BERMAD BEC PM1 User manual

Water Control Solutions

Installation & Operation Manual

BEC PM1 Controller

Time/Flow/Volume Controller

2

Table of Contents

Introduction

4

Chapter 1

Technical Data and I/O Connections 6

DC Solenoid 6

Power Supply 6

Hydrometer or Water Meter 6

Flow Switch / Rain Sensor 7

Wiring Table 7

Switching the Controller's Operation Modes 8

Chapter 2

Pressure Management according to Flow-rate Application 9

Background 9

The Control Panel Display Icons

10

Programming Steps

11

Basic Settings

11

AUTO Operation

13

Chapter 3

Pressure Management according to

Time Intervals Application 14

The Control Panel 14

Display Icons 15

Programming Steps 16

3

Basic Settings 16

Application Description 18

Programming the Pressure Management by

Time Intervals Application 18

Chapter 4

On/O Control Application 20

Dead-end Pipes Purging Application Settings 20

Chapter 5

On/O Irrigation Application 26

Display Icons 26

Programming Steps 27

Basic Settings 27

Irrigation Program Settings 29

Volumetric Irrigation Program Parameters 30

Irrigation Program Common Parameters 31

Operational Screens 33

Alerts 34

Fault Messages Table 35

Buttons 35

General Information for All Applications 36

Monitoring 36

Manual Operations 37

4

Introduction

This document provides installation and operation instructions for

the BEC PM1 controller as it is used with BERMAD’s control valves in

Waterworks and Irrigation Applications.

Very Important:

Chapter #1 of this document provides general installation and

operation instructions which are common to all the applications’

types while the rest of the chapters are organized by application

type.

Therefore before installing and operating this controller please read

carefully chapter #1 and then jump to the chapter related to your

specific application:

Pressure Management Applications:

Optimizing water supply and reducing non revenue water by using

the BEC PM1 controller is done by connecting it to BERMAD’s two

step pressure reducing valve installed at the entry point of a district

metering area.

Chapter #2

Pressure management according to flow rate:

For switching between the two pre-set pressure regimes of the PRV

according to high or low flow demand at the controlled district please

refer to chapter #2 of this document.

Chapter #3

Pressure management according to time

intervals:

For switching between the two pre-set pressure regimes of the

PRV according to time settings please refer to chapter #3 of this

5

document.

Chapter #4

On/Off Control:

The BEC PM1 enables a volumetric control of BERMAD’s On/Off

control valves that are used for purging pipe’s dead ends, refreshing

reservoirs and other such On/Off applications. Please refer to chapter

#4 if your specific application in of an On/Off type.

Chapter #5

Irrigation Control:

The BEC PM1 controller can be used as a single station irrigation

controller for agriculture or gardening. Please refer to chapter #5 if

your specific application is of an irrigation type.

6

The following I/Os are used for BERMAD’s waterworks and Irrigation

Applications:

DC Solenoid:

Connect the solenoid’s wires to the cable coming out of the

controller’s first station port. Connect the solenoid’s RED wire to the

controller’s RED wire and the BLACK wire to the controller’s BLACK

wire.

Power supply:

Open the battery’s compartment lid and connect a good-quality 9

Volt alkaline battery, then firmly close the lid.

When the battery is first connected, the controller performs a self-

test, closes the DC solenoid and displays the first settings screen.

Under normal use, the battery should last for at least one season.

Hydrometer or Water Meter:

BERMAD’s 900 series Hydrometer, or a water meter with dry contact

pulse output, is used in applications such as the following:

nnPressure management with flow rate reference applications

where switching to the high pressure setting is done in case of a

high demand for water.

nnPipes’ dead-end purging applications where the purged-out water

is measured by volume and not by time.

nnIn cases of fire protection or volumetric irrigation applications.

Connect the two water meter pulse wires to the two controller’s

RED wires. Please note that there is no polarity significance in this

connection.

Chapter #1

Technical Data and I/O Connections

7

Wire

Color

Task Remarks

DC type solenoid - 9V-12V DC Latch - for pressure management

according to flow-rate

RED To be connected to the

solenoid's RED wire

This wire is joint together with

the solenoid's RED wire in the

controller's black cable

BLACK To be connected to the

solenoid's BLACK wire

This wire is joint together with

the solenoid's BLACK wire in

the controller's black cable

DC type solenoid - 9V-12V DC Latch - for pressure management

according to time interval

RED To be connected to the

solenoid’s BLACK wire

This wire is joint together with

the solenoid's BLACK wire in

the controller's black cable

BLACK To be connected to the

solenoid's red wire

This wire is joint together with

the solenoid's RED wire in the

controller's black cable

Water meter

RED

Connect one of the water-

meter's pulse wires to one of

the controller's RED wires

There is no polarity significance

in this connection

RED

Connect the other water-

meter's pulse wires to one of

the controller's RED wires

There is no polarity significance

in this connection

Flow switch (or rain sensor for irrigation applications)

YELLOW

Cut the YELLOW loop and

connect one of the flow

switch wires to one of the

controller's yellow wires.

