Bergstrom Dual Zone Front HVAC User manual

2390 Blackhawk Road ●P.O. Box 6007 ●Rockford, IL 61125 ●www.bergstrom.com ●1-866-204-8570

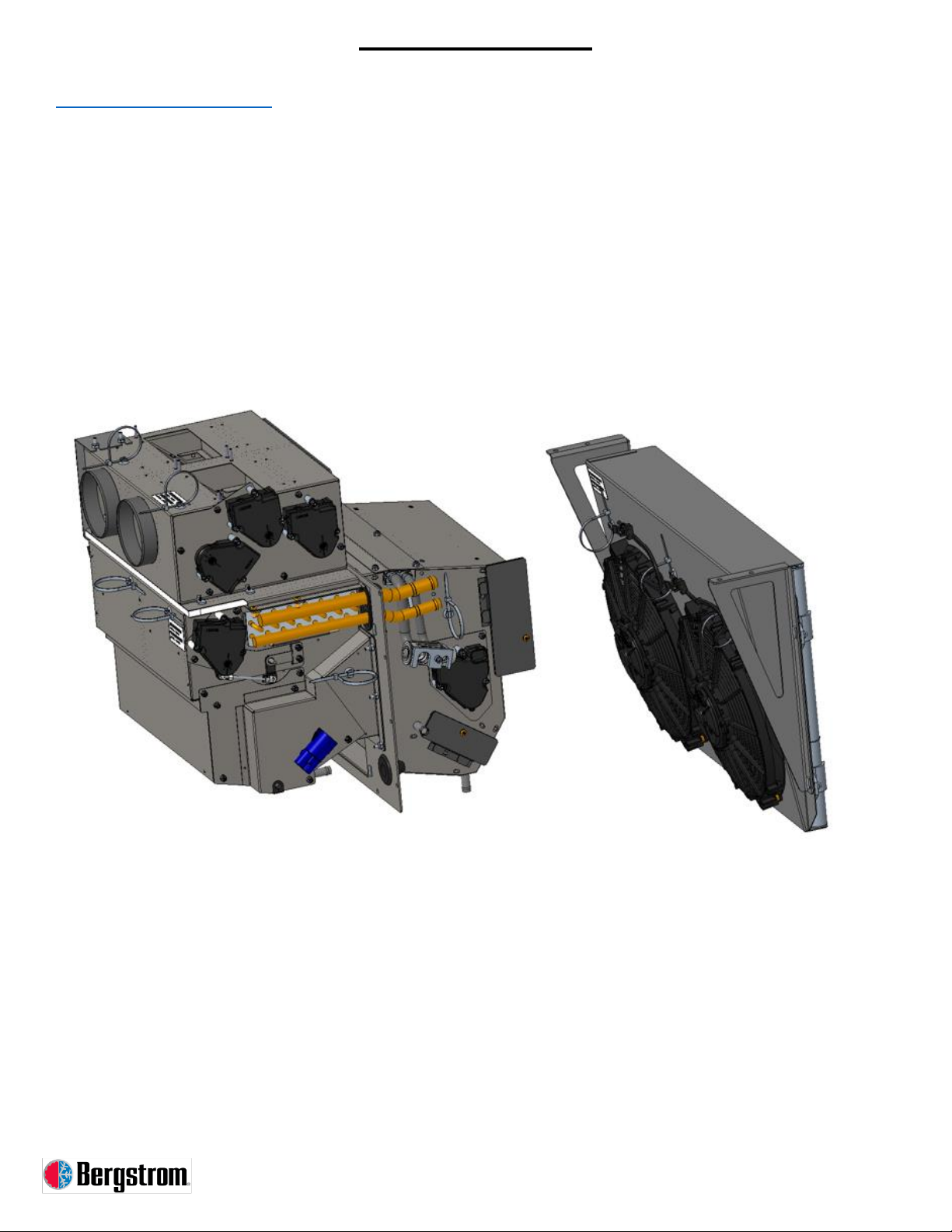

Recreational Vehicle

Dual Zone Front HVAC

Service Manual

Updated: 9/6/2023

Note (Not applicable for hard copies):

1. Phrases in blue are “hyperlinks” that allow user to jump directly to the respective section. Hold

“ctrl” and click the link to use.

