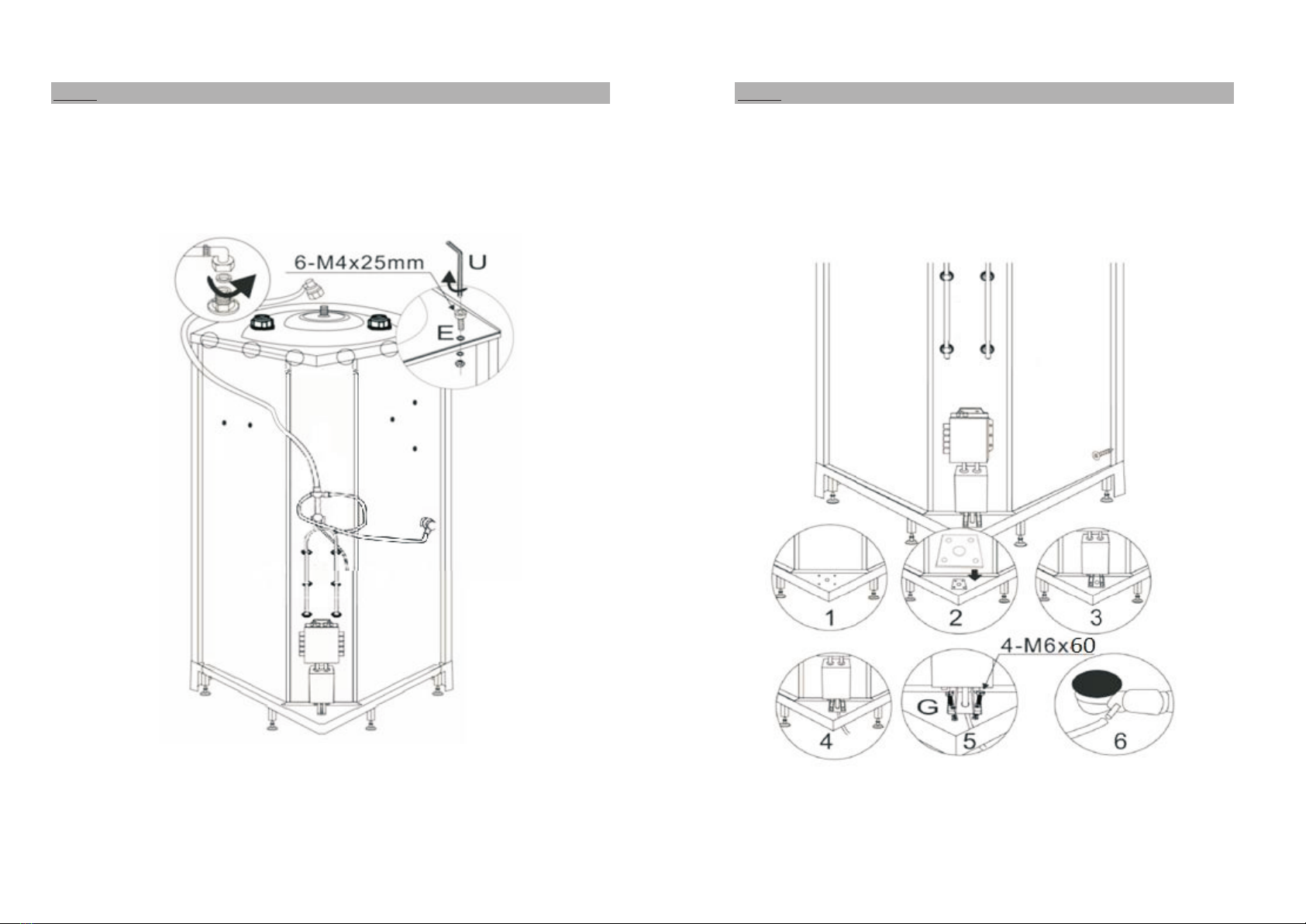

Information (Electrical work to be carried out by a Qualified Electrician) Parts

> This installation is a multiple person installation

> Ensure the glass is not chipped or cracked before installation

> AC Power supply of 220V + 10% 50 Hz which should be connected to

to an earthed 13amp fused spur switch, outside the bathroom.

