BERMAD Subtv User manual

Water Control Solutions

Installation & Operation Manual

Subtv Controller

for BERMAD Waterworks Applications

Table of Contents

Introduction 3

Technical Data & Installation Instructions 4 - 5

Control Panel 6 - 7

Programming 8 - 16

Monitoring 17

Manual Operation 18

Introduction

Installation & Operation Manual

SUBtv - DC Volumetric One Station Controller

This document provides installation and operation instructions

for the Subtv controller as it is used with the following Bermad

control valves waterworks applications:

■Pilot change at High/Low pressure management application

■Dead end pipes purging application

Subtv Controller

for BERMAD Waterworks Applications

4

Technical data and installation instructions

The following I/Os are used for Bermad’s waterworks applications:

DC Solenoid:

Connect the solenoid wires to the cable coming out of the

controller’s first station port. Connect the solenoid’s RED wire

to the controller’s RED wire and the BLACK wire to the controller’s

BLACK wire.

Power Supply:

Open the battery compartment lid and connect a good quality

alkaline 9 Volt battery, then firmly close the lid. When the battery

is first connected, the controller performs a self-test, closes the

DC solenoid and displays the first settings screen. Under normal

use, the battery should last for at least one season.

Hydrometer:

Bermad’s 900 series Hydrometer, or a water meter with pulse

output, is used in pipes dead-end purging application where

the purged-out water is measured by volume instead of by time.

Connect the two water meter pulse wires to the two controller’s

RED wires. Please note that there is no polarity significance in this

connection.

Flow Switch:

Flow switch can be used with the pressure management

application for switching to the high pressure setting in case of

a high demand for water, i.e. in case of fire. In order to connect

a Normally Closed flow switch, cut the YELLOW wire loop coming

out of the controller and connect the cut wires to switch.

Wiring Schematic:

The controller is supplied with the following wires connected to

its terminal strip:

5

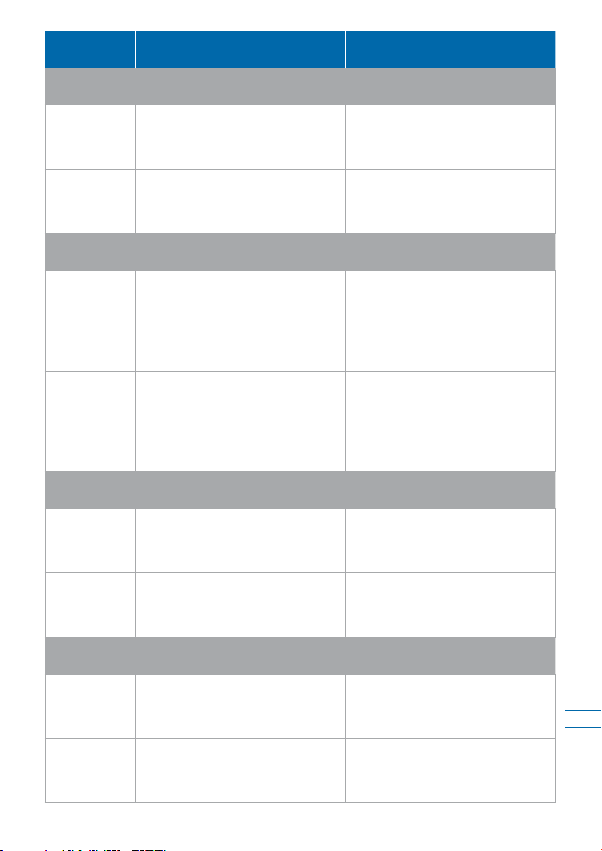

Wire Color Task Remarks

DC type solenoid - 9V-12V DC Latch

Red To be connected to the

solenoid's red wire

Joint together with the

solenoid's black wire in

a black cable

Black To be connected to the

solenoid's black wire

Joint together with the

solenoid's red wire in

a black cable

AC type solenoid - 24V AC

Red To be connected to one

of the solenoid's wires

Joint together with the

solenoid's black wire

in a black cable. No

polarity significance in this

connection.

Black To be connected to the

solenoid's black wire

Joint together with the

solenoid's red wire in

a black cable. No polarity

significance in this

connection.

Water meter

Red

Connect one of the water-

meter's pulse wires to one

of the controller's red wires.

There is no polarity

significance in this

connection.

Red

Connect the other water-

meter's pulse wire to the

second controller's red wire.

There is no polarity

significance in this

connection.

Flow switch

Yellow

Connect one of the flow

switch wires to one of the

controller's yellow wires.

There is no polarity

significance in this

connection.

