1 | GENERAL INFORMATION

4

1 GENERAL INFORMATION

1.1 General Notices

When you get the product, check immediately that the contents are

all present and undamaged. Contact the dealer if you notice

any problems.

The product' s installation must be carried out by an authorised

company that will issue a declaration of the installation's conformity

to the product's owner once the work has been completed,

indicating that the work has been carried out in accordance with the

standards of good practice, current National and Local regulations,

and the indications provided by in the instruction booklet

accompanying the device.

The product must be used for its intended purpose, as stated by

for which it has been expressly manufactured. shall

bear no responsibility, whether of a contractual or non-contractual

nature, for any damage caused to people, animals, or property due

to incorrect installation, adjustments, or maintenance, or improper

use.

Suitable clothing, instrumentation, and accident-prevention devices

must be utilized during the installation and/or maintenance

operations. shall bear no responsibility for any failure to

comply with current safety and accident-prevention regulations.

During installation and/or service operations, keep the area around

the unit tidy and clean.

Comply with the legislation in force on the country of deployment

with regard to the use and disposal of packaging, of cleaning and

maintenance products and for the management of the unit's

decommissioning.

Any repair and maintenance interventions must be carried out by

Technical Support Service, in accordance with the

provisions contained in this publication. Do not modify or tamper

with the unit as dangerous situations may arise and the unit

manufacturer will not be liable for any damage caused.

In the event of any functional anomalies or fluid leaks, set the

system's main switch to its "off" position. Promptly contact your

local Technical Support Service, and do not perform any

interventions upon the device on your own.

The units contain refrigerant gas: operate carefully so as to avoid

damaging the gas circuit and the fin bank.

Do not place any inflammable object (spray cans) within a 1 metre

radius from the air expulsion.

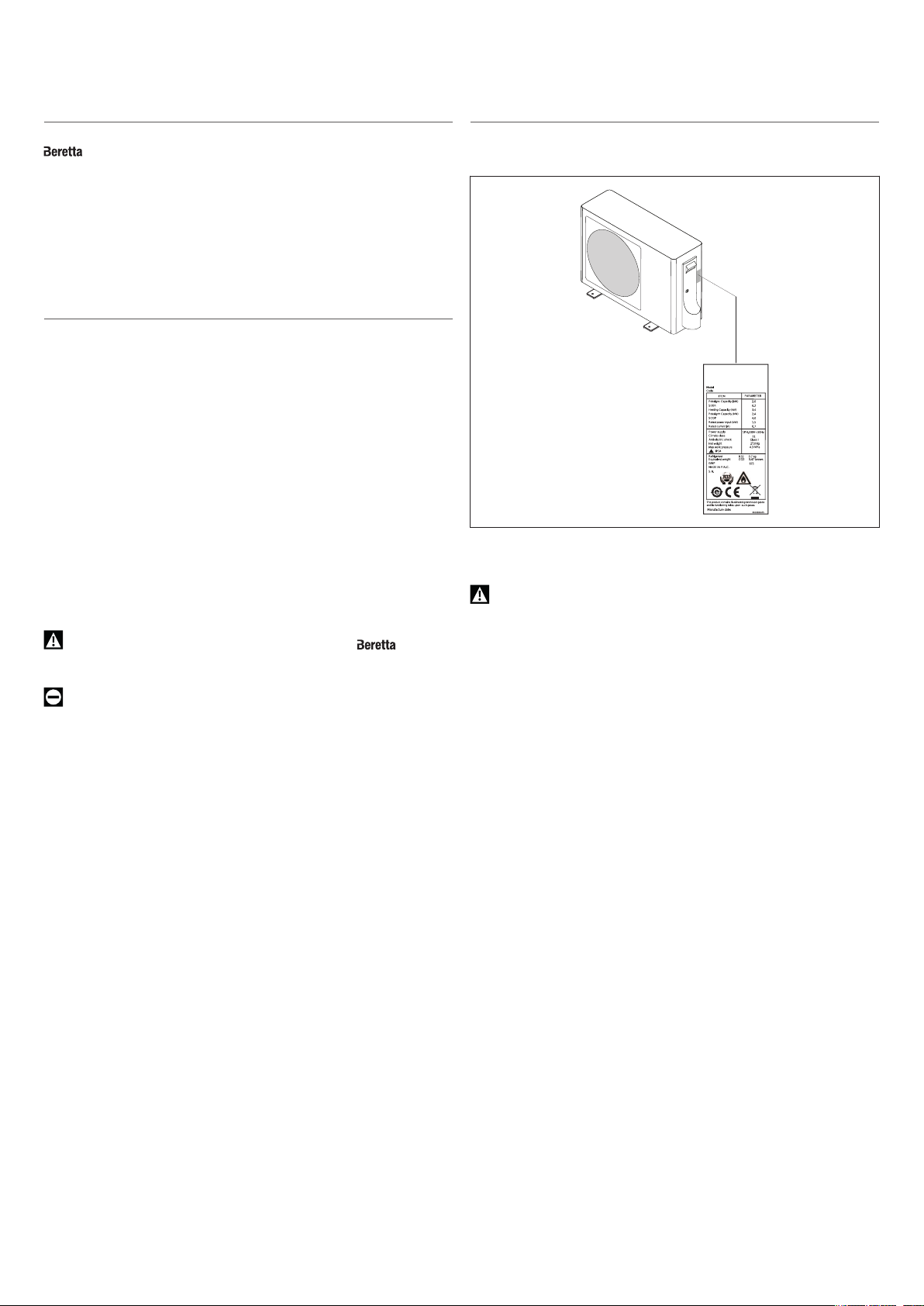

According to EU Regulation no. 517/2014 regarding certain

fluorinated greenhouse gases, the total amount of refrigerant

contained within the installed system must be indicated. This

information can be found on the unit technical data plate.

This unit contains fluorinated greenhouse gases covered by the

Kyoto protocol. Maintenance and disposal activities must be carried

out exclusively by skilled personnel.

The R32 refrigerant gas is slightly inflammable and odourless.

Carefully read the safety data sheet available from the dealer.

This booklet is an integral part of the device, and must therefore be

carefully preserved, and must ALWAYS accompany it, even in the

event that it is sold to another Owner or User, or is transferred to

another system. If it is damaged or lost, another copy can be

requested to Technical Support Service in your Area.

1.2 Safety precautions

It should be noted that the use of products that utilize electric energy

requires certain essential safety regulations to be respected, including the

following:

Do not allow children or unassisted disabled people to use the unit.

Do not touch the unit while barefoot and/or partially wet.

Do not spray or throw water directly on the unit.

It is forbidden to place weights on the device.

It is strictly forbidden to touch the coil fins, the moving parts, to place

any body parts between them, or to insert pointy objects into the

grilles.

It is forbidden to perform any technical interventions or cleaning

operations before having disconnected the device from its electrical

power supply, by setting the system's main switch to its "OFF"

position.

It is forbidden to modify the safety or regulation devices without the

authorisation of the manufacturer.

Do not pull, detach or twist the electrical wires coming out of the

unit, even when the unit is disconnected from the power grid.

The packing material must not be disposed of in the surrounding

environment and must be kept out of children reach, as it can be

dangerous. It must be disposed of according to the regulations in

force.