> Supply wiring to the unit should be no less than 4mm2

> Water supply pressure 1.5 - 4 bar

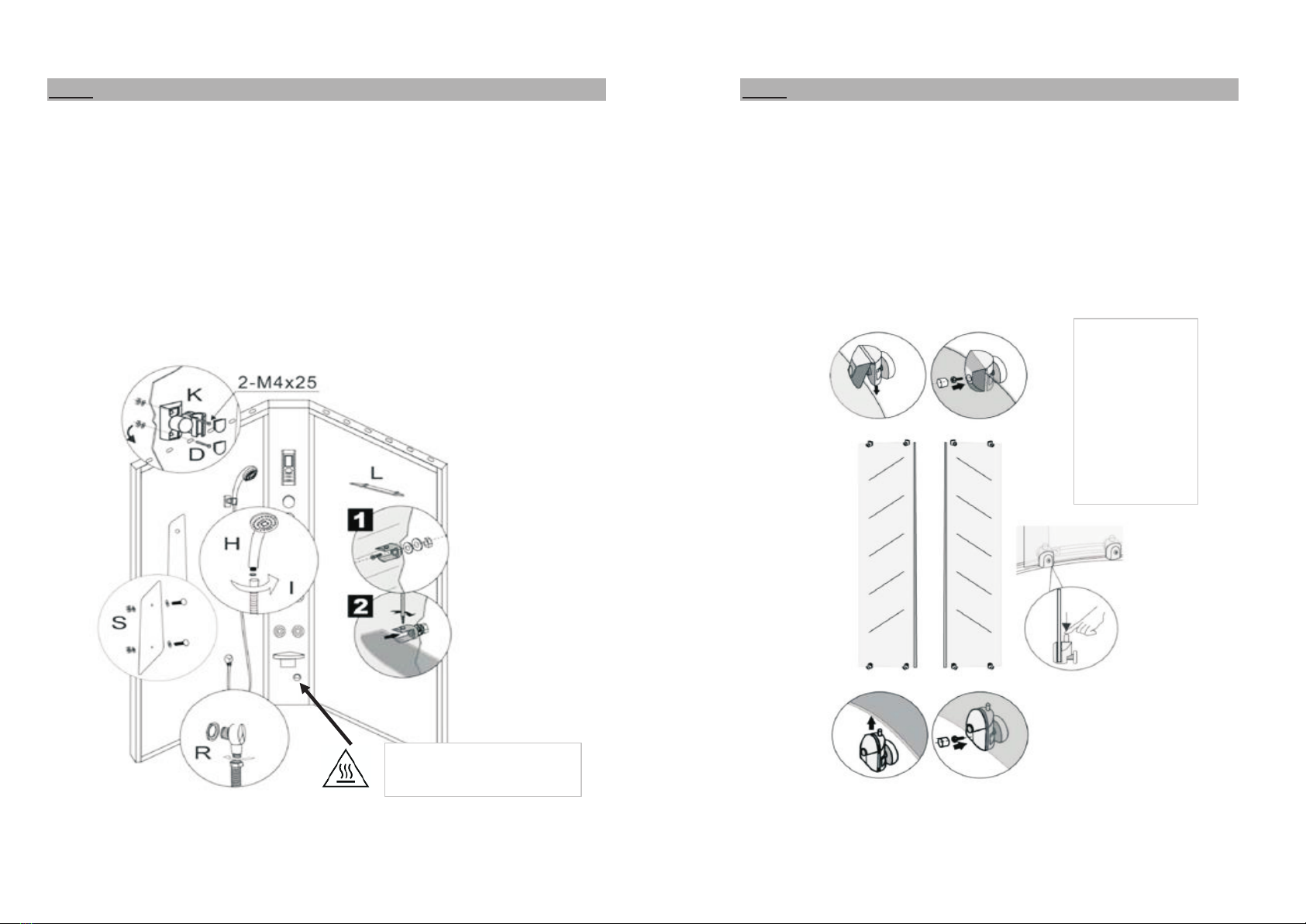

> The hot water supply should not exceed 65c

> The water supply pipes should be fitted with isolation valves and

be located to allow easy access.

> The steam generator and steam outlet become hot during use and

remain hot for a period after use, therefore contact with either can

cause injury, do not touch until fully cooled.

> After use always turn off the unit at the switch.

> Any maintenance should only be carried out once the power supply

to the unit has been isolated

> Any maintenance should only be carried out once the water supply

to the unit has been isolated

> Separate electrical appliances producing steam or humidity are not to be used

inside the cabin.

