BENSHAW EMX4e User manual

Other manuals for EMX4e

3

This manual suits for next models

1

Table of contents

Other BENSHAW Controllers manuals

BENSHAW

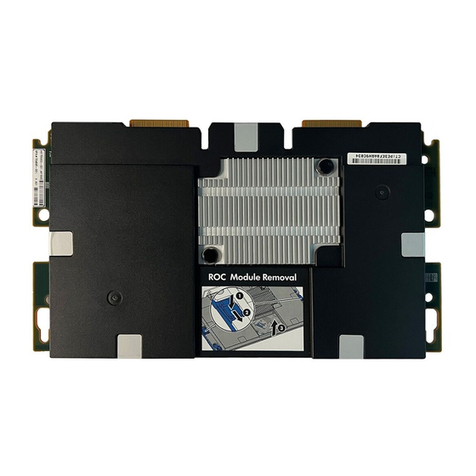

BENSHAW EMX4e User manual

BENSHAW

BENSHAW RediStart MX2 SEP User manual

BENSHAW

BENSHAW RediStart MX3 Series User manual

BENSHAW

BENSHAW EMX4e User manual

BENSHAW

BENSHAW POWERPRO PPFP Series User manual

BENSHAW

BENSHAW RediStart RB2 User manual

BENSHAW

BENSHAW EMX4e User manual

BENSHAW

BENSHAW RediStart EXEXMVRMX3 Series User manual

BENSHAW

BENSHAW EMX4e-0024B User manual

BENSHAW

BENSHAW RediStart MX2 SEP User manual

Popular Controllers manuals by other brands

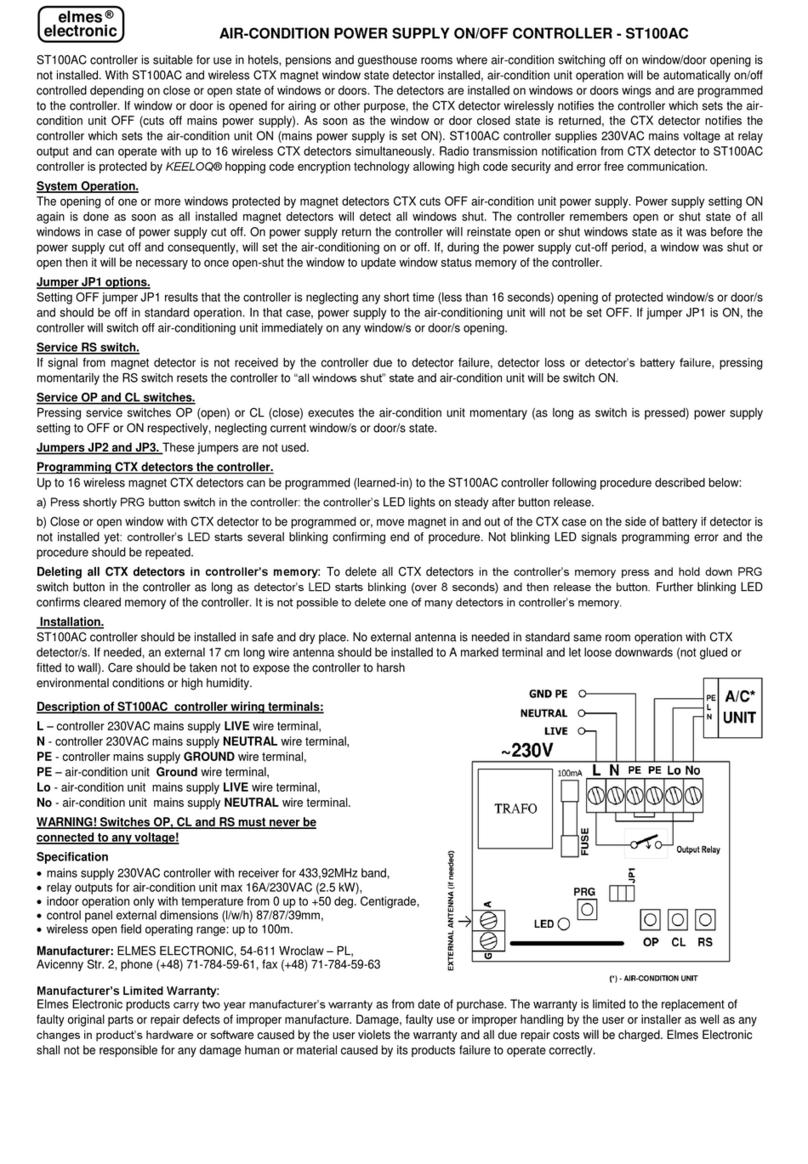

Elmes Electronic

Elmes Electronic ST100AC quick start guide

Linear

Linear ANALOG DEVICES DC2448A-D Demo Manual

Honeywell

Honeywell Temaline TS2 installation manual

Heatcraft

Heatcraft H-IM-QRC Installation and operation manual

brennenstuhl

brennenstuhl RC 2044 operating instructions

American Dynamics

American Dynamics AD1202 Installation and operating instructions

Festo

Festo CMXR-C1 Assembly and installation

Pilz

Pilz PNOZ mc1p operating manual

DoorBird

DoorBird A1081 Series installation manual

Siemens

Siemens 3RT2.1.-1 Original operating instructions

nord

nord NORDAC SK 1000E-101-340-A Hardware description

Honeywell

Honeywell HON R100NG Series User and maintenance manual