BevLes CS72 User manual

This equipment has been engineered to provide you with year round dependable service when used

according to the instructionsin this manual and standard commercialkitchen practices.

1

!!

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

!!

WARNING

Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing this

equipment.

!!

WARNING

Initial heating of unit may generate smoke or fumes and must be done in a

well-ventilated area. Overexposure to smoke or fumes may cause nausea or

dizziness.

Hot Holding Cabinet

Model: CS72 - CH13

P/N 8817600 9/04

INSTALLATION AND OPERATING

INSTRUCTIONS

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

Innovative Foodservice Equipment Custom

Designedfor Performance,Serviceand Value.

Phone: +1

Fax: +1 (214) 565-0976

Toll Free: +1 (800) 441-1601

Website: www.BevLes.com

(214) 421-7366

BevLes

729 Third Avenue

Dallas, TX 75226

ANSI/NSF 4

!

WARNING:

This symbol refers to a potential hazard or unsafe practice, which could result in

seriousinjuryordeath.

!

!

!

DANGER:

Thissymbolwarnsofimminenthazardwhichwillresultinseriousinjuryor death.

!

!

CAUTION:

This symbolrefers to a potentialhazardor unsafe practice,whichmay resultin minor or

moderateinjuryorproductorpropertydamage.

!

!

NOTICE:

This symbol refers to informationthat needs specialattentionor must be fully understood

eventhoughnotdangerous.

GENERAL INFORMATION

THIS MANUAL SHOULD BE RETAINED FOR FUTURE REFERENCE

The takes pride in the design and quality of our products. When used as intended and

with proper care and maintenance, you will experience years of reliable operation from this equipment. To

ensure best results, it is important that you read and follow the instructionsin this manual carefully.

Installation and start-up should be performed by a qualified installer who thoroughly read, understands and

followsthese instruction.

If you have questions concerning the installation, operation, maintenance or service of this product, write

TechnicalService Department Bevles Company, Inc., P.O. Box 965, Chino,CA91710.

Before installing and operating this equipment be sure everyone involved in its operation are fully trained

and are aware of all precautions.Accidents and problems can result by a failure to follow fundamental rules

andprecautions.

The following words and symbols, found in this manual, alert you to hazards to the operator, service

personnel or the equipment.The wordsare defined as follows:

Bevles Company

SAFETY PRECAUTIONS

!

CAUTION:

These models are designed, built, and sold for commercial use. If these models are

positioned so the general public can use the equipment make sure that cautions, warnings, and

operating instructions are clearly posted near each unit so that anyone using the equipment will

useit correctlyand not injurethemselvesorharmtheequipment.

!

!

WARNING:

Check the data plate on this unit beforeinstallation.Connectthe unit only to the voltage

andfrequencylistedonthedataplate.Connectonlyto1 or3 phase as listedonthe dataplate.

!

!

!

WARNING:

Electrical and grounding connections must comply with the applicable portions of the

nationalelectricalcodeand/orotherlocalelectricalcodes.

!

!

WARNING:

Disconnect device from electrical power supply and place a Tag Out-Lockout on the

powerplug,indicatingthat you areworkingonthe circuit.

WARNING:

Install per the spacing requirements listed in the installation section of this manual. We

strongly recommend having a competent professional install the equipment.A licensed electrician

should make the electrical connections and connect power to the unit. Local codes should always

be used when connecting these units to electrical power. In the absence of local codes, use the

latestversionof theNationalElectricalCode.

!

!

!

!

WARNING:

This device should be safely and adequately grounded in accordance with local

codes, or in the absence of local codes, with the National Electrical code, ANSI/NFPA 70, Latest

Edition to protect the user from electrical shock. It requires a grounded system and a dedicated

circuit, protected by a fuse or circuit breaker of proper size and rating. Canadian installation must

complywith theCanadianElectricalCode,CSAC22.2,asapplicable

2

!!

WARNING:

Never clean any electrical unit by immersing it in water. Turn off before cleaning

surface.

!!

WARNING:

An earthing cable must connect the appliance to all other units in the complete

installationandfromthereto anindependentearthconnection.

!!

NOTICE:

This productis intended forcommercialuse only. Not for householduse.

