Berger Lahr WS5-5 Series Instruction Manual

Power Drive

WS5-5

Doc.no. 211.347/DGB 08.02

Ident–No. 00441108390

Edition:b023 08.02

BERGERLAHRGmbH&Co.KG

Breslauer Str. 7

Postfach 1180

D-77901 Lahr

Sender

Name:

Company / Dept.:

Address:

Phone:

Suggestions and/or Corrections

Suggestions

Corrections

WS5-5

Power Drive

Issue:b023 08.02

Doc.no. 211.347/DGB08.02

If you have found any faults within this documentati-

on, or have any suggestions, we cordially invite you

to inform us on this form.

Safety requirements

Please read the following safety requirements prior to installation, operation, maintenance and repair

of the device.

•The intended use of the device is described in this manual in chapter "Purpose" and must be

observed.

•Installation, maintenance and repair of the device shall be performed by a qualified electrician.

National regulations concerning

– accident prevention

– installation of electrical and mechanical systems

– radio interference suppression

shall be observed.

•The technical data of the device, particularly the ambient conditions, shall be observed.

•The device shall only be operated by trained personnel.

BERGER LAHR offers training courses.

•The warranty is invalidated in case of unauthorized modification or opening of the device.

•Please ask your BERGER LAHR technical consultant prior to installing accessories not listed

in the chapter "Description of accessories".

The address is to be found on the rear cover.

•The safety symbols and notes on the device and in the manual shall be observed.

Explanation of symbols

ATTENTION

Reference to a danger for the device or components, possibly resulting

in the endangering of human life.

DANGER

Reference to a direct endangering of human life.

DANGER

High voltage at component, do not touch.

DANGER

High temperature at component, do not touch.

ATTENTION

Warning against electrostatic discharge (ESD).

Only touch the PC-board or component in an electrostatically-protected

environment.

NOTE

Important or additional information concerning the device or the manual.

