HYDRONIC UNIT LE

9

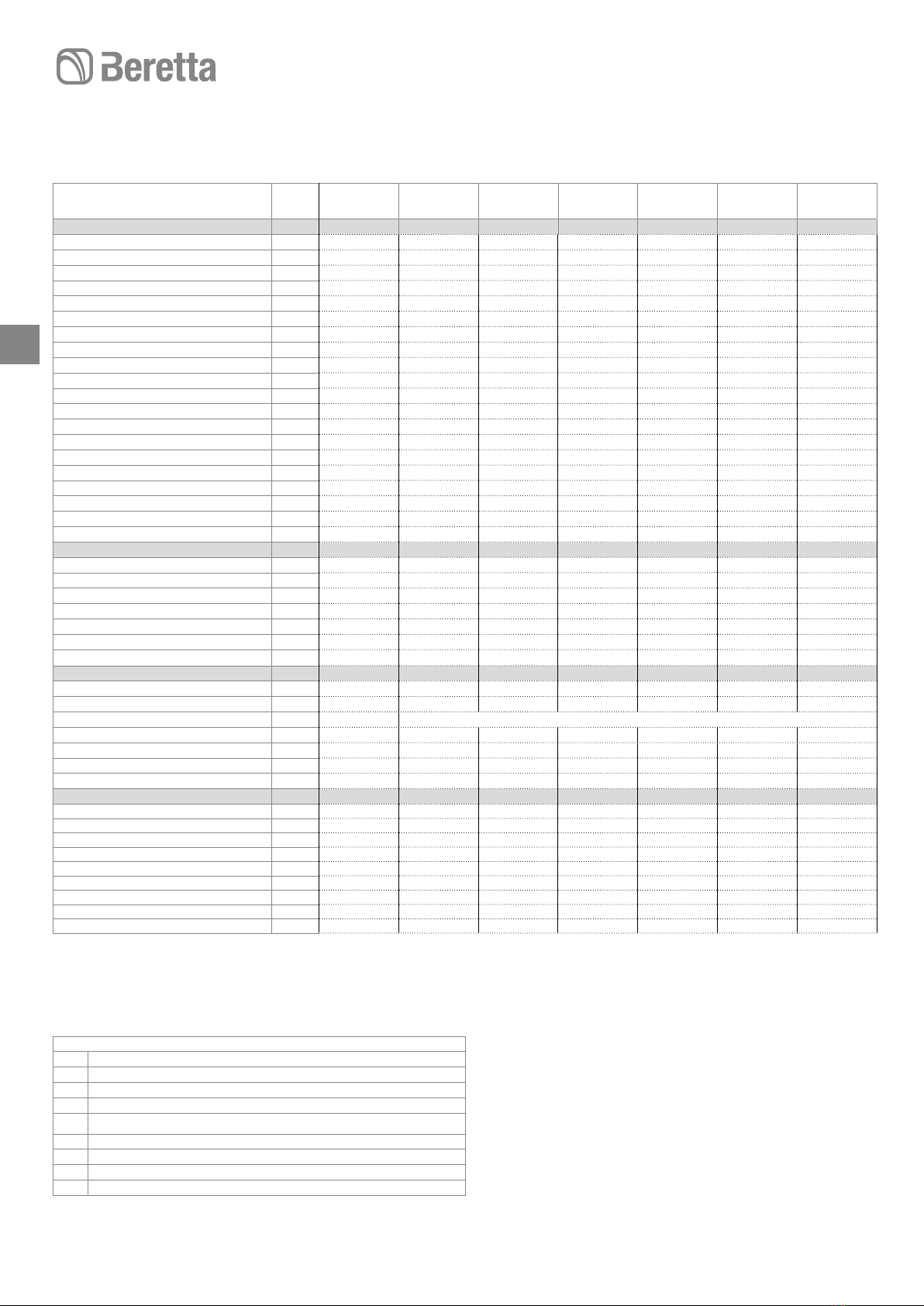

TECHNICAL DATA

Reference conditions

Sound pressure measured in a hemispheric field 4 metres

in front of the fan.

Unit performances have been provided in reference to

Directive UNI EN 14511:2011.

Fouling factor: 0.18 x 10-4 (m² K)/W.