2. All section titles are “hyperlinks” allowing the user to jump back to the top of the document.

2

Table of Contents

Page

Service

•Contact Information 5

•Request for Technical Support, Questionnaire 6

•Comments 7

Electrical Systems

•Electrical Schematics 8

•Diagnostic Guide 9

Air Flow Systems

•Basic Description 11

•Main HVAC System Components 12

Component Servicing

•Outdoor HVAC Unit 14

•Indoor HVAC Unit 15

•Freeze Probe 16

•Fresh and Recirculation Air Filters 17

•Actuator(s) 18

•Evaporator Coil 19

•Heater Core 20

•Blower Assembly 21

•Condenser Fan 22

•Condenser Coil 23

•Thermostatic Expansion Valve (TXV) 24

•Other Serviceable Components 25

3

Table of Contents

Air Conditioning System

•Diagnostic Guide 29

•A/C System Operation Check 31

•Expected A/C Performance 32

•Compressor Function Test 33

•Thermostatic Expansion Valve (TXV) Function Test 34

•Refrigerant Charge Information 35

•Service Tips 35

•R134a Temperature/Pressure Chart 36

Dual Zone Front HVAC Owner’s Manual

•Control Panel Operation 38

•Air Distribution 39

•Operating Features 40

•Warranty/Service 41

4

Service

Disclaimer:

WARNING!!

The technical information, provided in this service guide, is intended for use by

properly trained HVAC service personnel, who can ensure a safe and properly

operating system. It is assumed that the user of this guide is trained and experienced

in basic refrigeration principles, in addition to being familiar with Bergstrom HVAC

systems installed on Recreational Vehicles. Technicians who repair or service motor

vehicle A/C systems must be certified by Section 609 (MACS) approved by the EPA.

Before any air conditioning service is started, it is the technician's responsibility to

determine what type of refrigerant is contained in the system. Component marking

and/or service port peculiarities are good places to start to identify the contents.

Bergstrom advises that the usual precautions associated, with servicing a motor

vehicle, be exercised when servicing the HVAC system and assumes no liability

regarding vehicle damage or personal injury. Additionally, Federal and any Local

regulations regarding the handling and use of refrigerants should be always complied

with.

NOTES:

TECHNICAL SUPPORT IS PROVIDED TO CERTIFIED TECHNICIANS ONLY.

BERSTROM DOESN’T SUPPLY TECHNICAL SUPPORT TO RV OWNERS.

THE AIR CONDITIONING SYSTEM CONTAINS REFRIGERANT R134A, UNDER

HIGH PRESSURE, AND SHOULD BE SERVICED BY ONLY QUALIFIED

PERSONNEL.

REPAIRS THAT ALTER THE DESIGN OF THE BERGSTROM SYSTEM, INCLUDING

USE OF NON-BERGSTROM SUPPLIED PARTS, WILL VOID THE WARRANTY AND

ANY BERGSTROM LIABILITY FOR THE HVAC SYSTEM.

THE BERGSTROM HVAC SYSTEM SHOULD BE SERVICED BY A FULLY TRAINED

AND ENVIRONMENTALLY LICENSED TECHNICIAN. FAILURE TO AGREE TO ALL

STATEMENTS COULD RESULT IN SERIOUS INJURIES, FINES AND POSSIBLE

VOIDING OF ANY WARRANTIES.

6

Service

Request for Technical Support Questionnaire

Open the front service door of the coach and verify if you are servicing a

Bergstrom HVAC system by checking the base unit mounted on the front firewall.

Verify customer complaint by operating the vehicle. (Print this page for reference).

DESCRIPTION OF COMPLAINT:

DEALER:

CONTACT/TECH: PHONE #:

CHASSIS: MODEL YR: MODEL:

COACH MANUFACTURER:

CONDENSER TYPE & LOCATION

PRESSURE GAUGE READINGS:

LOW PSIG @ 1500 RPM, HIGH BLOWER SPEED

HIGH PSIG @ 1500 RPM, HIGH BLOWER SPEED

R134A REFRIGERANT CHARGE WEIGHT:

POUNDS

AIR TEMPERATURE & HUMIDITY READINGS:

HUMIDITY LEVEL: %RH

RECIRCULATION INLET AIR TEMPERATURE: ⁰F

DISCHARGE AIR TEMPERATURE (VENT CLOSEST TO BASE UNIT): ⁰F

SUBTRACT THE TWO AIR TEMPERATURES = ⁰F

DIFFERENTIAL

9

Electrical Systems

Diagnostics Guide

Problem

Possible Cause

Corrective Action

Control Panel is not

functional

1. Vehicle ignition switch

isn’t activated.

2. Loss of power supply.

3. Open circuit between

vehicle connection and

control panel.

4. Loose or wrong

connection(s) at the

control panel.

5. Failed control panel.

1. Activate vehicle ignition switch.

2. Examine the chassis’ HVAC

circuit’s protection device for

failure (i.e. fuse or circuit breaker).

3. Check primary connections at

vehicle connection and the control

panel. Verify vehicle voltage at

each connection. Verify ground

connection. Repair or replace

harness if necessary.