1 General Description 1-1

1.1 Construction and characteristics 1-1

1.2 Application/system integration 1-2

1.3 Function 1-3

1.4 Technical data 1-4

1.4.1 Electrical data 1-4

1.4.1.1 Mains connection 1-4

1.4.1.2 Motor connection 1-4

1.4.1.3 Signal connection of signal interface 1 1-4

1.4.1.4 Signal connection of signal interface 2 1-4

1.4.1.5 Equipment protection 1-4

1.4.2 Mechanical data 1-5

1.4.3 Ambient conditions 1-6

2 Installation 2-1

2.1 Parts specification 2-1

2.2 Accessories 2-2

2.3 Mounting 2-3

2.4 Cabling 2-3

2.4.1 General instructions 2-3

2.4.2 Connection of the motor 2-4

2.4.3 Adjustment of the equipment to mains voltage 2-5

2.4.4 Connecting of the mains cable 2-5

2.4.5 Connection of the signal cables 2-6

2.4.6 Wiring of the signal interfaces 2-7

2.4.7 Examples for application 2-9

2.4.7.1 Basic driving possibilities 2-9

2.4.7.2 Driving the WS5-5 via positioning unit from BERGER (WP111, WP311) 2-10

2.4.7.3 Driving of two WS5-5 via WP111 positioning unit from BERGER 2-11

2.4.7.4 Driving of two WS5-5 via WP311 positioning unit from BERGER 2-12

2.4.7.5 Driving via PLC IP267 from Siemens 2-13

2.4.7.6 Driving via PLC IP247 from Siemens 2-13

2.5 Initial operation 2-14

2.5.1 Checklist for initial operation 2-14

2.5.2 Basic settings 2-14

3 Operation 3-1

3.1 Signal description 3-1

3.1.1 Input signals 3-1

3.1.2 Output signals 3-3

3.2 Switching on 3-4

3.3 Operating facilities 3-4

3.4 Switching off 3-4

Table of Contents

WS5-5 Doc. no. 211.347/DGB 12.92

4 Errors / Faults 4-1

4.1 Status indicator 4-1

4.2 Troubleshooting table 4-2

4.3 Storage and shipping 4-3

5 Maintenance 5-1

6 Appendix 6-1

6.1 Description of accessories 6-1

6.1.1 Motor cable 6-3

6.1.2 Mains filter 6-3

6.1.3 Signal cable signal interface 1 6-3

6.1.4 Signal cable signal interface 2 6-4

6.3 Glossary of technical terms 6-5

7 Index 7-1

Table of Contents

WS5-5 Doc. no. 211.347/DGB 12.92

1 General Description

1.1 Construction and Characteristics

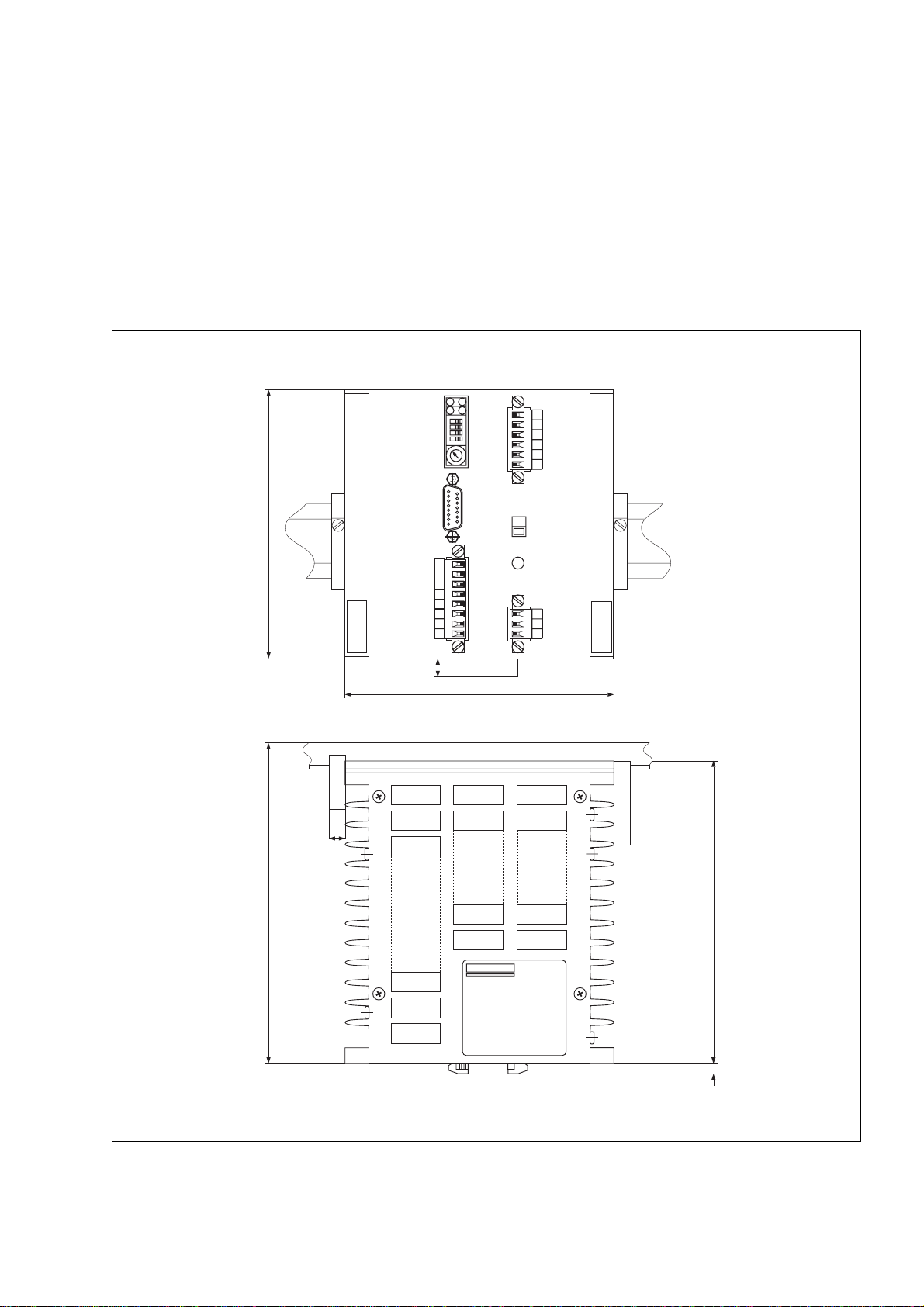

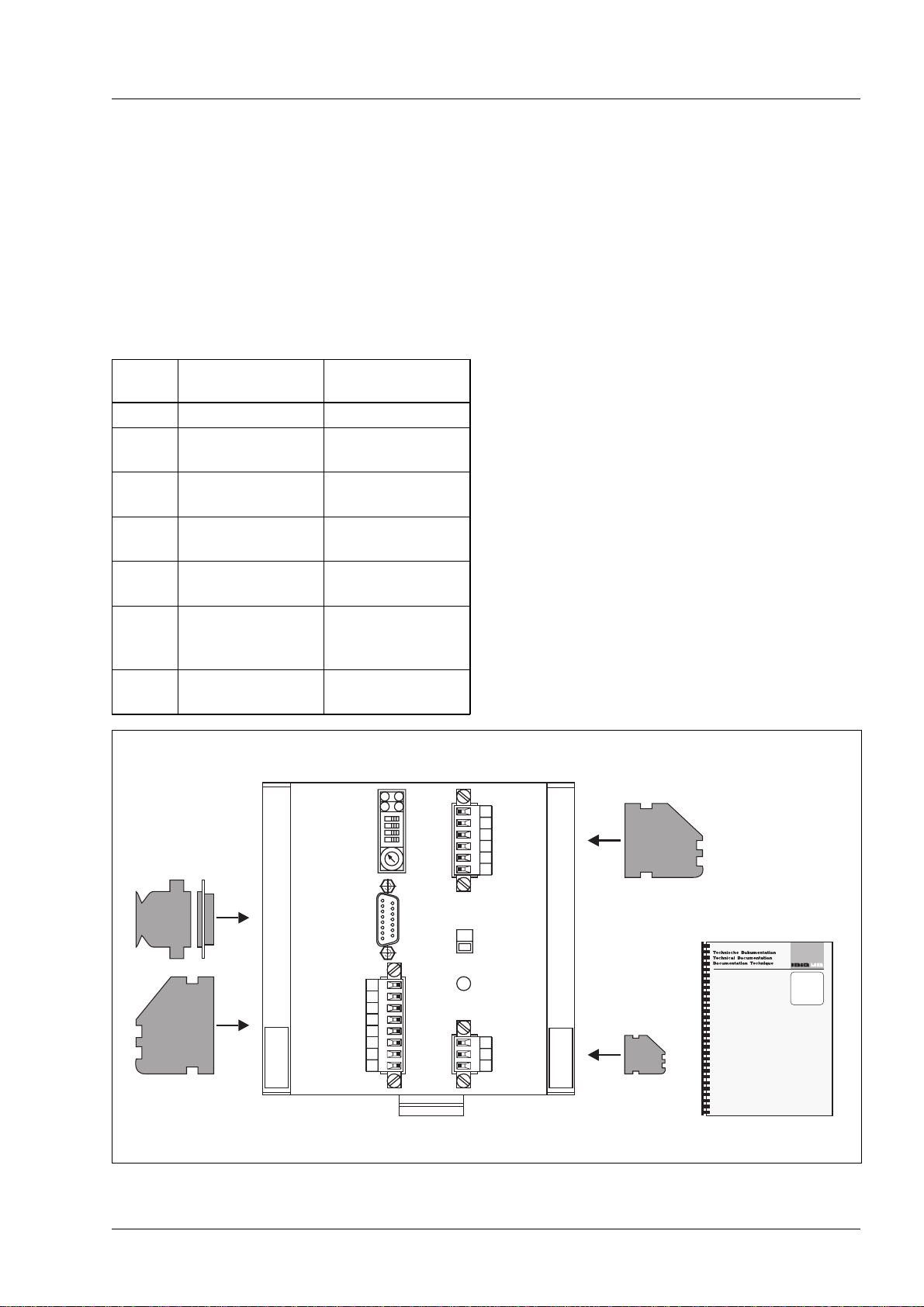

Construction

The power drive WS5-5 has the following compo-

nents (Figure 1-1):

•

Current selection switch

for selecting the motor

phasecurrent;

•

Parameter switch

for selecting the functions: cur-

rent zero-setting, boosting, current reduction, ro-

tation direction, step angle;

•

Voltage switch

between 115 V AC and

230 V AC;

•

LED display

for signalling of faults

•

Signal connection

for driving of the power unit

via signal interfaces 1 and 2;

•

Motor connection

for a 5-phase stepping motor;

•

Mains connection

for the power supply

(115 / 230 V AC);

•

Fasteners

at the back of the equipment for fixing

to mounting rails.

Characteristics

The power drive WS5-5 has been designed to be

fixed to a mounting rail, i.e.:

•the equipment can be fixed to a mounting rail

(TS 35 x 15) by means of the fasteners.

•all the operating controls, indicators and connec-