Model

HYDRONIC

UNIT LE 4 HYDRONIC

UNIT LE 6 HYDRONIC

UNIT LE 8 HYDRONIC

UNIT LE 12 HYDRONIC

UNIT LE 15 HYDRONIC UNIT

LE 12 T

HYDRONIC

UNIT LE

15 T

Performance in heating mode

Nominal capacity (1) kW 4,07 5,76 7,16 11,86 14,46 12 15

Power consumption (1) kW 0,98 1,35 1,80 3,00 3,54 2,79 3,57

COP (1) 4,15 4,28 3,97 3,95 4,09 4,30 4,20

Nominal capacity (2) kW 3,87 5,76 7,36 12,91 13,96 11,2 14,5

Power consumption (2) kW 1,19 1,89 2,31 4,26 4,32 3,34 4,39

COP (2) 3,26 3,05 3,19 3,03 3,23 3,35 3,30

Nominal capacity (3) kW 3,5 3,8 4,1 8 10,2 8,55 9,5

Power consumption (3) kW 1,13 1,23 1,31 2,6 3,29 2,69 3,02

COP (3) 3.1 3.1 3.1 3.1 3.1 3,17 3,15

Nominal capacity (4) kW 3,4 3,7 3,9 8 10,2 7,5 9,3

Power consumption (4) kW 1,31 1,42 1,48 3,08 3,92 2,78 3,50

COP (4) 2,6 2,6 2,6 2,6 2,6 2,70 2,65

Nominal capacity (5) kW 4,1 5,4 6,7 11,5 11,7 11,05 12

Power consumption (5) kW 1,51 2,09 2,91 4,64 4,18 3,95 4,21

COP (5) 2,71 2,58 2,3 2,48 2,8 2,80 2,85

Nominal capacity (6) kW 4,27 5,43 7,25 10,87 12,36 11,43 12,17

Power consumption (6) kW 1,46 1,95 2,58 4,05 4,09 3,66 4,08

COP (6) 2,92 2,77 2,81 2,68 3,02 3,12 2,98

Capacity (7) kW 1,06 1,50 1,86 4,68 4,78 4,78 4,78

COP (7) 2,75 2,82 2,81 2,70 2,75 2,75 2,75

Performance in cooling mode

Nominal capacity (8) kW 4,93 7,04 7,84 13,54 16,04 13,5 16

Power consumption (8) kW 1,17 1,90 1,96 3,70 4,17 3,25 4,20

EER (8) 4,2 3,7 3,99 3,66 3,85 4,15 3,81

Nominal capacity (9) kW 3,33 4,73 5,84 10,24 13,04 10,2 13

Power consumption (9) kW 1,10 1,58 1,96 3,46 4,42 3,40 4,47

EER (9) 3,02 3 2,98 2,96 2,95 3 2,91

ESEER (9) 4,36 4,51 4,15 4,22 4,31 4,40 4,31

Generalities

Sound pressure in heating mode dB(A) 42 42 44 47 48 48 48

Sound pressure in cooling mode dB(A) 44 44 45 48 49 49 49

Compressor

ROTARY DC INV.

TWIN ROTARY DC INVERTER

R410a refrigerant charge ** kg 1,195 1,35 1,81 2,45 3,39 3,385 3,385

Empty weight kg 57 61 69 104 112 116 116

Number of fans n 1 1 1 2 2 2 2

Fan diameter mm 495 495 495 495 495 495 495

Water circuit

Static pressure available kPa 60 60 56 70 58 70 55

Expansion tank capacity l 2223333

Expansion tank pre-charge kPa 200 200 200 200 200 200 200

System minimum water volume l 14 21 28 42 49 42 49

System maximum water volume * l 65 65 65 95 95 95 95

Machine water volume l 0,8 0,8 1,0 2,3 2,3 2,3 2,3

Maximum operating pressure kPa 300 300 300 300 300 300 300

Minimum filling pressure kPa 120 120 120 120 120 120 120

Hydraulic connections diameter Inches 1M 1M 1 M 1 M 1 M 1M 1M

* For greater water volumes it is necessary to provide an additional expansion tank

** The value of the refrigerant charge is indicative. The correct value is indicated on the technical data plate.

Note / Note

1outdoor temperature d.b. + 7 °C / w.b. + 6°C, water 35 - 30 °C.

2outdoor temperature + 7 °C / w.b. + 6°C, water 45 - 40 °C.

3outdoor temperature d.b. + 2 °C / w.b. +1°C, water 35 - 30 °C.

4outdoor temperature d.b. + 2 °C / w.b. +1°C, water 45 - 40 °C.

5outdoor temperature d.b. + 7 °C / w.b. + 6°C, water 55 °C.

6

outdoor temperature d.b. + 7 °C / d.b. + 6°C, water 47 - 55 °C.

EN 14511

7outdoor temperature -7 °C, water 35 °C (with rated water flow)

8outdoor temperature d.b. +35 °C / w.b. +24°C, water 18 - 23 °C.

9outdoor temperature d.b. +35 °C, water 7 - 12 °C.

d.b. dry bulb

w.b. wet bulb