Yellow

Connect the other flow

switch wire to the second

controller's yellow wire.

There is no polarity

significance in this

connection.

6

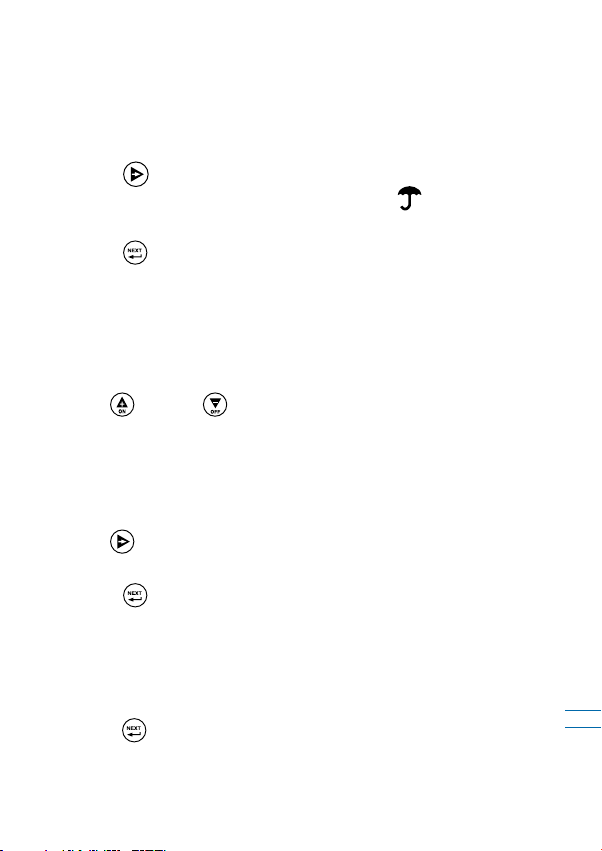

The Control Panel

The Subtv Human-Machine Interface consists of a graphical

display screen and a four keys keyboard:

NEXT STEP button - Used to advance to the next

screen or programming step

SHIFT button - Used to sequentially change the focus

between the items of the current screen

PLUSE / ON button - Used to increase numeric data,

set on operation days and start manual operation

MINUS / OFF button - Used to decrease numeric data,

set off operation days, and stop manual operation

7

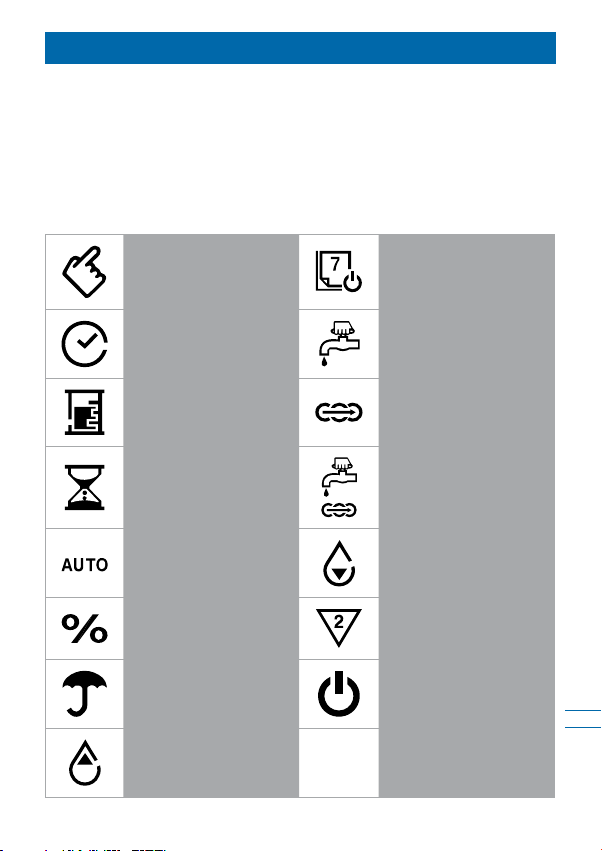

Display Icons

The following icons may appear on the display screen during

programming or operation modes:

Please note:

Some of the following icons are not related to BERMAD applications.

Operation DaysSetting Mode

Manual Operation

Set Time /

Time Mode

Sequential ProgramVolumetric Mode

Semi Auto seq.