tions are located on the front panel of the equip-

ment.

NOTE

Because the WS5-5 is designed for an

IP 20 degree of protection, the equip-

ment must be incorporated in a switch

cabinet or in another enclosed housing.

230V

Status displays

Motorconnection

Parameterswitch

Currentselectorswitch

Voltageswitch

LEDPoweron

Signalinterface 1

Mains connection

Signalinterface 2

Mountingrail

Figure 1-1 Power drive WS5-5

General Description

WS5-5 Doc. no. 211.347/DGB 12.92 1 – 1

Other characteristics include:

•Operation with mains power supply;

•Short-circuit protection of the power stage when

there is shorting between motor phases;

•Drive via signal interface 1 (with RS 422 signal

levels) and/or signal via interface 2 (with PLC

levels)

•Undervoltage, Excessive temperature and

phase monitoring of the power stage.

1.2 Application/System Integration

The purpose of the WS5-5 drive is to drive a 5-

phase stepping motor up to a current of 2.8 A

(70 V DC). It is the link between a positioning con-

troller (e.g. WP-311) or an SPC unit with indexer

(e.g. IP 247, IP 267) and the stepping motor

(Figure 1-2).

Motor types

The power drives of the WS5 series are designed

for 5-phase stepping motors up to a maximum rated

current of 2.8 A per winding.

Up to 10 WS5-5 units can be operated in parallel

via the high- impedance inputs of signal interface 1.

The selection as to which WS5-5 is in operation

(gate function) is made by signal interface 2.

NOTE

The 5-phase stepping motors are oper-

ated in pentagram connection (see

page 2-4).

Controller

Control signals (PULSE, DIRECTION, PWM)

Selection (GATE)

5-phase stepping motor 5-phase stepping motor

max. 10

units

Power drive

WS5-5 Power drive

WS5-5

SM SM

55

Figure 1-2 System integration

General Discription

1 – 2 WS5-5 Doc. no. 211.347/DGB 12.92

1.3 Function

Figure 1-3 shows the most important function

blocks of the unit:

•From the mains voltage of 230 V AC or 115 V

AC the

intermediate circuit voltage

of 70 V DC is

generated in the power unit.

•The

chopper-type power

supply unit provides

the supply voltages for the internal modules.

•The

parameter switches

are used to make the

basic settings for phase current, current reduc-

tion, current zero- setting, boost, direction rota-

tion and step angle (see section 2.5).

•The

"control electronics - power stage - current

controller"

closed-loop circuit converts the

PULSE and DIRECTION input signals into the

output signals for driving the stepping motor.

The

control electronics

block contains the

ring

counter logic

which defines the current pattern.

The current controller keeps the phase current

constant at the preset value.

•The status of the equipment is recorded in the

Monitoring and Protection

block. Any possible

errors are signalled externally via the fault indica-

tor and via the READY signal output (see sec-

tions 3.1.2 and 4.1).