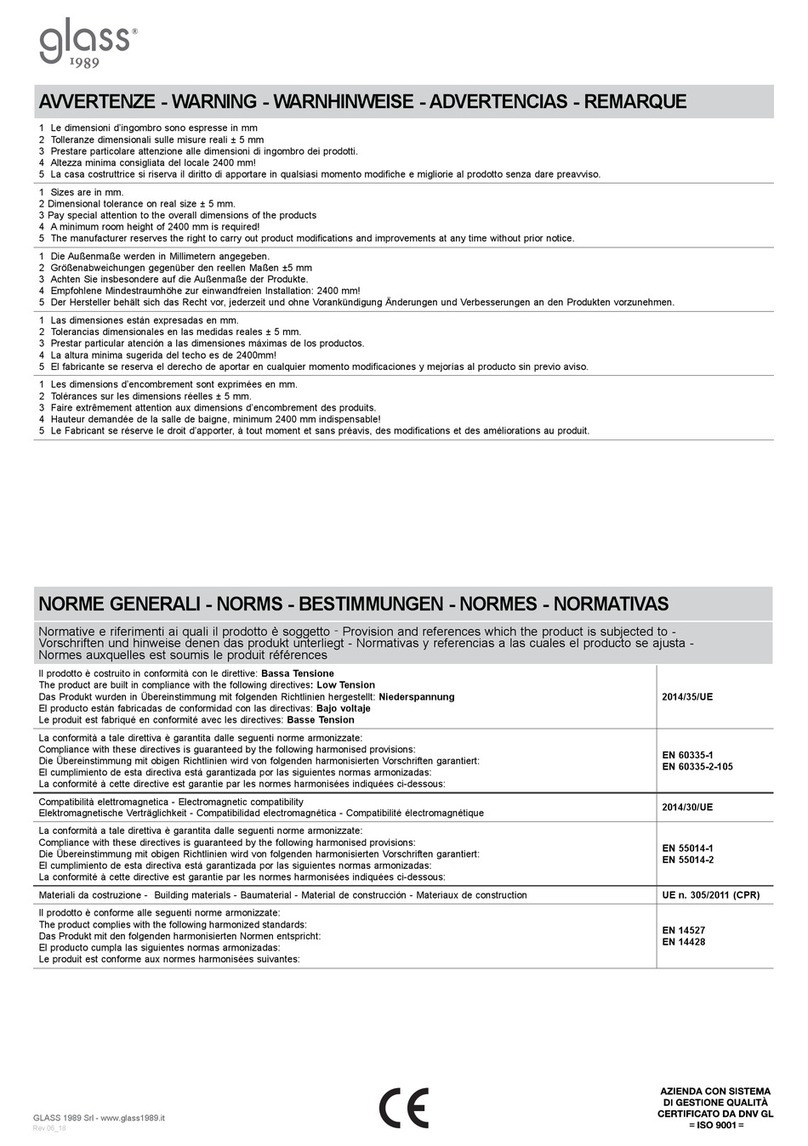

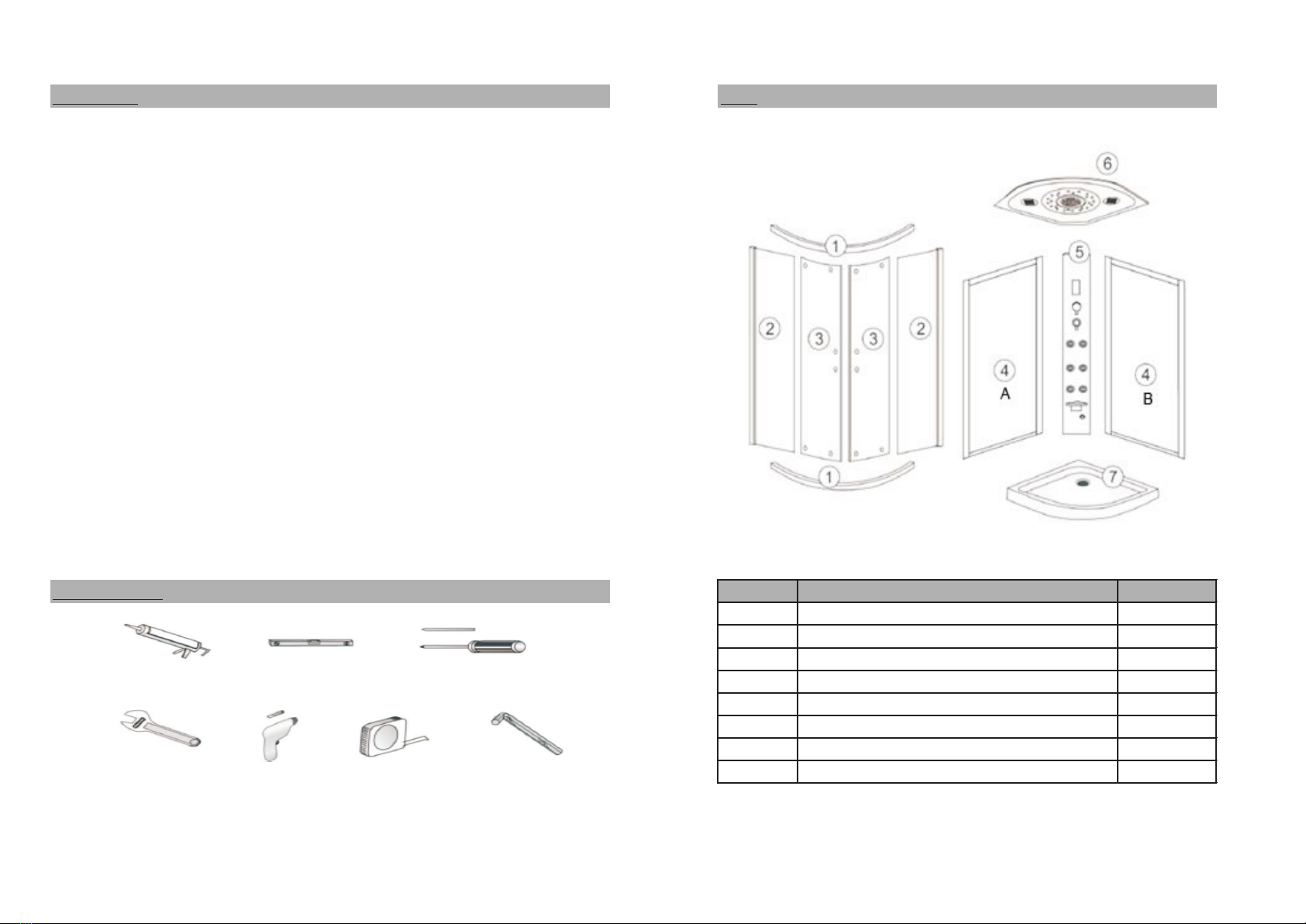

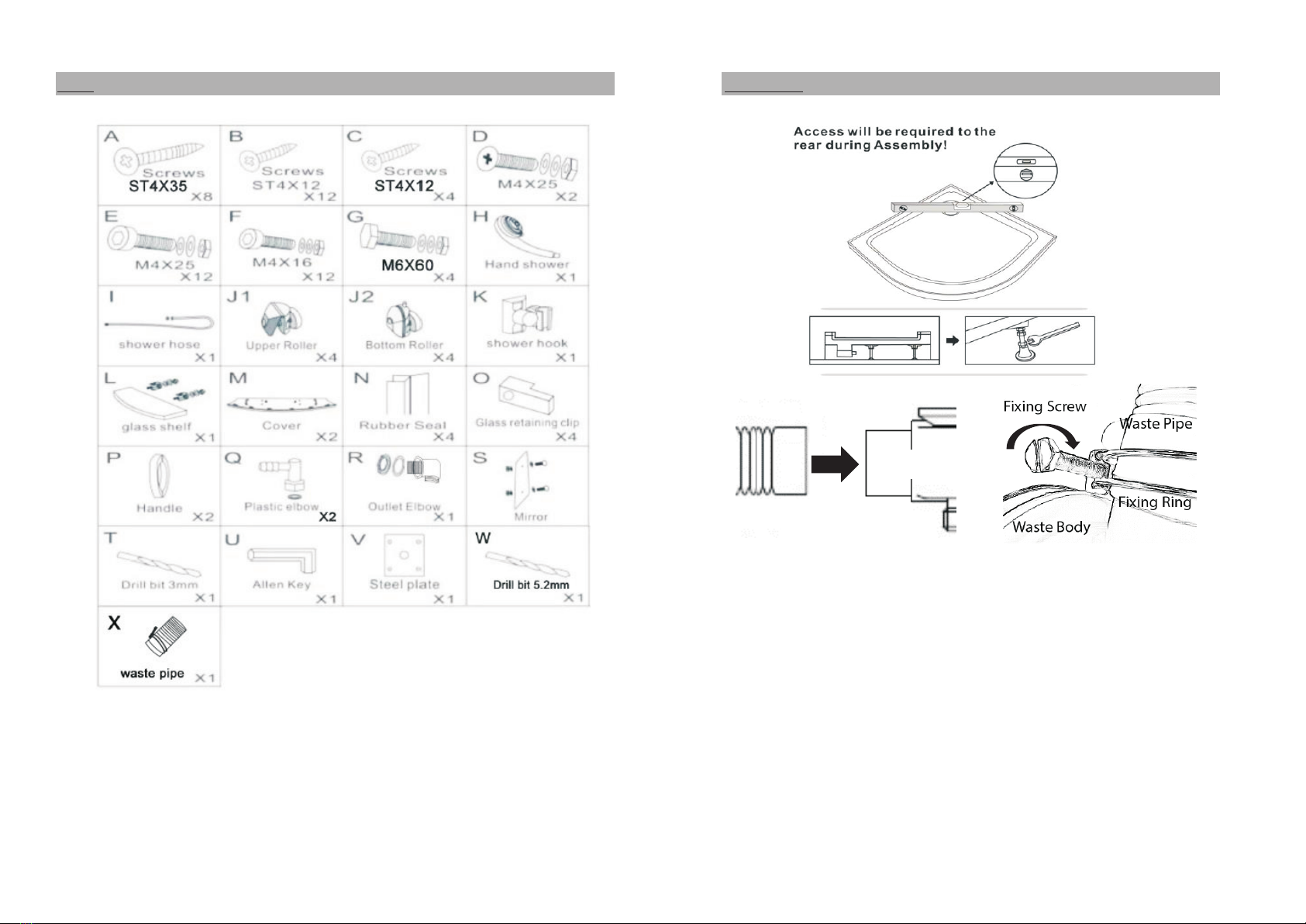