There is no polarity significance

in this connection

YELLOW

Connect the other flow switch

wire to one of the controller's

YELLOW wires.

There is no polarity significance

in this connection

Flow Switch/Rain Sensor:

Flow switch can be used with the time controlled pressure

management application for switching to the high pressure setting in

case of a high demand for water, i.e. in case of fire.

Wiring Table:

The controller is supplied with the following wires connected to its

terminal strip:

8

Switching the Controller's Operation Modes

The BEC PM1 controller has two distinctive operation modes:

Irr mode - this is the default operation mode of the controller which

is used for Irrigation, Time Intervals Pressure Management and On/

off applications.

Pr mode - this mode is used for the Pressure Management according

to Flow-rate application only.

Switching between these two operation modes is done by

simultaneously pressing the and keyboard buttons.

For example:

Changing from “Irr” to “Pr” mode:

Press the and buttons simultaneously for 5 second, the

system displays the mode name and starts switching to the Pr

mode. Continue pressing the buttons for additional 3 seconds until

the software version appears on screen (in a form of a number)

then release the buttons. The controller is now on its “Pr” mode.

Please note that changing the controller’s mode requires about 10

seconds of continuous buttons pressing time in total.

Changing from “Pr” to “Irr” mode:

Keep pressing the and buttons for another 3 second,

the system displays the new mode name and switches back to

the Irr mode.

Important! Before operation the controller for the first time

make sure that it is set to the correct operation mode for your

specific application.

9

Background

This application enables the user to set a flow rate SET POINT in

number of pulses per hour. The application automatically changes

the control state of the Two Step Pressure Reducing Valve which is

controlled by the BEC PM1 controller according to the actual real-time

flow-rate reading.

When the actual flow rate reading crosses the SET POINT, the

controller starts counting a stabilization time delay parameter

for ensuring that the flow-rate crossing of the set-point is not a

temporary pressure fluctuation.

If by the end of the delay counting the flow-rate reading remains

beyond the set point the solenoid state changes.

There are two delay time parameters: One for LOW to HIGH flow

crossing of the set-point and the other for HIGH to LOW flow

crossing.

This application has four screens:

The first three screens are used for setting the SET POINT flow

reference [SP:PH] and the two values of the delay timers [SP:tH] &

[SP:tL].

The fourth screen is the automatic operation screen (“AUTO”) that is

used for monitoring the application operation.

