Berger & Schroeter 31440 User manual

ATV/UTV

ATV/UTV

ATV/UTV

ATV/UTV ELECTRIC

ELECTRIC

ELECTRIC

ELECTRIC WINCH

WINCH

WINCH

WINCH

General

General

General

General Safety

Safety

Safety

Safety Precautions

Precautions

Precautions

Precautions

WARNING:

WARNING:

WARNING:

WARNING: FAILURE

FAILURE

FAILURE

FAILURE TO

TO

TO

TO READ

READ

READ

READ AND

AND

AND

AND FOLLOW

FOLLOW

FOLLOW

FOLLOW THE

THE

THE

THE SAFETY

SAFETY

SAFETY

SAFETY INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS IN

IN

IN

IN THIS

THIS

THIS

THIS OWNER

OWNER

OWNER

OWNER ’

’

’

’ S

S

S

S

MANUAL

MANUAL

MANUAL

MANUAL BEFORE

BEFORE

BEFORE

BEFORE INSTALLING

INSTALLING

INSTALLING

INSTALLING OR

OR

OR

OR USING

USING

USING

USING YOUR

YOUR

YOUR

YOUR ELECTRIC

ELECTRIC

ELECTRIC

ELECTRIC WINCH

WINCH

WINCH

WINCH COULD

COULD

COULD

COULD RESULT

RESULT

RESULT

RESULT IN

IN

IN

IN DAMAGE

DAMAGE

DAMAGE

DAMAGE TO

TO

TO

TO

YOUR

YOUR

YOUR

YOUR WINCH

WINCH

WINCH

WINCH AND

AND

AND

AND SERIOUS

SERIOUS

SERIOUS

SERIOUS OR

OR

OR

OR

FATAL

FATAL

FATAL

FATAL

INJURY!!

INJURY!!

INJURY!!

INJURY!!

C

C

C

Check all safety and environmental conditions prior and during use.

Before use, ensure that you are familiar with all winching performance and operation such as speed & direction.

A

wire rope should be replaced if it shows signs of excessive wear, broken wires, corrosion or any other defects.

The winches duty rating is S3 (intermittent – periodic)

If the winch fails to pull a load under normal conditions, stop the operation within 30 seconds otherwise motor

damage may occur.

Ensure that the winch is connected to the correct voltage of 12VDC only.

Check that the freespool shifter is in the “ Engaged ” position during and after use.

Remove the remote control from the winch when not in use.

Do not wrap the wire rope around the load and back onto it self. Always use a strap to ensure that the wire rope does

not fray or kink.

Keep hands and clothes away from the winch, wire rope, and fairlead during operation..

Never unplug the remote control and battery leads when winching a load.

To

avoid insufficient power when winching a load, the vehicle should be running and in neutral.

When winching a heavy load, lay a heavy blanket or jacket over the wire rope near to the hook end

If excessive noise or vibration occurs when running, stop the winch immediately and return it for repair.

OWNER'S GUIDE

The winch is rated for intermittent-periodic duty.

The winch is not to be used to lift, support or otherwise transport personnel.

A

minimum of five (5) wraps of rope around the drum are necessary to support the rated load.

The rated line pull of the winch must be powerful enough to overcome the added resistance caused by

whatever the vehicle is stuck in.

Never operate the winch under water.

Operate the winch cable in and cable out at no load after a winch was ingressed by water.

