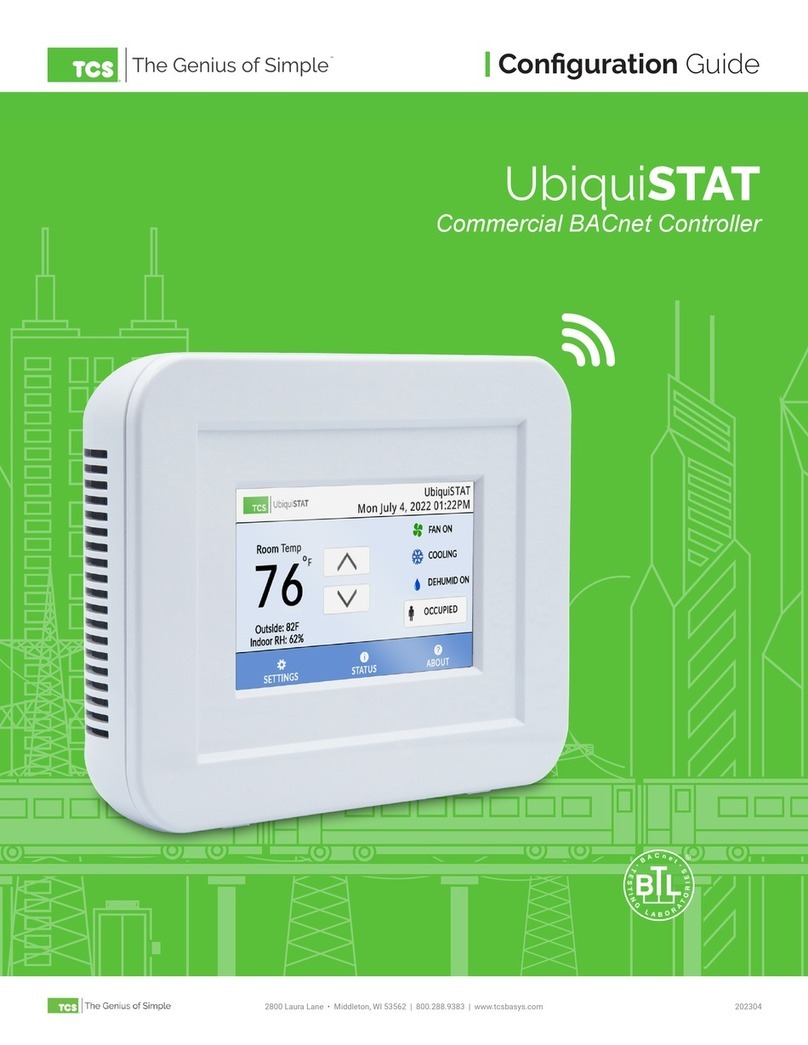

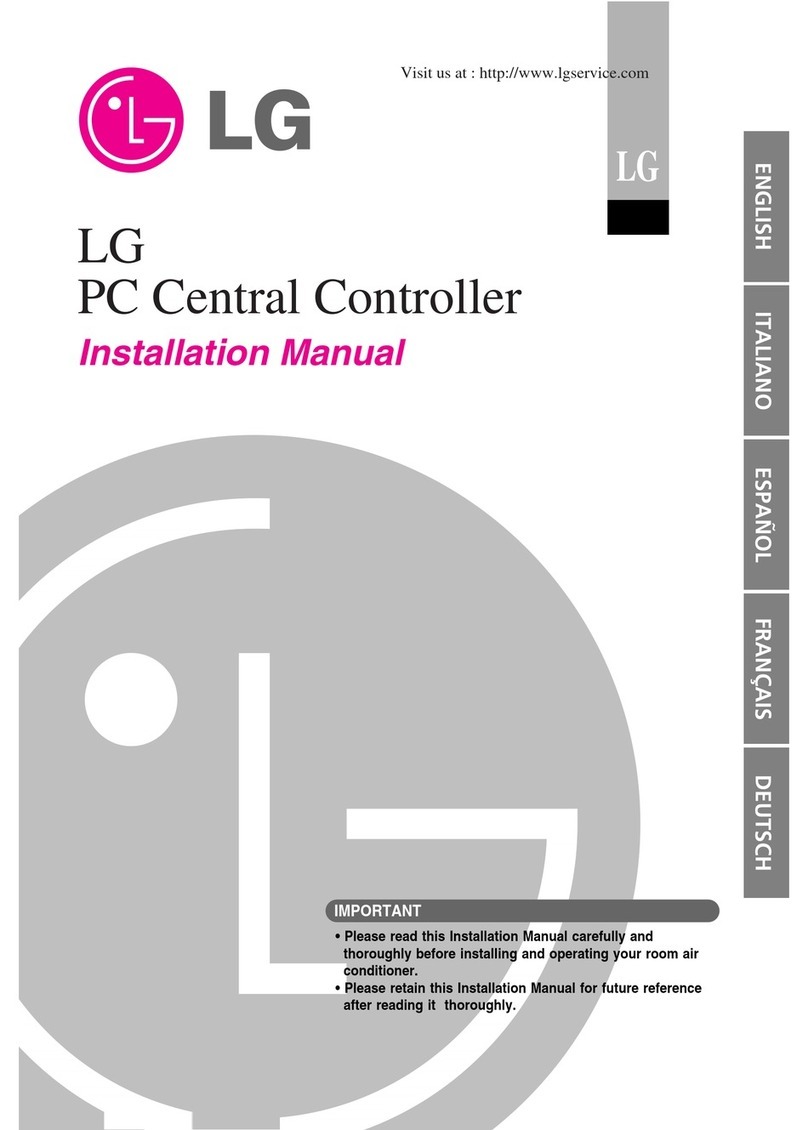

bentrup TC 505 User manual

21

54 6

879

30

start

stop

event 1

event 2

hold

shift select

t2

t1

t0

prog

memo

1050°C1180°C1250°C

150°C800°C900°C

rmp3

rmp1 rmp2

tmp2

tmp1

°C/h

h.min

°C

°F/h

°F

Z3

Z 1

Z2

THERMOCOMPUTER

TC 505

Technical Manual

Programme Controller

TC 505 / TC507

> V1.30 (flat case)

