Bernecker + Rainer 4XP0000.00-K64 Guide

4XP0000.00-K64

Technical documentation

Version: 1.40 (March 2017)

4XP0000.00-K64

All information contained in this manual is current as of its creation/publication. We reserve the right to change

the contents of this manual without notice. The information contained herein is believed to be accurate as of

the date of publication; however, Bernecker + Rainer Industrie-Elektronik Ges.m.b.H. makes no warranty, ex-

pressed or implied, with regard to the products or documentation contained within this manual. In addition,

Bernecker + Rainer Industrie-Elektronik Ges.m.b.H. shall not be liable for any incidental or consequential damages

in connection with or arising from the furnishing, performance or use of the product(s) in this documentation. Soft-

ware names, hardware names and trademarks are registered by their respective companies.

Table of contents

2 Data sheet V1.40 4XP0000.00-K64

1 Views.......................................................................................................................... 3

2 General information.................................................................................................. 5

2.1 Order data....................................................................................................................................................... 5

2.1.1 Description................................................................................................................................................. 5

2.1.2 Version information....................................................................................................................................5

2.2 Organization of safety notices........................................................................................................................ 6

2.3 Guidelines........................................................................................................................................................6

3 Complete system - Technical data..........................................................................7

3.1 Device interfaces.............................................................................................................................................7

3.1.1 X2X interface............................................................................................................................................. 7

3.1.2 Power supply............................................................................................................................................. 7

3.1.3 Functional ground...................................................................................................................................... 8

3.2 Technical data.................................................................................................................................................9

3.3 Dimensions....................................................................................................................................................10

3.4 Cutout installation..........................................................................................................................................11

3.5 Installation guidelines....................................................................................................................................12

3.6 Panel overlay design.................................................................................................................................... 13

3.6.1 Slide-in label design................................................................................................................................ 13

3.7 Device label...................................................................................................................................................14

3.8 Key and LED configuration...........................................................................................................................15

4 Safety guidelines.....................................................................................................16

4.1 Intended use................................................................................................................................................. 16

4.2 Protection against electrostatic discharge.................................................................................................... 16

4.2.1 Packaging................................................................................................................................................ 16

4.2.2 Guidelines for proper ESD handling....................................................................................................... 16

4.3 Policies and procedures............................................................................................................................... 17

4.4 Transport and storage.................................................................................................................................. 17

4.5 Installation..................................................................................................................................................... 17

4.6 Operation.......................................................................................................................................................17

4.6.1 Protection against touching electrical parts............................................................................................ 17

4.6.2 Environmental conditions - Dust, moisture, corrosive gases.................................................................. 17

4.6.3 Viruses and dangerous programs...........................................................................................................18

4.7 Environmentally friendly disposal..................................................................................................................18

4.7.1 Separation of materials........................................................................................................................... 18

5 Maintenance and servicing.................................................................................... 19

5.1 Cleaning........................................................................................................................................................ 19

5.2 Surface resistance of the panel overlay....................................................................................................... 19