Chapter #2

Pressure Management according to

Flow-rate Application

10

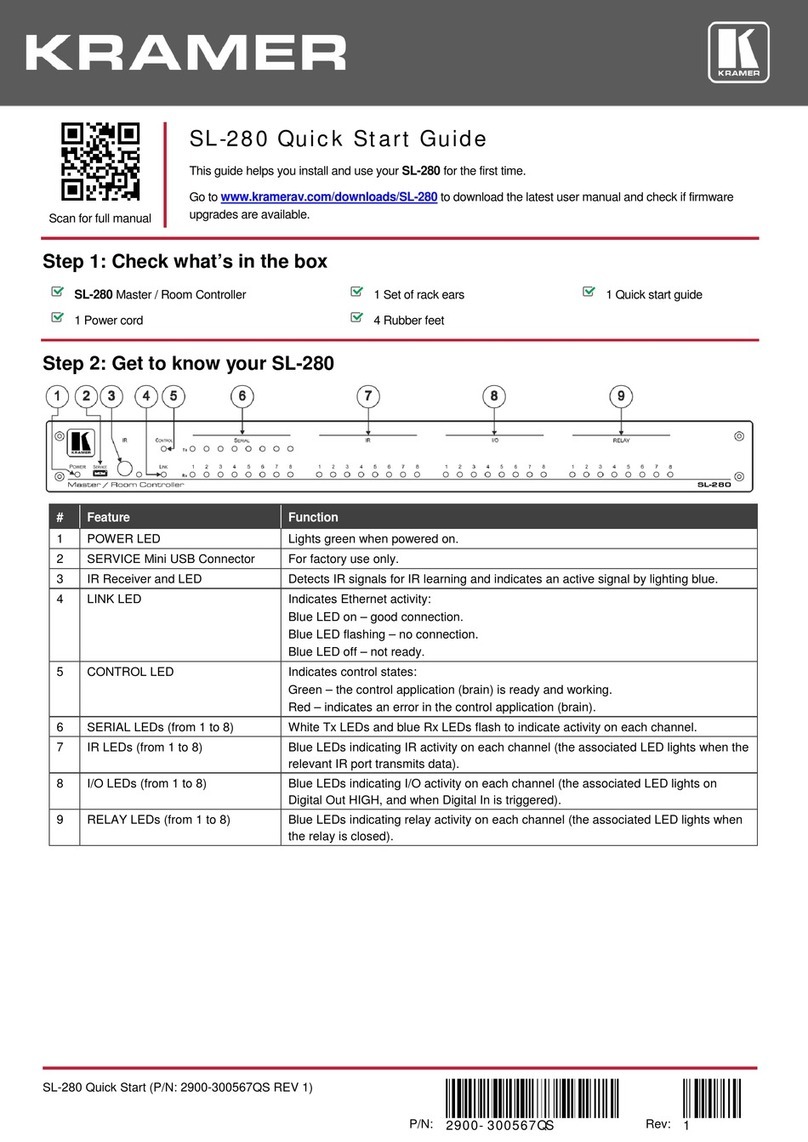

The Control Panel

UsageNameButton

Next Step button - used to

advance to the next screen

NEXT

Shift button - Not in use in this

application

SHIFT

Used for increasing a numeric

value

ON +

Used for switching between the

“Pr” and “Irr” operation modes

OFF -

Switch between Pressure

Management by Flow (“Pr”) and

Pressure Management by Time

(“Irr”) Applications

&

Display Icons

The following icons may appear on the screen

during programming or operation modes:

Pressure Management by Flow DescriptionIcon Symbol

Pressure Management indication

PM

Setting Mode

The last measured flow rate is higher than the

set point threshold [Pulses/Hour]

The last measured flow rate is lower than the

set point threshold [Pulses/Hour]

Automatic operation screen. Used for monitoring

the system operation

11

Programming Steps

Basic Settings:

Setting Flow Reference Set-point

Upon entering to this screen the display

shows the [SP:PH] (Set Point : Pulses per

Hour) title.

Use the or the buttons to set

the flow-rate value by number of pulses

per hour. This is the flow-rate that

distinguishes between high and low

pressure conditions.

Please note:

The flow reference entry ranges between 0 and 9999 pulses/hour.

The factory default value is 50 pulses per hour.

Press the button to move to the next screen.

Setting the Low to High flow stabilization delay timer

Upon entering to this screen the display

shows the [SP:tH]

(Set Point : High flow timer) title.

Use the or the buttons to set the

required delay time parameter which is

used for verifying that the change from

LOW flow to HIGH flow is stable.

Please note:

The timer values range between 0 and

60 minutes in 1 minute steps.

The factory default value is 1 minute.

Press the button to move to the next screen.

Fig.1 - Flow set-point

Fig.2 - High flow timer

12

Setting the High to Low flow stabilization delay timer

Upon entering to this screen the display

shows the [SP:tL]

(Set Point : Low flow timer) title.

Use the or the buttons to set the

required delay time parameter which is

used for verifying that the change from

High flow to Low flow is stable.

Please note:

The timer values range between 0 and

180 minutes in 1 minute steps.

The factory default value is 20 minutes.

Press the button to move to the next screen.

Fig.3 - Low flow timer

13

Auto operation

Monitoring

When no button is pressed in the controller’s keyboard for 3 minutes,

the controller moves to the main monitoring screen indicated by the

word AUTO in the middle of the screen. The AUTO screen displays the

following data items:

• The “AUTO” icon indicates that the

automatic Pressure Management

operation is active.

• The Display shows the current reading of

the system’s flow-rate.

• The Up arrow

indicates that the

current flow-rate is higher than the SET

POINT flow parameter.

High flow reading

• The DOWN arrow indicates that the

current flow-rate is lower than the SET

POINT flow parameter.

When the solenoid status is ON the

1

Icon appears

on the screen.

When the solenoid status is OFF the 1Icon disappears.

