BERMAD Omega Operating instructions

Installation and Operation Guide

Copyright © 2021 Bermad, all rights reserved.

2

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

Safety

Safety Conventions ................. 4

Safety Instructions .................. 5

FCC Notice ......................... 6

Declaration of Conformity ............ 6

Omega Controller Nameplate ......... 7

Introduction

Overview .......................... 9

Typical Connection Layout ........... 10

Omega Controller ................... 11

Cloud Management System........... 12

Installation

Mounting Omega ................... 14

Powering Omega ...................20

Connecting Peripherals ..............23

Communicating with Omega ..........27

Configuring Controllers

Registering ........................32

Logging In .........................33

Project Dashboard Overview. . . . . . . . . . 34

Managing Projects and Controllers .... 35

Basic Device Settings................42

Managing Programs .................50

Additional Device Settings ...........58

Managing Users ....................64

Monitoring Controllers

Manually Operating Valves ...........70

Manually Starting a Program. . . . . . . . . . 72

Alerts .............................73

Logs ..............................74

Graphs ............................77

Irrigation Calendar ..................78

Specifications

Warranty

Copyrights and Disclaimers

TABLE OF CONTENTS

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Safety |

3

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

1. SAFETY

This chapter reviews the Omega safety concerns and includes:

Safety Conventions

Safety Instructions

FCC Notice

Declaration of Conformity

Omega Controller Nameplate

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Safety Conventions

WARNING: Indicates a potentially

hazardous situation, which,

if not avoided, could result in

injury or death.

NOTE: Indicates additional

information to help the user

obtain optimum performance.

Notes are not safety-related to

the equipment or personnel.

CAUTION: Indicates that the

equipment or environment can

be damaged, or data can be

corrupted.

Tip: Indicates useful information

to simplify steps or procedures.

DANGER: Indicates an immediate

hazardous situation, which, if

not avoided, will result in serious

injury or death. This signal word

is limited to extreme situations.

Safety | Safety Conventions |

4

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Safety | Safety Instructions |

5

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

Safety Instructions

Prior to performing any work on the Omega controller, become familiar with the following safety concerns:

General Safety Instructions

Read this installation and operation guide prior to installing and servicing

the system.

Pay careful attention to all cautions and warnings in this guide.

Installation must comply with all local electrical and plumbing codes.

It is recommended that a licensed electrician performs all electrical

connections. Improper installation could result in shock or fire hazard.

Omega is not intended for use by children.

Battery Safety Instructions

BERMAD is not responsible for battery failures due to mishandling.

Do not crush, break, or disassemble the batteries.

Do not damage the battery label, which acts as an electrical insulation for

the battery can.

Do not install the batteries backwards, put in fire, submerge in fluids, or mix

with other battery types.

Do not weld or solder the batteries onto the battery compartment.

Dispose of batteries in accordance with local regulations.

Internal batteries are intended for operating in offline mode.

Contact BERMAD for battery replacement when depleted or damaged.

External Power Source Safety Instructions

Before connecting to an external power source, ensure the external power

polarity matches the one marked on the Omega connector board.

The power supply cables must first be connected to the Omega power

connectors before plugging into an external power source.

The Omega controller must first be unplugged from the external power

source before disconnecting the power supply cables from the power

connectors.

WARNING: Contact with

electrical equipment and

connections can cause electric

shock if the power supply is

turned on.

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Safety | FCC Notice |

6

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

Declaration of Conformity

This equipment has been tested and found to comply with EN 61010-1:2010 and IEC 61010-1:2010, AMD1:2016 standards

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Safety | Omega Controller Nameplate |

7

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

Omega Controller Nameplate

The Omega controller nameplate is located on the

back of the controller. It contains the following

information:

Manufacture date

Model type

(Omega or Omega RS)

QR code (contains serial number, link

to BERMAD cloud, and encrypted

controller activation code)

Serial number

Activation code

Power source data

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Introduction | Omega Controller Nameplate |

8

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

2. INTRODUCTION

This chapter reviews the Omega controller and includes:

Overview

Typical Connection Layout

Omega Controller

Cloud Management System

NOTE: This guide reviews all

possible Omega controller

configurations. Specific controller

configuration varies by model.