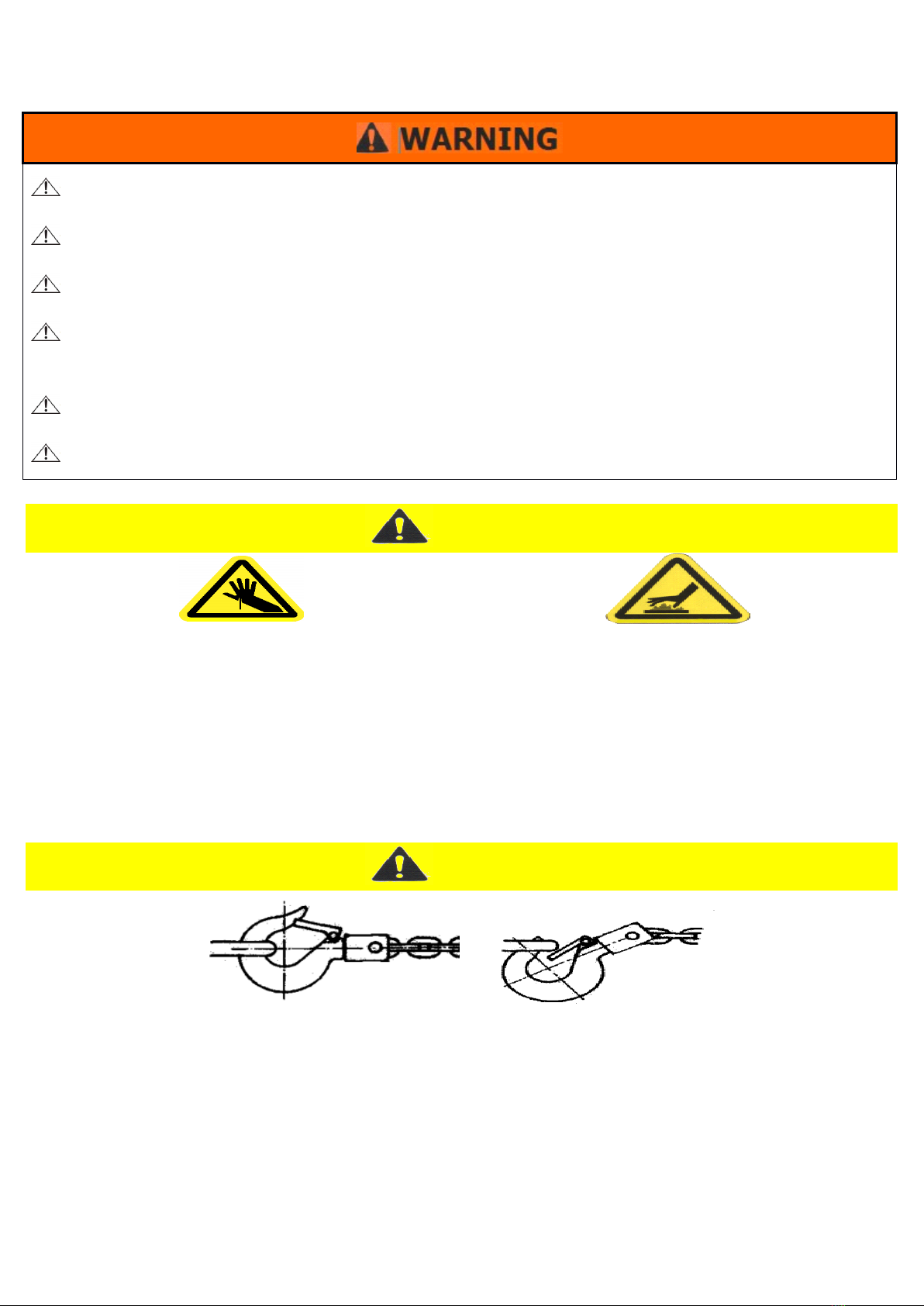

CAUTION

CAUTION

CAUTION

CAUTION

CUT

CUT

CUT

CUT AND

AND

AND

AND BURN

BURN

BURN

BURN HAZARD

HAZARD

HAZARD

HAZARD

Failure

Failure

Failure

Failure to

to

to

to observe

observe

observe

observe these

these

these

these instructions

instructions

instructions

instructions could

could

could

could lead

lead

lead

lead to

to

to

to minor

minor

minor

minor to

to

to

to moderate

moderate

moderate

moderate injury.

injury.

injury.

injury.

To

To

To

To

avoid

avoid

avoid

avoid injury

injury

injury

injury to

to

to

to hands

hands

hands

hands and

and

and

and fingers:

fingers:

fingers:

fingers:

•

•

•

• Always

Always

Always

Always wear heavy leather gloves when handling a wire rope.

•

•

•

• Never

Never

Never

Never let wire rope slip through your hands.

•

•

•

• Always

Always

Always

Always be aware of possible hot surface at winch motor, drum or wire rope during or after winch use.

CAUTION

CAUTION

CAUTION

CAUTION

Moving

Moving

Moving

Moving Parts

Parts

Parts

Parts Entanglement

Entanglement

Entanglement

Entanglement Hazard

Hazard

Hazard

Hazard

Failure

Failure

Failure

Failure to

to

to

to observe

observe

observe

observe these

these

these

these instructions

instructions

instructions

instructions could

could

could

could lead

lead

lead

lead to

to

to

to minor

minor

minor

minor to

to

to

to moderate

moderate

moderate

moderate injury.

injury.

injury.

injury.