For more details about the meaning and function of

the various control signals, see section 3.1

115VAC

or

230VAC

~

Moni-

toring

115/230VAC

switching

Status

indicator

(LED)

Fault

indicator

(4LED´s)

Chopper-

type

power

supply

Mains power unit

Power unit

Power stage

Motor

70VDC

15VAC

15VAC

Control

electronics

(5-phase

logic)

Signal

interface1

(RS422)

Signal

interface2

(PLC)

Current

adjustment

Monitoringand

protection

External

control Current

controller

5

Figure 1-3 Function connection diagram of WS5-5

General Description

WS5-5 Doc. no. 211.347/DGB 12.92 1 – 3

1.4 Technical Data

1.4.1 Electrical data

1.4.1.1 Mains connection

Mains connection voltage,

switchable to: 115 V AC, -20% +15%

230 V AC, -20% +15%

Current at make 30 A

Fuse 6.3 A slow-blow

Frequency 50-60 Hz

Power consumption max. 600 VA

Power dissipation max. 80 W

1.4.1.2 Motor connection

Protected in case of short-circuit between motor

phases

Max. cable length 50 m

Cable diameter 0.75 mm2for cable length ≤30 m

1.5 mm2for cable length >30 m

Screen connection both sides

Motor voltage 70 V DC

Phase current in 16 stages from 0.55 to 2.8 A

Connection system pentagram

1.4.1.3 Signal connection of signal interface 1

Signal levels of the inputs correspond to the RS

422 interface; there is no electrical separation of

the inputs and outputs from the motor voltage. The

earth (GND) is connected internally to the protec-

tive conductor.

Inputs:

•Low-level -0.1 V to -30 V

•High-level 0.1 V to 30 V

READY output: Open Collector (npn)

UCEsat <1.2 V

Imax 10 mA

short-circuit proof up to 6 V DC

Pin 6 and 14 (+,- READY) are connected in parallel

with signal interface 2.

1.4.1.4 Signal connection of signal interface 2

Signal levels are designed for driving by PLC

standard signals; there is no electrical separation

of the inputs and outputs from the motor voltage.

The earth (GND) is connected internally to the

protective conductor.

Inputs:

Active high-logic inputs connected with pull-down re-

sistor

RPull Down 4.7 kΩ; ±10%

Input voltage

Low-level 0 V to 3 V

High-level 13 V to 30 V

Outputs:

Plus-switching final control elements

Voltage supply 24 V

Ext. voltage (to GND) -30 V to +30 V

Ext. voltage for operation min. 15 V to max. 30 V

Load current 0.4 mA to 25 mA

Residual voltage for 25 mA max. 3 V

Leakage current max. 0.2 mA

Switching frequency max. 8 Hz

Short-circuit protected

1.4.1.5 Equipment protection

Type of protection IP 20 as per

DIN 40050 / IEC 529

Protection class 1

Protection circuits:

Power unit/power stage overvoltage-proof as

per VDE 0160 Cl.2

Short-circuit monitoring;

Excessive temperature recognition;