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Introduction | Overview |

9

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

Overview

Omega is an advanced cloud-based irrigation controller. It provides a user-friendly and cost-effective solution for irrigation heads as well as water distribution, data

acquisition, and pre-paid systems.

Controller Features

Offline and online control.

Volumetric and time-based irrigation.

High/low flow monitoring (when used with a water meter pulse sensor).

Leak detection.

Up to five latch outputs, four digital inputs, and two analog inputs.

Option to connect up to ten extension controllers in parallel via RS-485,

allowing for a total of 44 latch outputs, 44 digital inputs, and 22 analog

inputs. (RS models only)

Option to connect up to forty RF remote units via an RF gateway, each

with a single latch output. (RS models only)

Comprehensive log registry allows for long periods of offline operation.

Up to 5 years battery-powered operation in low-energy mode, with option

to connect to external power source.

Industrial grade electronic components (-35 °C to 75 °C).

IP65 rated with UV protection for outdoor installation.

CE and FCC standard compliant.

Communication Features

Built-in GSM modem with global data SIM card for worldwide Internet

connectivity.

Secured end-to-end communication using 4G modem with 2G fallback.

Supports NB-IoT, CAT-M, and GPRS protocols.

Real-time alert notifications to a PC, tablet, and smartphone.

BLE communication, enabling local smartphone connection to the Omega

controller.

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Introduction | Typical Connection Layout |

10

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

Typical Connection Layout

The following can connect to the Omega controller's connection

terminals (see Connecting Peripherals):

Latch output connection terminals:

▪Latch solenoids - irrigation valves and master valve

▪Latch relay - water pumps

Digital input connection terminals:

▪Water meters

▪Dry contact and open collector digital sensors

Analog input connection terminals:

▪Analog sensors

Up to ten extension controllers –

total of 44 latch outputs, 44 digital

inputs, and 22 analog inputs

(RS models only)

RF

Gateway

RF

Remote

Unit

RF

Remote

Unit

RF

Remote

Unit

RS-485 RS-485

Tip: When installing open

collector sensors, verify the

polarity matches what is marked

on the Omega connector board

Up to five

latch outputs

Up to four

digital inputs

Up to two

analog inputs

Up to forty RF remote units

–total of 44 latch outputs, 4

digital inputs, and 2 analog

inputs (RS models only)

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Introduction | Omega Controller |

11

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

Omega Controller

The Omega controller includes the following:

Connection terminals

Mounting bracket

SIM card

RS-485 connector1

Battery

compartment

Power connector

SMA connector for

external antenna2

1Available in Omega RS, RF, and X models only

2Not standard

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Introduction | Cloud Management System |

12

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

Cloud Management System

BERMAD Cloud provides a centralized web-based user interface for the Omega

controller, allowing for anywhere-anytime management and real-time visual

monitoring of the irrigation system using a PC, tablet, or smartphone.

BERMAD Cloud offers the following benefits:

Password protected login.

Dynamic dashboard.

Irrigation management and monitoring tools.

Alert controls.

Log information and report generation.

Omega

Cloud

Management

software

NB-IoT

GPRS

BLE

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Installation | Cloud Management System |

13

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

3. INSTALLATION

This chapter reviews Omega installation and includes:

Mounting Omega

Powering Omega

Connecting Peripherals

Communicating with Omega

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Installation | Mounting Omega |

14

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

Mounting Omega

This section reviews mounting the Omega controller and includes:

Wall Mounting

Valve Mounting

Pole Mounting

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Installation | Mounting Omega |

15

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

Wall Mounting

Perform the following steps to mount the Omega controller to a wall:

1.

Attach the mounting

bracket to the wall using

two screws

2.

Position the Omega

controller onto the bracket

3.

