BestCode Next 8 Series Manual

Next Series 8 CIJ Printer

Operators guide

Part Number: 49-0001-01

Software version 01.04.07+ , Jan 2020

PERSONAL INJURY: ALWAYS WEAR RUBBER GLOVES AND SAFETY GLASSES WHEN HANDLING

INKS AND SOLVENTS.

PERSONAL INJURY: ALWAYS WEAR RUBBER GLOVES AND SAFETY GLASSES DURING FLUIDIC

MAINTENANCE.

PERSONAL INJURY: INKS AND SOLVENTS ARE POISONOUS, DO NOT INGEST.

PERSONAL INJURY: DO NOT USE SOLVENT TO WASH INK FROM SKIN. IF EXPOSED, GENTLY

RINSE AREA WITH SOAPY WATER. IF IRRITATION PERSISTS, SEEK MEDICAL ATTENTION.

PERSONAL INJURY: BE AWARE OF DANGERS ASSOCIATED WITH FLUIDS. DO NOT USE A FLUID

UNTIL YOU ARE FAMILIAR WITH THE SDS AND THE INGREDIENTS.

PERSONAL INJURY: FOLLOW ALL SAFETY GUIDELINES OUTLINED IN THE SDS OF THE FLUIDS

BEING USED.

EQUIPMENT DAMAGE: DO NOT ADD FLUIDS UNLESS INSTRUCTED BY INDICATORS.

EQUIPMENT DAMAGE: THE PRINTHEAD MUST BE DRY BEFORE STARTING PRINTER.

EQUIPMENT DAMAGE: THE PRINTHEAD SHOULD NEVER BE COMPLETELY SUBMERGED IN

SOLVENT.

EQUIPMENT DAMAGE: DO NOT ATTEMPT TO USE MULTIMETER TO TAKE MEASUREMENTS ON

ANY COMPONENT WHILE THE MACHINE IS POWERED ON.

EQUIPMENT DAMAGE: DO USE MULTIMETER TO ATTEMPT TO MEASURE THE CHARGE

VOLTAGE AT THE PRINTHEAD. THIS WILL PERMANENTLY DAMAGE THE MAIN BOARD

FIRE HAZARD: INKS AND SOLVENTS ARE HIGHLY FLAMMABLE. NO SMOKING OR OPEN FLAMES

NEAR PRINTER OR FLUID STORAGE.

ELECTRICAL SHOCK: DISCONNECT MAIN POWER CABLE PRIOR TO SERVICING MACHINE.

ELECTRICAL SHOCK: NEVER RUN MACHINE WHILE ELECTRONICS COMPARTMENT DOOR IS

OPEN.

EQUIPMENT DAMAGE: The Next Series 8 CIJ must be Grounded/Earthed! Failure to

provide adequate grounding/earthing will result in damage to the circuit board,

printhead, and the power supply. This damage will occur over time. The Next Series 8

CIJ Power Supply generates a DC Ground to support the function of the Printer, but

this does not protect from static or power surges.

PERSONAL INJURY & EQUIPMENT DAMAGE: Do not use any power cord that is not provided by

BestCode. Power cords must have 3 prongs, live, neutral, and ground provided. Power socket-outlet

must provide reliable earth ground. Power cord and outlet must remain clean and dry. The socket-

outlet shall be installed near the equipment and shall be easily accessible. Do not use extension cords!

Follow all local safety regulations during installation and operation of the Next Series 8 CIJ.