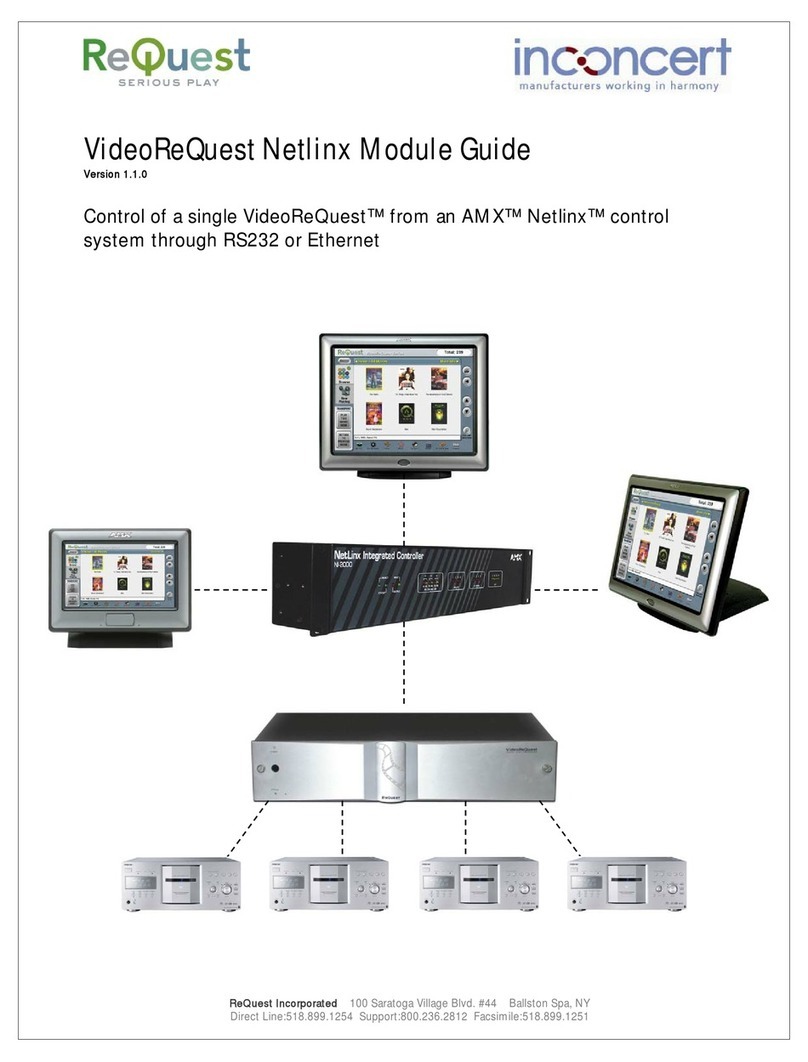

21

54 6

87 9

30

start

stop

o

event 1

event 2

shift select

prog

memo

dwell

time

ski p! hold!

endp.hold

°C /h

h. min

°C

°F/h

°F

k

prog#

seg# value

rmp

tmp

Z3

Z1

Z2

THERMOCOMPUTER

TC 50 7

2

1. General Informat on

In most applications the bentrup TC500 series controller (TC505 and TC507) can adapted by the

controller configuration as described in the operating instructions Appendix C (simple

configuration mode). However, some applications require controller features which can not be

accessed by the simple configuration mode (Examples: Using motorized valvues, adapting error

conditions etc.).

2. Extended Conf gurat on Mode

In the Extended Configuration Mode you can access the entire controller structure and adapt

your bentrup TC500 series controller to virtually all applications. You change parameters of

every control loop, combine outputs logically, assign inputs to any outputs etc. More than 2000

parameters leave you enough options for even most strange applications.

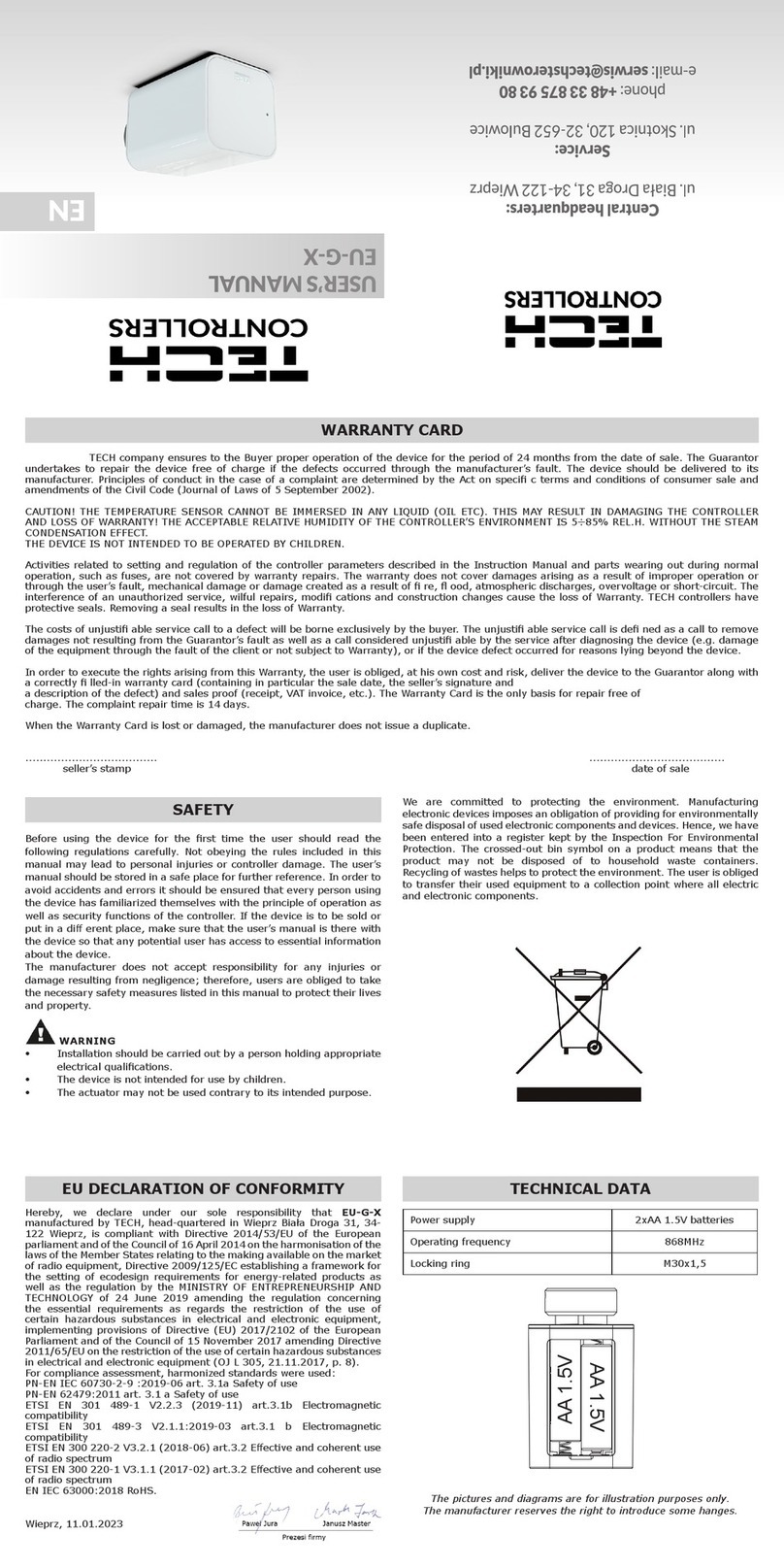

To change the controller to Extended Configuration Mode an internal jumper needs to be set.

pen the controller and located the jumper bridge. Set the jumper as shown

After changing to the Extended Configuration Mode all parameters are set corresponding to the

simple configuration mode. In other words, setting the jumper does not change any operation

mode by itself. However, when you enter the configuration mode the parameter display looks

different as described in the following chapter.

XCFG

Jumper OPEN

(simple configuration)

Jumper CLOSED

(extended configuration)