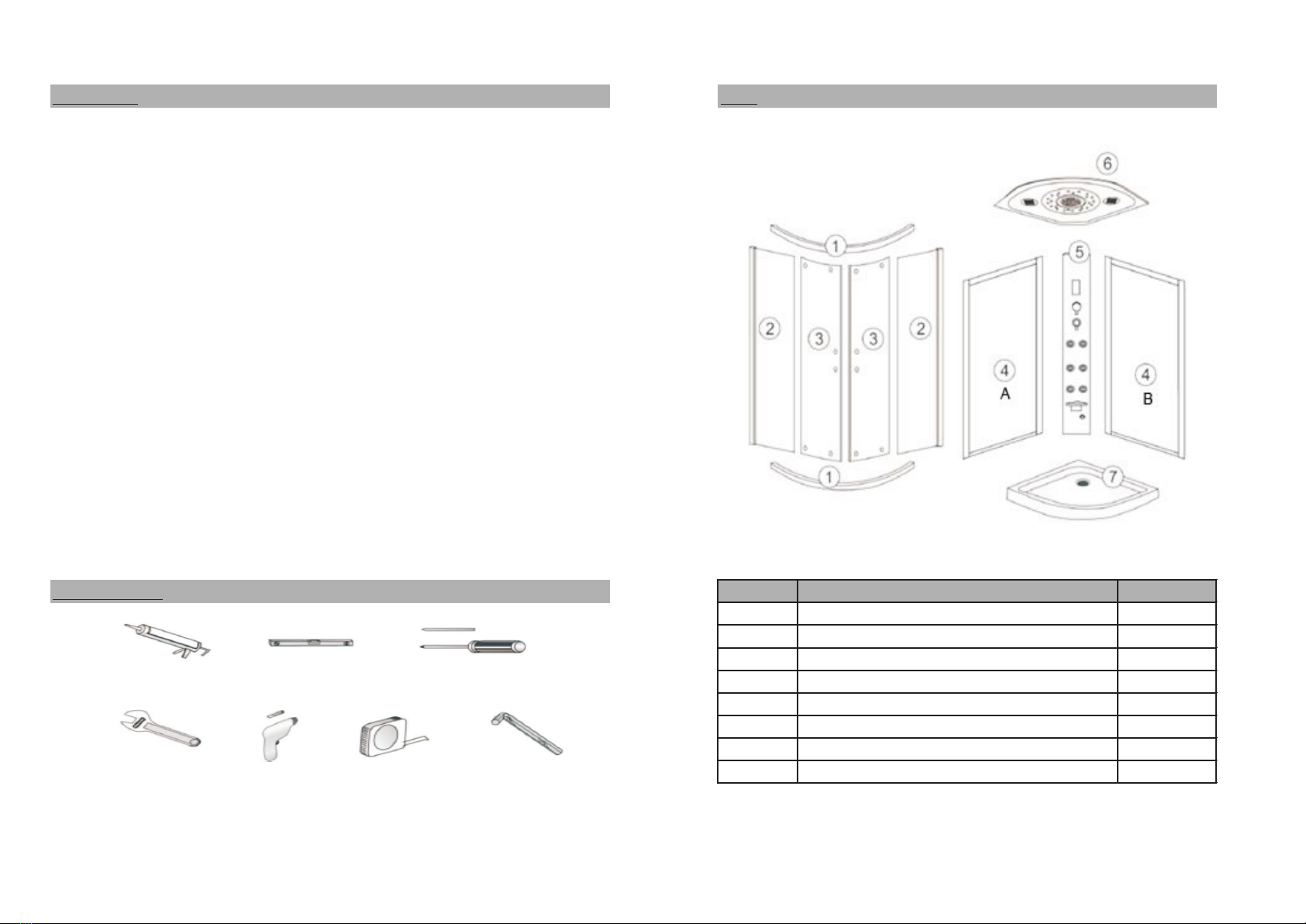

Tools Required No Description Qty

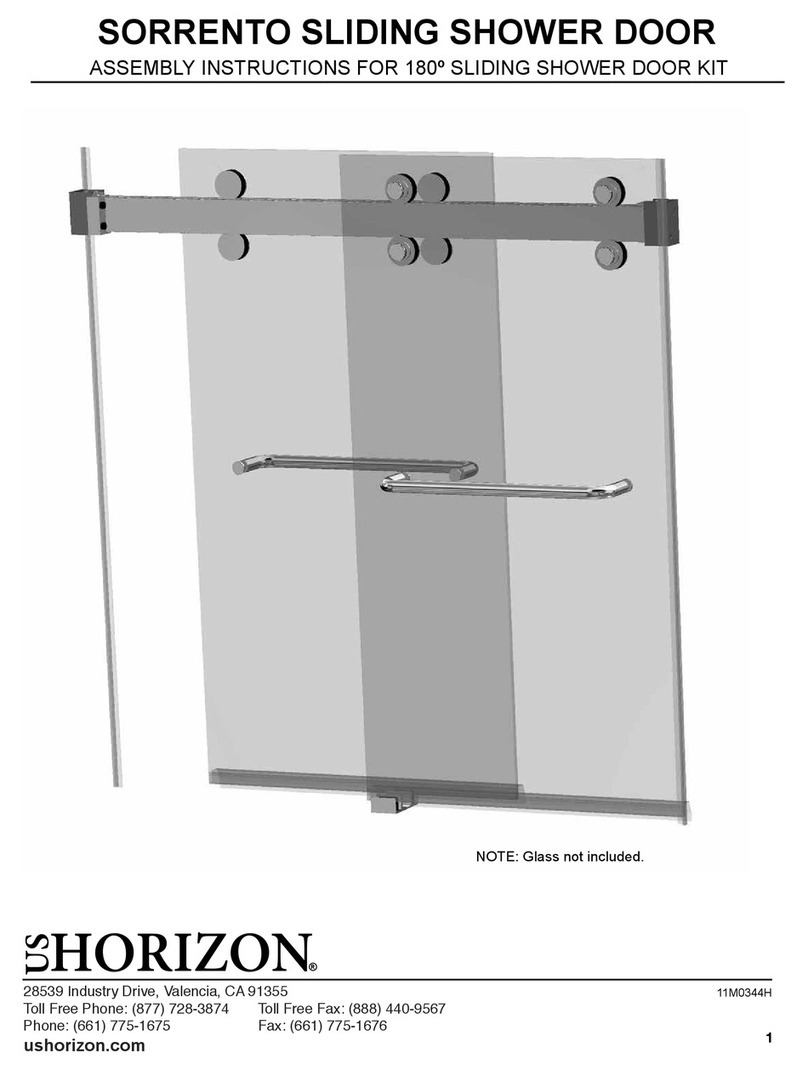