4. Ensure all connections are mated

properly. Ensure the harness is

pinned properly in the connector

using the wiring diagram.

5. Replace control panel.

Discharge and/or inlet air

systems are not functioning

properly.

1. Open circuit between

control panel and ECU.

Open circuit between

ECU and actuator.

2. Faulty shutter actuator.

3. Faulty control panel.

4. Faulty ECU.

1. Verify vehicle voltage and ground

at actuator. Perform continuity

test of CAN high and low between

control panel and ECU. Perform

continuity test of actuator signal

between ECU and actuator.

Repair or replace harness if

necessary.

2. Replace the actuator if needed.

Refer to ACTUATOR(S)

3. Replace the control panel if

needed.

4. Replace ECU if necessary.

Blower does not operate at

any speed

1. Open circuit in harness

between the vehicle

connection and blower

connection.

2. Open circuit between

ECU and blower

connection.

3. Faulty ECU

1. Verify vehicle voltage and ground

at vehicle connection and blower

connection. Perform continuity

test between connections. Repair

or replace harness if necessary.

2. Perform continuity test between

ECU and blower connection for

blower speed control. Repair or

replace harness if necessary.

3. Rotate the blower control between

LOW and HIGH speed. Verify

voltage change when speed is

adjusted. Replace ECU if

necessary.

10

Electrical Systems

Problem

Possible Cause

Corrective Action

A/C Clutch does not operate

1. Blower switch is not

activated.

1. Blower must be ON for A/C clutch

to operate.

A/C Clutch does not operate.

Blower is operating properly

1. A/C switch is not

activated.

2. Open circuit between

control head and ECU.

3. Defective A/C freeze

probe.

4. Faulty A/C clutch.

1. Verify A/C switch is depressed

and illuminating correctly.

Replace control panel if

necessary.

2. Perform continuity test of CAN

high and low between control

panel and ECU. Repair or replace

harness if necessary.

3. Perform continuity check for

freeze probe power and ground

between probe and ECU. Replace

harness if no continuity. Replace

probe otherwise.

4. With the engine OFF apply a

separate 12V+ supply directly to

clutch terminals and listen for

clutch engagement. Replace

clutch if there is no engagement.

11

Air Flow Systems

Basic Description

The Bergstrom Dual Zone HVAC System for Jayco consists of four HVAC modules

designed to provide air that has been conditioned to the occupants of the vehicle

cockpit. The driver zone and passenger zone of the panel mode outlets can be

controlled independently for air temperature and blower speed. Two of the HVAC

modules are mounted under the dash, and two under the vehicle hood. The

serviceable components are located within these modules.

