CHIEF AIR JACK

USERS MANUAL

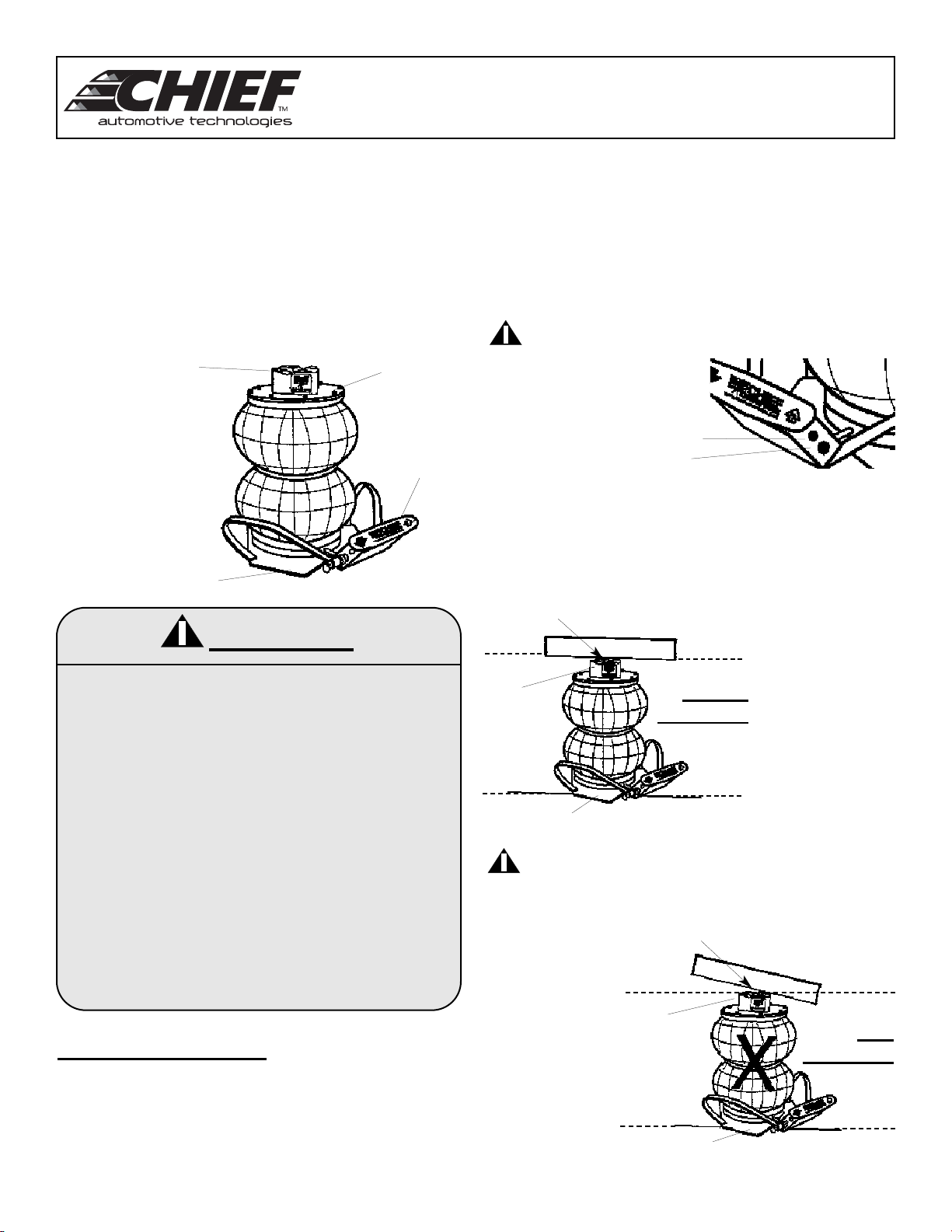

The Chief AirJack (see Figure 1) is a lightweight lifting

tool that is easy to use. The device is ideal for tire and

alignment shops, body shops, and service garages that fre-

quently need to elevate the front end, rear end or side of

a vehicle for tire removal / installation.

Read all of the instructions and warnings provided before

attempting to operate the Chief Air Jack. Also, make sure

all personnel who are to use the Chief Air Jack are familiar

with its operation.

To operate the Chief air jack:

1. Position vehicle on solid flat surface and engage its

parking brake.

2. Block vehicles front and rear wheels.

3. Attach air hose to air jack and position jack on solid flat

surface directly below structural component to be lifted.