Verify the bracket

is fully inserted into

the controller slot

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Installation | Mounting Omega |

16

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

Valve Mounting

Perform the following steps to mount the Omega controller to a valve:

2.

Attach the bracket adapter

plate to the valve using the bolt

and nut which were removed

1.

Remove the bolt

and nut from the valve

NOTE: The bracket adapter plate

provided by BERMAD is designed

for horizontal installations, and

is suitable for the BERMAD 200

series controllers without further

need for adjustments

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Installation | Mounting Omega |

17

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

3.

Insert the mounting

bracket into the Omega

controller

4.

Verify the bracket

is fully inserted into

the controller slot

5.

Position the mounting

bracket onto the bracket

adapter plate

6.

Verify the bracket adapter

plate clicks in place and is securely

fastened to the mounting bracket

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Installation | Mounting Omega |

18

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

Pole Mounting

Perform the following steps to mount the Omega controller to a pole:

1.

Attach the bracket adapter

plate to the U-clamp using a

bolt and nut

2.

Attach the U-clamp to

the pole using two nuts

NOTE: The U-clamp is an optional

accessory that must be ordered

separately. The U-clamp provided

by BERMAD fits 1" (DN25) to 2"

(DN50) pole diameters.

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Installation | Mounting Omega |

19

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

3.

Insert the mounting

bracket into the Omega

controller

4.

Verify the bracket

is fully inserted into

the controller slot

5.

Position the mounting

bracket onto the bracket

adapter plate

6.

Verify the bracket adapter

plate clicks in place and is securely

fastened to the mounting bracket

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Installation | Powering Omega |

20

Omega | Installation and Operation Guide | Rev A | Doc P/N: PIEAE21-OMEGA

Powering Omega

This section reviews powering the Omega controller and includes:

Battery Power Supply

External Power Source

WWW

SAFETY

INSTALLATION

CONFIGURING

CONTROLLERS

MONITORING

CONTROLLERS

SPECIFICATIONS

INTRODUCTION

Other manuals for Omega

2

Table of contents

Other BERMAD Controllers manuals

Popular Controllers manuals by other brands

GIA

GIA GIATSU GIA-XK46 Owners and installation manual

LEGRAND

LEGRAND Wattstopper LMRC-101 user guide

Roger Technology

Roger Technology B70/1DC Instruction and warnings for the installer

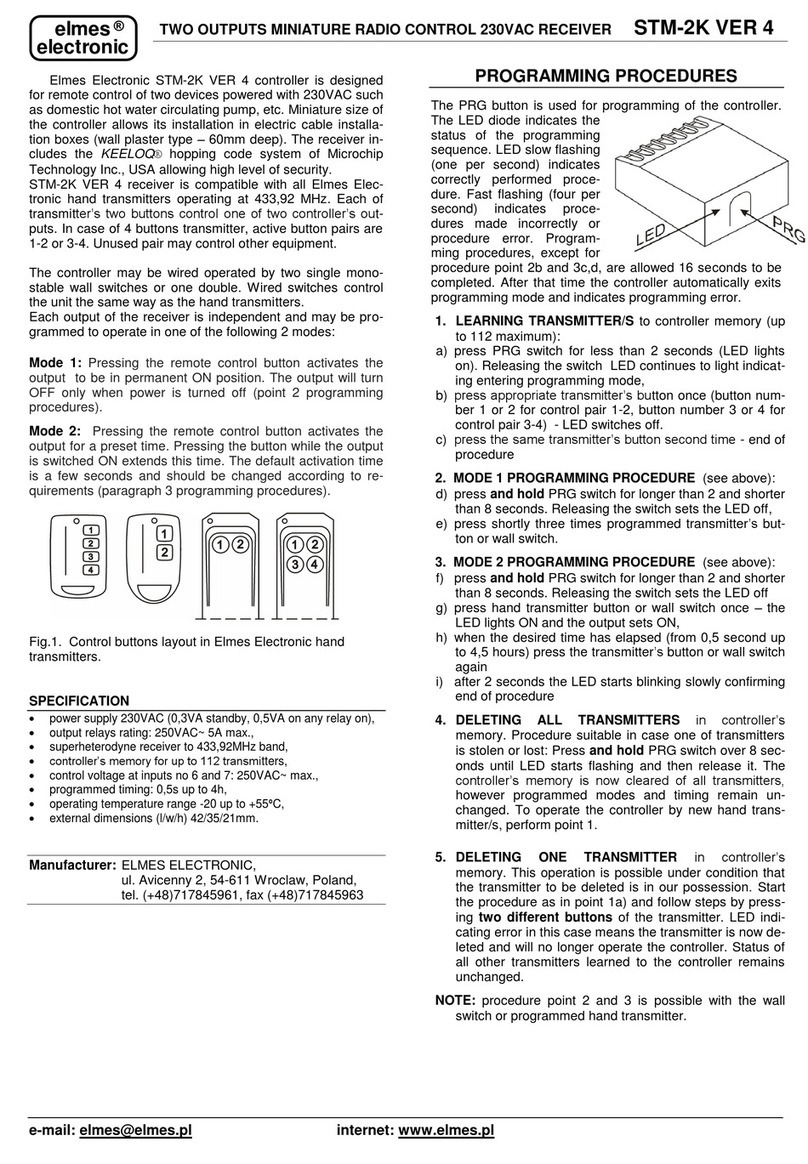

Elmes Electronic

Elmes Electronic STM-2K VER 4 quick start guide

Britten

Britten BANNERDROP user guide

KaVo

KaVo EWL 9045 operating instructions

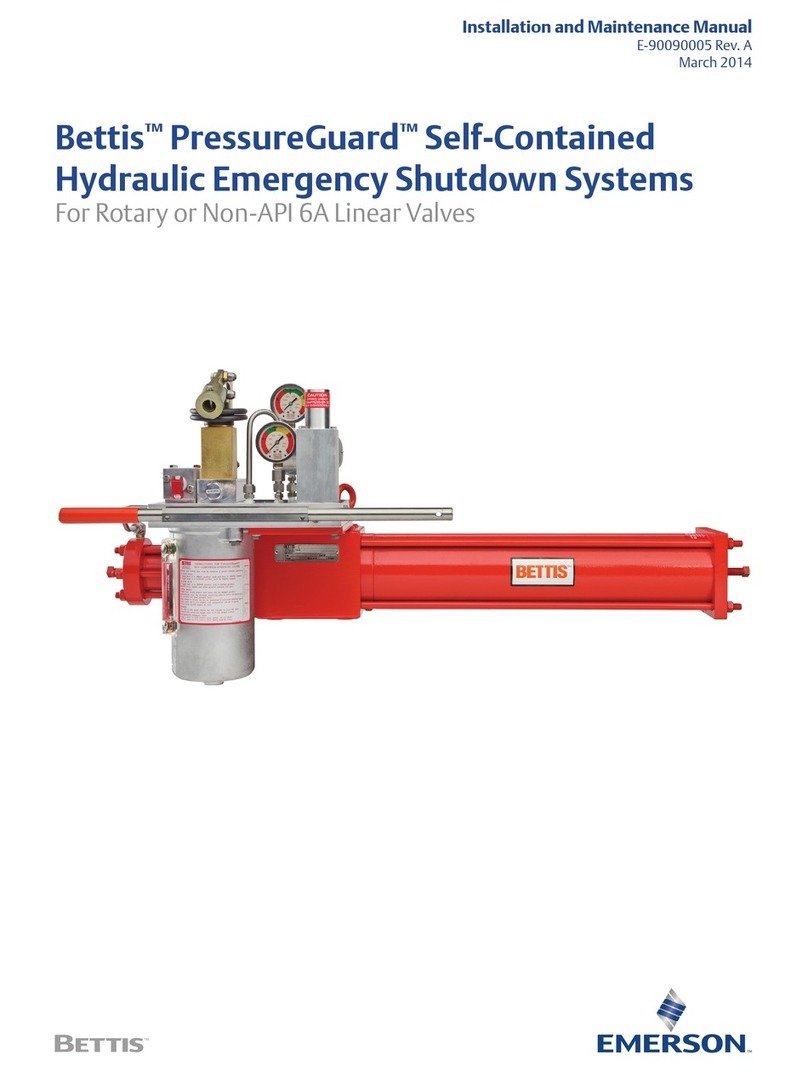

Emerson

Emerson Bettis PressureGuard Installation and maintenance manual

