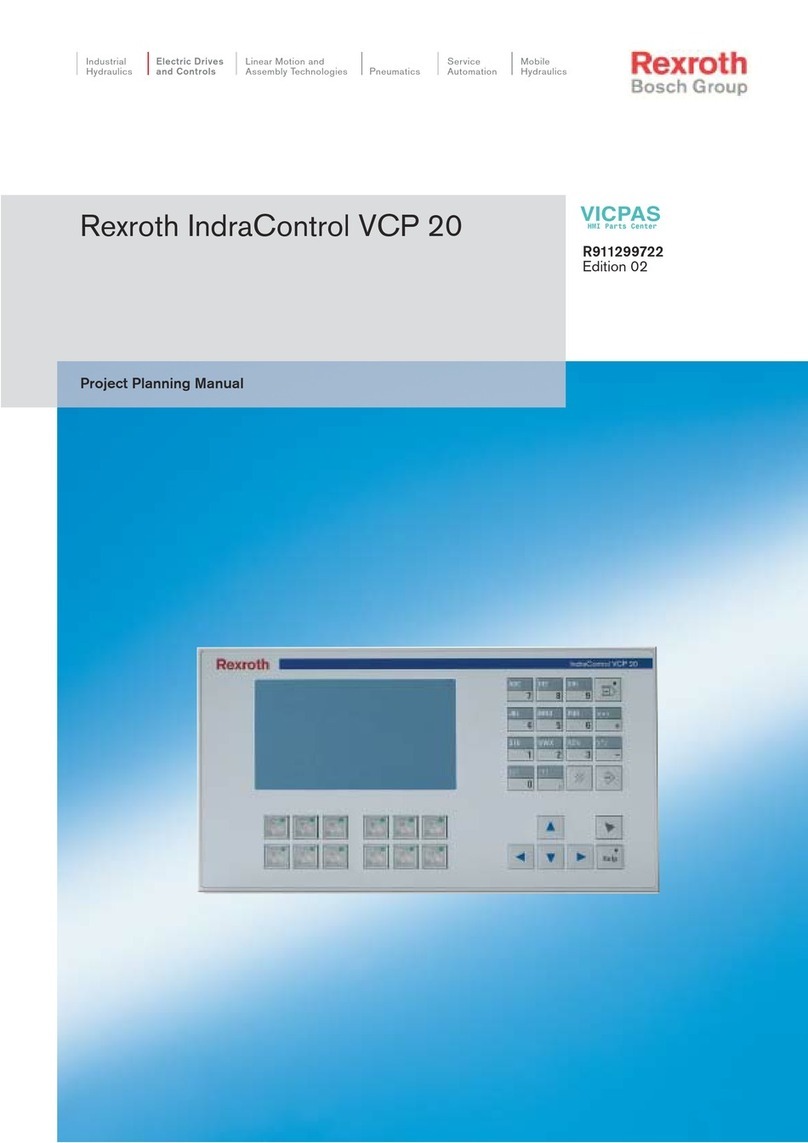

IV Bosch Rexroth AG | Electric Drives and Controls Rexroth IndraControl VCP 25 |R911299720 / 02