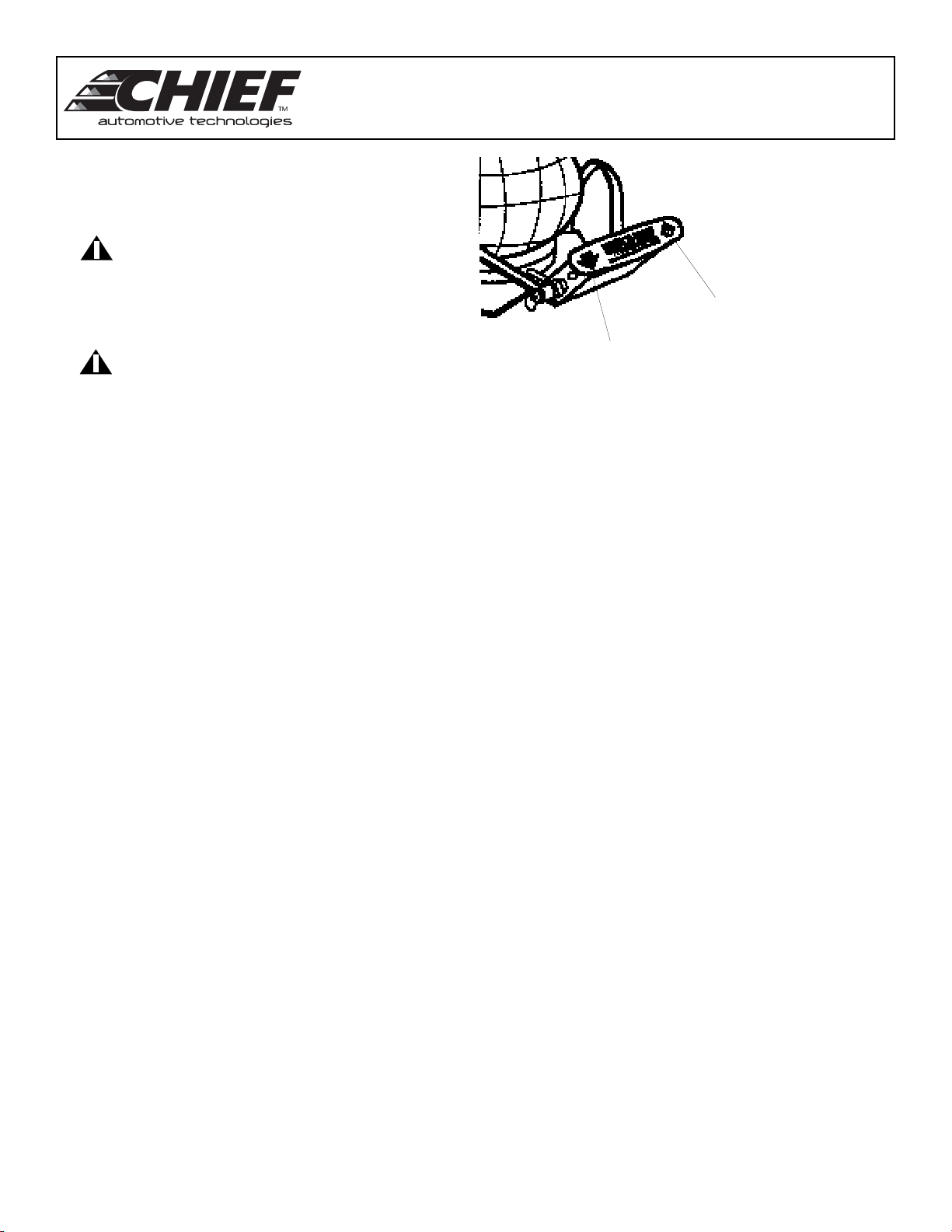

NOTE: • Air inlet on control base handle accepts 1/4

inch NPT fitting. (See Figure 2.) Add a

fewdrops of pneumatic tool oil to air inlet

monthly.

• Position handle assembly for easy access.

WARNING! DO NOT remove brass plug from

handle assembly.

4. Check the intended lifting point on the structural compo-

nent. This location must be parallel with base of air jack

and lift pad. (See Figure 3.) If it is not parallel (see Figure

4), the load may drop suddenly, creating a potential for

severe injury or death.

WARNING! To prevent slippage, lifting point on

structural component must always be parallel

with base of air jack and lift pad.

Figure 2

Figure 1

Figure 3

Figure 4

1

WARNING!

• Visually inspect air jack prior to each use.

DO NOT use if scars, abrasions, rips,

punctures are detected in the air bag.

• Always wear safety glasses.

• DO NOT use as a jack stand.

• Avoid contact with petroleum based

products or chemicals of any kind.

• Use jack stand on firm level surfaces only.

• Avoid sharp objects that may puncture

air bag.

• DO NOT use near open flame, sparks, or

temperatures exceeding 120° F (49° C).

• Maximum air pressure, 105 PSI (7.24 Bar) .

• Maximum load, 2 ton (1800 kg.)

Handle

Assembly

Base

Lift Pad Top Plate

Air Inlet

Brass Plug

Lifting Point On Structural Component

Base

Parallel

Alignment

Lift

Pad

Lifting Point On Structural Component

Base

Non

Alignment

Lift

Pad