Beta Marine D Panel User manual

Operators

Maintenance

Manual

Control Panel D - Digital

Operators

Maintenance

Manual

Control Panel D - Digital

1

Is our most technically advanced engine control/monitor

whose module is water resistant to IP67 and has a super

bright screen that facilitates viewing in both strong

sunlight and also at night, simply select the appropriate

setting to ensure that it is always easy on the eye.

As well as controlling the engine ‘STOP’, ‘PRE-HEAT’ and

‘START’ functions at the press of a button it also allows

you to digitally monitor engine RPM, engine temperature,

oil pressure and provides a voltmeter for either single or

twin alternators.

The panel uses standard Micro-C connection which allows

data to be relayed and viewed all across your on-board

network. It is compatible with NMEA 2000 & IEC 61 162-3

On vessels with twin engine installations each engine

control panel needs to be programmed as Port and

Starboard to facilitate dual or independent viewing on

other network devices.

CONTROL PANEL ‘D’ - DIGITAL

{

Port Engine

(or Single Installation)

Primary

Control Location

Secondary

Control Location

Starboard Engine

Fuel Tank GPS

Power Source

Radar Depth Sounder

2

STARTING

1. Switch the panel on via the ‘POWER switch.

Note: The screen takes 5 - 10 seconds to power up

the display, during this time you can continue to...

2. Press and hold the ‘HEAT’ for 7 seconds.

3. Press and hold the ‘START’ button until the engine

starts. No more than 3 seconds as this could damage

the starter motor.

STOPPING

1. Press the ‘STOP’ button until the engine stops. This

should not be more than 5 seconds.

2. Switch off the ‘POWER’ switch. Any alarm will be

shown on the display screen.

OPERATING THE ENGINE

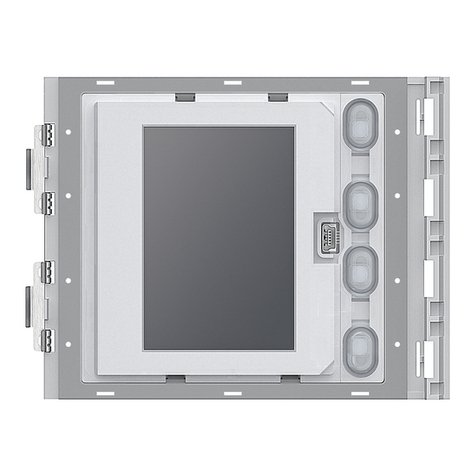

{

Digital

Dashboard

Display

Control Button

Power Switch

For Display Only

Push Buttons

For Engine Control

(Functionality retained even

when display is powered off)

PANEL LAYOUT

{

3

Along the bottom of the display there are 5 display control buttons.

USING THE DISPLAY

{

DISPLAY BUTTON FUNCTIONALITY:

1

This button displays general over view of engine

speed, oil pressure, water temp and alarms. Pressing

a second time will change the display to the night

screen.

2

This button displays water temp oil pressure and

battery voltage. (If you have a second alternator

fitted this will display domestic battery as well).

Pressing a second time will change to night screen.

3

This button displays a bar graph version of all

readable values. Pressing a second time will change

to night screen.

4

This button displays software version and/or revision.

5

This button displays the screen adjustment menu.

1 2 3 4 5

4

DEMO ON/OFF

When highlighted in a yellow bar the sales demonstration

mode can be switched on or off by pressing button

4

.

If no further functionality changes are required, pressing

button

5

again saves settings and exits the CONFIG

menu, returning the screen view to the normal digital

dashboard.

Press button

1

to scroll up or

2

to scroll down the

screen to highlight CONFIG menu options.

SETTINGS

When highlighted in a yellow bar, pressing button

4

allows access to the full SETTINGS menu.

CONFIG MENU

{

DISPLAY BUTTON FUNCTIONALITY:

1

Decreases display brightness.

2

Increases display brightness.

3

Decreases display contrast.

4

Increases display contrast.

5

Saves settings and exits menu.

DISPLAY SCREEN ADJUSTMENT MENU

{

1 2 3 4 5

1 2 3 4 5

5

1 2 3 4 5

1 2 3 4 5

BLEEP ON/OFF

When highlighted as a yellow bar you can turn the key

sound on or off by pressing button

4

. If no further

functionality changes are required pressing button

5

saves settings and exits the SETTINGS menu.

Press button

2

to scroll down the screen to highlight -

RPM Calibrate

When highlighted as a yellow bar enter this option by

pressing button

4

.

By starting and pre-setting the engine speed in advance

with a tachograph to 1000RPM then navigating back to

this menu option and then pressing the right arrow button

3

the engine calibration is updated and saved

automatically.