Monitoring of undervoltage and

motor phase interruption

General Discription

1 – 4 WS5-5 Doc. no. 211.347/DGB 12.92

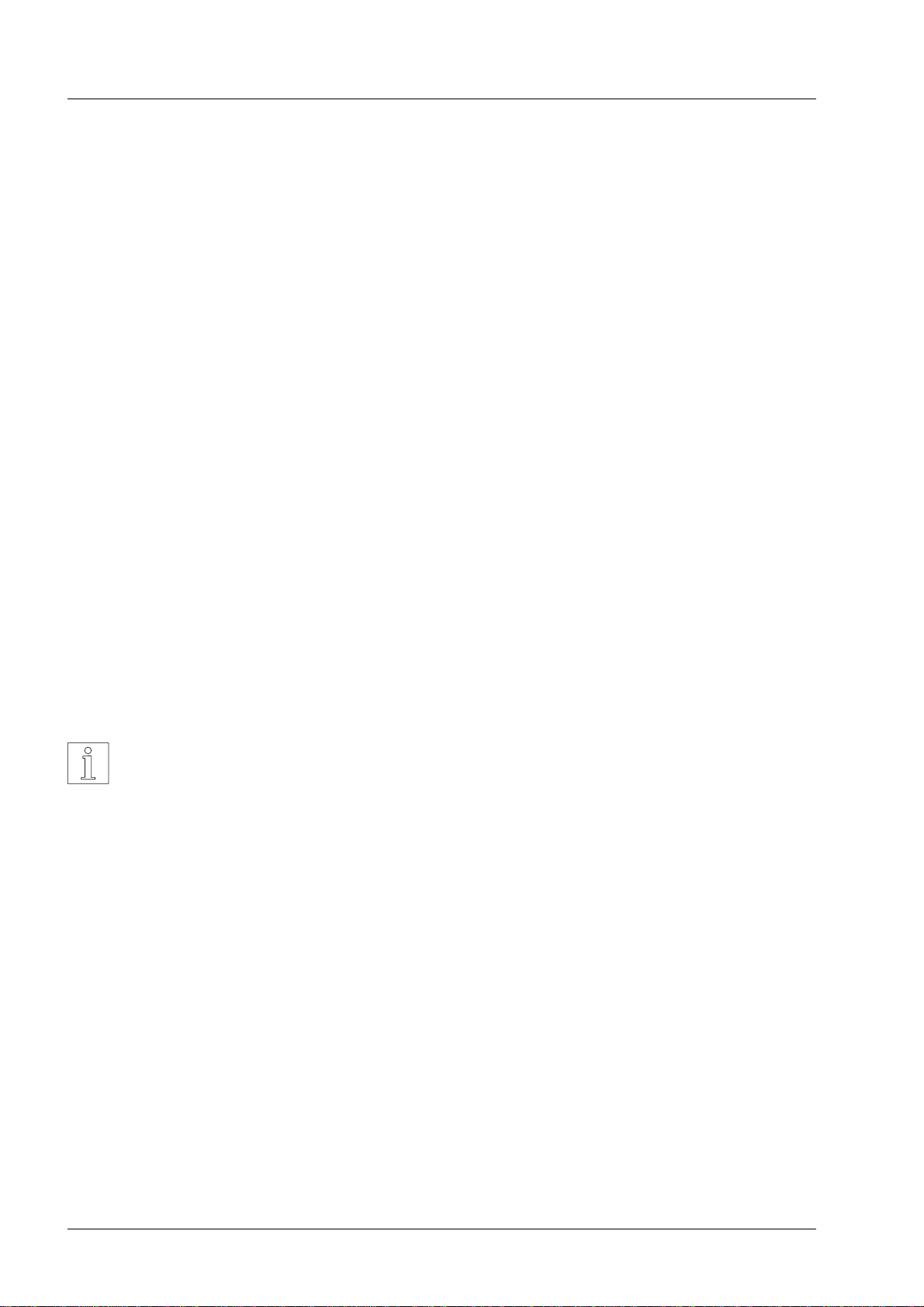

1.4.2 Mechanical data

Dimensions (L x W x H) 135 x 135 x 157 mm

Weight 2.8 kg

230V

135

135

9,5

7,5

157

10

166,5

Figure 1-4 Dimensions of the equipment

General Description

WS5-5 Doc. no. 211.347/DGB 12.92 1 – 5

1.4.3 Ambient conditions

Ambient temperature:

Working 0°C to 50°C

Storage/transportation -25°C to 70°C

Change in ambient temperature:

Working max. 10 K/h

Storage/transportation max. 20 K/h

Humidity class - components F as per DIN 40040

Humidity class tested according to IEC 68 part 2-3

at:

•air temperature +40°C, +2°C

•relative air humidity 93%; +2%-3%

Radio shielding with external filter as

per VDE 0871-A

Overvoltage stability as per VDE 0160

Resistance to interference as per

VDE 0843 / IEC 801

Dew formation not permitted

NOTE

When the WS5-5 is mounted in a

switch cabinet, it must be remembered

that the power loss which can be

removed depends on the design of the

cabinet, its ambient temperature and

the arrangement of the equipment.