Views

Data sheet V1.40 4XP0000.00-K64 3

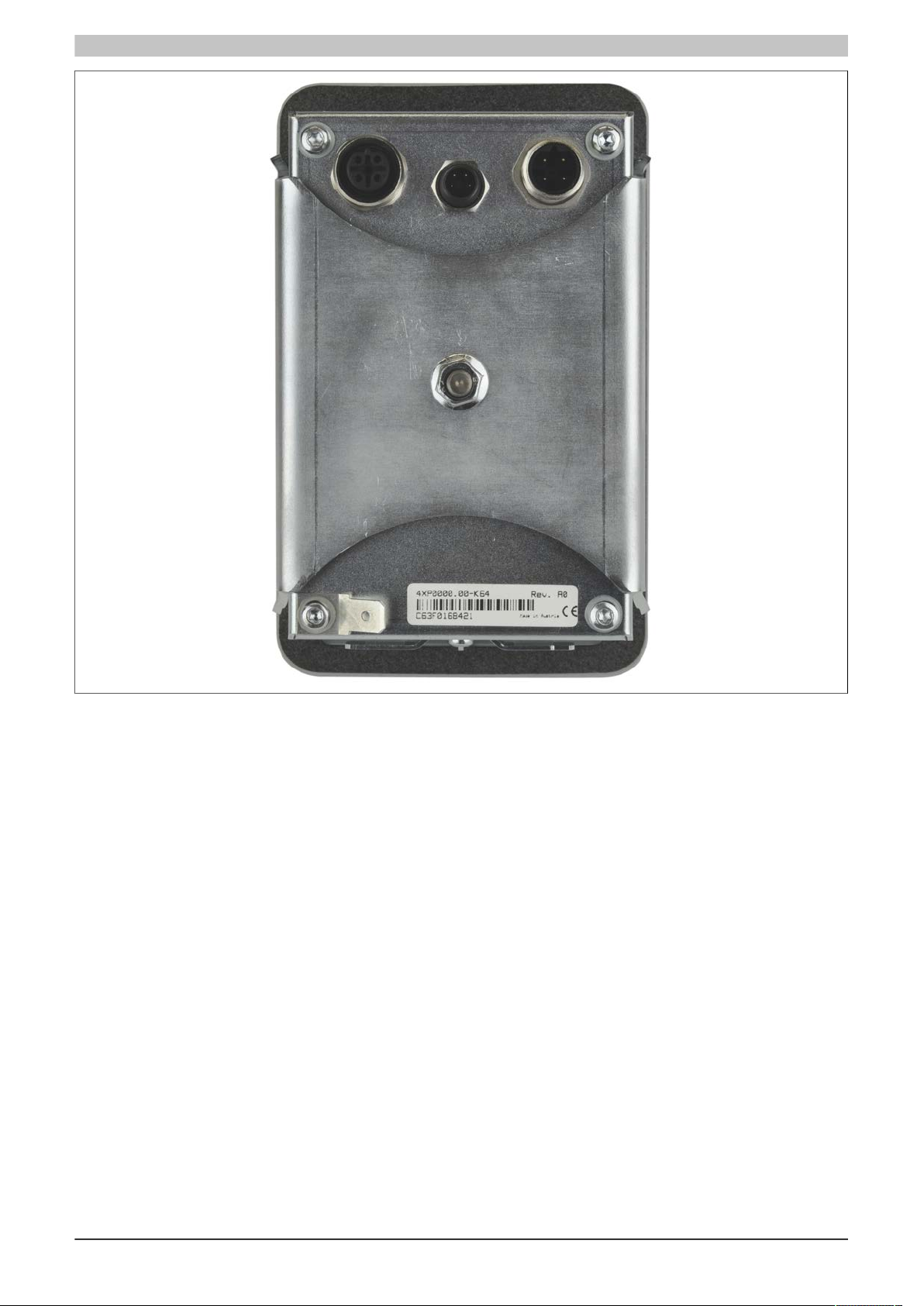

1 Views

Figure 1: 4XP0000.00-K64 - Oblique view

Views

4 Data sheet V1.40 4XP0000.00-K64

Figure 2: 4XP0000.00-K64 - Rear view

General information

Data sheet V1.40 4XP0000.00-K64 5

2 General information

Information:

B&R makes every effort to keep technical descriptions as current as possible. The latest version of

this technical description can be downloaded in PDF format from the B&R website at www.br-automa-

tion.com.

This user's manual is not intended for end customers! It is the responsibility of the machine manufac-

turer or system provider to provide the safety guidelines relevant to end customers in the operating

instructions for the end customer in the respective local language.