13

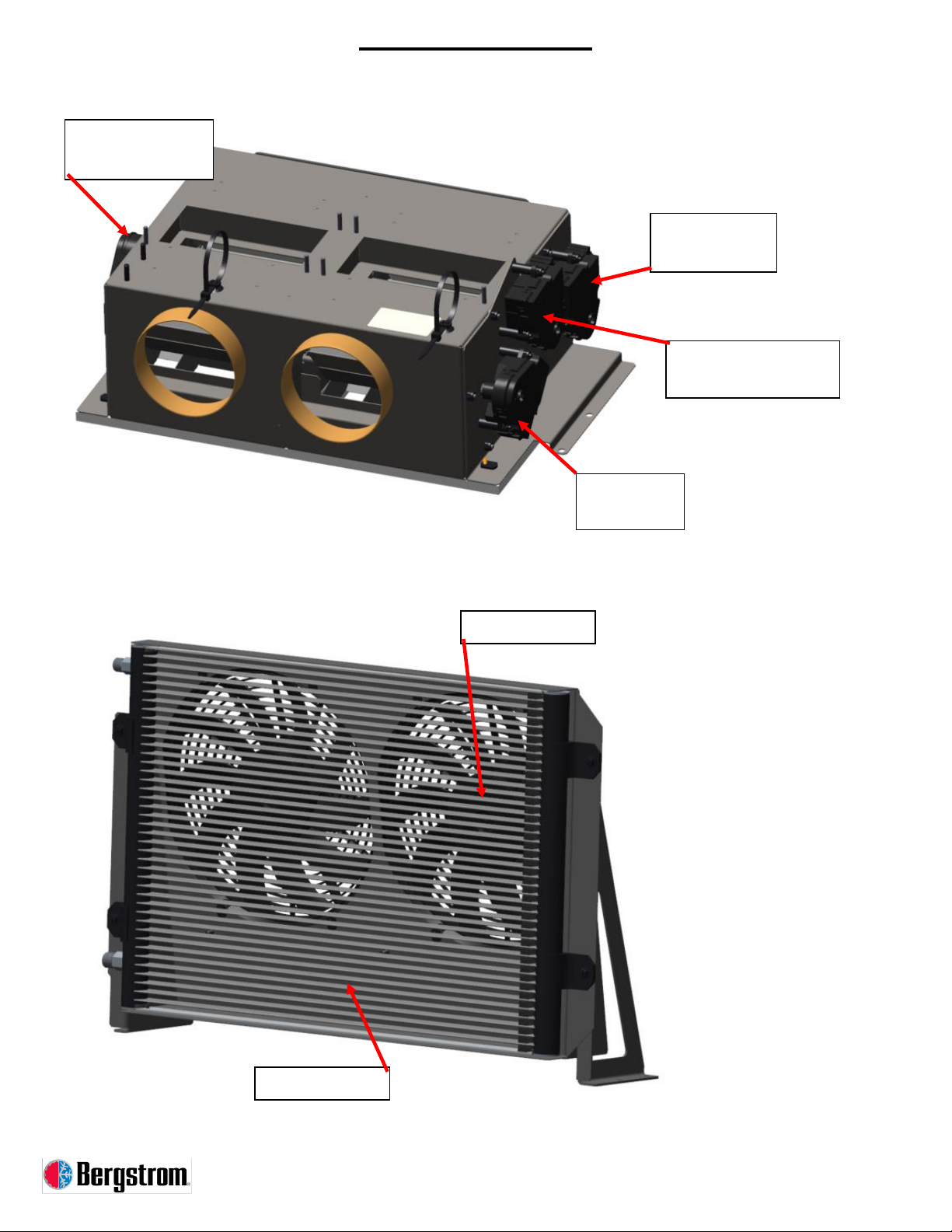

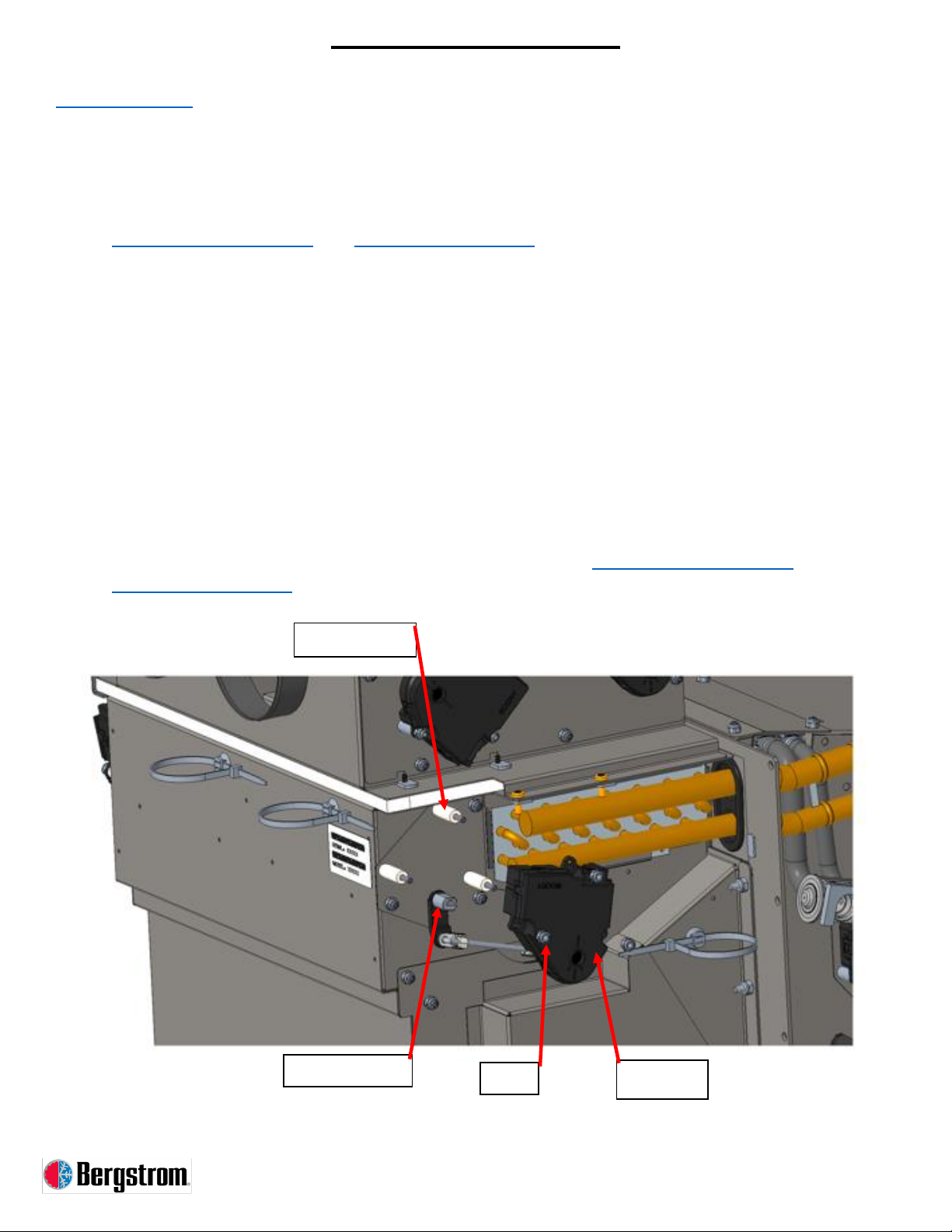

Air Flow Systems

Mode Box

Condenser Assembly

Driver Zone Panel

Mode Actuator

Passenger Zone

Panel Mode Actuator

Defrost Mode

Actuator

Floor Mode

Actuator

Condenser Coil

Condenser Fan

14

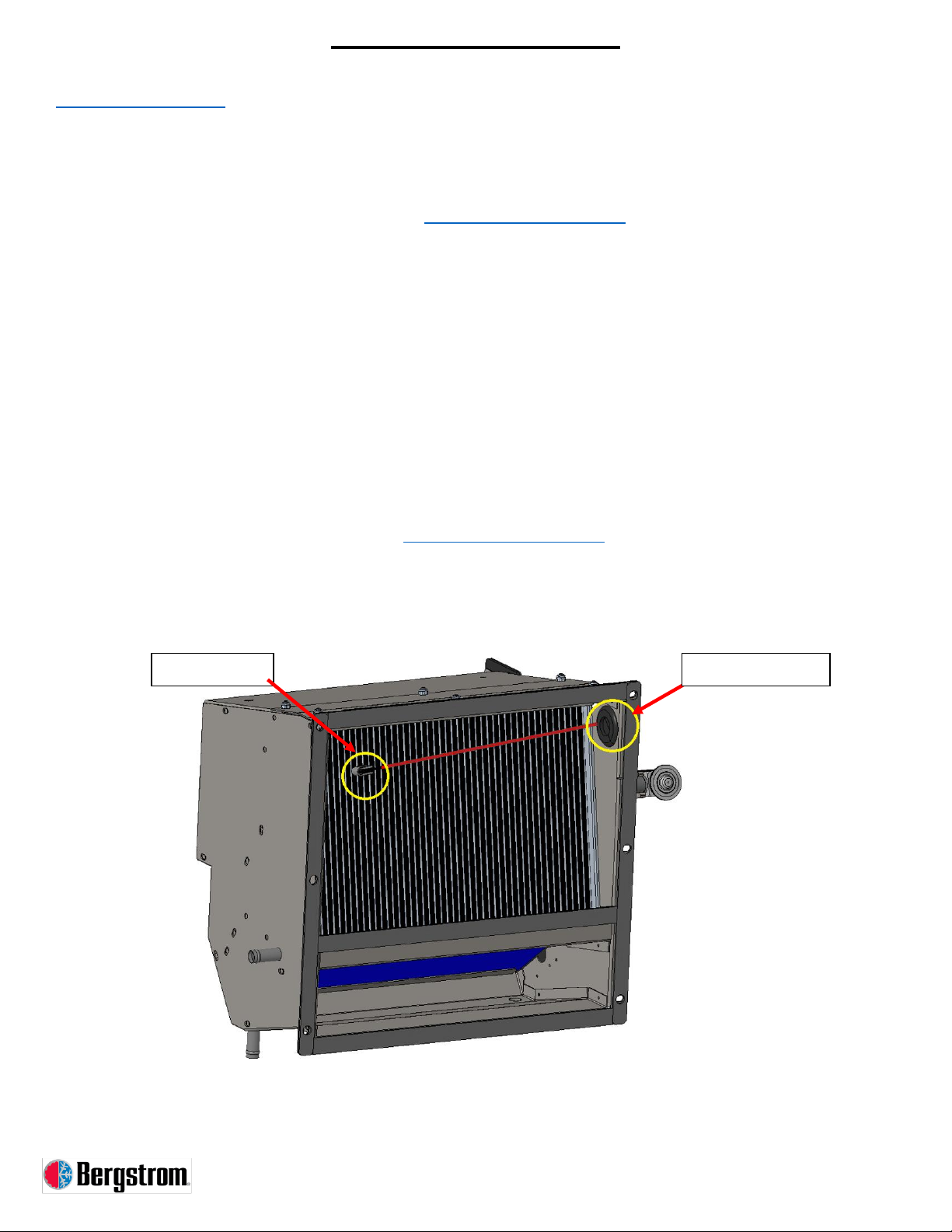

Component Servicing

Outdoor HVAC Unit

Outdoor HVAC Unit Removal

1. Discharge A/C system. Refer to REFRIGERANT CHARGE INFORMATION

