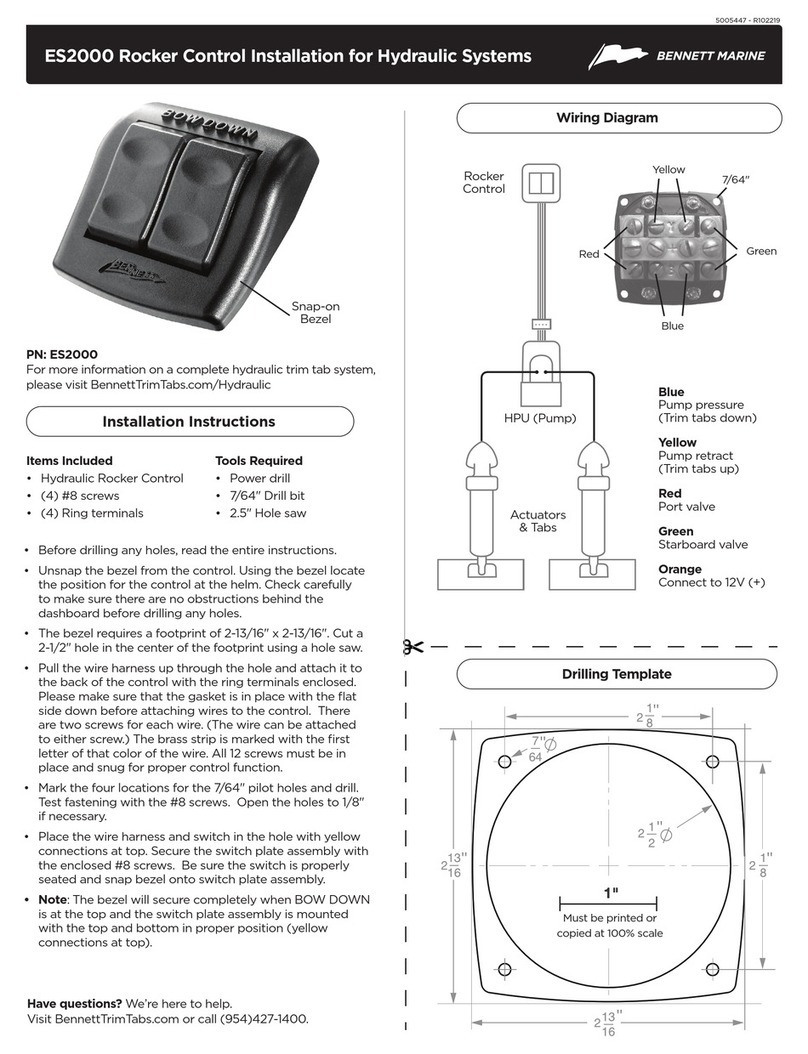

Bennett Marine ES2000 User manual

Bennett Marine

Bennett Marine BOLT Instruction Manual

Bennett Marine

Bennett Marine BOLT User manual

Popular Marine Equipment manuals by other brands

Sailmon

Sailmon MAX quick start guide

Eaton

Eaton X 10 DC Quick install guide

Aritech

Aritech DB2368IAS Series installation instructions

Regal-Beloit

Regal-Beloit Velvet Drive LIBERTY Series owner's manual

Boss Audio Systems

Boss Audio Systems MR637U Manual de usuario

Raymarine

Raymarine C-Series operating guide