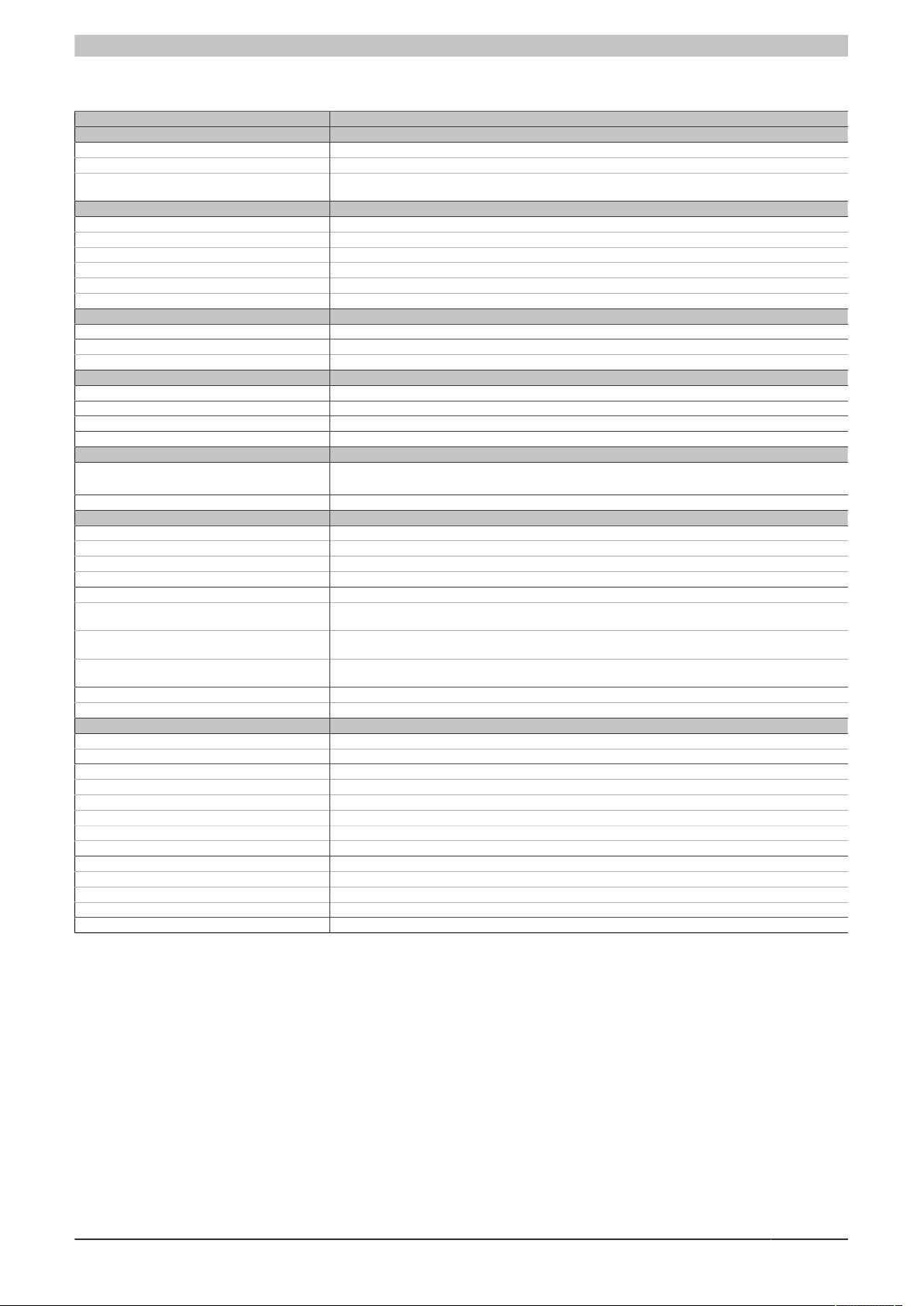

2.1 Order data

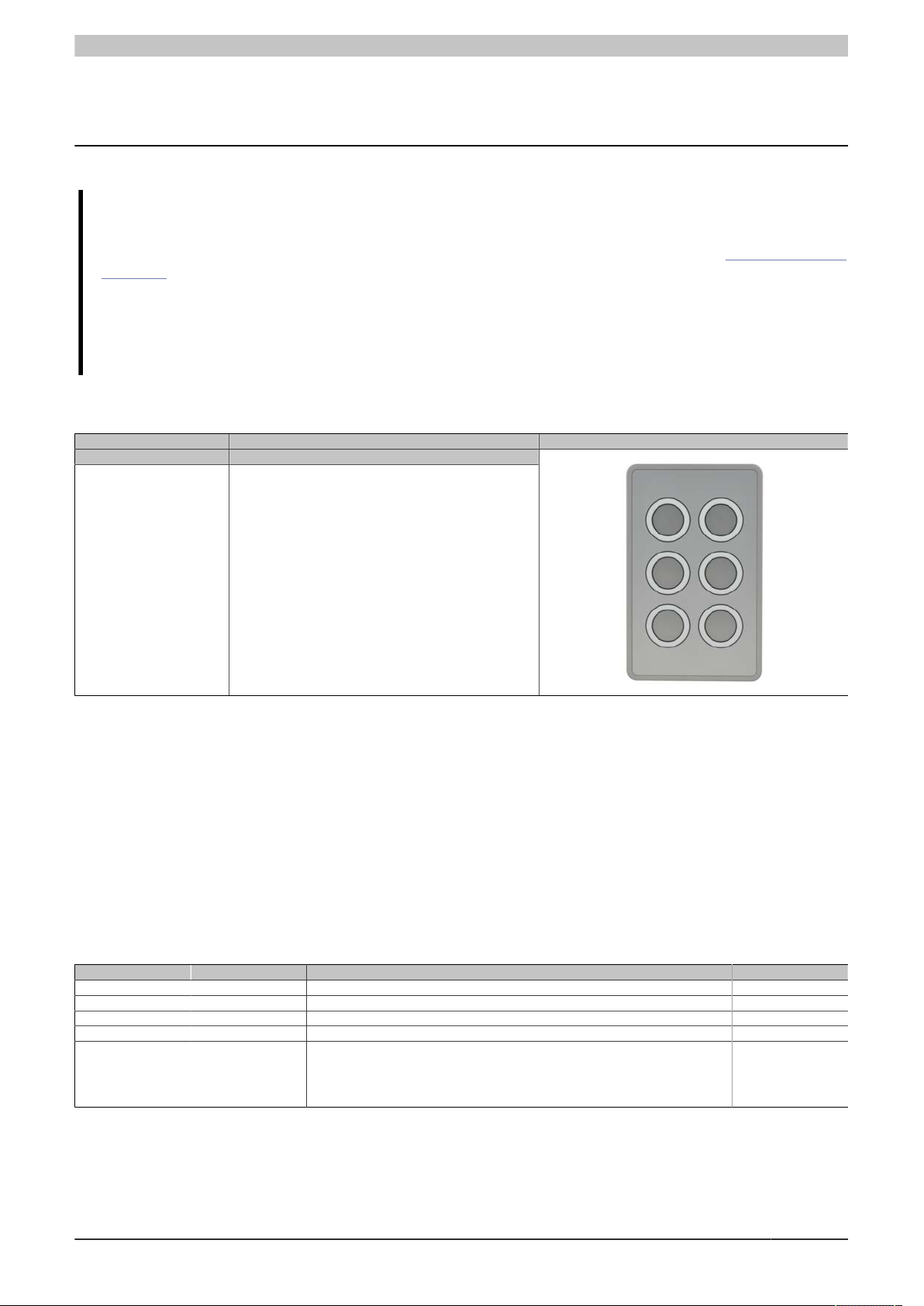

Model number Short description Figure

Keypad modules

4XP0000.00-K64 X2X keypad module, 6 B&R illuminated ring keys, 4-color

(green, yellow, red, white), IP65 protection, fast mounting using

single screw; connection made using M8/M12 circular connec-

tors

Table 1: 4XP0000.00-K64 - Order data

2.1.1 Description

4XP0000.00-K64 is a generally available add-on keypad with the following specifications:

•X2X keyboard

•Aluminum front with anodized surface

•6 B&R illuminated ring keys (green, yellow, white, red)

•Front and back: IP65 protection

•Fast mounting using a single screw

2.1.2 Version information

Version Date Comment Responsible

1.00 2011-09-16 First edition Anna Sigl

1.10 2012-03-21 Redesign Anna Sigl

1.20 2012-03-28 Pinout valid in Rev. C0 and later Anna Sigl

1.30 2013-01-11 Temperature specification Anna Sigl

1.40 2017-03-01 Updated data sheet.

•Updated information about power supply.

•Updated IP65 protection on front and back.

•Updated UL certification.

Nadine Koch

Table 2: Version information

General information

6 Data sheet V1.40 4XP0000.00-K64

2.2 Organization of safety notices

Safety notices in this manual are organized as follows:

Safety notice Description

Danger! Disregarding these safety guidelines and notices can be life-threatening.

Caution! Disregarding these safety guidelines and notices can result in severe injury or substantial damage to property.

Warning! Disregarding these safety guidelines and notices can result in injury or damage to property.

Information: This information is important for preventing errors.

Table 3: Organization of safety notices

2.3 Guidelines

E

European dimension standards apply to all dimension diagrams in this document.

All dimensions are specified in mm.

Unless otherwise specified, the following general tolerances apply:

Range of nominal sizes General tolerance according to

DIN ISO 2768 (medium)