!!

WARNING: -

SHOCK HAZARD

De-energize all power to equipment before cleaning the

equipment.

!

!

NOTICE:

The unit when installed, must be electrically grounded and comply with local codes, or in

the absence of local codes, with the national electrical code ANSI/NFPA70- latest edition.

Canadian installation must comply with CSA-STANDARD C.22.2 Number 0 M1982 General

Requirements-CanadianElectricalCodePartII, 109-M1981-CommercialCookingAppliances.

!

!

NOTICE:

Local codes regarding installation vary greatly from one area to another. The National

Fire Protection Association, Inc. states in its NFPA96 latest edition that local codes are Authority

Having Jurisdiction when it comes to requirement for installation of equipment. Therefore,

installationshouldcomplywith alllocalcodes.

!!

WARNING: -

SHOCKHAZARD

Donot open any panelsthatrequiretheuse of tools.

IMMEDIATELYINSPECT FORSHIPPINGDAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If equipment is received damaged, either apparent

or concealed, a claim mustbe made with the delivering carrier.

A) Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then be signed

by the carrier representative (Driver). If this is not done, the carrier may refuse the claim. The carrier can

supplythe necessaryforms.

B) Concealed damage or loss if not apparent until after equipment is uncrated, a request for inspection

must be made to the carrier within 15 days. The carrier should arrange an inspection. Be certain to hold all

contents and packagingmaterial.

Installation and start-up should be performed by a qualified installer who thoroughly read, understands and

followsthese instructions.

3

TABLE OF CONTENTS

SECTION ITEM PAGE

Safety Precautions 2

General Information 2

1 Introduction 4

2 Specifications 4

3 Installation 4

4 Operational Procedure 4

5 Cleaning 5

6 Wiring Diagram 6

7 Parts List & Exploded View 6

8 Warranty 8

4

1. INTRODUCTION

Bevles Hot Holding Cabinets are designed and engineered to hold prepared foods within a precise

temperature range. Built from the finest materials available, Bevles Hot Holding Cabinets are custom

designedfor performance, serviceandvalue.

All models are U.L.,C.U.L., and N.S.F. listed and approved.

Cabinet is furnished with an 8-foot power cord with a 20 amp twist locking plug. A NEMA L5-20R

receptacle is required.

Cabinet is equipped with self-closing door hinges designed to open to a maximum of 180°, but a

door stop plate has been installed to preventdoors from opening past 90°.

Hot Holding Cabinets require a minimum of 4 between the sides and top of the cabinet and other

equipment or surfacesfor proper air circulation to and fromfan motor air vents.

All personnel responsible for the operation and maintenance of Bevles Hot Holding Cabinets

should become familiarwith this manual prior to operatingthe equipment.

Notes

Do not place any objects over motor air vents on right side of cabinettop.

