INSTRUCTIONS FOR:

12 & 24V ELECTRIC POWER WINCHES

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

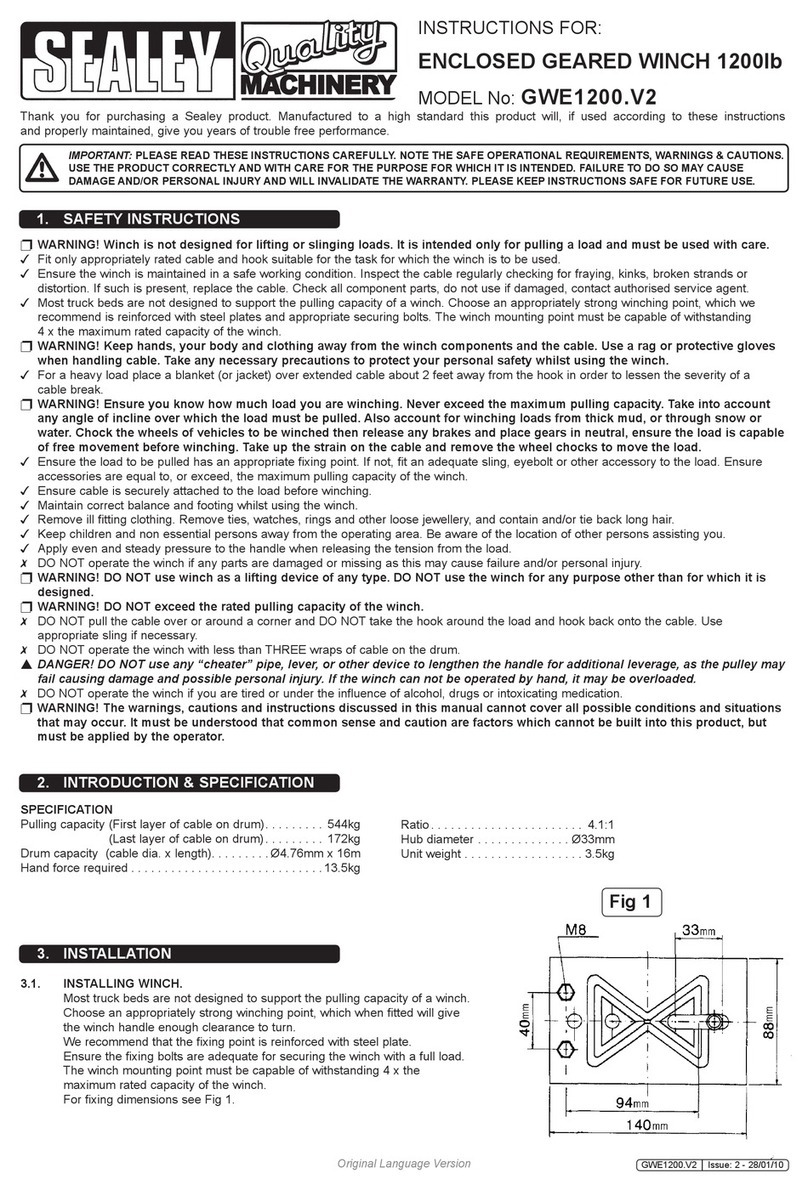

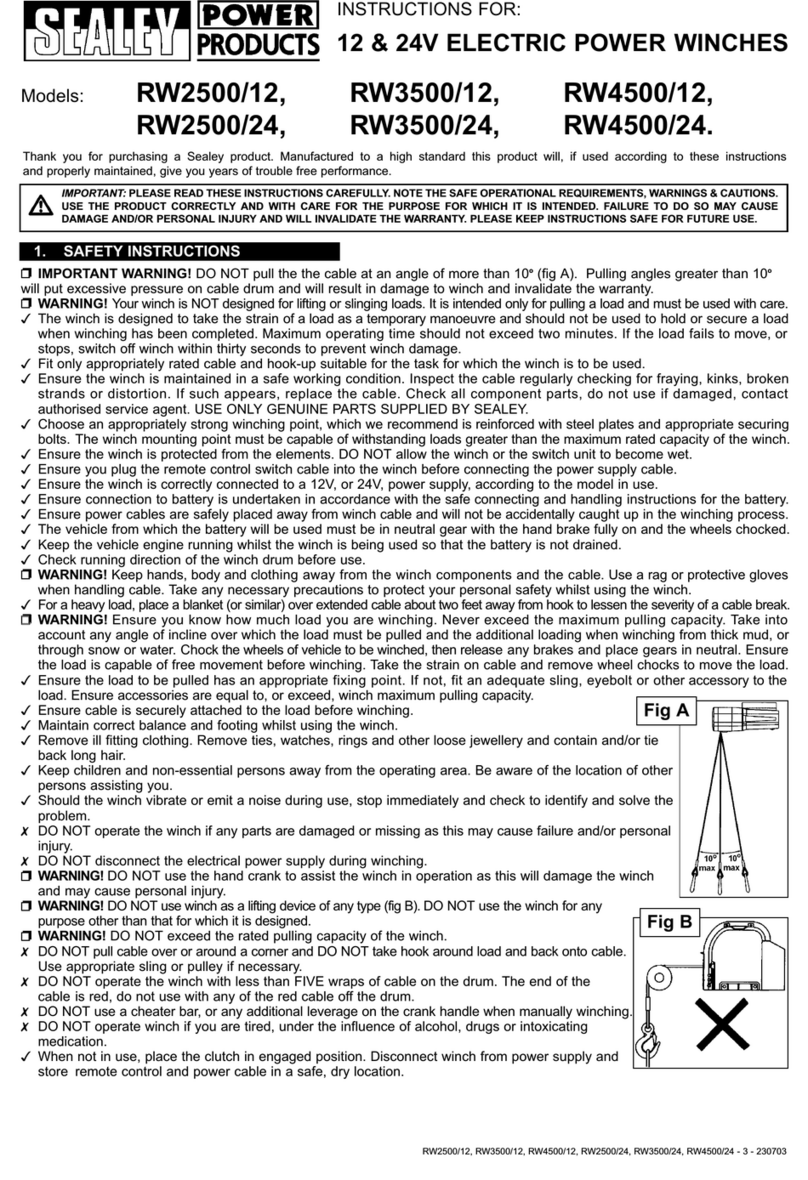

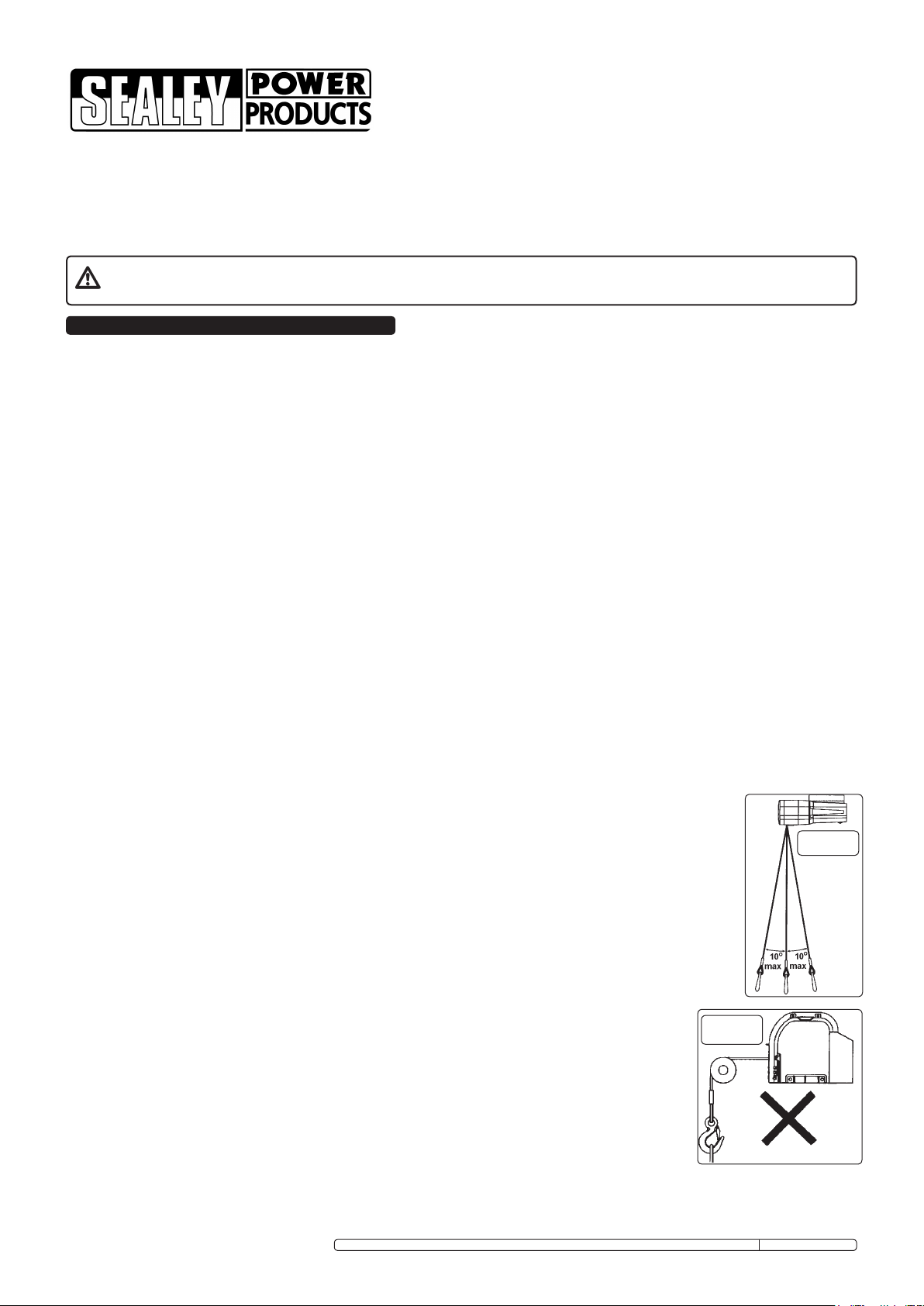

IMPORTANT WARNING! DO NOT pull the the cable at an angle of more than 10°(fig A). Pulling angles greater than 10°

will put excessive pressure on cable drum and will result in damage to winch and invalidate the warranty.

WARNING! Your winch is NOT designed for lifting or slinging loads. It is intended only for pulling a load and must be used with care.

The winch is designed to take the strain of a load as a temporary manoeuvre and should not be used to hold or secure a load

when winching has been completed. Maximum operating time should not exceed two minutes. If the load fails to move, or

stops, switch off winch within thirty seconds to prevent winch damage.