Operation

Operation Time

Uncontrolled Water

Meter

Automatic Operation

Station Number

Seasonal

Adjustment

Flow OFF / Low

Battery

Stopped by Flow

Switch

High Flow (seconds)

8

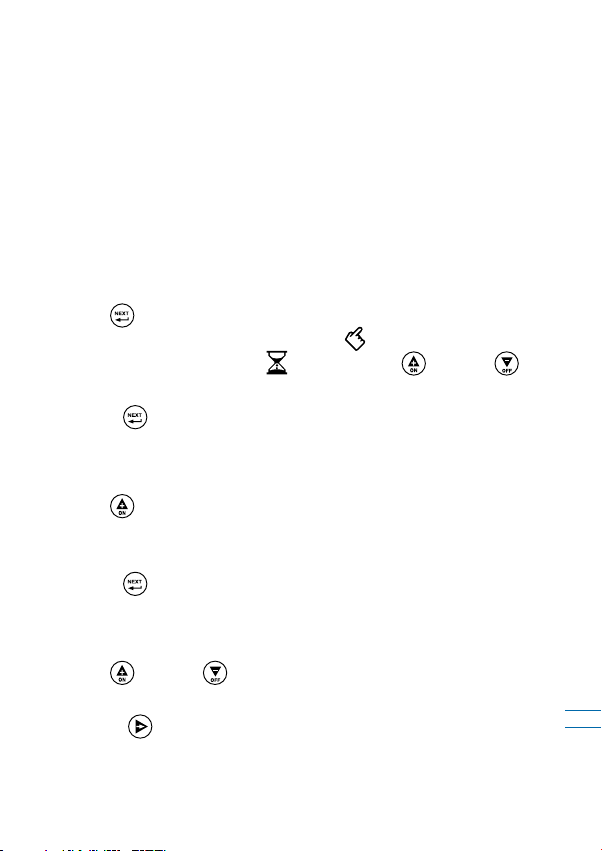

Programming Steps

This chapter describes the required programming steps of the

controller and it is divided into three sections: Basic Settings,

Pressure management settings, and end of line flushing settings.

Basic Settings:

First Basic Settings Screen

The basic controller setting should be done once the controller

is wired to the system and the power is connected, or after a total

reset operation is performed. The first setting screen appears

displaying 3 optional settings:

1. Solenoid Type:

Upon initial start-up the connected solenoid type is checked

by the controller; it must be a DC latch solenoid for BERMAD

applications. The word dC appears on screen indicating that

the type of solenoid found is DC. When the controller is operated

by a 9V battery the solenoid type is DC only and it cannot be

changed by the operator.

2. Clock Mode:

Press the button and set the system clock to 12 or 24 hour

clock. Factory default - 24h.

3. Time / Volume Operation:

Press the button and select the required operation mode.

Select TIME for BERMAD’s pressure management application

and VOLUME for BERMAD’s purging application.

Note the icons change according to your selection:

for time operation and for volumetric operation.

Factory default - Time.

Press the button to move to the next basic settings screen.

9

Second Basic Settings Screen

In the second setting screen the operator can set the Flow Switch

usage mode. Please note that a flow switch can be used only for

BERMAD’s pressure management application.

Flow switch mode:

Press the button to enable or disable the flow switch

operation. When a flow switch is enabled the icon appears

on screen. Factory default - flow switch enabled.

Press the button to move to the next basic settings screen.

Third Basic Settings Screen

The third setting screen is used for setting the system time and

day of the week.

System Time:

Use the and the buttons to set the system time.

Hold the button pressed to quickly advance the digits.

Press both buttons simultaneously to reset the time and day

to the factory default setting.

Day of the week:

Use the button to scroll through days of the week and set

the current day.

Press the button to exit the basic settings screens and move

to the operation programming screens.

Total Reset Operation

In order to return the controller to its factory defaults setting,

erasing the memory, and restarting the controller operation,

press the button for at least 6 seconds.

10

Pressure Management Application Settings

BERMAD’s pilot switch pressure management application is

based on a series 700 control valve equipped with two pressure

reducing pilots: one for high pressure setting and the other for low

pressure setting. Normally the high pressure pilot controls the

valve, while the low pressure pilot is on standby mode. A Subtv

controller with a DC solenoid can switch the high pressure pilot

with the low pressure pilot according to a pre defined time based

operation regime.

Such arrangement can switch the system to low pressure

settings during night, while maintaining high pressure during

day time.

The system is also equipped with a high flow switch that can stop

the low pressure regime when higher demand for water is

detected, such as in case of fire.

The following chapter describes the programming steps required

for setting-up this application:

Programming a Pressure Management Application

The Subtv operation programs consist of three parameters

per each valve program: Operation Time or Volume, Operation

Days, and Start Time.

For controlling BERMAD’s Pressure Management Application

the controller is supplied with a single solenoid (valve), operated

by time with up to three start times a day, and with a flow switch.