•

•

•

• Never

Never

Never

Never apply load to hook tip or latch. Apply load only to the center of hook.

•

•

•

• Never

Never

Never

Never use a hook whose throat opening has increased, or whose tip is bent or twisted.

Winch

Winch

Winch

Winch &

&

&

& Roller

Roller

Roller

Roller Fairlead

Fairlead

Fairlead

Fairlead Mounting

Mounting

Mounting

Mounting

1. It

is

very important that the winch shall be mounted on a flat hard surface in order to make sure the motor, drum and

gearbox housing are aligned correctly.

2. If a different mounting plate

is

used, the thickness shall be 5 mm (3/16 ” ). If different hardware

is

used, it must be SAE

grade 8 minimum.

3. Four (4) included M8x 25L Grade 8.8 High Tensile Steel Bolts must be used for securing the winch on the mounting

plate in order to sustain the loads imposed on the winch mounting.

4. Two (2) included M8 x 20L Grade 8.8 High Tensile Steel Bolts must be used for securing the roller fairlead on the

mounting plate.

Solenoid

Solenoid

Solenoid

Solenoid Mounting

Mounting

Mounting

Mounting

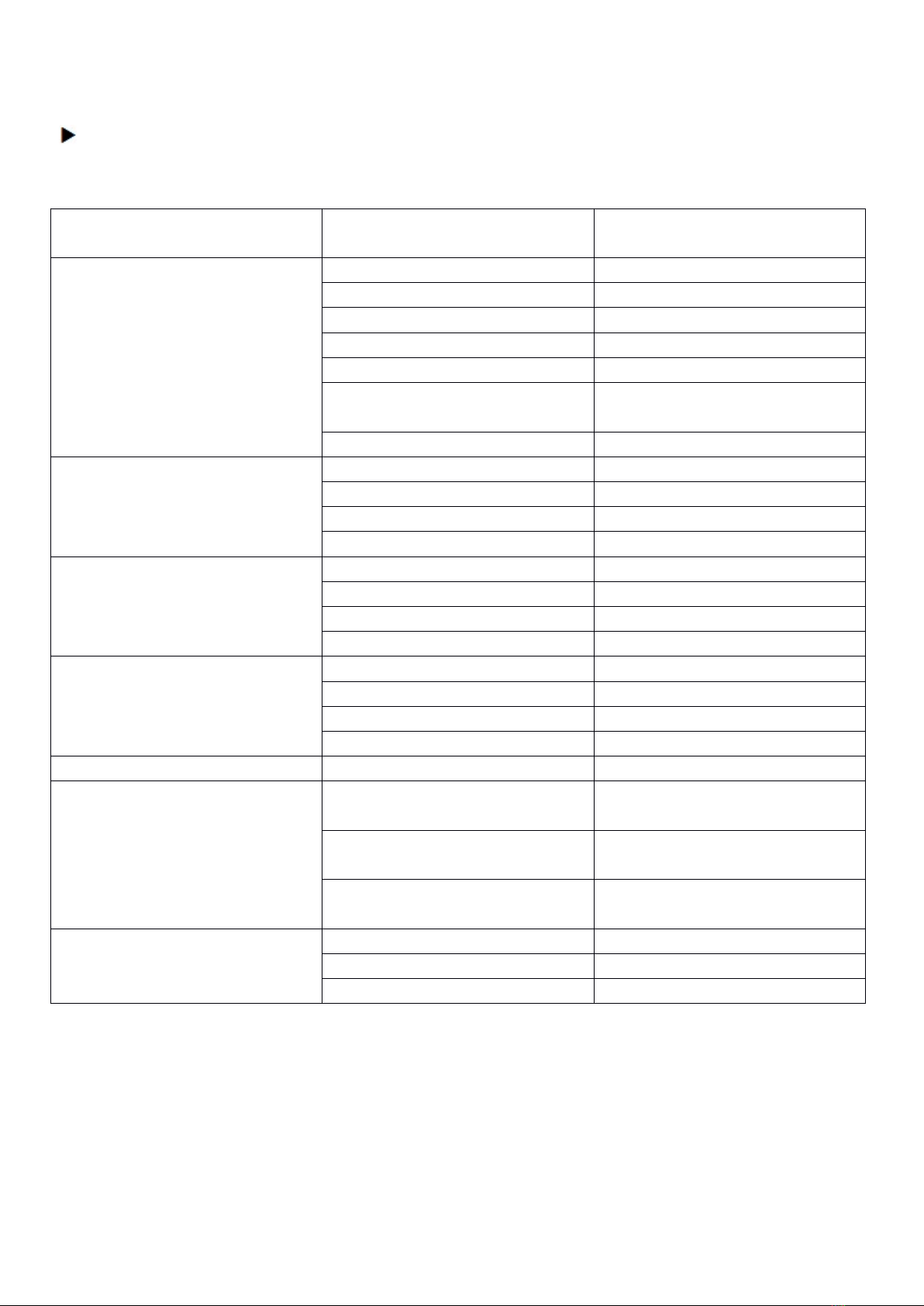

1. It disconnects your winch from the power source when the vehicles

is

not in use

2. It should be mounted close to the battery and keep the location from all metal structures

If

If

If

If with

with

with

with control

control

control

control box

box

box

box (

(

(

( solenoid

solenoid

solenoid

solenoid in

in

in

in it

it

it

it )

)

)

)