POSITION OF JUMPER MIGHT

VARY DEPENDING ON MODEL

3. Chang ng Parameters n the Extended Conf gurat on Mode

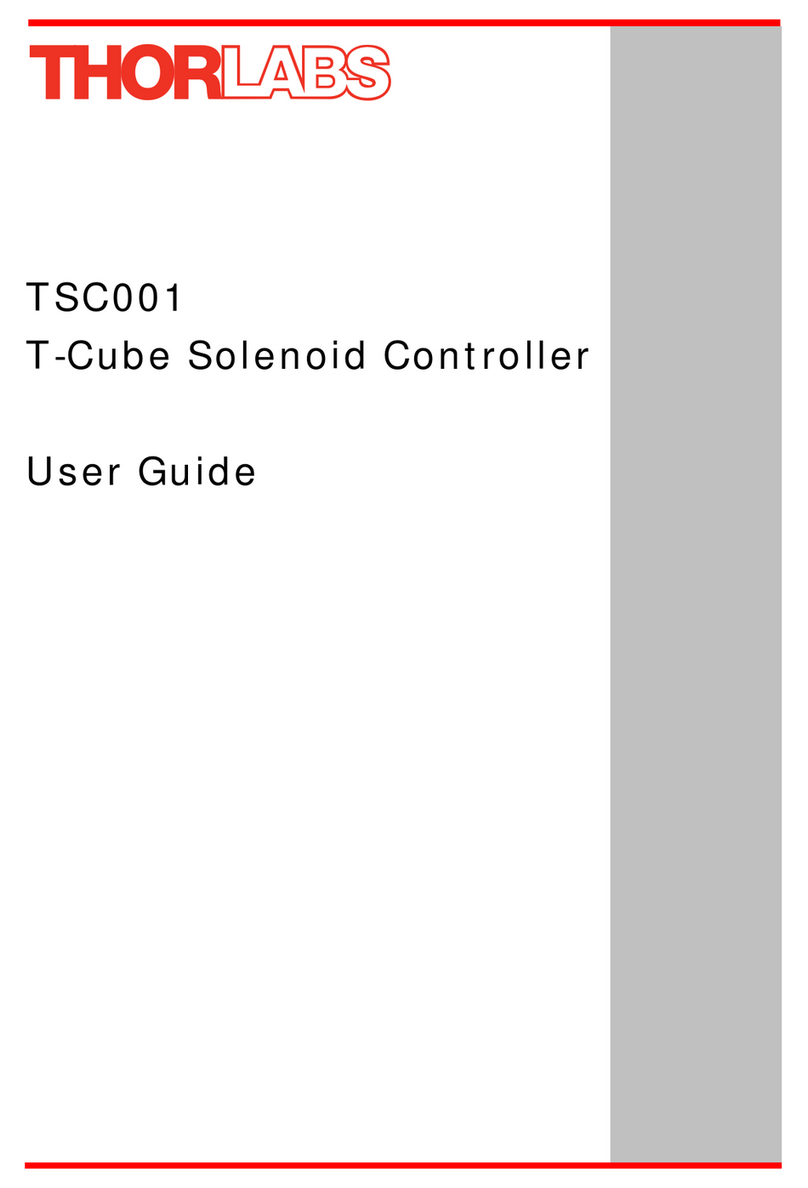

Enter the configuration mode as usually (pess and hold key „select“ until display changes). The

controllers display appears as shown:

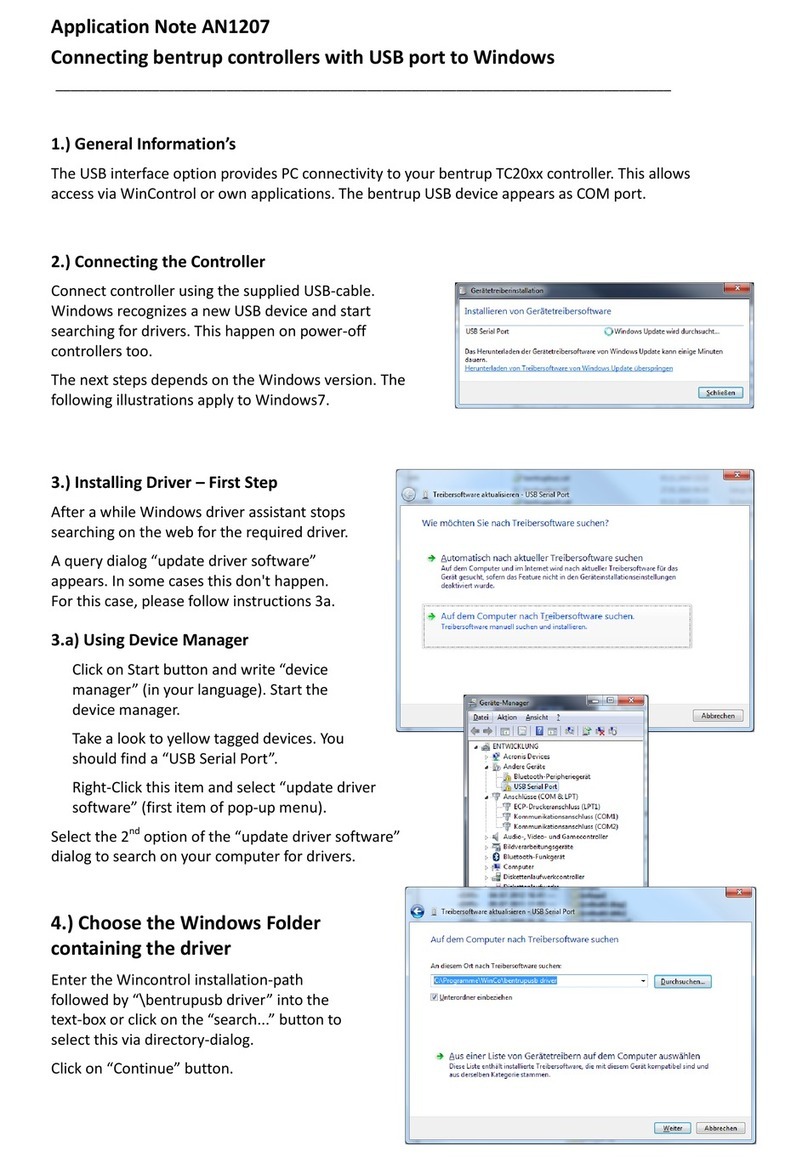

TC505 TC507

1 table number 5 keys to select row

2 column number 6 keys to select column / table

3 row number 7 keys to directly select table

4 parameter value 8 keys to change value

The configuration parameters of the TC500 controllers are organized as 12 tables. Every table

specifies one kind of parameter (e.g. table 0=real time clock, table 1=misc. adjustments, ..).

Each row of the table holds one parameter; multiple columns specify settings for repeated

devices (e.g. one column for each control output).

Please find as an example the digital output configuration table (control outputs):

rmp1 rmp2 t2rmp3

tmp1

tmp2

+

-

t1

t0

°C/h

h.min

°C

°F/h

°F

Z3

Z 1

Z2

1 2 3

4

876

5

tmp

dwell

rmp

time

°C/h

h.min

°C

°F/h

°F

prog#

seg# value

Z3

Z 1

Z2

-

+

1 2 3

4

8

5

6

3

4

D ......................digital output (e.g. switching output)

DI........................digital input (e.g. status input)

A ......................analog output (e.g. 0-10V output)

AI........................analog input (e.g. measure input)

The number following this designator specifies the input/output. Examples:

D 0.0................1st switching output of the controller

D 0.1................2nd switching output of the controller

AI 0.0..................1st analog input (e.g. thermocouple) of the controller

Use the keys as specified before to navigate through the parameters and modify as requested.

Since also minor changes of the parameters might cause major changes in controller operation

you need to familiarize yourself entirely with the configuration.

To save the changes permanently press and hold the key „select“ and keep it pressed until the

display shows „Sav. kY“. If you release the key too early (e.g. during „Sav.CfG“) all changes

will be lost! Note: If you get mixed up with the parameter changes at anytime simply turn off

and turn back on the controller to return to the previous parameter settings.

4. Deta led Explanat on of all Parameters

All paramters are explained in detail. See file „TC500.html“ (german) or TC500e.html (english)

supplied as a seperate file.

5. Chang ng Parameters by a PC

If your TC500 controller is fitted with a RS232 or RS485 interface you can use the free bentrup

software WinConfig to do all parameter changes very easy. WinConfig makes parameter setting

simple as well you can save configurations on disk and reload etc.

The RS232 or RS485 interface can be also added to exisiting TC500 controllers at very

reasonable costs. The configuration table shown earlier in this manual is a screenshot from

WinConfig.

6. Return ng to S mple Conf gurat on

Simply remove the jumper to return to Simple Configuration Mode. This configuration mode has

priority ie. the TC500 controller will disregard all enhanced configuration mode settings.