Up to 6 mm ±0.1 mm

For 6 to 30 mm ±0.2 mm

For 30 to 120 mm ±0.3 mm

For 120 to 400 mm ±0.5 mm

For 400 to 1000 mm ±0.8 mm

Table 4: Range of nominal sizes

Complete system - Technical data

Data sheet V1.40 4XP0000.00-K64 7

3 Complete system - Technical data

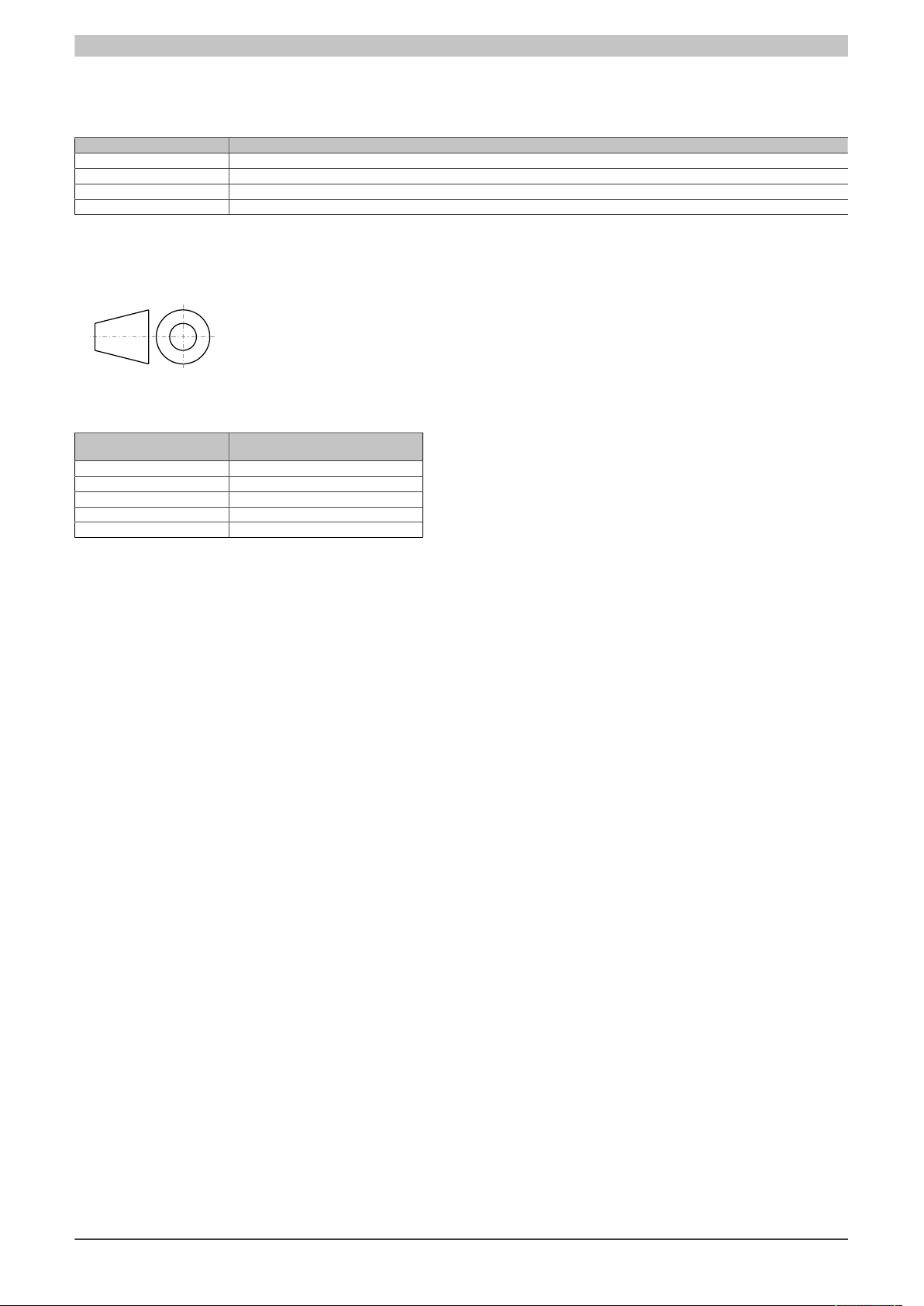

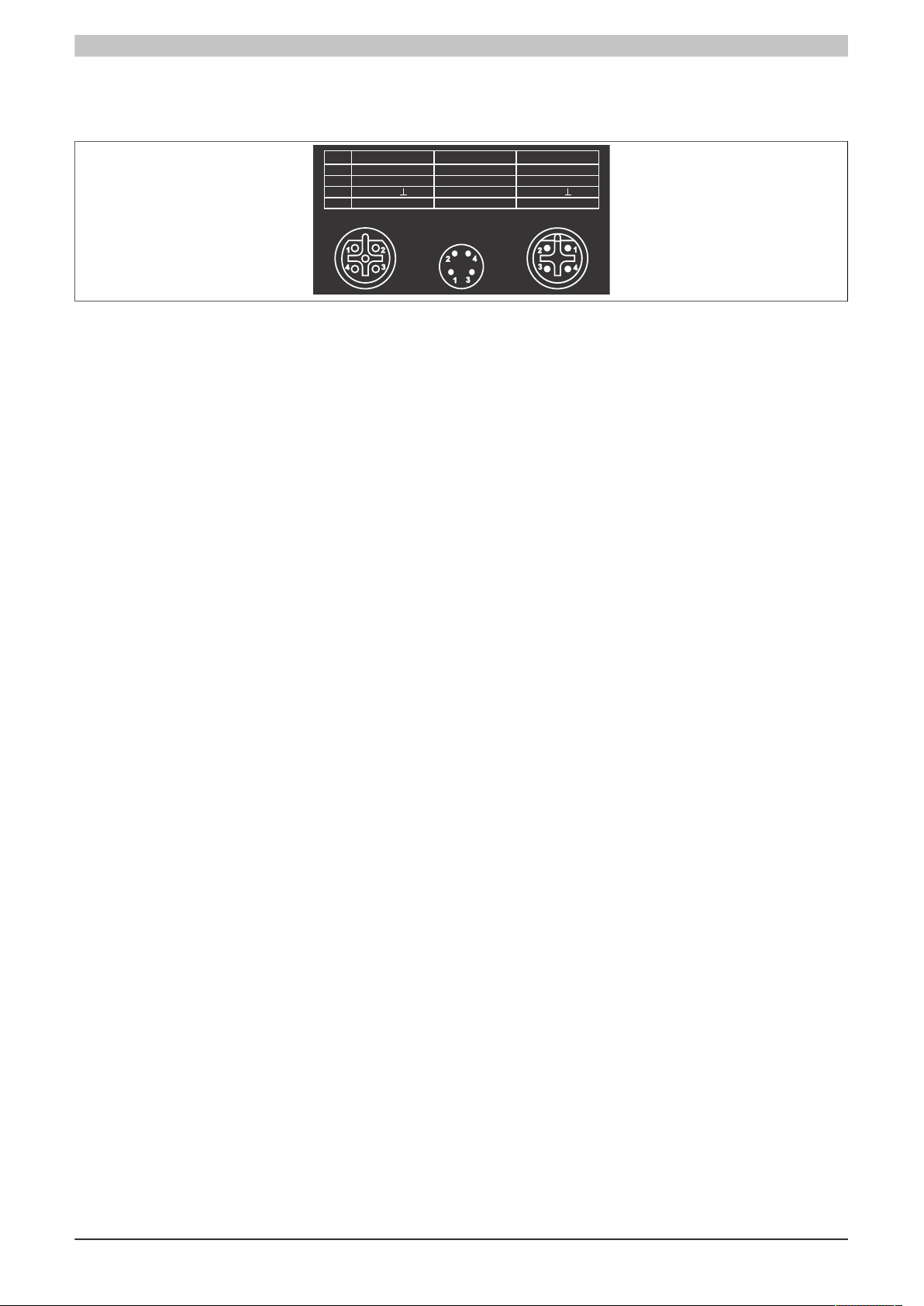

3.1 Device interfaces

X2X OUT Power supply

X2X IN

Figure 3: 4XP0000.00-K64 - Device interfaces

3.1.1 X2X interface

X2X IN & OUT (M12 connectors)