In municipal water systems the demand for water in residential

neighborhoods is high during the mornings and evenings and low

during the night and mid day hours; therefore, the control valve

is set for the high pressure during high demand hours.

11

Operating the valve with the Subtv controller reduces the too

high pressure settings during the low demand hours.

For example, in typical such pressure regime, the day low

pressure hours are between 10:00 AM and 06:00 PM and the

night low pressure hours are between 10:00 PM and 06:00 AM,

during the high demand hours the valve maintains the high

pressure setting.

Therefore, the three required program parameters of the controller

are: Operation Time - 8 hours, Operation Days - 7 days and two

Start Times one at 10:00 and the other at 18:00.

1. Operation Time:

Use the button to move to the Operation Time programming

screen, this is the screen with blinking icon, blinking triangle

with the digit 1 in it, and the icon. Use the and the

buttons to set the required operation time (8:00 hours in our example).

Press the button to move to the next programming screen

which is the Operation Days screen.

2. Operation Days:

Use the to set a particular day as an operation day, the cursor

will advance to the next day. In our example set all 7 week days

for operation.

Press the button to move to the next programming screen

which is the Start Times screen.

3. Start Times:

Use the and the buttons to set the first required Start

Timed (10:00 in our example).

Press the button to move to the second Start Time and set

it as required (22:00 in our example).

The controller is now set for automatically operating the Pressure

Management Application.

12

Dead-end Pipes Purging Application Settings

Due to operational conditions, in some municipal and industrial

water systems, there is a need for periodic purging of the

systems dead-ends of pipes for refreshing the water supply.

BERMAD’s control valves equipped with Subtv controllers can be

installed in these systems. BERMAD’s Dead-end Pipes Purging

Application accounts for the purging out of the system. This task

is automatically performed based on three major parameters:

1. Purging interval - set at specific days of the week or as

day’s interval

2. Amount of purged water - set by operation time or by volume

3. Start time - set for the operation day (with up to three start

times per such day)

The following examples depict three typical scenarios:

A. Purging interval by Days of the Week and purging

amount by operation time:

In this example the pipe needs to be purged for 5 minutes every

Monday and Friday at 08:00 AM. Therefore, the three required

program parameters of the controller are: Operation Time - 5

Minutes, Operation Days - Monday and Friday, and Start Time

at 08:00 AM.

1. Operation Time:

Use the button to move to the Operation Time programming

screen - this is the screen with blinking icon, blinking triangle

with the digit 1 in it and the icon. Use the and the

buttons to set the required operation time (00:05 minutes in

our example).

Press the button to move to the next programming screen

which is the Operation Days screen.

13

2. Operation Days:

Use the to set a particular day as an operation day, the cursor

will advance to the next day. In our example set Monday and

Friday for operation.

Press the button to move to the next programming screen

which is the Start Times screen.

3. Start Time:

Use the and the buttons to set the required Start Time

(08:00 in our example).

The controller is now set for automatically operating this Dead

end Pipes Purging Application.

B. Purging interval by Days Interval and purging amount

by operation time:

In this example the pipe needs to be purged for 5 minutes every

10 days at 08:00 AM. Therefore the three required program

parameters of the controller are: Operation Time - 5 Minutes,

Operation Interval - 10 days, and Start Time at 08:00 AM.

1. Operation Time:

Use the button to move to the Operation Time programming

screen - this is the screen with blinking con, blinking triangle

with the digit 1 in it and the icon. Use the and the

buttons to set the required operation time (00:05 minutes in

our example).

Press the button to move to the next programming screen

which is the Operation Days screen.

14

2. Operation Interval:

On the days of the week screen press the button to 7 times

for skipping the operation by days of the week and advancing

the cursor to the Days Cycle line. Two numbers appear on this

line: the right number presents the program’s Days Interval

and the left number display the number of days left till the next

operation day. Note that during the first setup of this program

the number of day till next operation number is zero.

Use the and the buttons to set the required Days Interval

(10 days in our example). Note that the maximal interval is

30 days.

Press the button to move to the next programming screen

which is the Start Times screen.

3. Start Time:

Use the and the buttons to set the required Start Time

(08:00 in our example).

The controller is now set for automatically operating this

Dead-end Pipes Purging Application.

C. Purging interval by days of the week and purging

amount by Water Volume:

In this example the pipe needs to be purged for 50 water

meter pulses every Monday and Friday at 08:00 AM. Therefore,

the three required program parameters of the controller are:

Operation Volume - 50 pulses, Operation Days - Monday and

Friday, and Start Time at 08:00 AM.