7. Chang ng type of Thermocouple S/R to J/K and v ce versa

Usually type of thermocouple should not be changed from S/R to J/K since different

compensating cable is needed. However, if this is considered this change is done by adjusting

the other jumper (marked as „T/C J/K“, see chapter 2.). Note: This only applies if the controller

operates in simple configuration mode. Keep in mind that mismatch of thermocouple and

controller setting causes severe damage to the kiln and goods. 5

6

bentrup TC505/507 Configuration Table Version 1.12

Table 0: clock / calender

The controller uses its real time clock / calender for different purposes. It allows the automatic commencing of

programmes at predefined times as well the real time clock / calender is used to time stamp logged data and

events. When configuring the controller using bentrup WinConfig / WinControl the controller is automatically

updated with the PCs time / date information, Therefore manually changeing time / date is disabled

.

00: time (hours)

(value range 00 to 23)

current time (hours) of the real time clock

01: time (minutes)

(value range 00 to 59)

current time (minutes) of the real time clock

02: date (weekday)

(options MON, TUE, WED, THU, FRI, SAT, SUN)

current date (weekday) of the real time calendar

03: date (day)

(value range 01 to 31)

current date (day) of the real time calendar

04: date (month)

(options JAN, FEB, MAR, APR, MAY, JUN, JUL, AUG, SEP, OCT, NOV, DEC)

current date (month) of the real time calendar

05: date (year)

(value range 00 to 99)

current date (year) of the real time calendar

06: cfg.lock level

(value range 0 to 5)

reserved for future used

.

.

Table 1: misc. adjustments

The following miscalleneous adjustments determine general operation parameters of the controller

.

00: max. segments

(value range 5 to 98)

maximum number of segments per programme. Entering a smaller number increases the number of

programmes you can save in your controller. In most applications a maximum of 20 segments is suitable. Note:

After changing this value all programmes must be reentered because of the required reorganisation of the

controllers memory

01: ramp mode(s)

(options TIME, GRAD, BOTH)

Specifies how to define ramps:

TIME: Ramps entered as segment time

GRAD: Ramps entered as gradient (e.g. 200°C/h)

BOTH: Ramps can be entered as segment time as well as gradient

02: prg.end Temp

(value range 20 to 1800)

Defines the temperature the final ramp of the programme is finished. Parameter applies not to TC507

03: manual enable

(options OFF, ON)

7

The manual mode allows the user to individually operate the control outputs (digital outputs and analog

outputs) manually. This feature is very helpful for kiln commissioning. Caution: For safety reasons only enable

this MODE if the operator is familiar with it !

04: auto P. starts

(options OFF, ON)

This feature allows automatic commencing programmes by the weekly switching clock. Depending on

configuration up to 99 real time clock / weekdays controlled jobs can be entered. Enable this feature only if

necessary to avoid unintentional programme commencing

05: lock programs

(options OFF, ON)

Allows locking of all programmes (temperature curves) to avoid any unauthorized changes

06: communicat. ID

(value range OFF to 62)

Sets the communication ID of the controller. Affects external communication only. Make sure that this ID fits

the setting in the communcation software (e.g. bentrup WinControl). Each ID must be unique on the

communication network

07: RS485 baudrate

(value range 9600 to 38400)

Baud rate of the communication

08: fctn.on pow.up

(value range 0 to 3)

Verhalten nach dem Einschalten: 0=Regler aus (IDLE), 1/2=automatischer Programmstart wenn alle

Bedingungen erfüllt sind (1=Zeit-Limit in Sekunden / 2=Zeit-Limit in Minuten). 3=automatischer Programmstart

09: ..only if Dxx

(value range OFF to 5)

Programme is continued only if the selected output was ON before power breakdown. When selecting and

output controlled by a programme EVENT, this feature can be used to enable programme continuation after a

power breakdown for each segment

10: only if t<time

(value range -1 to 240)

Programme is continued only if the duration of the power failure was less than this parameter. Depending on

the selection of "fctn. on pow. up" this time limit is seconds or minutes

11: dT input sel

(value range OFF, IN00 to IN03)

Selects the process value check for drop in temperature during a power breakdown

12: ..only if dT<x

(value range -9999 to 9999)

Programme is continued only if the selected process value did not drop more than a the given value during

power breakdown

.

8

.

Table 2: analog input

Specifies the analog input signals for the controller. Analog inputs are used to connect sensors like

thermocouples, resistors, voltage/current signals to the controller. You can exactly define signal type (voltage,

resistance, current) as well as signal range, signal conversion and correction, unit etc. The most common signal

types are predefined. Each column of the table defines one process value which are named IN00, IN01 etc. The

maximum number of analog input depends on the hardware.

.

00: input mode

(options END, T/C, LIN, ATMS, RES)

type of the analog input signal. Choose the appropriate kind of signal conversion from the given options:

T/C: Thermocouple input type. Selection of thermocouple and compensation mode see parameter below

LIN: Linear input type for generic use. This mode is used to convert any kind of linear input signal (as defined in

the corresponding parameters) into its process parameter. An example for a typical application is to convert a

4-20mA signal from a pressure transducer into 0 to 100 Pa process parameter

ATMS: Atmosphere signal conversion. Use this selection to convert the typical signal of a circonoxyde probe

into the kiln atmosphere reading. The controller uses the equation of Nerntzsch to convert the probe signal

into % of oxygen. The probe temperature required for oxygen calculation is specified in the corresponding

parameters as well as the kind of gas required for the carbonmonoxyde calculation. Note below on

temperatures below 650°C no oxygen calculation is done (no reliable probe signal)

RES: Resistance temperature sensor conversion. Converts the resistance characteristic of most commonly used

resistance sensors (like Pt100) into temperature reading

01: signal source

(value range AI0.0 to AI1.0)

Specifies a physical input (AI..) of the controller. The process parameter is created from the signal on this

physical input. To create two different process parameters from one physical input make sure that both signal

types and ranges equals

02: average cycles

(value range 1 to 11)

Specifies the low pass signal filter. This options is used to smoothen the input signal. Can be used to eliminate

signal interference as well as to improove signal quality. Setting this option to "1" disables the filter. A higher

setting causes higher smoothening (low pass frequency is 1/n Hz). A setting of 4 suits most applications.

03: units

(options °C, °F, °K, dg, mV, mA, O2, CO, %, ev, mb, m³, m³h, kh, kwh, Pa, AT)

Specifies the unit of the process value

04: trim +/- %

(value range -10.0 to 10.0)

Allows full scale input signal correction. In certain applications it is required to compensate for any deviations

of the installation. Example: Setting this parameter to -5.0% will cause the process value to be trimmed to 95°C

instead of 100°C. Note: This parameter should be used with care since on most applications deviations errors

should to be compensated by eliminating the real cause of the deviation rather then compensating on the

controller

05: offset +/- val

(value range -10.0 to 10.0)

Allows zero offset signal correction. Adjust this parameter if you need to adjust the input offset value. Note:

This parameter should be used with care since on most applications deviations errors should to be

compensated by eliminating the real cause of the deviation rather then compensating on the controller

06: min value

(value range -9999 to 9999)

Minimum value of the process value. Specifies the lower value limit of the process parameter. Any lower value

is respected as underrun (causing an error)

07: max value

(value range -9999 to 9999)

Maximum value of the process value. Specifies the upper value limit of the process parameter. Any higher

9

value is respected as overrun (causing an error)

following parameters apply on selection T/C only:

08: thermocouple

(options S, R, K, J, B)

Select the IEC code of the thermocouple used

09: external CJC

(value range OFF, IN00 to IN03)

Could junction compensation temperature. Set to "OFF" for internal compensation (recommended). Make sure

that the proper compensating wire is used

following parameters apply on selection LIN only:

18: signal type

(options OFF, 0-20mV, 0-50mV, 0-5V, 0-10V, 0-20mA, 4-20mA, -500R2, -

500R3)

Type of input signal. Set this parameter to fit the signal of the device connected to the physical input. Note:

Adapt the jumper settings of the physical input accordingly (done automatically on some devices)

19: val.@zeropoint

(value range -2000.0 to 2000.0)

Process value at lower reference of input value. Example: A pressure transducer supplying 4 to 20mA at -250 to

+250 Pa. Set this parameter to "-250" since this is the process value at the lower reference of 4mA

20: val.@fullscale

(value range -2000.0 to 2000.0)

Process value at upper reference of input value. Example: A pressure transducer supplying 4 to 20mA at -250 to

+250 Pa. Set this parameter to "250" since this is the process value at the upper reference of 20mA

following parameters apply on selection ATMS only:

28: temp. source

(value range IN00 to IN03)

Selects the process value representing the temperature of the atmosphere sensor. The temperature is required

for the calculation of the oxygen

29: min. CO temp

(value range 600 to 1800)

Minimum temperature in centigrade Kelvin required for carbonmonoxyde calculation. A minimum

temperature of 900°C (1273°K) is recommended for reliable calculation

30: press.source

(value range OFF, IN00 to IN03)

Selects the process value representing the over pressure of the reference air. This is used to supervise the

referece air for the oxygen probe. Set to "OFF" if not used

31: min. pressure

(value range 0 to 250)

Minimum pressure limit of reference air. Oxygen process value is set to "INVALID" if reference over pressure

falls below this limit

32: type of gas

(options NATGAS, PROPAN, BUTHAN)

Kind of the gas used. This selection is only used for calculating carbonmonoxyde

following parameters apply on selection RES only:

38: resist.type

(options PT100)

Kind of the resistance sensor used

39: signal type

(options -500R2, -500R3)

Type of input signal. Set this parameter to fit the signal of the device connected to the physical input. Note:

Adapt the jumper settings of the physical input accordingly (done automatically on some devices)

.

10

.

Table 3: digital input

Digital inputs can be used for different purposes. First they are used to create a process value depending on a

frequency or number of pulses. Second they are used to control programme execution in different ways. Third,

they are used by the optional PLC. Note: PLC provides you with total flexibility of the controller. If you are using

the PLC of the controller you must not do any adjustments in this digital input section since all features are

programmed by PLC networks

.

00: input mode

(options END, CNT)

Sets the operation mode of the digital inputs. Set to END when using the PLC

CNT: Pulse signals supplied to this input are converted into a process value. Obsolete feature

01: signal source

(value range DI0.0 to DI1.0)

Physical input used for the function

02: units

(options °C, °F, °K, dg, mV, mA, O2, CO, %, ev, mb, m³, m³h, kh, kwh, Pa, AT)

no explanation available

03: min value

(value range -9999 to 9999)

no explanation available

04: max value

(value range -9999 to 9999)

no explanation available

following parameters apply on selection CNT only:

05: count unit x /

(value range -2000.0 to 2000.0)

no explanation available

06: count unit / x

(value range -2000.0 to 2000.0)

no explanation available

.

.

Table 4: analog output

Analog outputs are used to drive of analog devices like steady power control units (thyristor controls), voltage

controlled frequency converters or any kind of recorders. The analog output can be any kind of voltage (0 to

10V etc.) or current (0-20mA etc.) signal. The controller can be configured to drive an analog output by any

kind of process value (control channel output, process value output etc.)

.

00: output mode

(options END, PRZ, ANA)

Sets the operation mode of the analog output:

PRZ: Sets the analog output to be used to send the channel output value for controlling the heating resp.

cooling device. Example: Use this mode to provide a 4-20mA steady output signal (according to 0 to 100%

heating) for driving a thyristor

ANA: Sets the analog output to send any internal process value as analog signal within adjustable boundaries.

Example: Use this mode to create a 0 to 10V output signal according to 0°C to 1000°C programme setpoint

01: output type

(options OFF, 0-20mV, 0-50mV, 0-5V, 0-10V, 0-20mA, 4-20mA)

Signal type. Note that changing from voltage to current mode (and vice versa) requires adapting the jumper

11

settings resp. reconnecting the outlets to a different position

02: destination

(value range AO0.0 to AO0.2)

Selects the physical output of the signal

following parameters apply on selection PRZ only:

03: channel source

(value range CH00 to CH02)

Selects the control channel (loop) used to drive the output. The options MX../A resp. MX../G are the outputs of

the air / gas mixer (for combustion units)

04: output charact

(value range 0 to 4)

Specifies the operation range of the output. Used to limit an output assigned to a heating / cooling loop (range

+100% to -100%) to the physical range of operation. In an typical application one output (eg. controlling the

heating elements) is set to "0 to +100%" and a 2nd output (eg. controlling a fan) is set to "0 to -100%" (both

outputs assigned to the same control channel). The available settings are 0=0% to +100% / 1=+100% to 0% /

2=0% to -100% / 3=-100% to 0% / 4=-100% to +100% / 5=+100% to -100%

05: outp.% on IDLE

(value range 0 to 100)

Whenever the controller is IDLE the output is fixed to this value

06: outp. % on ERR

(value range 0 to 100)

Whenever the entire controller is in ERROR status the output is fixed to this value. Note that this only applies

on system errors and not an operation error on a single channel

07: min. output %

(value range 0 to 100)

Lower output signal limit. The output will never drop below this limit. Can be used for instance to obtain

permanent minimum heating. Care should be taken since high settings might interfere with the control loop

08: max. output %

(value range 0 to 100)

Upper output signal limit. The output will never exceed this limit. Can be used for instance to limit the

maximum heating of a kiln. Note that limiting can cause problems if the applications lacks of heating power

(gradient check errors etc.)

following parameters apply on selection ANA only:

13: outp. param.

(value range SP00 to CH19)

Selects a process value sent to the analog output. The output is driven according to to the process value in the

range given by the following parameters "lower base value" and "upper base value". Example: Assuming a

signal type 0 to 10V / lower base value 0°C / upper base value 1000°C the output provides 7,5 V on a process

value of 750°C

14: lower base val

(value range -9999 to 9999)

Sets the lower base value for a process value output. For details refer to the example given at "outp. param."

15: upper base val

(value range -9999 to 9999)

Sets the upper base value for a process value output. For details refer to the example given at "outp. param."

12

.

Table 5: digital output

Digital outputs are used to switch any kind of ON/OFF devices as well as motorized valves (using 2 digital

outputs in sequence). Depending on controller hardware the output is either a switching relay output (8A /

250V) or a logic output (OFF=0V / ON=12V). The following parameters select the kind of operation (control

outputs, alarms, events etc.). Digital outputs used by the PLC must not be assigned in this section

.

00: output mode

(options END, PRZ, MOT, LIM, PRC, EVE, TAB, CMB, ---)

Selects an operation mode of the digital outputs:

PRZ: Used to provide the output value of a control channel (loop) to an ON/OFF device. The most common

application is to control a contactor used for heating

MOT: Used to provide the output value of a control channel (loop) to a servomotor device. A typical application

when controlling a motorized butterfly valve on a gas kiln. A servomotor is controlled by 2 digital outputs

(OPEN and CLOSE). The physical output CLOSE is automatically assigned to the output following OPEN

LIM: Output works as limit switch (commonly called ALARMs). Any kind of comparison of process of constant

values can be done

PRC: Indication of selectable process conditions. Can be used to activate an output on programme end, process

errors, process holds etc.

EVE: Used to configure the output as programme event. Can be programmed to ON or OFF for each segment.