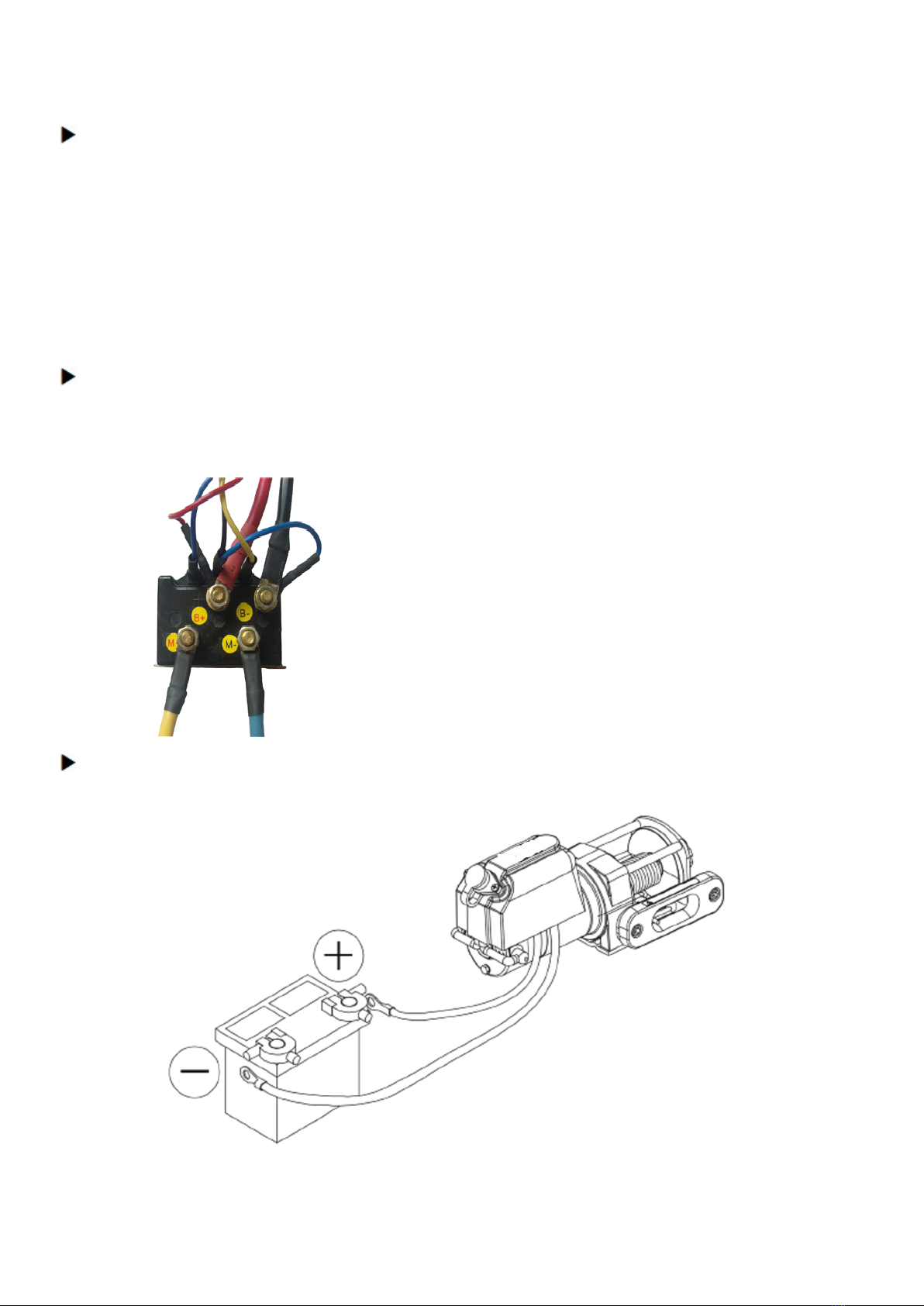

''B +'' means to connect to the Positive +of Battery

''B-'' means to connect to the Negative - of Battery

''M +'' means to connect to the Positive +(red) of motor

''M-'' means to connect to the Negative - (white) of mtor

Handlebar

Handlebar

Handlebar

Handlebar Remote

Remote

Remote

Remote Control

Control

Control

Control Mounting

Mounting

Mounting

Mounting

Handlebar mounted trigger switch can be operated without removing your hand from the grip.

• It

is

recommended that the switch be installed on the left handlebar.

A

piece of electrical tape

around the handlebar will help prevent rotation of mount on the handle bar.

• Do NOT tighten over any hoses or cables .

Operation

Operation

Operation

Operation

Cable

Cable

Cable

Cable In

In

In

In and

and

and

and Out

Out

Out

Out

1).

To

determine “ Cable Out “ , turn to the “ Out ” position

2).

To

determine “ Cable In “ , turn to the “ In ” position

3).

To

stop winching, release the trigger level

Freespool

Freespool

Freespool

Freespool Funtion

Funtion

Funtion

Funtion

The freespool allows rapid pay-out of the wire rope for hooking onto a load or anchor points and

is

operated by a freespool shifter located on the end of the winch.

1).

To

engage the freespool, turn the freespool shifter counter-clockwise to the “ Engaged ” position.

The winch

is

now ready for pulling.

2).

To

disengage the freespool, turn the freespool shifter clockwise to the “ Disengaged ” position.

Wire rope can now be free spooled off the drum.

Maintenance

Maintenance

Maintenance

Maintenance

Wire

Wire

Wire

Wire Rope

Rope

Rope

Rope Replacement

Replacement

Replacement

Replacement

Before installing a new wire rope, wrap the end of the wire rope with tape to prevent fraying. Wind the