Fit only appropriately rated cable and hook-up suitable for the task for which the winch is to be used.

Ensure the winch is maintained in a safe working condition. Inspect the cable regularly checking for fraying, kinks, broken

strands or distortion. If such appears, replace the cable. Check all component parts, do not use if damaged, contact

authorised service agent. USE ONLY GENUINE PARTS SUPPLIED BY SEALEY.

Choose an appropriately strong winching point, which we recommend is reinforced with steel plates and appropriate securing

bolts. The winch mounting point must be capable of withstanding loads greater than the maximum rated capacity of the winch.

Ensure you plug the remote control switch cable into the winch before connecting the power supply cable.

Ensure the winch is correctly connected to a 12V or 24V power supply, according to the model in use.

Ensure connection to battery is undertaken in accordance with the safe connecting and handling instructions for the battery.

Ensure power cables are safely placed away from winch cable and will not be accidentally caught up in the winching process.

The vehicle from which the battery will be used must be in neutral gear with the hand brake fully on and the wheels chocked.

Keep the vehicle engine running whilst the winch is being used so that the battery is not drained.

Check running direction of the winch drum before use.

WARNING! Keep hands, body and clothing away from the winch components and the cable. Use a rag or protective gloves

when handling cable. Take any necessary precautions to protect your personal safety whilst using the winch.

For a heavy load, place a blanket (or similar) over extended cable about two feet away from hook to lessen the severity of a cable

break.