In order to operate the above program the system should be

based on BERMAD’s series Hydrometer, or on other BERMAD’s

control valve and a water meter. The Subtv controller should be

also set to volumetric operation, which can be done only at the

15

initial setup process of the controller (when power is connected

or when the controller’s reset operation is performed).

1. Operation Volume:

Make sure that the controller is configured for Volume operation

as described in the BASIC SETTINGS chapter at the beginning

of this document.

Once a Volumetric operation is set on the first setup screen,

press the icon to move to the next water meter setting

screen. This screen allows the user to set the following water

meter parameters:

High Flow Rate (H.F.R.) - indicated by the on-screen icon.

This parameter defines the minimal allowed time between two

water meter pulses. When pulses are received in shorter interval

than this parameter a High Flow indication is presented by the

controller and the operation stops. (See the fault messages

paragraph in the monitoring chapter below.) The factory default

is 60 seconds; use the and the buttons to set the required

H.F.R. parameter.

Press the button to move to the next water meter

setup parameter.

Timer Override (T.O.R.) - indicated by the on-screen icon.

This parameter defines the maximal allowed time between two

water meter pulses. When pulses are received in longer interval

than this parameter a water meter malfunction indication is

presented by the controller and the operation stops. (See the fault

messages paragraph in the monitoring chapter below.)

The factory default is 10 minutes; use the and the buttons

to set the required T.O.R. parameter.

Press the button to move to the next water meter

setup parameter.

16

Fill-Up Time (F.U.T.) - indicated by the on-screen icon.

This parameter defines the time it takes to fill-up the system

pipes at the beginning of the valve operation. During this time

the system does not enter to High Flow fault. In purging systems

where the purged water is released by open-end pipe to the

atmospheric pressure, the flow rate can be high. Make sure

that the F.U.T. and the H.F.R. parameters are correctly set for

your system requirements. The F.U.T. factory default value is

6 minutes and it can be changed by the and buttons.

Press the button to move to the next programming screen.

Move to the Operation length programming screen, this is the

screen with blinking icon, blinking triangle with the digit 1

in it, and the icon. Use the and the buttons to set

the required operation volume (050 pulses in our example).

Press the button to move to the next programming screen

which is the Operation Days screen.

2. Operation Days:

Use the to set a particular day as an operation day, the cursor

advances to the next day. In our example set Monday and Friday

for operation.

Press the button to move to the next programming screen

which is the Start Times screen.

3. Start Time:

Use the and the buttons to set the required Start Time

(08:00 in our example).

The controller is now set for automatically operating this

Dead-end Pipes Purging Application.

17

Monitoring

When no button is pressed in the controller’s keyboard for

3 minutes, the controller moves to the main monitoring screen

indicated by the word AUTO in the middle of the screen.

The AUTO screen displays the current status of the controller,

which includes the current time and day, as well as the opened

valve indication and its remaining operation time or volume.

During a fault or malfunction mode the relevant fault message

overrides the AUTO screen data, see the faults table below.

To cancel the fault check the system for the cause of the fault,

repair the necessary components and then press the and

the buttons simultaneously for 2 seconds.

Please note:

■When a fault message is displayed on the AUTO screen moving

to the other screens is not possible.

■In case the controller has more than one fault, this screen

alternates the current fault messages every few seconds.

Fault Messages Table

Type Display Operation stopped at: Remarks

Low Battery "AL:bt" All Valves (!) "OFF" icon is lit

Too High

Current

Usage

"AL:Cr" The faulty valve only The valve's

number icon is lit

High Flow "AL:HF" The faulty valve only The valve's

number icon is lit

Timer

Override "AL:tr" All Valves (!) Automatically canceled

at midnight

18

Manual Operation

The operator may manually start / stop the operation of the valve

at the manual operation screen.

Move to the manual operation screen by pressing the button

at any screen for 2 seconds. The icon appears.

Use the and the buttons to start or stop the operation

of the valve. Please note that when manually started, the valve

operates for the duration of its programmed operation time or

operation volume.

Disclaimer

The Subtv is a general purpose controller supplied as an

electronic device controlling BERMAD valves. Therefore this

document is limited to BERMAD’s applications only.

Table of contents

Other BERMAD Controllers manuals

Popular Controllers manuals by other brands

Extron electronics

Extron electronics PC 101 Setup guide

Envirowise

Envirowise D30 Installer's and owner's manual

YASKAWA

YASKAWA Motoman DX200 instructions

EuroLite

EuroLite D-4 user manual

Linak

Linak Deskline DL7 system user manual

Sentera Controls

Sentera Controls MTP-D010 Series Mounting and operating instructions