X2X IN

Pin Description

1 X2X +

2 X2X

3 X2X ⊥

4 X2X \

X2X OUT

Pin Description

1 X2X +

2 X2X

3 X2X ⊥

4 X2X \

Table 5: X2X IN & OUT (M12 connectors)

Information:

The connector's pin assignments are designed so that standard X67 bus cables can be used.

3.1.2 Power supply

24 VDC voltage supply (M8 connector)

Power supply

Pin Description

1 24 V DC

2 24 V DC

3 GND

4 GND

Table 6: Power supply

Complete system - Technical data

8 Data sheet V1.40 4XP0000.00-K64

Information:

No bus power supply is necessary to operate the device (X2X Link power supply). The panel does not

have a power supply to provide bus voltage to additional devices.

The bus power supply is simply routed from the X2X IN connection to the X2X OUT connection and

can only supply additional bus stations using power supply modules with an X2X Link power supply.

3.1.3 Functional ground

A functional grounding clip is located next to the power supply connector. This grounding clip (functional ground)

must be connected to a central grounding point on the control cabinet using a 6.3 mm tab connector and the

shortest possible path with the least resistance possible (e.g. copper strip, at least 2.5 mm²).

Important!

The functional ground (pin 2) must be connected to ground (e.g. control cabinet) using the shortest

possible path. Using the largest possible conductor cross section on the power supply connector is

recommended.

Complete system - Technical data

Data sheet V1.40 4XP0000.00-K64 9

3.2 Technical data

Model number 4XP0000.00-K64

General information

Certification

CE Yes

UL cULus E115267

Industrial Control Equipment

Interfaces

X2X

Type X2X slave

Design 4-pin M12 connector

Internal bus supply Yes

Distance between 2 stations 100 m

Electrical isolation Yes

Keys

Illuminated ring keys 6x B&R illuminated ring keys

Illuminated ring keys

Color Red, green, yellow, white

Electrical characteristics

Nominal voltage 24 VDC

Power consumption Max. 8 watts

Voltage range 18 - 30 VDC

Current consumption Max. 320 mA (at nominal voltage)

Operating conditions

EN 60529 protection •Front: IP65

•Back: IP65

UL 50 protection Front: Type 4X indoor use only

Environmental conditions

Temperature

Operation 0 to +50°C

Storage -20 to +60°C

Transport -20 to +60°C

Relative humidity

Operation T ≤ 40°C: 5 to 85%, non-condensing

T > 40°C: < 75%, non-condensing

Storage T ≤ 40°C: 5 to 90%, non-condensing

T > 40°C: < 75%, non-condensing

Transport T ≤ 40°C: 5 to 90%, non-condensing

T > 40°C: < 75%, non-condensing

Elevation

Operation Max. 3000 m

Mechanical characteristics

Housing

Material Sheet metal, galvanized

Front

Frame Naturally anodized aluminum

Design RAL 9006

Panel overlay

Material Polyester

Gasket Flat gasket around display front

Dimensions

Width 77 mm

Height 123 mm

Depth 52.6 mm

Weight 450 g

Table 7: 4XP0000.00-K64 - Technical data

Complete system - Technical data

10 Data sheet V1.40 4XP0000.00-K64

3.3 Dimensions

Figure 4: 4XP0000.00-K64 - Dimensions

Complete system - Technical data

Data sheet V1.40 4XP0000.00-K64 11

3.4 Cutout installation

The cutout hole must be made according to the following dimensions for cutout installations. These devices are

best installed in a cutout using the mounting clips on the housing or clamping blocks (various designs possible).

469 4

8

110

5

Cutout dimensions:

110 0.5 mm x 69 0.5 mm+ +

Figure 5: 4XP0000.00-K64 - Cutout installation

Warning!

Ensure that slide-in labels do not become caught when installing the module.

Complete system - Technical data

12 Data sheet V1.40 4XP0000.00-K64

3.5 Installation guidelines

Mount the device in the cutout using the mounting bracket and an M5 Durlok nut (maximum torque 1.2 Nm).

Max. 1.2 Nm

Figure 6: 4XP0000.00-K64 - Installation guidelines

Complete system - Technical data

Data sheet V1.40 4XP0000.00-K64 13

3.6 Panel overlay design

Important:

This image is not a true representation of the colors used on the panel overlay.

The actual colors may vary slightly.

= RAL 9006 White aluminum

= Pantone Process black C

Color description:

= Translucent white B&R 017

Colors matched to

provided color sample!

= Transparent/Unprinted

Figure 7: 4XP0000.00-K64 - Panel overlay design

3.6.1 Slide-in label design

Important:

This image is not a true representation of the colors used on the panel overlay.

The actual colors may vary slightly.

= RAL 9006 White aluminum

= Pantone Process black C

Color description:

= Translucent white B&R 017

Colors matched to

provided color sample!