2. Remove any hoses/fittings connected to the TXV and the front mounting plate by removing the

1 Allen screw.

3. Disconnect the actuator harness and freeze probe harness.

4. Remove outdoor HVAC unit from the front of the indoor HVAC unit by removing 6 nuts.

Outdoor HVAC Unit Installation

1. Install outdoor HVAC unit to the front HVAC unit with 6 nuts.

2. Connect actuator harness and freeze probe harness.

3. Install hoses/fittings to TXV with front mounting plate and 1 Allen screw (Torque 10 Nm).

4. Charge A/C system. Refer to REFRIGERANT CHARGE INFORMATION

TXV Front

Mounting Plate

TXV

Nut

15

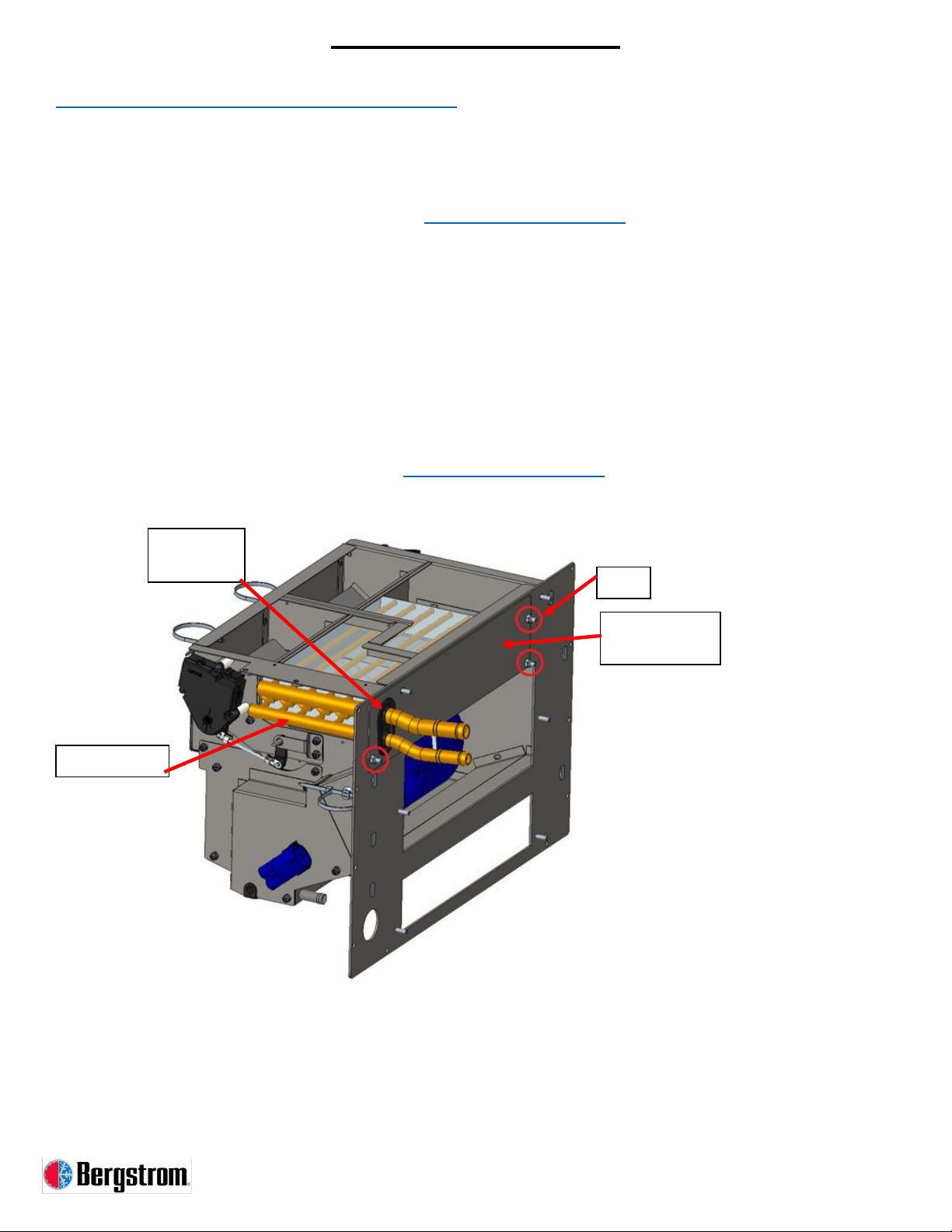

Component Servicing

Indoor HVAC Unit

Indoor HVAC Unit Removal

1. Remove outdoor HVAC unit. Refer to OUTDOOR HVAC UNIT

2. Drain engine coolant from heater core and connected heater hoses.

NOTE –Before removing heater hoses, label hoses to ensure correct installation.