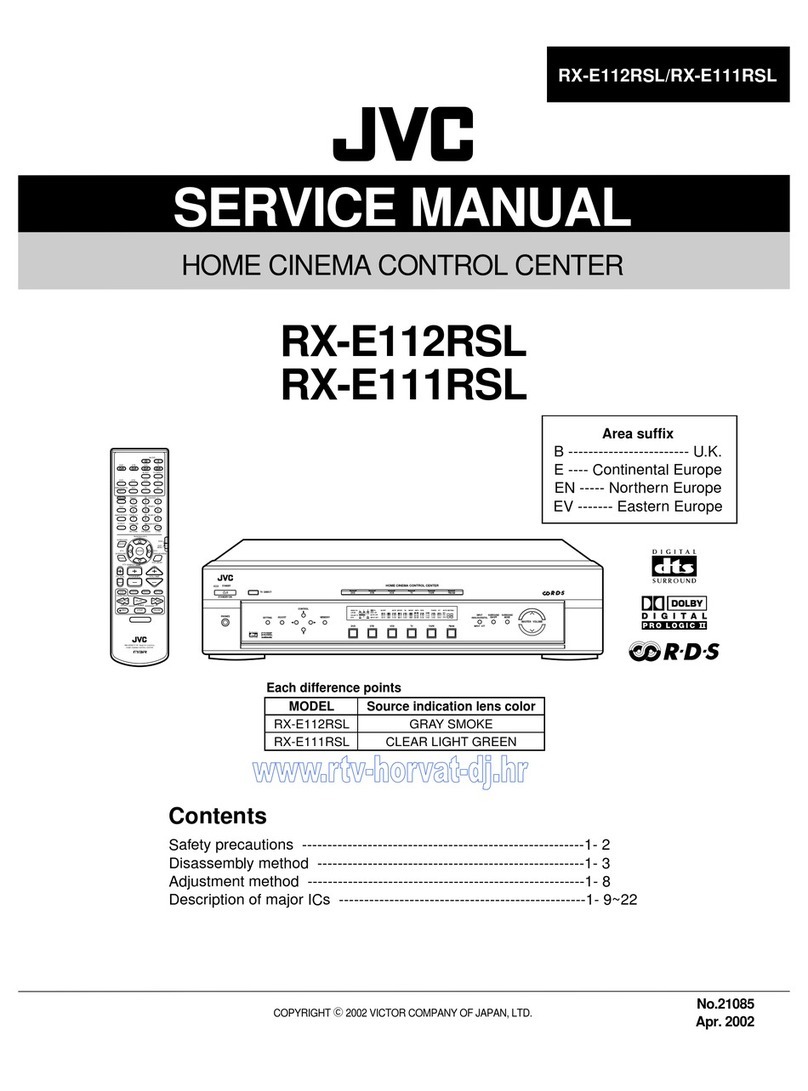

JVC

JVC RX-E112RSL Service manual

Mitsubishi

Mitsubishi QD75M1 user manual

Leviton

Leviton Decora Illumatech IPF05-1L installation instructions

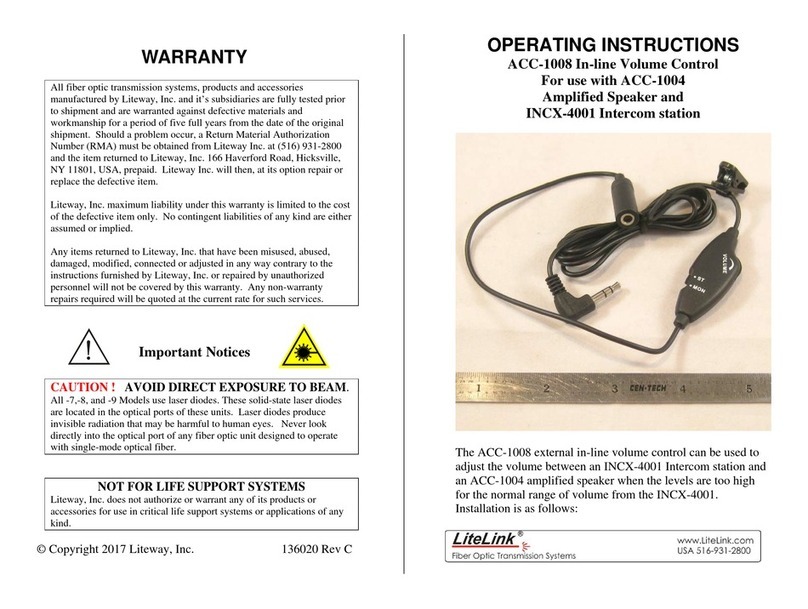

Litelink

Litelink ACC-1008 operating instructions

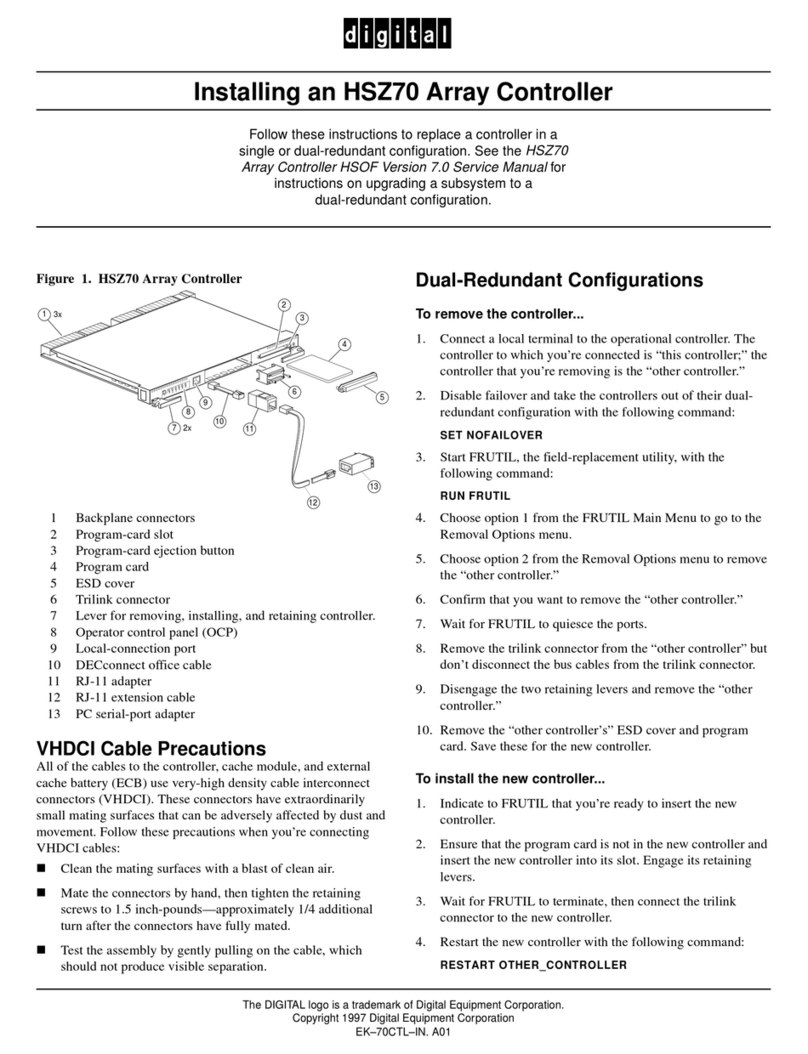

Digital Equipment

Digital Equipment StorageWorks HSZ70 Installing