High flow reading

Low flow measurment

14

The Control Panel

The BEC PM1 Human-Machine Interface consists of a graphical display

screen and a four keys keyboard:

NEXT STEP button - Used to advance to the next screen

or programming step

SHIFT button - Used to sequentially change the focus

between the items of the current screen

PLUSE / ON button - Used to increase numeric data, set

on operation days and start manual operation

MINUS / OFF button - Used to decrease numeric data, set

off operation days and stop manual operation

Chapter #3

Pressure Management according to

Time Intervals Application

15

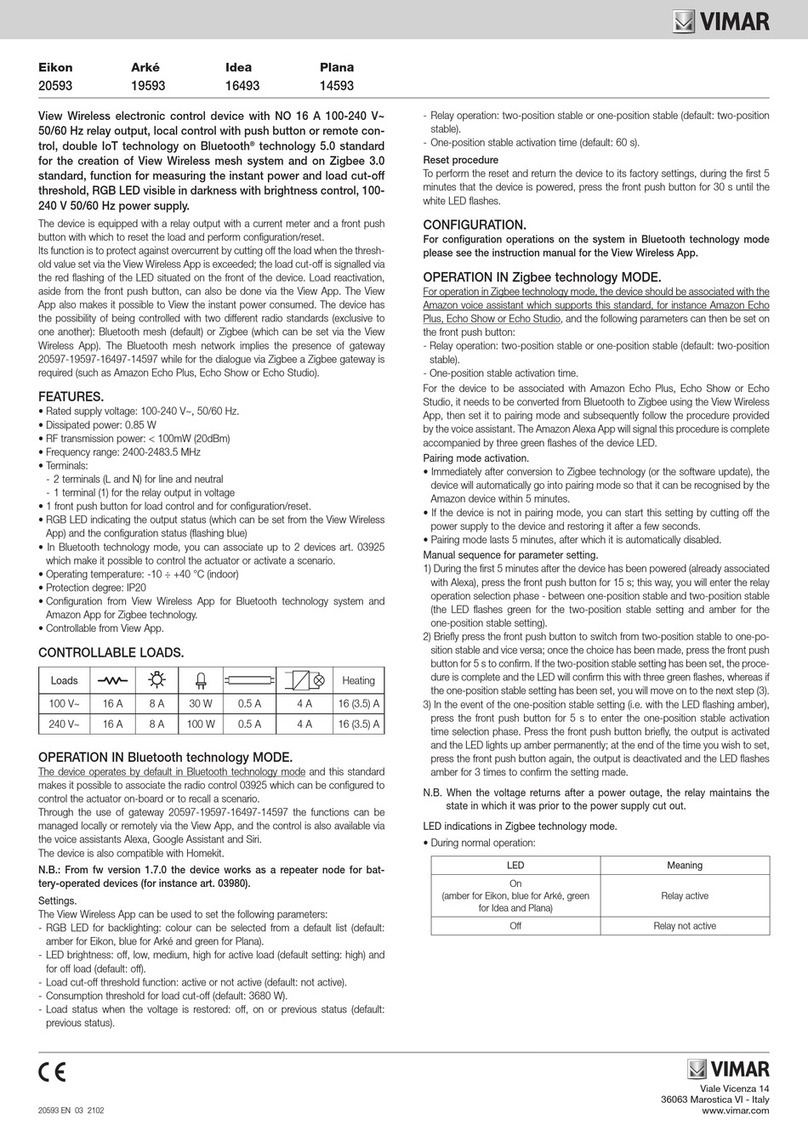

Display Icons

The following icons may appear on the display screen during

programming or operation modes:

High Flow

[seconds]

Setting Mode

Operation Days

Set Time / Time

Mode

Manual OperationVolumetric Mode

Uncontrolled Water

Meter [minutes]

Operation Time

Station Number

1

Automatic

Operation

Flow OFF

Seasonal

Adjustment

Low Battery

AL:bt

Stopped by Flow

Switch

16

Programming Steps

This chapter describes the required programming steps of the

controller and it is divided into three sections: Basic Settings,

Pressure management settings, and end of line flushing settings.

Basic Settings:

First Basic Settings Screen

The basic controller setting should be done once the controller is

wired to the system and the power is connected, or after a total

reset operation is performed. The first setting screen appears

displaying 3 optional settings:

1. Solenoid Type:

Upon initial start-up the connected solenoid type is checked by the

controller; it must be a DC latch solenoid.

2. Clock Mode:

Press the bbutton and set the system clock to 12 or 24 hour

clock. Factory default - 24h.

3. Time / Volume Operation:

Press the button and select the required operation mode. Select

TIME for BERMAD’s pressure management by time application.

Note the icons change according to your selection: the icon should

be selected for time operation. Factory default - Time.

Press the button to move to the next basic settings screen.