During programme run the output is set accordingly

TAB: Used to control a group of outputs according to the bit pattern provided in the corresponding column of

the programme table. Typically used in combination with a PLC

CMB: Output is driven according to the result of the network defined by the following parameters. Used to

create simple logic networks, ie. output do0.2 is only if do1.0 and do1.1 is active. For more complex networks

ask for the optional, integrated PLC

01: destination

(value range OFF, DO0.0 to DO0.4)

Selects the physical output of the signal

following parameters apply on selection PRZ only:

02: channel source

(value range CH00 to CH02)

Selects the control channel (loop) used to drive the output

03: output charact

(value range 0 to 5)

Specifies the operation range of the output. Used to limit an output assigned to a heating / cooling loop (range

+100% to -100%) to the physical range of operation. In an typical application one output (eg. controlling the

heating elements) is set to "0 to +100%" and a 2nd output (eg. controlling a fan) is set to "0 to -100%" (both

outputs assigned to the same control channel). The available settings are 0=0% to +100% / 1=+100% to 0% /

2=0% to -100% / 3=-100% to 0% / 4=-100% to +100% / 5=+100% to -100%

04: outp.% on IDLE

(value range 0 to 100)

Whenever the controller is IDLE the output is fixed to this value

05: outp. % on ERR

(value range 0 to 100)

Whenever the entire controller is in ERROR status the output is fixed to this value. Note that this only applies

on system errors and not an operation error on a single channel

06: min. output %

(value range 0 to 100)

Lower output signal limit. The output will never drop below this limit. Can be used for instance to obtain

permanent minimum heating. Care should be taken since high settings might interfere with the control loop

07: max. output %

(value range 0 to 100)

13

Upper output signal limit. The output will never exceed this limit. Can be used for instance to limit the

maximum heating of a kiln. Note that limiting can cause problems if the applications lacks of heating power

(gradient check errors etc.)

08: cyclus time

(value range 0 to 100)

Cyclus time (in seconds) of the digital output. The output value is converted into an ON and OFF period

accordingly (T on + T off = T cyclus). Decreasing the cyclus time improves accuracy but might decrease lifetime

of the heating device. A typical value for contactors on kilns is 30

following parameters apply on selection MOT only:

12: channel source

(value range CH00 to CH02)

Selects the control channel (loop) used to drive the output

13: output char.

(value range 0 to 5)

Specifies the operation range of the output. Used to limit an output assigned to a heating / cooling loop (range

+100% to -100%) to the physical range of operation. In an typical application one output (eg. controlling the

heating elements) is set to "0 to +100%" and a 2nd output (eg. controlling a fan) is set to "0 to -100%" (both

outputs assigned to the same control channel). The available settings are 0=0% to +100% / 1=+100% to 0% /

2=0% to -100% / 3=-100% to 0% / 4=-100% to +100% / 5=+100% to -100%

14: outp.% on IDLE

(value range 0 to 100)

Whenever the controller is IDLE the output is fixed to this value

15: outp.% on ERR

(value range 0 to 100)

Whenever the entire controller is in ERROR status the output is fixed to this value. Note that this only applies

on system errors and not an operation error on a single channel

16: travel time

(value range 0 to 250)

Enter the time (in seconds) for the servomotor to move over the entire actual operation range (fully close to

fully open)

17: delay 1/10s

(value range 0 to 150)

Delay time of the servomotor on direction changes. This parameter (given as 100ms units) is used to

compensate for gearbox lags etc.

18: update time

(value range 0 to 250)

Rate in seconds the servomotor position is updated. Decreasing this rate causes more stress to the servomotor

19: hyst. %/steps

(value range 0 to 100)

Hysteresis for updating the servomotor position. Decreasing this rate causes more stress to the servomotor.

However, in most application a hysteresis of 1% is recommended

20: feedback input

(value range OFF, IN00 to IN03)

The position feedback option is used for best tracking of the actual servomotor position. Typically a position

potentiometer is connected to an analog input (configured as linear resistance input 0-100%). Enter the

process parameter number of this input here. Set to OFF is unused

21: steps (MOT808)

(value range -9999 to 9999)

no explanation available

following parameters apply on selection LIM only:

22: compare mode

(options 1>2+c, 1<2+c, dif<c, dif>c)

Selects the kind of equation of the formula given as limit 1 ? limit 2 + limit const. The "?" is replaced depending

on this parameter: 0 stands for ">=", 1 stands for "<=", 2 means "limit 1 - limit 2 less then limit const", 3 means

"limit 1 - limit 2" more than limit const. The digital output is ON when the equation is true. Example: To activate

the output whenever the actual temperature exceeds the setpoint more than 30°K (= overtemperature alarm)

14

set the parameters as follows: compare more = 0 / limit 1 = IN00 / limit 2 = SP00 / limit const = 30

23: limit 1

(value range OFF, SP00 to CH19)

Selects the process value used as "limit 1" in the formula. This can be a setpoint, an actual temperature, a

channel (loop) output or "OFF" to insert "0" in the formula. For detailed explanation including an example refer

to "compare mode"

24: limit 2

(value range OFF, SP00 to CH19)

Selects the process value used as "limit 2" in the formula. This can be a setpoint, an actual temperature, a

channel (loop) output or "OFF" to insert "0" in the formula. For detailed explanation including an example refer

to "compare mode"

25: limit const

(value range -9999 to 9999)

The constant value used as "limit const" in the formula. For detailed explanation including an example refer to

"compare mode"

26: output on IDLE

(value range 0 to 2)

Defines the state of the digital output when the controller is IDLE: 0 = same as during programme run / 1 = OFF

/ 2 = ON

27: output on ERR

(value range 0 to 2)

Defines the state of the digital output when the controller enters a system error: 0 = same as during

programme run / 1 = OFF / 2 = ON

following parameters apply on selection PRC only:

32: process mode

(value range 0 to 18)

Selects the process state the digital output is indicating: 0=programme run (also ON during segment 0 and at

the end of the firing) / 1=programme run (also ON during segment 0) / 2=programme run / 3=end of the firing /

4=any channel error / 5=programme HOLD / 6=OFF / 7=ON / 10/11/12=mixer in air

excess/stochiometric/cooling mode / 13=programme continues after power breakdown / 14=do0.6 and not

do0.7 / 15=do0.6 and do0.7 / 16=not do0.6 and do0.7 / 17=control channel off band / 18=programme

interrupted due to off band / 19=any monitored channel error / 20=final temperature matches in all monitored

channels / 21=any monitored channel in control range / 22=any monitored channel out of control range

following parameters apply on selection EVE only:

42: EVENT number

(value range 0 to 10)

Digital output works as programme EVENT number #. This number must fit the EVENT number specified in the

programme table

43: output on IDLE

(value range 0 to 1)

Defines the state of the digital output when the controller is IDLE: 0 = OFF / 1 = ON

44: output on ERR

(value range 0 to 1)

Defines the state of the digital output when the controller enters a system error: 0 = same as during

programme run / 1 = OFF / 2 = ON

following parameters apply on selection TAB only:

52: table dat.src

(value range TA00 to TA04)

Select the column number of the programme table the programme value is taken

.

15

.

Table 6: programme table

The programme table determines the parameters and the sequence to be entered for each programme

segment. The first programme parameter is always a time followed by a temperature. Depending on the

application the following programme segment parameters could be for instance offset temperatures (for

multizone kilns), programme events etc. The parameter sequence after the 1st temperature is variable;

however, keeping all programme EVENTs togather saves programme memory

.

00: value type

(options END, TIME, VAL-L, ---, VAL-S, EVENT, ATMS)

Select the kind of value in each column of the programme table:

TIME: The very first column of the programme table holds the segment time

VAL-L: Programme value in the range of -10000 to 10000. Typically used for any kind of absolute value (like kiln

temperature etc.)