= Transparent/Unprinted

Figure 8: 4XP0000.00-K64 - Slide-in label design

Complete system - Technical data

14 Data sheet V1.40 4XP0000.00-K64

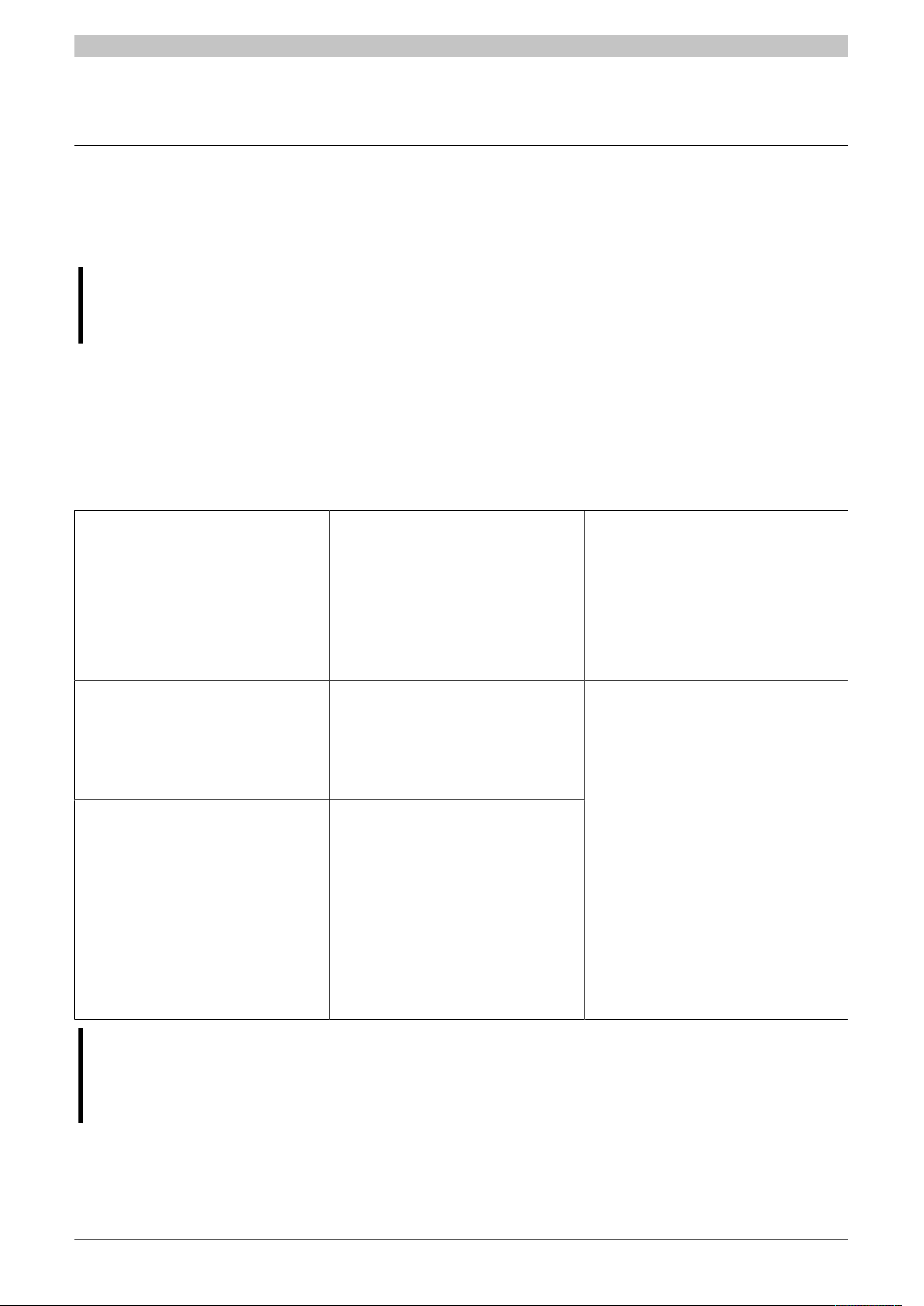

3.7 Device label

This label is attached to the back as a way to identify the interfaces.