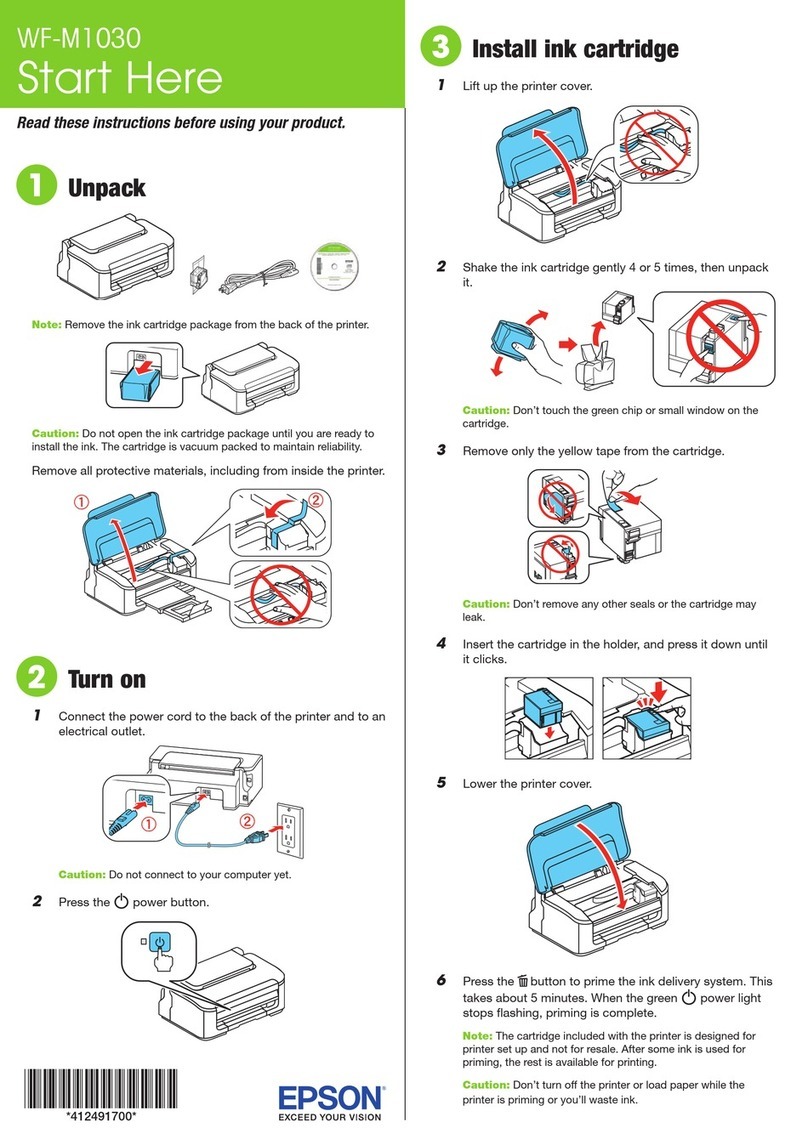

Ideal Mounting

Setup Time: 30 minutes

1. Follow instructions included with 40-0019-01

Controller Stand.

2. Plug the attached power cord into the power socket.

The socket-outlet shall be installed near the

equipment and shall be easily accessible.

Printhead mounting

Setup Time: 15 Minutes

1. Secure the printhead into the printhead clamp.

Clamp is included with:

Kit 40-0003-01 Printhead Floor Mount

Kit 40-0004-01 Printhead Conveyor Mount

2. The gutter should always be towards the floor.

3. Keep the gap between the product and the print slot

at 1/16”-1/2” inch.

4. Keep printhead square to the product to prevent print

distortion.

A 5°-10° angle between head and product may be

necessary in high static environments.

1

2

Power On / Off

Power On

Power Off

Start / Stop Jet

Start Jet

Stop Jet

Clean Start & Clean Stop are the normal production starts and stops. These use a small amount of makeup per

routine. The software will automatically protect the operator from adding too much makeup. When the

operator is logged in using the Technician Level Password, all Starts & Stops from the Home screen will be clean

stops. This is to help diagnose Cleam Start and Clean Stop problems.

Selecting a message for print

1. Press the Messages

Button.

2. Select the desire message.

3. Press the Select button.

4. The selected message will

now be the actively

printed message.

When to Add Ink

The BestCode Next Series 8 CIJ will begin requesting

an Ink bottle be added when the Float switch in the

Ink Tank is in the low state.