Second Basic Settings Screen

In the second setting screen the operator can set the Flow Switch

usage mode. Please note that a flow switch can be used only for

BERMAD’s pressure management by time intervals application.

17

Flow switch mode:

Press the button to enable or disable the flow switch operation.

When a flow switch is enabled the icon appears on screen.

Factory default - flow switch enabled.

Press the button to move to the next basic settings screen

Third Basic Settings Screen

The third setting screen is used for setting the system time and day

of the week.

System Time:

Use the and the buttons to set the system time. Hold the

button pressed to quickly advance the digits. Press both buttons

simultaneously to reset the time and day to the factory default

setting.

Day of the week:

Use the button to scroll through the days of the week and set

the current day.

Press the button to exit the basic settings screens and move to

the operation programming screens.

18

Pressure Management Application Settings

BERMAD’s pressure management by time application is based on

BERMAD control valve equipped with two pressure reducing pilots:

one for high pressure setting and the other for low pressure setting.

Normally the high pressure pilot controls the valve, while the low

pressure pilot is on standby mode. A BEC PM1 controller with a DC

solenoid can switch the high pressure pilot with the low pressure

pilot according to a pre-defined time based operation regime. Such

arrangement can switch the system to low pressure settings during

night, while maintaining high pressure during day time.

The system is also equipped with a high flow switch that can stop

the low pressure regime when higher demand for water is detected,

such as in case of fire.

The following chapter describes the programming steps required for

setting-up this application:

Programming the Pressure Management

by Time Intervals Application

The BEC PM1 operation programs consist of three parameters per

each valve program: Operation Time, Operation Days, and Start Time.

For controlling BERMAD’s Pressure Management by Time Interval

Application the controller is supplied with a single solenoid (valve),

operated by time with up to three start times a day, and with a flow

switch.

In municipal water systems the demand for water in residential

neighborhoods is high during the mornings and evenings and low

during the night and mid-day hours; therefore, the control valve is

set for the high pressure during high demand hours.

Operating the valve with the BEC PM1 controller reduces the

otherwise too high pressure settings during the low demand hours.

19

For example, in typical municipal pressure regime, the day low

pressure hours are between 10:00 AM and 06:00 PM and the night

low pressure hours are between 10:00 PM and 06:00 AM, during the

high demand hours the valve maintains the high pressure setting.

Therefore, the three required program parameters of the controller

are: Operation Time - 8 hours, Operation Days - 7 days and two Start

Times one at 10:00 AM and the other at 10:00 PM.

1. Operation Time:

Use the button to move to the Operation Time programming

screen, this is the screen with the blinking icon, the blinking

triangle with the digit 1 in it, and the icon. Use the buttons to

set the required operation time (8:00 hours in our example).

Press the button to move to the next programming screen

which is the Operation Days screen.

2. Operation Days:

Use the button to set a particular day as an operation day, or use

the button to skip the day, the cursor will advance to the next

day. In our example set all 7 week days for operation.

Press the button to move to the next programming screen

which is the Start Times screen.

3. Start Times:

Use the and the buttons to set the first required Start Timed

(10:00 AM in our example).

Press the button to move to the second Start Time and set it as

required (10:00 PM in our example).

The controller is now set for automatically operating the Pressure

Management by Time Intervals Application.

20

The BEC PM1 enables a volumetric or time based control of

BERMAD's On/Off control valves that are used for purging pipe's

dead ends, refreshing reservoirs and other such On/Off applications.

This chapter describes the Dead-end Pipes Purging Application

Settings.

Dead-end Pipes Purging Application

Settings

Due to operational conditions, in some municipal and industrial

water systems, there is a need for periodic purging of the systems

dead-ends of pipes for refreshing the water supply. BERMAD’s

control valves equipped with BEC PM1 controllers can be installed

in these systems. BERMAD’s Dead-end Pipes Purging Application

accounts for the purging out of the system. This task is automatically

performed based on three major parameters:

1. Purging interval - set at specific days of the week or

as day intervals

2. Amount of purged water - set by operation time or by volume

3. Start time - set for the operation day

(with up to three start times per such day)

The following examples depict three typical scenarios:

Chapter #4

On/O Control Application

Table of contents

Other BERMAD Controllers manuals

Popular Controllers manuals by other brands

Novanta

Novanta ScanMaster user manual

LOVATO ELECTRIC

LOVATO ELECTRIC RGK600 installation manual

Solid State Logic

Solid State Logic Nucleus user guide

Filtration Group

Filtration Group MFS-05 Translation of the original instructions

NI

NI PXI-8104 installation guide

Allen-Bradley

Allen-Bradley 1756-L5 Programming manual