See section 2.3

General Discription

1 – 6 WS5-5 Doc. no. 211.347/DGB 12.92

2 Installation

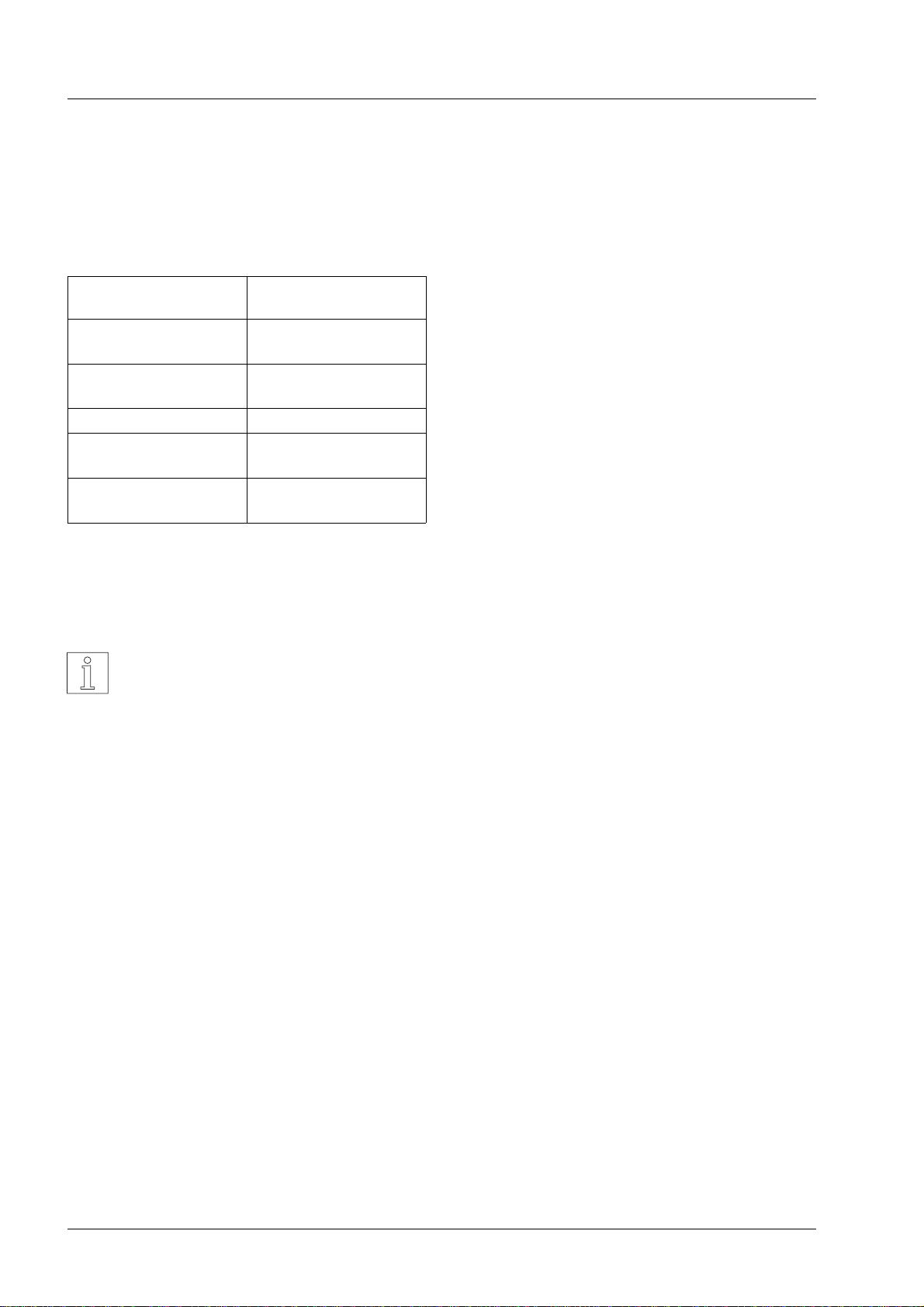

2.1 Parts Specification

The specification must be checked for complete-

ness.

The specification includes (Figure 2-1) comprises:

Q’ty Description Order number

1 WS5-5.281-00 64652810006

1 Plug shell Mains

connection 98050060642

1 Plug shell Motor

connection 98050060600

1 Plug shell for

signal interface 2 98050060642

1 Sub-D socket

(15 pole) 98050060558

1 Housing for

Sub-D socket

(15 pole)

98050060298

1 WS5-5 Technical

documentation Doc. no.

211.347/DGB

230V

WS5-5

Figure 2-1 Parts specification

Installation

WS5-5 Doc. no. 211.347/DGB 03.96 2 – 1

2.2 Accessories

The following accessories can be supplied by

special order:

Description Order number

Signal cable for signal

interface 1 see Appendix

Signal cable for signal

interface 2 see Appendix

Motor cable see Appendix

Stepping motor see catalogue

Doc. no. 350

End bracket EW 35 038356 from Fa.

Weidmüller

The signal cables for signal interface 1 have con-

nectors at both ends and have a length of 1.5 m.

NOTE

For a description of the accessories,

see Appendix 6.2

Installation

2 – 2 WS5-5 Doc. no. 211.347/DGB 03.96

2.3 Mounting

CAUTION

The WS5-5 must be housed in a

switch cabinet so as to ensure resist-

ance to interference and prevent the

equipment from being contaminated.

Make sure that there are adequate pro-

visions for the dissipation of heat!

The equipment is fitted to a supporting rail on the

mounting wall by means of the fasteners at the

back of the equipment and is secured at the sides

by the end brackets. The minimum clearance be-

tween several WS5 units or from other pieces of

equipment must be 10 cm. The outer surfaces of

the equipment act as a heat sink to remove the

heat. The maximum power dissipation of the equip-

ment is 80 W.

2.4 Cabling

2.4.1 General instructions

All the electrical connections will be made by multi-

pole plug connections on the front panel of the

equipment (Figure 2-3). Ready-made cables are

available as accessories (see section 2.2).

DANGER

•Switch off mains voltage before con-

necting cables!

•The power connections (motor,

mains) should be carried out only by

qualified electrical engineers in ac-

cordance with VDE 0105!

CAUTION

•Make sure that the cables are

screened and fitted with strain-relief

clamps!

•Twist every pair of signalling cables

before connecting them!

•Lay mains, motor and signal cables

so that there is a space between

them!

230V

Motor

connection

Mains

connection

Signal

interface1

Signal

interface2

Figure 2-3 Overview of connections

T

am

=ambienttemperature

I

phase

=phasecurrent

T

am

[˚C]

Forcedcooling≥1m/s

Convectioncooling

I

phase

[A]

50

25

1,6 2,8

Figure 2-2 Cooling

Installation

WS5-5 Doc. no. 211.347/DGB 03.96 2 – 3

2.4.2 Connection of the motor

1. Prepare the 5 wires of the motor cable and the

screen which are to be connected to the plug

end with boot lace ferrules.

2. Insert the 6 wires into cap of the mating plug as

shown in Figure 2-4 and tighten the screws.

3. Join the two plug shell halves together.

4. Set the plug to connection 09 and tighten screws.

CAUTION

•To minimise the losses in the cable

and the power drive, it is advisable

to have as short a cable route as

possible.

•The maximum length of the motor

cable is 50 m.

•For cable diameter, see technical

data.

DANGER

The locking mechanism of the motor

plug may only be opened when the

mains voltage has been disconnected.

Circuitry of the motor

The circuitry of the motor uses a pentagram connec-

tion, see Figure 2-5.

NOTE

In the pentagram circuit twice the

phase current flows in the motor con-

necting wires.

A1

A2

A3

A4

A5

A6

Phase1

Phase2

Phase3

Phase4

Phase5

Screen(PE)

yellow

blue

orange

grey

brown

09

Figure 2-4 Motor connection

W4

W4

W5

W5

W1

W1

W3

W3

W2

W2

5

4

3

2

1

6

BN

GY

OG

BU

YE

BU

BU

RD

RD

OG

OG

GN

GN

GY

GY

BK

BK

BN

BN

VI

VI

YE

YE

WH

WH

.

.

.

.

.