An on-screen pop-up Ink Warning, 10-0003 will

occur every 6 minutes while the Ink Tank is in this

State.

After 250,000,000 drops have been printed while in

the low state, the system will give the Empty

warning 10-0002.

A bottle of SmartFill Ink must be added to the

machine before the Jet can be started.

How to Add Ink

1. Place 1 capped bottle of Ink in the Ink

Smartfill Cup.

2. Make sure the SmartFill symbols are

aligned.

3. Press the Ink Status button on the

Screen.

4. This process works for Low and Empty

situations.

Low

Empty

5. Wait for the pop-up (10-0001)

6. DO NOT PRESS OK

Heavy Pigment fluids must

be shaken for 1 to 2 minutes

to ensure that the pigment is

suspended in the fluid and

not caked to bottle. Failure

to shake to bottle will result

no pigment being in the tank.

This will make faint print that

is not bright.

7. Remove the Ink bottle, and remove the

cap

8. Insert the bottle and press firmly to

break the foil seal

9. Wait for 1-2 minutes for the bottle to

drain

10. Discard the empty ink bottle in

accordance with local regulation.

11. Press OK on the Success screen pop-up

(10-0001)

When to Add Makeup

The BestCode Next Series 8 CIJ will allow a

Makeup bottle to be added when the Float

switch in the Makeup Tank is in the OK state.

The BestCode Next Series 8 CIJ will begin

requesting a Makeup bottle be added when the

Makeup float switch in the Makeup Tank is in the

low state.

An on-screen pop-up Makeup Warning, 11-0003

will occur every 6 minutes while the Makeup

Tank is in this State.

When the Makeup float switch is in the low

state, 15 Makeup Adds will be allowed, and then

a Makeup Fault 11-0002 will occur.

The Jet cannot be started again until a new

bottle of SmartFill Makeup is added.

How to Add Makeup

1. Place 1 capped bottle of Makeup in the

Makeup Smartfill Cup .

2. Make sure the SmartFill symbols are aligned.

3. Press the Makeup Status button on the

Screen.

4. This process works for Low, Empty, and OK

situations.

Empty

Low

OK

5. Wait for the pop-up (11-0001)

6. DO NOT PRESS OK

7. Remove the Makeup bottle, and remove the

cap

8. Insert the bottle and press firmly to break the

foil seal.

9. Wait for 1-2 minutes for the bottle to drain

10. Discard the empty Makeup bottle in

accordance with local regulation.

11. Press OK on the Success screen pop-up (11-

0001)

Backflush Nozzle

1. Place the Printhead into the Printhead Clean Station

(P/N 40-0020-01)

2. Press the Back Flush button (Service screen OR Clean

screen).

3. Using the cleaner for the ink type of the machine,

immediately spray makeup directly onto the nozzle plate

for 10 seconds. (50-100ml of cleaner).

4. Focus on cleaning the Drop Generator Nozzle, Phase

Detector, Charge Electrode Slot, High Voltage Plates,

Gutter, and Print Slot.

5. Allow the head to completely dry before starting the jet.

BestCode Information

3034 SE Loop 820 Phone: (+1) 817-349-8555 For product questions email:

Fort Worth TX Fax: 817-349-8480 info@bestcode.co

76140 USA

www.bestcode.co

BestCode product and fluids are available through distribution around the globe.

Contact your local BestCode distributor for ordering information.

Made in the USA

Other manuals for Next 8 Series

2

Table of contents

Other BestCode Printer manuals

Popular Printer manuals by other brands

Epson

Epson SC-p400 series user guide

Seiko I Infotech

Seiko I Infotech IP-5620 user guide

Epson

Epson Stylus Pro 7880 ColorBurst Edition - Stylus Pro 7880... user guide

Samsung

Samsung CLP 610ND - Color Laser Printer Service manual

NSR Marine

NSR Marine NPT-100 user manual

Rimage

Rimage Everest Encore Setup and installation guide