---: selection not used

VAL-S: Programme value in the range of -127 to 128. Typically used for any kind of relative values (like offset

temperature for zones)

EVENT: EVENT value, ie. holds ON or OFF. When requiring multiple events defining them one after the other

saves programme memory

ATMS: Programme value to define an atmosphere

01: designator

(alphanumerical characters)

Used to give each programme table column an individual name (consisting of up to 3 alphanumeric letters)

following parameters apply on selection TIME only:

02: lower time lim

(value range -101 to 0)

Limits the value range entered as a time. Note that the values smaller than minus 2 enable the programme link

feature (-3 = allow linking to programme number 1, -4 = allow linking to programme number 2 etc.)

03: upper time lim

(value range 1 to 5999)

Upper limit when adjusting the time. The 1000 steps beyoind this limit stand for setting the gradient as

centigrade kelvin per period

following parameters apply on selection VAL-L only:

12: value unit

(options °C, °F, °K, dg, mV, mA, O2, CO, %, ev, mb, m³, m³h, kh, kwh, Pa, AT)

Specifies the unit of the programme table value

13: lower val. lim

(value range -9999 to 9999)

Lower limit of the programme table value. Used for instance to ensure the values entered by the user stay

within the operation limits of the kiln

14: upper val. lim

(value range -9999 to 9999)

Upper limit of the programme table value. Used for instance to ensure the values entered by the user stay

within the operation limits of the kiln

following parameters apply on selection --- only:

22: value unit

(options °C, °F, °K, dg, mV, mA, O2, CO, %, ev, mb, m³, m³h, kh, kwh, Pa, AT)

Specifies the unit of the programme table value

23: lower val. lim

(value range -9999 to 9999)

Lower limit of the programme table value. Used for instance to ensure the values entered by the user stay

within the operation limits of the kiln

16

24: upper val. lim

(value range -9999 to 9999)

Upper limit of the programme table value. Used for instance to ensure the values entered by the user stay

within the operation limits of the kiln

following parameters apply on selection VAL-S only:

32: value unit

(options °C, °F, °K, dg, mV, mA, O2, CO, %, ev, mb, m³, m³h, kh, kwh, Pa, AT)

Specifies the unit of the programme table value

33: lower val. lim

(value range -128 to 127)

Lower limit of the programme table value. Used for instance to ensure the values entered by the user stay

within the operation limits of the kiln

34: upper val. lim

(value range -128 to 127)

Upper limit of the programme table value. Used for instance to ensure the values entered by the user stay

within the operation limits of the kiln

following parameters apply on selection EVENT only:

42: EVENT number

(value range 0 to 2)

This unique number identifies the EVENT in the programme table for the digital output

following parameters apply on selection ATMS only:

52: atmosphere cde

(options AT)

Wählt die Einstellungsart des Atmosphären-Sollwertes aus. Wert nicht veränderbar

.

.

Table 7: process flow

The parameters of this section specify the reaction of the controller to any kind of unusual conditions that

might happen during a programme run. Examples for unusual conditions are broken temperature sensors, heat

up problems of the kiln, control channel errors etc. As well the conditions to enter the next segment during a

running programme can be adjusted as required

.

00: time in ramps

(options KEEP, UPDAT)

If the temperature of the pilot input (IN00) is higher than the start temperature of the ramp the time of the

ramp can be either kept or reduced accordingly

KEEP: Segment time is kept, setpoint begins as programmed

UPDAT: Segment time is reduced accordinly. Example: Segment 0 is 0°C, segment 1 is "in 2 hours to 500°C".

Assuming a kiln temperature of 250°C when starting the firing, the time is reduced to 1 hour (causing a setpoint

of 250°C)

01: monitor ch

(value range -CH02 to CH02 )

Only the channels specified are monitored for process problems. This setting allows to include only the

channel(s) which are important for the process. Either a single channel can be selected (e.g. on single zone

kilns) or a range of channels (e.g. ch00 to ch02 on a 3 zone kiln). A range is entered as minus channel (e.g. "-

ch02" stands for ch00 to ch02)

02: temp match %o

(value range 0.0 to 100.0)

An uncontrolled ramp (SKIP) the end of the segment is determined by match of actual temperature and final

segment temperature. Since the controller slows down temperature move at the end to avoid

over/undershoot it might take some time to finally reach the temperature althought it is not required by the

process. This parameter allows to specify a window to earlier complete the segment. Example: 2.0 ppm of

1320°C (max. channel temperature) = 2.64°C, SKIP segment ends at 997.36°C assuming a final ramp

17

temperature of 1000°C

03: num of matches

(value range 1 to 250)

An uncontrolled ramp (SKIP) is only completed if the temperature matched the specified number of cycles. The

check is done each 0.5 seconds. This is used to avoid leaving the segment if the temperature only overshoots

for a short time. Example: The setting of 6 lets the controller to complete the current segment if the

temperature matched for at least 3 seconds

04: end of SKP seg

(options DISR, WAIT.X, INFIN)

An uncontrolled ramp (SKIP) usually is only completed if the actual temperature reached the final ramp

temperature. The following options are considered:

DISR: Causes the controller to disregard the temperature, ie. to leave a SKIP segment immediately

WAIT.X: Causes the controller to wait for temperature match, but maximum for the specified time (see next

parameter). This option is strongly recommended on multi zone kilns, e.g. at a time of 10 minutes. Otherwise

the process might lock up itself. For instance in a cooling SKIP, the thermocouple of zone 2 has a little deviation

an therefore zone 2 is heated 4°C higher; if the heating affects zone 1 this zone will never cool down as

neccessary. The time begins to count if the first zone starts to control. If the time is elapsed the segment is

finished disregarding the temperature of the zones matches

INFIN: Causes the controller to wait for temperature match for infinite time

05: max wait (sec)

(value range 0 to 9999)

wait time in seconds for the feature specified previously

06: act.on CH unco

(options DISR, WAIT.BR, WAIT.CO, INFI, INFI, INFI)

In a controlled ramp it might happen that the kiln temperature can not follow the requested increase although

the controller asks for maximum heating (resp. the requested decrease in a cooling segment). The following

actions can be selected:

DISR: Causes the controller to disregard this situation

WAIT.BR: Causes the controller to hold the firing to give the kiln temperature time to catch up. If the kiln

couldn't catch up within the specified time (see next parameter) the firing is interrupted (break). The hold

mode (same as hold used during programme run) can also be released manually by pressing the hold skip

button

WAIT.CO: Bei dieser Einstellung hält der Regler den Brennvorgang ebenfalls an, führt den Brennvorgang aber

nach der eingestellten Zeit fort, wenn die Temperatur nicht aufholt wird

INFI: Causes an immediate break if the temperature can not follow.

07: max hold (sec)

(value range 0 to 9999)

wait time in seconds for the feature specified previously

08: uncontr = ..CH

(options ALL, ANY)

Selects the criteria the controller judges to the kiln as non following the temperature increase:

ALL: all channels out of control (maximum or minimum heating)

ANY: any channel out of control

.

18

.

Table 8: programme setpoint

The programme setpoints are calculated according to the programme resp. temperature curve entered by the

operator. Some adjustments are possible for easy operation. Automatic setpoint calculation required for

cascade control systems is also entered by the following settings

.