Alternatively, calibration can be manually set without the

engine running by pressing buttons

1

or

2

to achieve

the relevant value as shown within the RPM Calibration

Chart or alternatively by using the calibration factor

calculation both found on page 9.

Button

1

increases the value, button

2

decreases the

value. Once the correct value is highlighted press button

3

to save the setting.

Press button

5

to exit and return to the SETTINGS menu.

Pressing button

5

once more returns to the CONFIG

menu, pressing once more returns to the normal digital

dashboard.

Press button

2

to scroll down the SETTINGS screen to

highlight -

6

Single engine or Port engine

When highlighted as a yellow bar, pressing button

4

allows you to switch identity from Single engine or Port

Engine to Starboard engine identification.

On a twin engine vessel with an on-board network it is

important to set one engine as Single or Port and the

other as Starboard to ensure all correct data and views are

available within on-board network devices.

Pressing button

5

once more returns to the CONFIG

menu, pressing once more returns to the normal digital

dashboard.

Press button

3

to scroll down the SETTINGS screen to

highlight -

Units

When highlighted as a yellow bar, pressing button

4

allows you to enter the full Units menu.

Using buttons

1

&

2

scroll up or down the screen to

highlight each Units menu option.

When highlighted as a yellow bar, engine temperature

measurement maybe switched between Celsius or

Fahrenheit by pressing button

4

.

When highlighted as a yellow bar, engine oil pressure

measurement maybe switched between BAR or PSI by

pressing button

4

.

When highlighted as a yellow bar, press button

4

to

enter the hour counter.

To adjust engine hours up press

1

down press

2

clear

press

3

.

Press button

5

to exit and return to the Units menu.

Press button

5

to exit and return to the SETTINGS menu.

Pressing button

5

once more returns to the CONFIG

menu, pressing once more returns to the normal digital

dashboard.

Press button

2

to scroll down the SETTINGS screen to

highlight -

1 2 3 4 5

7

Alarm Thresholds

Panel D has Beta Marine recommended Alarm Threshold

values set as default. Depending on the vessel, application

and its use it may be appropriate to raise or lower these

values.

Note: This should not be done without consulting

Beta Marine for technical advice/approval. If an alarm

threshold has been changed without consultation and

the consequential result is engine damage, Beta Marine

limited will not accept any liability.

Engine temperature, oil pressure & alternator voltage

parameters can all be adjusted.

When highlighted as a yellow bar, pressing button

4

allows you to enter the full Alarm Thresholds menu.

Using buttons

1

&

2

scroll up or down the screen to

highlight each Alarm Thresholds menu option.

When Alarm Threshold menu option is highlighted button

3

will raise the value & button

4

will increase the

value.

Once all new values has been set pressing button

5

will

save, exit & return to the SETTINGS menu.

Pressing button

5

once more returns to the CONFIG

menu, pressing once more returns to the normal digital

dashboard or using buttons

1

&

2

scroll up or down

the CONFIG menu screen to highlight -

DIAGNOSTICS

This function does not provide engine diagnostics but

records software and interface data for integration to the

on-board network if applicable.

When highlighted in a yellow bar, pressing button

4

allows access to the full DIAGNOSTICS menu.

The on-board network specialist may view both CAN &

UART data by using buttons

1

&

2

to scroll up & down

and button

4

to enter each option.

In these views button functionality is highlighted visually.

Press button

5

once to return to the DIAGNOSTICS menu.

Press button

5

once more to return to the CONFIG menu,

press once more to return to the normal digital dashboard

or using buttons

1

&

2

scroll up or down the CONFIG

menu screen to highlight -

1 2 3 4 5

1 2 3 4 5

8

RESTORE DEFAULTS

This function resets the D Panel to factory default settings,

engine hours and any custom configuration will be lost.

Note: If used it will necessary to recalibrate engine RPM

and re-enter any previous custom configuration previously

stored.

When highlighted by a yellow bar press button

4

to

enter RESTORE DEFAULTS, press button

1

to restore

default settings.

Press button

5

once to return to the CONFIG menu.

Press button

5

once more to return to the normal digital

dashboard or using buttons

1

&

2

scroll up or down

the CONFIG menu screen to highlight -

ABOUT

This menu displays the software version installed on the D

Panel.

Beta Marine conducts continuous product development

and reserves the right to change design, specification and

functionality.

It is recommended that from time to time you contact us

in regards to the latest software version available and its

suitability for being installed on your D Panel hardware.

Please refer page 10.

When highlighted by a yellow bar press button

4

to

enter ABOUT, press button

1

to view the software

version data.

Please note the data and refer to UPDATING THE DISPLAY

SOFTWARE.