C0036464-02

X2X IN

X2X OUT

POWER

SUPPLY

X2X IN

X2X OUT

4

1

2

3

Pin

POWER SUPPLY

24 V DC

GND

24 V DC

GND

X2X +

X2X

X2X \

X2X

X2X +

X2X

X2X \

X2X

Figure 9: 4XP0000.00-K64 - Device label

Complete system - Technical data

Data sheet V1.40 4XP0000.00-K64 15

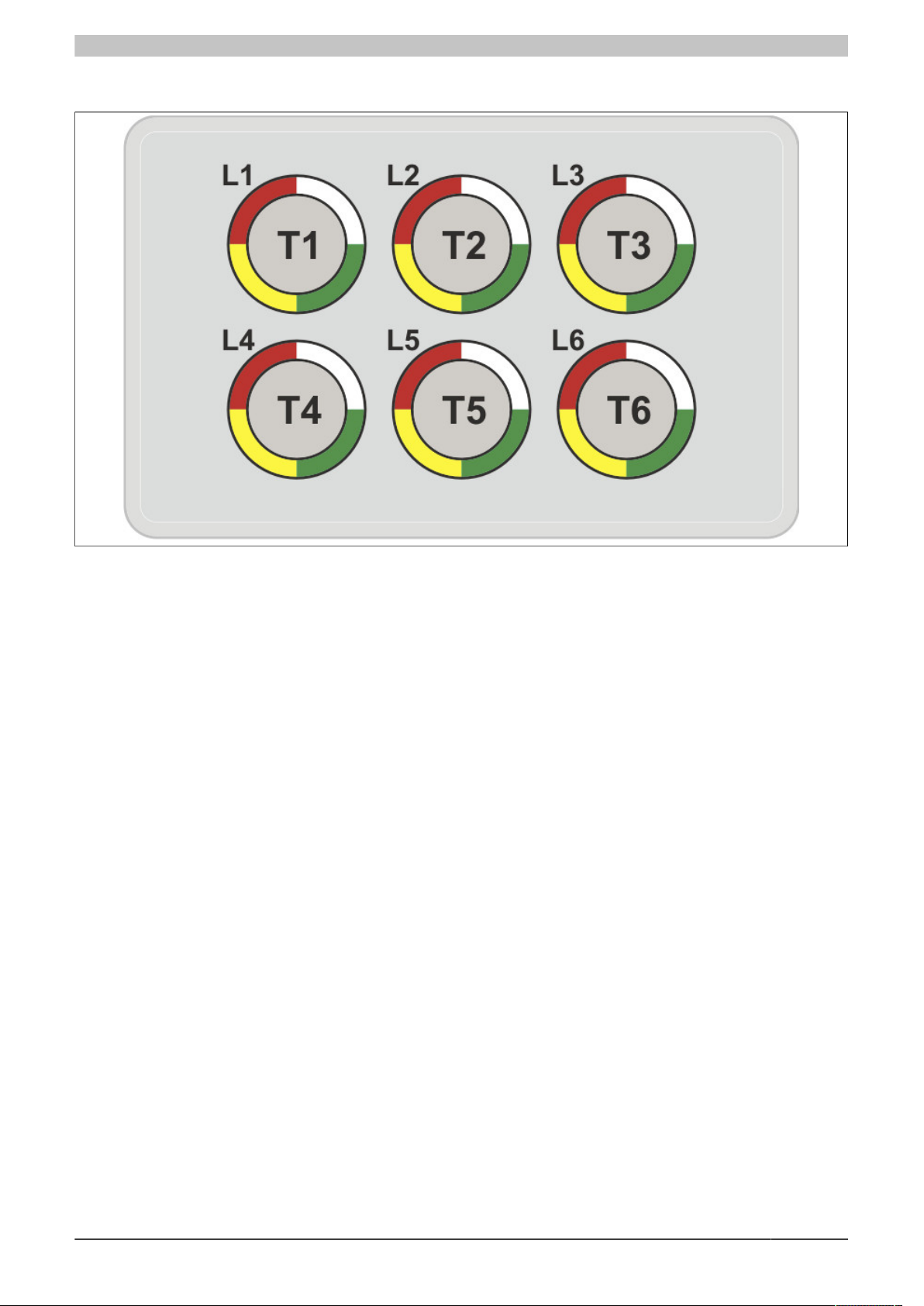

3.8 Key and LED configuration

Figure 10: 4XP0000.00-K64 - Key and LED matrix

Safety guidelines

16 Data sheet V1.40 4XP0000.00-K64

4 Safety guidelines

4.1 Intended use

Programmable logic controllers (PLCs), operating/monitoring devices (industrial PCs, Power Panels, Mobile Pan-

els, etc.) and B&R uninterruptible power supplies have been designed, developed and manufactured for conven-

tional use in industrial environments. They were not designed, developed and manufactured for any use involving

serious risks or hazards that could lead to death, injury, serious physical damage or loss of any kind without the

implementation of exceptionally stringent safety precautions. In particular, such risks and hazards include the use

of these devices to monitor nuclear reactions in nuclear power plants, their use in flight control or flight safety sys-

tems as well as in the control of mass transportation systems, medical life support systems or weapons systems.

4.2 Protection against electrostatic discharge

Electrical components that can be damaged by electrostatic discharge (ESD) must be handled accordingly.

4.2.1 Packaging

•Electrical components with a housing

...do not require special ESD packaging but must be handled properly (see "Electrical components with

a housing").

•Electrical components without a housing

…are protected by ESD-suitable packaging.

4.2.2 Guidelines for proper ESD handling

Electrical components with a housing

•Do not touch the connector contacts on connected cables.

•Do not touch the contact tips on circuit boards.

Electrical components without a housing

The following points apply in addition to the points listed under "Electrical components with a housing":

•Any persons handling electrical components or devices with installed electrical components must be

grounded.

•Components are only permitted to be touched on their narrow sides or front plate.

•Components should always be stored in a suitable medium (ESD packaging, conductive foam, etc.). Metal-

lic surfaces are not suitable storage surfaces!

•Components should not be subjected to electrostatic discharge (e.g. through the use of charged plastics).

•Ensure a minimum distance of 10 cm from monitors and TV sets.

•Measuring instruments and equipment must be grounded.

•Probes on potential-free measuring instruments must be discharged on sufficiently grounded surfaces be-

fore taking measurements.

Individual components

•ESD protective measures for individual components are thoroughly integrated at B&R (conductive floors,

footwear, arm bands, etc.).

•These increased ESD protective measures for individual components are not necessary for customers

handling B&R products.

Safety guidelines

Data sheet V1.40 4XP0000.00-K64 17

4.3 Policies and procedures

Electronic devices are never completely failsafe. If the programmable control system, operating/monitoring device

or uninterruptible power supply fails, the user is responsible for ensuring that other connected devices, e.g. motors,

are brought to a secure state.

When using programmable logic controllers or operating/monitoring devices as control systems together with a soft

PLC (e.g. B&R Automation Runtime or comparable product) or slot PLC (e.g. B&R LS251 or comparable product),

safety precautions relevant to industrial control systems (e.g. the provision of safety devices such as emergency

stop, etc.) must be observed in accordance with applicable national and international regulations. The same applies

for all other devices connected to the system, such as drives.

All tasks such as the installation, commissioning and servicing of devices are only permitted to be carried out by

qualified personnel. Qualified personnel are those familiar with the transport, mounting, installation, commissioning

and operation of devices who also have the appropriate qualifications (e.g. IEC 60364). National accident preven-

tion regulations must be observed.

The safety notices, connection descriptions (type plate and documentation) and limit values listed in the technical

data are to be read carefully before installation and commissioning and must be observed.

4.4 Transport and storage

During transport and storage, devices must be protected against undue stress (mechanical loads, temperature,

moisture, corrosive atmospheres, etc.).

4.5 Installation

•These devices are not ready for use upon delivery and must be installed and wired according to the spec-

ifications in this documentation in order for the EMC limit values to apply.

•Installation must be performed according to this documentation using suitable equipment and tools.

•Devices are only permitted to be installed by qualified personnel without voltage applied. Before installation,

voltage to the control cabinet must be switched off and prevented from being switched on again.

•General safety guidelines and national accident prevention regulations must be observed.

•Electrical installation must be carried out in accordance with applicable guidelines (e.g. line cross sections,

fuses, protective ground connections).

4.6 Operation

4.6.1 Protection against touching electrical parts

To operate programmable logic controllers, operating and monitoring devices, and uninterruptible power supplies,

certain components must carry dangerous voltage levels over 42 VDC. Touching one of these parts can result in

a life-threatening electric shock. This could lead to death, severe injury or damage to property.