00: setpoint type

(options END, CON, MOD, CHA)

The following basic types creating a setpoint can be selected:

CON: Use initial value of the programme segment only. Typical applications are offset values for zone

temperatures or flap positions

MOD: Programme setpoint modulated by the segment time. This is the common setting causing the

programme setpoint to count upwards resp. downwards over the segment time (e.g. within 2:00 hours from

0°C up to 1000°C)

CHA: Setpoint calculated by cascade control algorithm - for details refer to the example below

following parameters apply on selection CON only:

01: table source

(value range CH/Z2 to TA04)

Selects the column of the programme table used for setpoint calculation. TA01 is the 1st column, ie. usually the

primary temperature

02: offset src SP

(value range OFF, SP00 to SP02)

Defines a setpoint which refers to an existing setpoint, ie. the setpoint is calculated by adding another setpoint

to it. Used e.g. for the setpoint of the slave zones of a multizone kiln. Using this option allows the operator to

enter the temperature of the slave zones as offset (temperature difference) relative to the master zone

setpoint. In this example the master zone setpoint is entered in this option

03: idle setpoint

(value range -9999 to 9999)

Setpoint whenever the controller is not in a programme run (IDLE). Can be used to ensure a certain

temperature is maintained without a programme run. Entering "0" switches off this feature

04: error setpoint

(value range -9999 to 9999)

Setpoint whenever the controller is not in a programme run (IDLE). Can be used to ensure a certain

temperature is maintained without a programme run. Entering "0" switches off this feature

following parameters apply on selection MOD only:

11: table source

(value range CH/Z2 to TA04)

Selects the column of the programme table used for setpoint calculation. TA01 is the 1st column, ie. usually the

primary temperature

12: offset src SP

(value range OFF, SP00 to SP02)

Defines a setpoint which refers to an existing setpoint, ie. the setpoint is calculated by adding another setpoint

to it. Used e.g. for the setpoint of the slave zones of a multizone kiln. Using this option allows the operator to

enter the temperature of the slave zones as offset (temperature difference) relative to the master zone

setpoint. In this example the master zone setpoint is entered in this option

13: idle setpoint

(value range -9999 to 9999)

Setpoint whenever the controller is not in a programme run (IDLE). Can be used to ensure a certain

temperature is maintained without a programme run. Entering "0" switches off this feature

14: error setpoint

(value range -9999 to 9999)

Setpoint whenever the controller is not in a programme run (IDLE). Can be used to ensure a certain

temperature is maintained without a programme run. Entering "0" switches off this feature

19

following parameters apply on selection CHA only:

21: based on SP

(value range SP00 to SP02)

Selects the programme setpoint used for the cascade control, ie. the programme setpoing for the target

22: charg.ctrl.CH

(value range CH00 to CH02)

Selects the master control channel (loop). The basic idea of a cascade control is as follows: An application

requires a large target (e.g. a piece of aluminium) to follow a temperature curve. An appropriate solution is

using an air convection kiln. Using an ordinary control it will give different problems depending on the position

of the thermocouple: When sensing the ambient temperature the actual temperature of the target

(aluminium) will be far (might be even hundreds of degrees centigrade) behind since it is very lag. Sensing the

target temperature might cause damage to the kiln since the controller does not pick up the temperature of

the heaters. Additionally, temperature oscillations are likely when the target temperature is getting close. A

cascade control eliminates these problems and works as follows: Two control channels are combined. The

master control channel is configured as normal, ie. using the programme temperature as setpoint and the

target temperature as actual temperature. The output of this channel is used to create a 2nd temperature

setpoint according to the settings in this section. This setpoint and the actual ambient temperature are

assigned to the slave control channel driving directly the heating device of the kiln. Note that the master

control channel is configured as heating/cooling loop with a wide proportional range and slow integral time

(P/I/D = 10.0% / 400 s / 0 s)

23: max. temp.diff

(value range -9999 to 9999)

Limits the maximum difference in temperature between the target and the ambient temperature. Used to

avoid damage of the target if sensitive. A high limit, however, speeds up the process of the target reaching the

programme setpoint

24: max envir.temp

(value range -9999 to 9999)

Limits the maximum ambient temperature. Used to avoid damage of the target if sensitive. A high limit,

however, speeds up the process of the target reaching the programme setpoint

.

.

Table 9: control channel

The control loops are designed to operate in totally different modes. Each operation mode can be tuned

individually

.

00: ctrl.algorithm

(options END, PID, C-PID, D-HYS, P-DIR, ---)

Depending on your application different control algorithms are available

PID: Default control algorithm suitable for most applications

C-PID: As before, but provides independent disable feature for heating and cooling range. Important on

heating/cooling applications where heating and cooling depends on external conditions. Also used to avoid

heating and cooling ranges chasing each other. Activation is done by any bit (e.g. a digital output). Typical

applications are gas kilns where heating range (0 to +100%) is disabled once the burner control bit goes OFF

D-HYS: Hysteresis control for heating devices which require either temperature deviation or do not allow short

cyclic activation (e.g. discontinuous burners)

P-DIR: Direct control. The setpoint is directly converted into a control value refering to the given value

boundaries. Typical application is setting a flap position directly (e.g. 0 to 100%)

01: setpoint chn

(value range SP00 to CH19)

Selects the setpoint used for this control channel

02: input chn

(value range SP00 to CH19)

Selects the process value used for this control channel

20

03: power % on ERR

(value range -100 to 100)

Predefined process output if an error occurs in the control channel. The control channel enters error state if a.)

the process value fails (overrun, underrun, invalid), b.) the process value exceeds the process value limit

specified in the channel configuration or c.) the gradient check indicates failure

04: maximum value

(value range 0 to 9999)

Maximum process value. Used to limit the process input value for safety reasons as well as setting the

operation range. If the process value exceeds the limit the control channel enters error state which can only be

cleared by re-starting the programme. Set this value above the actual operation range to allow overshooting

05: grdnt check s

(value range 0 to 3600)

The gradient check is used for safety reasons. Prevents the unit from damage if the feedback signal (e.g. the

thermocouple) fails. Checking the increase of the process value is performed on maximum output (typically

+100%). This parameter defines the checking period in seconds. Set to "0" to disable checking. If the gradient

check determines an error the channel is switched off (gradient error state)

06: grdnt chk dif

(value range 0 to 9999)

Increase of the process value required per checking period on maximum heating

07: ctrl charact

(value range 0 to 3)

Depending on the application select the operation range of the control channel to one of the following options:

0 = 0% to 100% / 1 = 100% to 0% / 2 = -100% to +100% / 3 = +100% to -100%

following parameters apply on selection PID only:

08: prop. band %

(value range 0.0 to 999.9)

Control parameter "proportional band" in % of the maximum value

09: integral time

(value range 0 to 9999)

Control parameter "integral time" in seconds

10: derivat. time

(value range 0 to 9999)

Control parameter "derivative time" in seconds

11: prop. shift

(value range 0 to 4)

Determines the operating range of the proportional band: 0 = prop. band below setpoint / 1 = prop. band one

quarter above setpoint / 2 = .. half above setpoint / 3 = .. three quarters above setpoint. In most applications a

setting of "1" ensures best results (ie. fast reaching the setpoint with minimum overshoot)

following parameters apply on selection C-PID only:

18: prop. band %

(value range 0.0 to 999.9)

Control parameter "proportional band" in % of the maximum value

19: integral time

(value range 0 to 9999)

Control parameter "integral time" in seconds

20: derivat. time

(value range 0 to 9999)

Control parameter "derivative time" in seconds

21: prop. shift

(value range 0 to 4)

Determines the operating range of the proportional band: 0 = prop. band below setpoint / 1 = prop. band one

quarter above setpoint / 2 = .. half above setpoint / 3 = .. three quarters above setpoint. In most applications a

setting of "1" ensures best results (ie. fast reaching the setpoint with minimum overshoot)

22: + activat. DOx

(value range OFF, DO0.0 to DO1.0)

Selects the bit (digital output) which activates the positive operation range (heating). When the bit is off the

Other manuals for TC 505

1

This manual suits for next models

1

Table of contents

Other bentrup Controllers manuals