wire rope on the drum by pull a force to keep the tension constant. Never use a wire rope of a different size

or material and only use aircraft grade wire ropes.

1). Disengage the freespool.

2). Spool the old wire rope, and then remove it from the drum.

3). Have horizontal roller and bolts apart from the roller fairlead, then place the replacement wire rope

through the roller fairlead throat, pass below the drum, and insert it into the hole on the drum core.

4). Use a hex wrench to tighten the screw downwards to secure the wire rope.

5). Tighten the horizontal roller and bolt of roller fairlead

6) . Wear leather gloves and use a strap when guiding the wire rope off the drum.

7). It

is

very important that the winch shall be mounted on a flat surface , with the wire rope feeding form

the bottom of the drum.

8) .

To

rewind wire rope on the drum correctly , it

is

necessary to keep a slight load on the wire rope while

cable in.

Lubrication

Lubrication

Lubrication

Lubrication

All moving parts in the winch are permanently lubricated at the time of assembly. Under normal conditions

factory lubrication will suffice. If re-lubrication

is

necessary after repair or disassembly use a marine type

grease.

Check

Check

Check

Check the

the

the

the System

System

System

System

Before using the winch, verify the following:

1) Wiring to all components

is

correct. All loose wires are tie wrapped tight.

2) There are no exposed wiring or terminals. Cover any existing terminal exposures with terminal boots,

heat shrink tubing or electricians tape.

3) Turn

ATV

key switch to ON position. Check winch for proper operation. The wire rope should spool in

and out in the direction indicated on the switch.