3. Remove 2 spring clamps and disconnect both heater hoses from heater core tubes.

4. Use inside duct top access panel to remove 2 nuts and slide clamp plate away. Remove 2

screws on opposite side.

5. Remove 10 screws holding indoor unit to vehicle.

Indoor HVAC Unit Installation

1. Insert indoor unit and secure to vehicle with 10 screws.

2. Use inside duct top access panel to position clamp plate under top flange of indoor unit and

over the top of mode box, securing with 2 nuts. Secure 2 screws on opposite side.

3. Install heater hoses onto heater core tubes. Fill coolant system.

4. Install outdoor HVAC unit. Refer to OUTDOOR HVAC UNIT

Screw

Inside Duct Top

Access Panel

Nut

16

Component Servicing

Freeze Probe

Freeze Probe Removal

1. Remove outdoor HVAC unit. Refer to OUTDOOR HVAC UNIT

2. Gently pull freeze probe out of the face of the evaporator, noting probe depth and location of

indentation left behind.

3. Remove rubber grommet from side of HVAC module and from freeze probe.

4. Pull freeze probe out of HVAC module.

Freeze Probe Installation

1. Route new freeze probe thorough hole on side of HVAC unit.

2. Gently push freeze probe into the face of the evaporator at the same location and to the same

depth as noted during removal.

3. Secure rubber grommet around freeze probe wires and into the hole on the side of the HVAC

module.