WH

YE

VI

BN

BK

GY

GN

OG

RD

BU

=

=

=

=

=

=

=

=

=

=

white

yellow

violet

brown

black

grey

green

orange

red

blue

0

3

2

1

45678

9

Figure 2-5 Circuitry of the motor

Installation

2 – 4 WS5-5 Doc. no. 211.347/DGB 03.96

2.4.3 Adjustment of the equipment to mains

voltage

The equipment can be adjusted to mains voltages

115 V AC or 230 V AC.

1. Disconnect mains voltage to the WS5-5.

2. Using a screw driver, for example, turn voltage

switch 10 into the desired position:

switch at top: 115 V AC

switch at bottom: 230 V AC.

The position which has been set is indicated on the

switch.

CAUTION

The mains voltage must always be

turned off before any alteration is

made to the position of the voltage

switch.

2.4.4 Connecting of the mains cable

1. Prepare the wires of the mains by fitting boot lace

ferrules at the plug end.

2. Insert the 3 wires into mating plug terminal block

as shown in Figure 2-7 and tighten screws.

3. Join the plug shell halves together.

4. Set the plug to connection 12 and tighten screws.

DANGER

Make sure that the mains voltage is

disconnected before loosening the

mains cable!

230V

10

11

VoltageSwitch

LEDLineOn

Figure 2-6 Adjustment of the mains voltage

L

N

Mains

Protectiveconductor

(PE)

12

Figure 2-7 Mains connection

Installation

WS5-5 Doc. no. 211.347/DGB 03.96 2 – 5

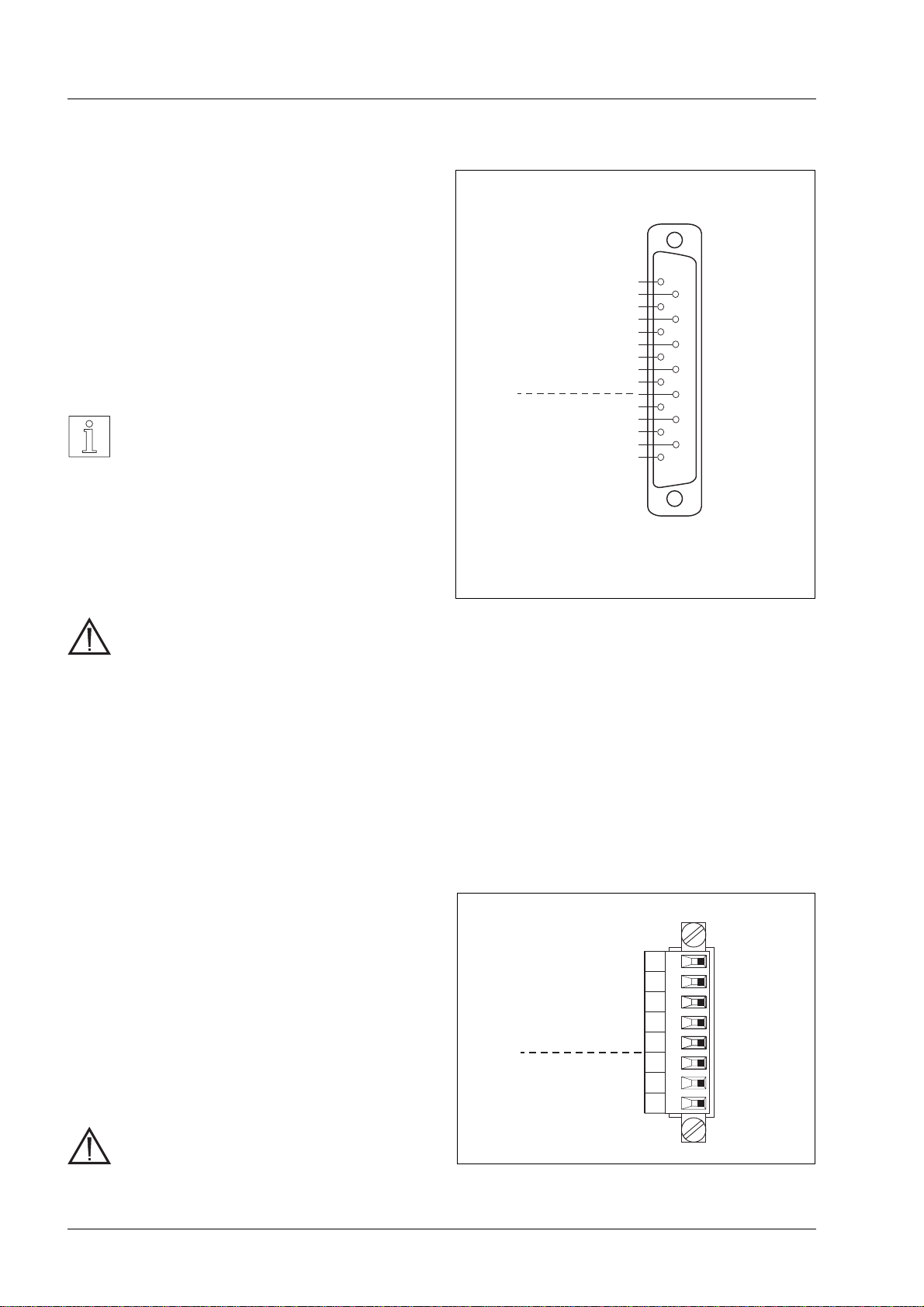

2.4.5 Connection of the signal cables

Signal cable of signal interface 1

1. Twist the wires of the signal cable for signal

interface 1 in pairs and solder to the terminals of

the 15-pole sub-D socket connector strip as

shown in Figure 2-8.