Know

Know

Know

Know your

your

your

your winch

winch

winch

winch

• Take time to fully understand your winch and the winching operation by reviewing the

manual

with your

winch.

Maintenance

Maintenance

Maintenance

Maintenance Schedule

Schedule

Schedule

Schedule

Carry out all inspections listed below on schedule and inspections are divided into Daily, Monthly and 3

Monthly. Clean all connections because corrosion on electrical connections will reduce performance or may

cause a short.

Classification of check

Item

Item

Item

Item

Checking

Checking

Checking

Checking method

method

method

method

Checking

Checking

Checking

Checking reference

reference

reference

reference

Daily

Periodical

One

month

Three

month

*

Complete winch

Operate the winch in

and out

Minimum corrosion of

the internal motor

components

*

Installation

Mounting bolts &

alignment.

Bolts tension & wear.

Tightened and aligned

*

Remote

control

Working

Manual

Reasonable actuation

*

Wearing in contact

points

Visual.

Free of wear or damage.

*

Wire rope

Broken strands

Visual, measuring

(monthly )

Less than 10%

*

*

Decrease in rope

diameter

Visual, measuring

(monthly )

7% of nominal diameter

max

*

Deforming or corrosion

and fastening condition

of end

Visual

No existence

of abnormalities

*

Freespool

Wear in spring

Visual evidence of wear

Free of wear or damage.

*

Motor

Staining, damage

Visual evidence of wear

No existence of

abnormalities

*

Brake

Wearing of lining

Visual evidence of wear

Free of wear or damage

*

Performance

Visual

Reasonable actuation

*

Gear train

Damage, wearing

Visual evidence of wear

Free of wear or damage

and

distortion.

Trouble

Trouble

Trouble

Trouble Shooting

Shooting

Shooting

Shooting

When the winch fails to operate after several attempts, or if there

is

any fault operation while winching,

check followings.

Symptom

Possible Cause

Remedy

Winch will not operate

Cut circuit or loosing

Check battery cable.

Weak battery or insufficient power

Recharge or replace battery

Damaged over load protector

Replace over load protector

Loose connection of wirings

Checking all wirings

Damaged or stuck solenoid

Replace solenoid

Defective remote control

Check winch operation with an

auxiliary switch

Damaged motor or worn carbon brush

Replace motor or carbon brush

Motor runs in one direction.

Broken wiring or bad connection

Reconnect or replace wiring

Damaged or stuck solenoid

Replace solenoid

Switch inoperative

Replace switch

Dropt or lost wiring

Replace wiring and tighten.

Drum will not freespool.

Freespool not disengaged

Engaged freespool

Damaged brake or freespool ass ’ y

Replace brake or freespool ass ’ y

Damaged drum bushing

Replace drum bushing

Damaged gear box

Replace gear box

No brake

Damaged or inoperative pressed spring

Replace pressed spring

Disengaged freespool

Engaged

Damaged output shaft

Replace output shaft

Damaged 1st shaft

Replace 1st shaft

Brake distance is too long

Worn or damaged brake

Replace or adjust brake

Winch runs opposite direction

Motor leads crossed

Reverse electrical connections to

motor

Solenoid control crossed

Reverse black and red wires on the

solenoid

Remote control or trigger switch

crossed

Reverse electrical connections

Motor runs extremely hot

Long period of operation

Stop operation to have it cooled

Over-load

Reduce load

Damaged or inoperative brake

Replace or repair brake

This manual suits for next models

1

Table of contents

Other Berger & Schroeter Winch manuals

Popular Winch manuals by other brands

Perel

Perel WHW420 user manual

Comeup

Comeup Seal Gen2 12.5rs Instruction guide

Comeup

Comeup CP-500T quick start guide

Ingersoll-Rand

Ingersoll-Rand force5 FA5A-SXK1 Parts, operation and maintenance manual

TRAC

TRAC Big Water 45 Installation and operating instructions

Warrior Winches

Warrior Winches 80RVSHY owner's manual

Sealey

Sealey RW2500/12.V2 instructions

Mile Marker

Mile Marker HI9000 Installation and operator's manual

Harken

Harken 70.3 ST EL Installation and maintenance manual

HERKULES

HERKULES SHZ 125 operating instructions

Ramsey Winch

Ramsey Winch 600 Series Operating, Service and Maintenance Manual

Tulsa

Tulsa 354IRL Service manual