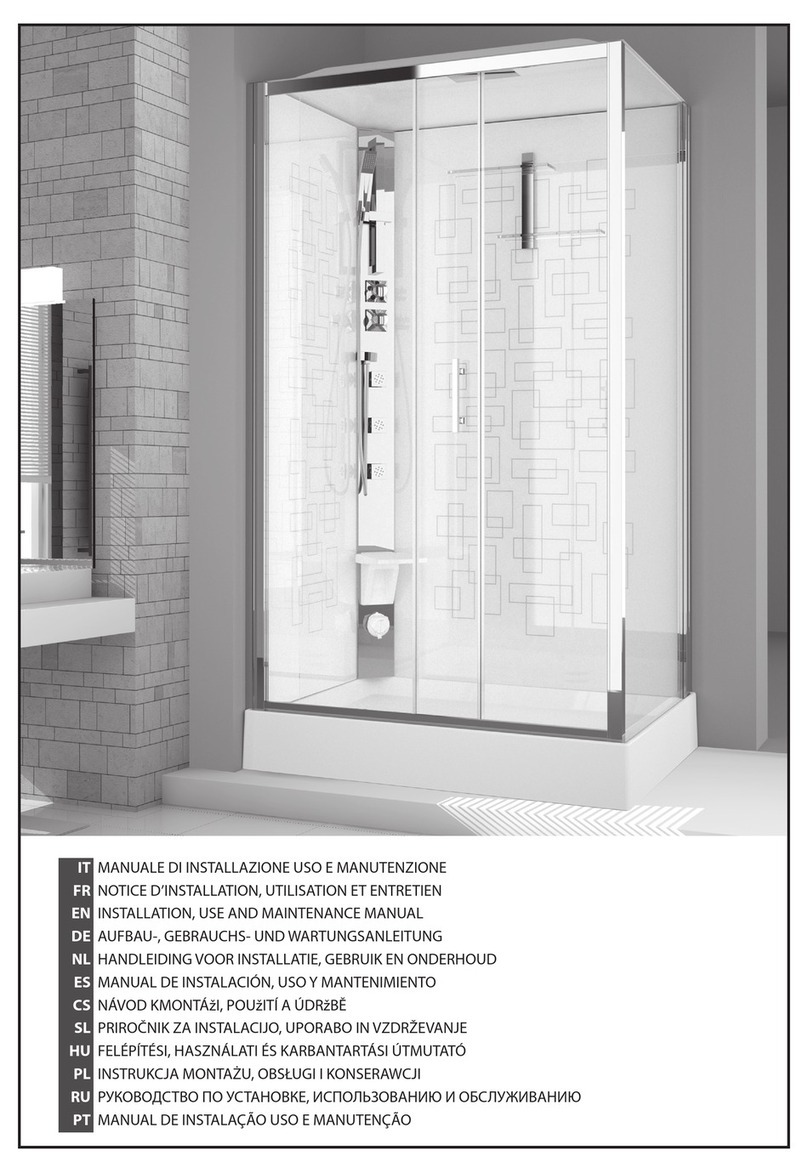

No.1 Chrome rail 2

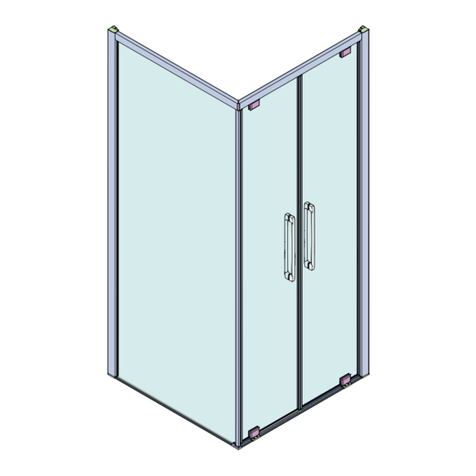

No.2 Fixed panel 2

No.3 Door 2

Silicone Sealant Spirit Level Screwdriver No.4A Shower kit black back panel 1

No.4B Shelf black back panel 1

No. 5 Control panel inc steam box & electrics 1

No.6 Roof - inc speaker, fan and lights 1

Spanner Drill Tape Measure Hex Key No.7 Tray inc waste 1

SEPT 18 - V6BB