WARNING! Ensure you know how much load you are winching. Never exceed the maximum pulling capacity. Take into

account any angle of incline over which the load must be pulled and the additional loading when winching from thick mud, or

through snow or water. Chock the wheels of vehicle to be winched, then release any brakes and place gears in neutral.

Ensure the load is capable of free movement before winching. Take the strain on cable and remove

wheel chocks to move the load.

Ensure the load to be pulled has an appropriate fixing point. If not, fit an adequate sling, eyebolt or

other accessory to the load. Ensure accessories are equal to, or exceed, winch maximum pulling capacity.

Ensure cable is securely attached to the load before winching.

Maintain correct balance and footing whilst using the winch.

Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellery and contain and/or tie

back long hair.

Keep children and non-essential persons away from the operating area. Be aware of the location of other

persons assisting you.

Should the winch vibrate or emit a noise during use, stop immediately and check to identify and solve the

problem.

DO NOT operate the winch if any parts are damaged or missing as this may cause failure and/or personal

injury.

DO NOT disconnect the electrical power supply during winching.

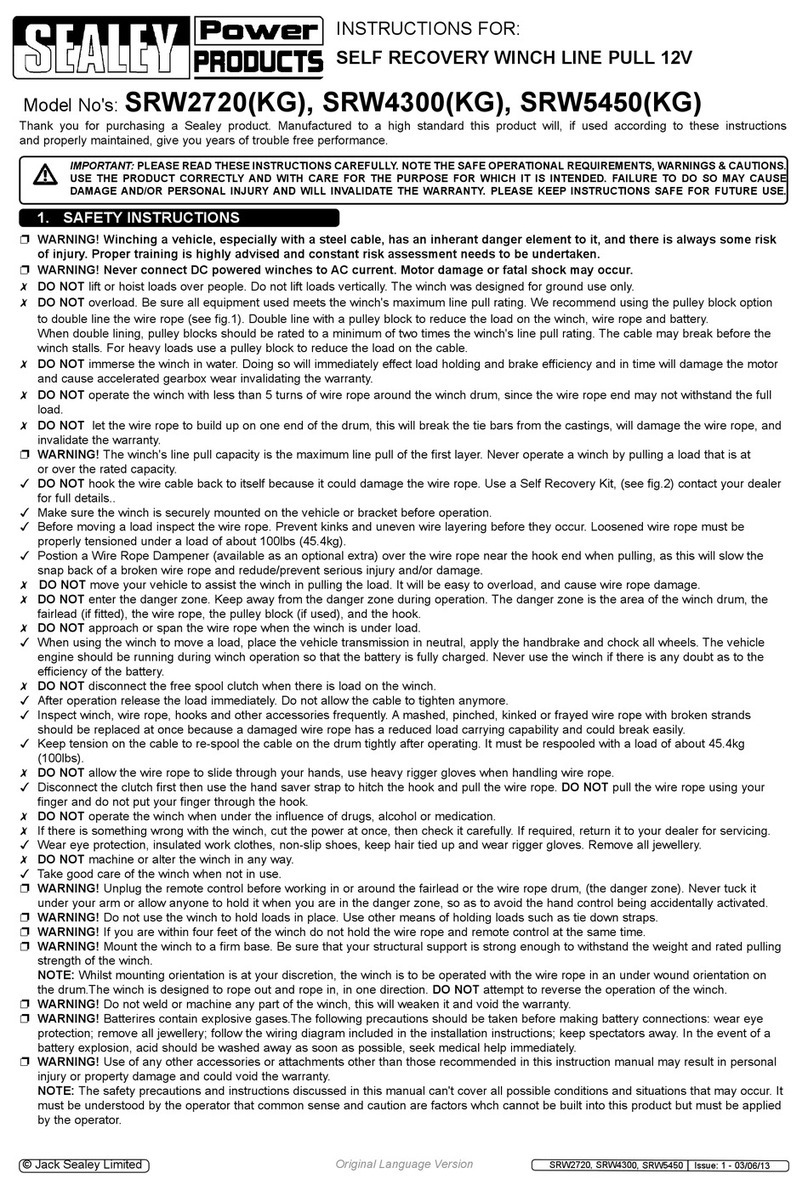

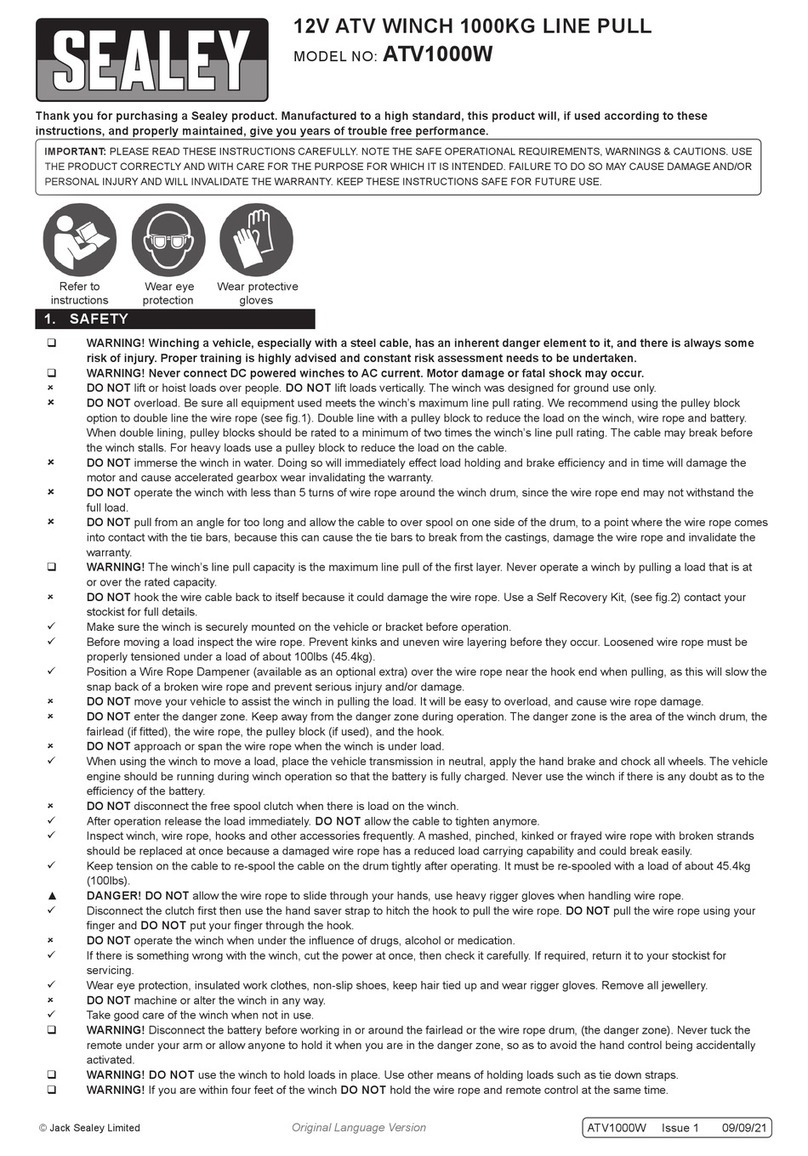

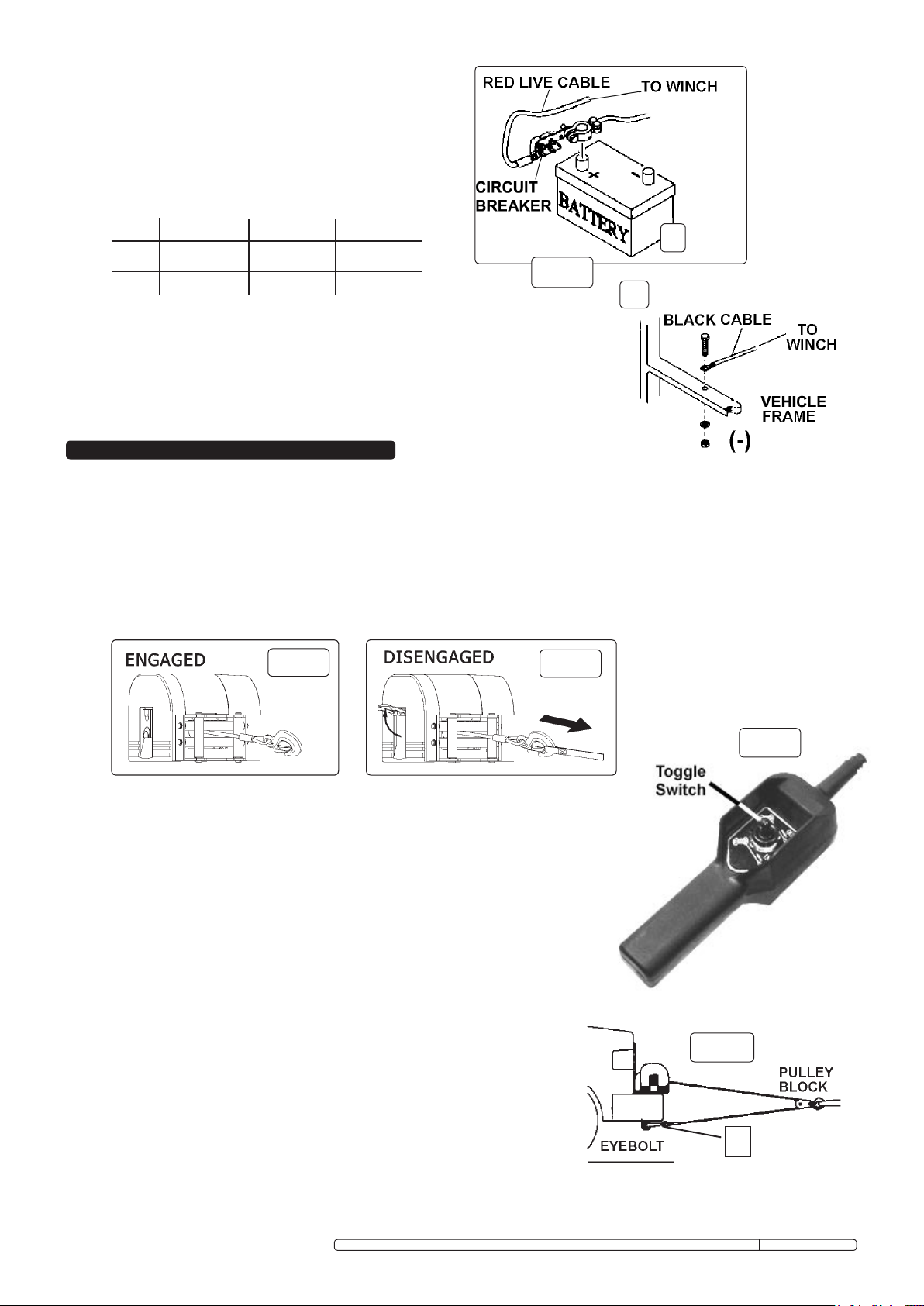

WARNING! DO NOT use winch as a lifting device of any type (fig B). DO NOT use the winch for any

purpose other than that for which it is designed.

WARNING! DO NOT exceed the rated pulling capacity of the winch.

DO NOT pull cable over or around a corner and DO NOT take hook around load and back onto cable.

Use appropriate sling or pulley if necessary.

DO NOT operate the winch with less than FIVE wraps of cable on the drum. The end of the

cable is red, do not use with any of the red cable off the drum.

DO NOT operate winch if you are tired, under the influence of alcohol, drugs or intoxicating

medication.

When not in use, place the clutch in engaged position. Disconnect winch from power supply and store remote control and

power cable in a safe, dry location.

Model No's: RW2500/12.V2, RW3500/12.V2, RW4500/12.V2,

RW2500/24.V2, RW3500/24.V2, RW4500/24.V2.

Fig B

Fig A

Original Language Version RW2500/12.V2, RW3500/12.V2, RW4500/12.V2, RW2500/24.V2, RW3500/24.V2, RW4500/24.V2 Issue: 9 - 22/04/10