Before turning on the programmable logic controller, operating/monitoring devices or uninterruptible power supply,

the housing must be properly grounded (PE rail). Ground connections must be established even when testing or

operating operating/monitoring devices or the uninterruptible power supply for a short time!

Before switching on the device, all parts that carry voltage must be securely covered. During operation, all covers

must remain closed.

4.6.2 Environmental conditions - Dust, moisture, corrosive gases

The use of operating/monitoring devices (e.g. industrial PCs, Power Panels, Mobile Panels, etc.) and uninterruptible

power supplies in very dusty environments should be avoided. Dust collection on the devices can affect functionality

and may prevent sufficient cooling, especially in systems with active cooling systems (fans).

The presence of corrosive gases can also lead to malfunctions. When combined with high temperature and hu-

midity, corrosive gases – e.g. with sulfur, nitrogen and chlorine components – can induce chemical reactions that

can damage electronic components very quickly. Signs of the presence of corrosive gases are blackened copper

surfaces and cable ends on existing equipment.

For operation in dusty or moist conditions, correctly installed (e.g. cutout installations) operating/monitoring devices

like the Automation Panel or Power Panel are protected on the front. The back of all devices must be protected

from dust and moisture and cleaned at suitable intervals.

Safety guidelines

18 Data sheet V1.40 4XP0000.00-K64

4.6.3 Viruses and dangerous programs

This system is subject to potential risk each time data is exchanged or software is installed from a data medium

(e.g. diskette, CD-ROM, USB flash drive, etc.), a network connection or the Internet. The user is responsible for

assessing these dangers, implementing preventive measures such as virus protection programs, firewalls, etc. and

making sure that software is only obtained from trusted sources.

4.7 Environmentally friendly disposal

All B&R programmable controllers, operating/monitoring devices and uninterruptible power supplies are designed

to inflict as little harm as possible on the environment.

4.7.1 Separation of materials

It is necessary to separate different materials so the device can undergo an environmentally friendly recycling

process.

Component Disposal

Programmable logic controllers

Operating/Monitoring devices

Uninterruptible power supply

Batteries and rechargeable batteries

Cables

Electronics recycling

Cardboard box / Paper packaging Cardboard box / Paper recycling

Plastic packaging Plastic recycling

Table 8: Environmentally friendly disposal

Disposal must comply with applicable legal regulations.

Maintenance and servicing

Data sheet V1.40 4XP0000.00-K64 19

5 Maintenance and servicing

This chapter describes servicing / maintenance work that can be carried out by a qualified end user.

5.1 Cleaning

Danger!

Switch off this device before cleaning in order to prevent unintended functions from being triggered

when handling the touch screen or pressing keys.

Use a moist cloth to clean this device. Only use water with detergent, a screen cleaning agent or alcohol (ethanol)

to moisten the cloth. Apply the cleaning agent to the cloth beforehand; do not spray it directly on the device! Never

use aggressive solvents, chemicals, scouring agents, pressurized air or steam jets.

5.2 Surface resistance of the panel overlay

The panel overlay conforms to DIN 42115 (Part 2). This means it is resistant to exposure to the following chemicals

for a 24-hour period with no visible signs of damage:

Ethanol

Cyclohexanol

Diacetone alcohol

Glycol

Isopropanol

Glycerine

Methanol

Triacetin

Dowandol

DRM/PM

Formaldehyde 37%-42%

Acetaldehyde

Aliphatic hydrocarbons

Toluene

Xylene

White spirits

Trichloroethane

Ethyl acetate

Diethyl ether

n-Butyl acetate

Amyl acetate

Butylcellosolve

Ether

Acetone

Methyl ethyl ketone

Dioxan

Cyclohexanone

Methylisobutylketone (MIBK)

Isophorone

Formic acid <50%

Acetic acid <50%

Phosphoric acid <30%

Hydrochloric acid <36%

Nitric acid <10%

Trichloracetic acid <50%

Sulphuric acid <10%

Ammonia <40%

Caustic soda <40%

Potassium hydroxide

Alkali carbonate

Bichromate

Potassium

Acetonitrile

Sodium bisulphate

Cutting oil

Diesel oil

Linseed oil

Paraffin oil

Ricinus oil

Silicon oil

Turpentine oil substitute

Brake fluid

Aviation fuel

Gasoline

Water

Sea water

Decon

Sodium chloride <20%

Hydrogen peroxide <25%

Potassium carbonate

Washing agents

Tenside

Fabric conditioner

Iron (II) chloride

Iron (III) chloride

Dibutyl phthalate

Dioctyl phthalate

Sodium carbonate

Information:

The specified characteristics, features and limit values only apply to this individual component and can

deviate from those specified for the complete system. For the complete system in which this individual

component is used, refer to the data given specifically for that device.

The panel overlay conforms to DIN 42115 Part 2 for exposure to glacial acetic acid for less than one hour without

visible damage.

Figure index

20 Data sheet V1.40 4XP0000.00-K64

Figure 1: 4XP0000.00-K64 - Oblique view............................................................................................. 3

Figure 2: 4XP0000.00-K64 - Rear view..................................................................................................4

Figure 3: 4XP0000.00-K64 - Device interfaces...................................................................................... 7

Figure 4: 4XP0000.00-K64 - Dimensions............................................................................................. 10

Figure 5: 4XP0000.00-K64 - Cutout installation................................................................................... 11

Figure 6: 4XP0000.00-K64 - Installation guidelines..............................................................................12

Figure 7: 4XP0000.00-K64 - Panel overlay design.............................................................................. 13

Figure 8: 4XP0000.00-K64 - Slide-in label design................................................................................13

Figure 9: 4XP0000.00-K64 - Device label............................................................................................ 14

Figure 10: 4XP0000.00-K64 - Key and LED matrix............................................................................... 15

Table of contents

Popular Control Unit manuals by other brands

GBD

GBD CB24 Instructions for installations

Xylem

Xylem McDonnell & Miller 750B-C3 Series instruction manual

GEZE

GEZE GCVR 800 Touch Assembly and installation instructions

Watts

Watts 2300 Series installation instructions

Kohler

Kohler GM77177-KP1-QS installation instructions

EOS

EOS EMOTEC L 09 Relay Assembly and operating instructions