Press button

5

once to return to the CONFIG menu.

Press button

5

once more to return to the normal screen

view information dashboard.

BUTTON

5

Will always return you to the previous menu step when

pressed once, pressing repeatedly will ultimately return

the view to the normal digital dashboard.

9

RPM Calibration Chart

This chart has produced with standard pulley ratios at the time of printing. If you are unsure of any information provided

or for further information please contact Beta Marine. Date produced: 18-03-15 rev 00.

Kubota Alternator & Kubota Alternator & Iskra Iskra

Engine Standard Vee Drive Standard Poly-Vee Drive 45/65/70A 95/100A

Beta 10 - - - -

Beta 14 - 5.5 5.7 -

Beta 16 - 5.8 5.5 -

Beta 20 - - 6.0 -

Beta 25 - 5.8 5.1 -

Beta 28 5.2 - - -

Beta 30 - - - 5.8

Beta 35 - 4.3 - 5.8

Beta 38 5.5 - - -

Beta 43 5.2 - 5.8 3.7

Beta 45 - - - -

Beta 50 - - - 4.2

Beta 60 4.9 - 5.8 4.3

Beta 70 - - - -

Beta 75 - - - 4.6

Beta 85 - - - -

Beta 90 4.6 - - -

Beta 105 - - - -

Beta 150 - - - -

Calibration Factor Calculation

To calculate your calibration factor:

1. Measure the diameter of the alternator pulley in mm (A)

2. Measure the diameter of the crank pulley in mm (C)

3. Add measurements into the following sum: (A/C)*9.5=CAL

Example: An alternator pulley with a 75mm diameter and crank pulley with a 180mm will calculate as 75 divided by

180 = 0.416 multiplied by 9.5 will give a calibration factor of 3.9.

Note: Please note this is only for 12 pole alternators.

10

The software from time to time will be updated, this

maybe to add features or options. Beta Marine can

provide up to date files on request.

Before updating your software please read the

following instructions carefully and be aware that it is

extremely important that only a USB stick is used that only

has the required two Beta Marine files within and contains

no other data.

Note: Panel D is permanently live to the engine start

battery for engine stop/start. The panel power switch only

turns on or off the panel display screen. For your safety

please ensure that when requested the starter battery is

isolated from the panel.

Before proceeding with a software update the current

engine hours must be recorded. Please refer to CONFIG

MENU section of this manual.

To ensure you software is up to date please email:

spares@betamarine.co.uk or telephone: +44 (0)1452

723492.

If your software is not current and an update is required

Beta Marine will require visual proof of existing engine

hours before free issuing the new software.

Note: Due to the narrow recess and depth of the USB

connection socket it will be necessary to have a USB

connection extension lead available. Depending on cable

flexibility it may have to be supported with an appropriate

guide.

UPDATING THE DISPLAY SOFTWARE

{

Fig 1

SOFTWARE INSTALLATION

1. Switch off/isolate engine battery and remove the D

Panel from the vessels installation point but keep the

11-way plug connected.

2. Remove the rubber grommet/bung from the rear of

the panel (Fig 2 & Fig 3).

Fig 2 Fig 3

11

3. Insert the USB connection lead & connect to panel USB

slot. Connect USB stick to USB connection lead (fig 4

& 5) then reconnect engine battery and switch panel

display on.

4. While updating, the screen will flash yellow, once

upload complete the screen will flash green. At this

point switch off/isolate the D panel from the engine

battery and remove the USB stick & connection

lead. Then switch back on and check the display is

functioning correctly (Fig 7) before finally switching off

the display and switch off/isolate engine battery.

5. Replace the rubber grommet/bung into the D panel.

(Fig 2 & Fig 3).

6. Refit D panel into the vessels installation point. Once

engine battery is reconnected and display panel is

switched on, you must reset the RPM calibration and

engine hour meter. Please refer to CONFIG MENU

section of this manual.

Fig 7

Fig 6

Fig 4 Fig 5

12

13

14

Beta Marine Limited, Davy Way, Waterwells, Quedgeley, Gloucester, GL2 2AD. UK.

Tel: +44 (0)1452 723492 Fax: +44 (0)1452 883742 Email: [email protected] Website: www.betamarine.co.uk

Ref: OM 221-10643 REV 01

Table of contents

Popular Control Panel manuals by other brands

Satel

Satel CA-6 KLED-S user manual

SonicAire

SonicAire COMMAND15 owner's manual

Texecom

Texecom Premier 412 Premier 816 Premier 832 installation manual

Lasermet

Lasermet ICS-6-OEM instruction manual

DMP Electronics

DMP Electronics XR150CAN Series installation guide

Plum

Plum ecoSTER 200 Operation and maintenance manual