4. Install outdoor HVAC unit. Refer to OUTDOOR HVAC UNIT

Freeze Probe

Rubber Grommet

17

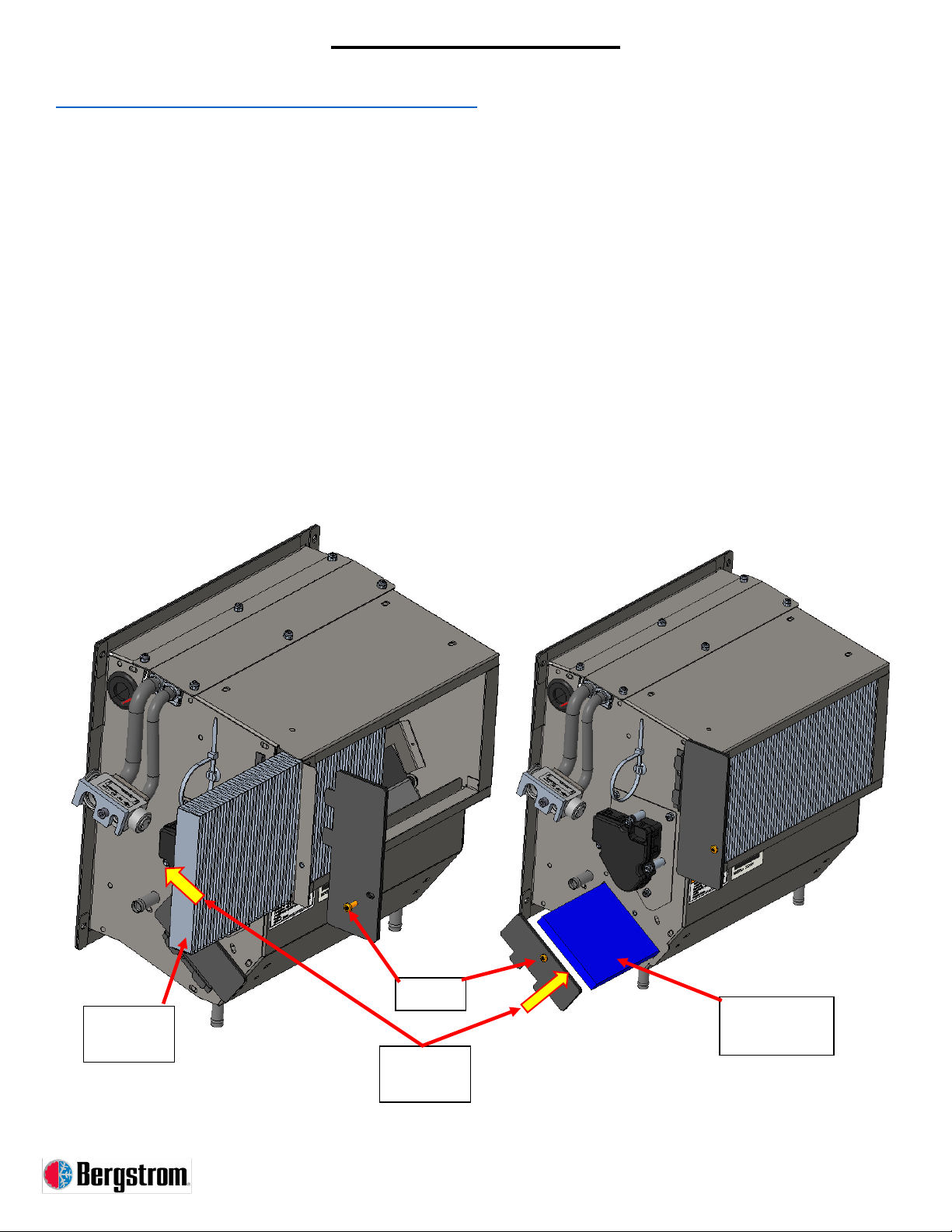

Component Servicing

Fresh and Recirculation Air Filters

Fresh or Recirculation Air Filter Removal

1. Identify outdoor HVAC unit. It is the unit with the TXV.

2. Remove 1 screw and slide cover tabs out of slots.

3. Remove filter by pulling straight out of the door.

Fresh or Recirculation Air Filter Installation

1. Insert filter into respective area.

NOTE –Orient printed filter arrow with airflow direction as shown (towards unit).

2. Secure door by sliding tabs into slots and with 1 screw.

Fresh Air

Filter

Screw

Recirculation

Air Filter

Airflow

Direction

18

Component Servicing

Actuator(s)

Actuator Removal

1. Depending on actuator location, removal of outdoor or indoor unit may be necessary. Refer to

OUTDOOR HVAC UNIT and INDOOR HVAC UNIT

2. Disconnect electrical connector from the specific actuator that is being replaced (passenger

zone blend door actuator shown for reference).

3. Remove 3 nuts to remove actuator.

4. Check to make sure the 3 nylon spacers behind the actuator stay in place over the threaded

studs on the HVAC module.

5. Check to make sure the door adaptor piece stays located on the door rod protruding from the

HVAC module.

Actuator Installation

1. Secure actuator to HVAC unit using 3 nuts.

2. Connect electrical connector to actuator.

3. If necessary, install outdoor or indoor HVAC unit. Refer to OUTDOOR HVAC UNIT and

INDOOR HVAC UNIT

Door Adaptor

Nylon Spacers

Actuator

Nut

19

Component Servicing

Evaporator Coil

Evaporator Coil Removal

1. Remove outdoor HVAC unit. Refer to OUTDOOR HVAC UNIT

2. Remove evaporator access cover from the HVAC module by removing 6 nuts.

3. Remove freeze probe. Refer to FREEZE PROBE

4. Slide evaporator-TXV subassembly out of the HVAC module.

Evaporator Coil Installation

1. If A/C system is to be flushed, perform that operation before re-assembling the system. Refer

to REFRIGERANT CHARGE INFORMATION

NOTE –During installation, always lubricate O-rings on fittings with mineral-based oil.

2. Slide evaporator-TXV subassembly into the HVAC module.

3. Install freeze probe. Refer to FREEZE PROBE

4. Secure evaporator access cover using 6 nuts.

5. Install outdoor HVAC unit. Refer to OUTDOOR HVAC UNIT

Evaporator-TXV

Subassembly

Access Cover

Nut

20

Component Servicing

Heater Core (Indoor HVAC Unit)

Heater Core Removal

1. Remove outdoor HVAC unit. Refer to OUTDOOR HVAC UNIT

2. Remove heater access cover from indoor HVAC unit by removing 3 nuts.

3. Remove and retain rubber grommet from heater tubes and service cover.

4. Pull heater core out of the indoor HVAC unit.

Heater Core Installation

1. Push heater core into indoor HVAC unit.

2. Secure heater access cover using 3 nuts.

3. Secure rubber grommet into plate around tubes.

4. Install outdoor HVAC unit. Refer to OUTDOOR HVAC UNIT

Heater Core

Rubber

Grommet

Heater

Access Cover

Nut

Table of contents

Other Bergstrom Fan manuals

Popular Fan manuals by other brands

BrookVent

BrookVent AIRSTREAM XE+ Installation, maintenance and user manual

S&P

S&P ARTIC N GR Series User instructions

KDK

KDK M40R operating instructions

Euromatic

Euromatic KYT40-5 instruction manual

Zehnder Rittling

Zehnder Rittling ComfoAir 155 WM installation instructions

Sealey

Sealey HVF20PO instructions