Contents

5.1.3 Side View, Mounting Depth .......................................... 5–4

5.1.3.1 Standard Device ........................................................ 5–4

5.1.3.2 Field Bus Device........................................................ 5–5

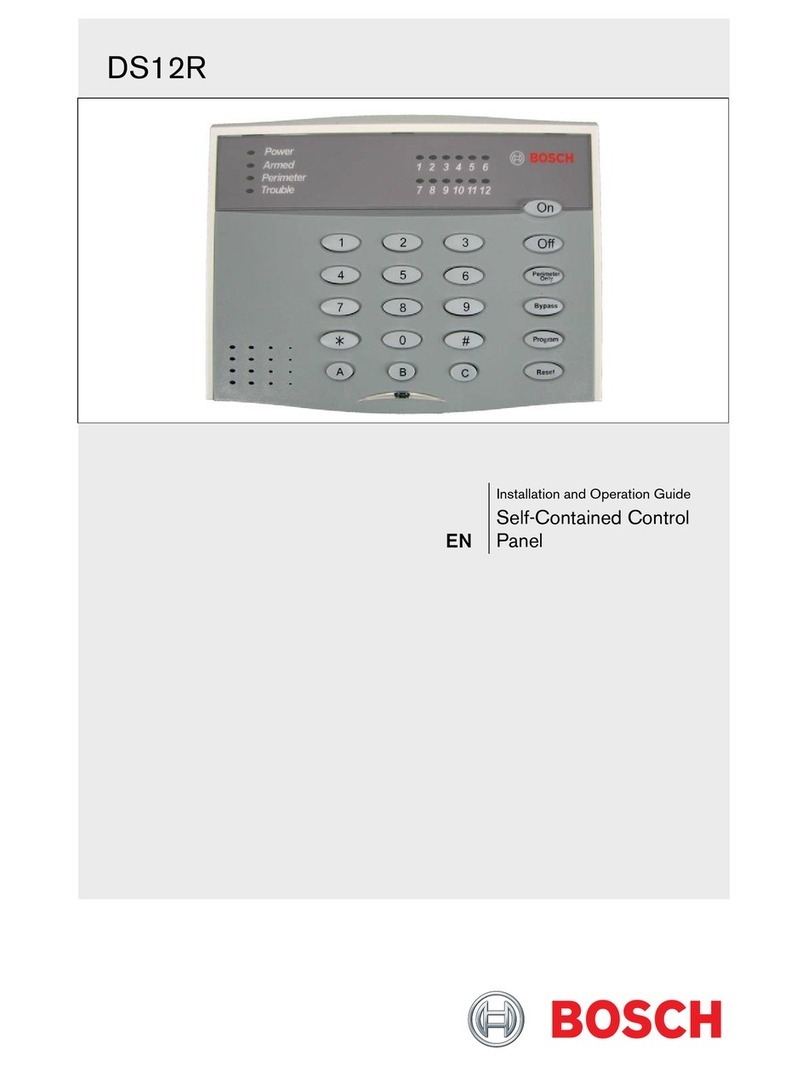

6 Display and Operating Components......... 6–1

6.1 Display............................................................................. 6–1

6.1.1 Setting the Contrast / Brightness.................................. 6–1

6.1.2 Default Contrast / Default Brightness Setting ............... 6–2

6.1.3 Character Attributes...................................................... 6–2

6.1.4 Fonts............................................................................. 6–2

6.2 Touch Screen .................................................................. 6–3

6.3 Reset Key........................................................................ 6–3

6.4 User Mode Switch ........................................................... 6–3

7 Interfaces ..................................................... 7–1

7.1 Standard Interfaces ......................................................... 7–2

7.1.1 TTY / 20 mA Current Loop (X3-SER1) ......................... 7–4

7.1.1.1 Pin Assignment.......................................................... 7–4

7.1.1.2 Termination................................................................ 7–5

7.1.2 RS485 (X3-SER1) ........................................................ 7–6

7.1.2.1 Pin Assignment.......................................................... 7–6

7.1.2.2 Termination................................................................ 7–6

7.1.3 RS232c (X3-SER1) ...................................................... 7–8

7.1.3.1 Pin Assignment.......................................................... 7–8

7.1.3.2 Termination................................................................ 7–8

7.1.4 RS232c (X3-SER2) ...................................................... 7–9

7.1.4.1 Pin Assignment.......................................................... 7–9

7.2 Field Bus Interfaces....................................................... 7–10

7.2.1 DeviceNet ................................................................... 7–10

7.2.1.1 Pin Assignment........................................................ 7–12

7.2.1.2 Cable ....................................................................... 7–12

7.2.1.3 Termination.............................................................. 7–13

7.2.1.4 Diagnostics .............................................................. 7–13

7.2.2 INTERBUS ................................................................. 7–14

7.2.2.1 Pin Assignment........................................................ 7–16

7.2.2.2 Cable ....................................................................... 7–17

7.2.2.3 Diagnostics .............................................................. 7–17

7.2.3 PROFIBUS DP ........................................................... 7–18

7.2.3.1 Pin Assignment........................................................ 7–20

7.2.3.2 Cable ....................................................................... 7–20

7.2.3.3 Termination.............................................................. 7–21

7.2.3.4 Diagnostics .............................................................. 7–21

7.3 Memory Card (Option)................................................... 7–22

7.3.1 Inserting the Memory Card ......................................... 7–22

7.3.2 Ejecting the Memory Card .......................................... 7–23

7.4 Shielding D-SUB Connectors ........................................ 7–23

8 Maintenance and Installation..................... 8–1

8.1 General Information......................................................... 8–1

8.2 Exchange of Hardware Components .............................. 8–1