2. Insert cable underneath the strain relief clamp

and secure. Connect screen to earth (GND) on

control side.

NOTE

When using a push-pull drive, it may

be useful to connect the screen to the

plug shell on both ends of the cable.

3. Fit socket shell.

4. Plug socket to socket connector strip 07, and

screw tight.

CAUTION

•For maximum cable length to signal

interface 1, see standard for RS 422

interfaces.

•All signal connections must be safely

isolated from the mains.

•The earth (GND) of signal interfaces

1 and 2 is connected internally to the

protective conductor.

•It is not permitted to apply a voltage

between earth (GND) and protective

conductor in order to avoid damage.

Signal cable of signal interface 2

1. Prepare the 8 wires of the signal cable for signal

interface 2 and fit to plug with boot lace ferrules.

2. Insert the wires into mating plug terminal block as

shown in Figure 2-9 and screw tight.

3. Join the plug shell halves together.

4. Fit plug to terminal 08 and screw tight.

CAUTION

•Maximum length of signal cable:

50 m.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

PULSE

PULSE

DIRECTION

DIRECTION

ENABLE

ENABLE

PWM/BOOST

PWM/BOOST

GND

READY

READY

GND

READY*

+

-

+

-

+

-

+

-

+

-

07

OPENCOLLECTORoutput(npn)

I

max

=10mA

U

CEsat

≤1.2V

(short-circuit-proofupto6V)

*

InputsOutputs

Figure 2-8 Connector pin assignment for signal

interface 1

8

7

6

5

4

3

2

1

GND

READY

READY

ZEROPHASE

ZEROPHASE

PWM/BOOST

GATE

ENABLE

-

+

-

+

08

OutputsInputs

Figure 2-9 Connector pin assignment for signal

interface 2

Installation

2 – 6 WS5-5 Doc. no. 211.347/DGB 03.96

2.4.6 Wiring of the signal interfaces

The WS5-5 is activated by an external controller via

signal interface 1 and/or 2.

The two interfaces differ with respect to their pin as-

signments (see Figures 2-8 and 2-9) and the inter-

nal input connections with the signal levels (see

Figures 2-10 and 2- 12).

Signal interface 1

The input signal level of signal interface 1 corre-

sponds to the RS 422 standard value (see section

1.4.1.3). The drive may be achieved, for example,

by a Siemens PLC IP 247 or IP 267 stored-program

controller.

NOTE

Because of the high-impedance

RS 422 interface inputs, up to 10 units

can be connected in parallel on the

input side.

CAUTION

If an input of the RS 422 interface is

not used, the +input of the appropriate

signal can be connected to earth

(GND) in order to ensure resistance to

interference.

NOTE

The inputs of the RS 422 interface

may also be driven via open-collector

outputs; for the possible connections,

see Figure 2-11. The resistance to in-

terference depends on the respective

circuit configuration; the line length as

specified in the RS 422 standard is not

usually reached.

Signal+

Signal-

Signal+*

Signal-*

Signal-*

Signal+*

Signal-

Signal+

GND

R**

R**

R**

R**

GND

GND

GND

Plusswitching

non-inverting

Plusswitching

inverting

Minusswitching

non-inverting

Minusswitching

inverting

10-30V

10-30V

10-30V

10-30V

Becauseofinternalwiring,openinputsassumealevelof5V.

R=2.4kΩfor24Vsupplyvoltage

*

**

Installation

WS5-5 Doc. no. 211.347/DGB 03.96 2 – 7

++

+

U

S

U 33V

I

L

=10mA

100Ω

1, 2, 3, 4

9, 10, 11, 12

8

15

+ 5 V

U

S high

=0,1Và30V

U

S low

=-0,1Và-30V

R

i

≥10kΩ

Inputs

Outputs

Figure 2-10 Internal wiring of signal interface 1

Signal interface 2

The input level of signal interface 2 corresponds to

the PLC standard. The drive may be provided by

any commercial PLC.

NOTE

The outputs +READY (pin 6) and

-READY (pin 14) of signal interface 1

are connected in parallel to +READY

(pin 6) and -READY (pin 7) of inter-

face 2.

+

U

S

+

U33V 2kΩ

1, 2, 3

4, 6

5, 7

8

U

S low

=0Vto3V

U

S high

=13Vto0V

R

i

≥4,7kΩ

I

L

=0,4mAto25mA

Inputs

Outputs

Figure 2-12 Internal wiring of signal interface 2

Installation

2 – 8 WS5-5 Doc. no. 211.347/DGB 03.96

This manual suits for next models

2

Table of contents

Popular DC Drive manuals by other brands

Nord Drivesystems

Nord Drivesystems SK 180E Series manual

SEW-Eurodrive

SEW-Eurodrive MOVIMOT MM D Series operating instructions

Aerotech

Aerotech MPS50SV Hardware manual

SEW-Eurodrive

SEW-Eurodrive MOVITRAC LTP-B operating instructions

BMG

BMG CRUSADER ONE 72H-033 instruction manual

AVL

AVL Compu-Dobby 5 quick reference

ABB

ABB ACS880 Series Supplement

KB Electronics

KB Electronics Penta Power KBRG-255 Installation and operating instructions

Danfoss

Danfoss MCB 113 operating guide

Toshiba

Toshiba Tosvert VF-A5 instruction manual

BeiJer

BeiJer BFI-H3 Start-up

Rockwell Automation

Rockwell Automation PowerFlex 755TM Original instructions