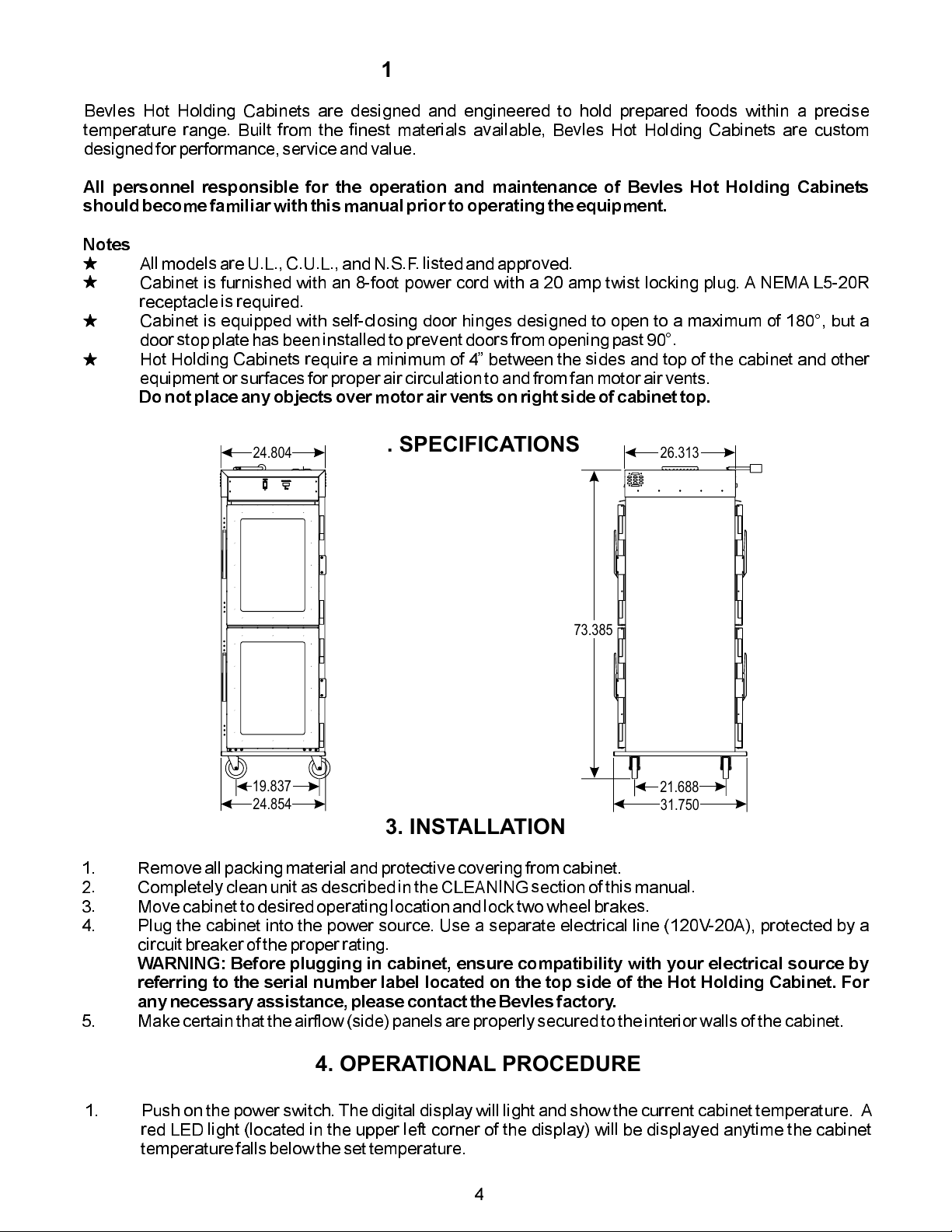

2. SPECIFICATIONS

24.854

19.837

24.804

31.750

21.688

26.313

73.385

3. INSTALLATION

1. Remove all packing material and protectivecovering from cabinet.

2. Completely clean unitas described in the CLEANINGsection of this manual.

3. Move cabinet to desiredoperating location and lock twowheel brakes.

4. Plug the cabinet into the power source. Use a separate electrical line (120V-20A), protected by a

circuit breaker of the properrating.

5. Make certain that the airflow (side) panels are properly securedto the interior walls of the cabinet.

WARNING: Before plugging in cabinet, ensure compatibility with your electrical source by

referring to the serial number label located on the top side of the Hot Holding Cabinet. For

anynecessaryassistance, pleasecontacttheBevlesfactory.

4. OPERATIONAL PROCEDURE

1. Push on the power switch. The digital display will light and show the current cabinet temperature. A

red LED light (located in the upper left corner of the display) will be displayed anytime the cabinet

temperaturefalls below the set temperature.

5

2. After five minutes, check the digital display and the air flow inside the cabinet to be sure that it is

heatingproperly.

3. Allow the cabinet to preheatfor 1 hour before placing productin cabinet.

This unit has a maximum operatingtemperature of 185°F.

1. Push power switch to OFFposition.

2. Unplug power cord from power source.

.

3. Open door(s) to 90º position.

4. If needed, remove the top mounted heatingmodule.

.

5. Remove the airflow (side) panels by carefully lifting each panel and tilting the bottom toward the

center of the cabinet. .

6. Clean all parts thoroughly with soapy water and soft cloths or sponges. Never use steel wool or

causticcleaning compounds.

IF YOU HAVE ANY QUESTIONS REGARDING THE INSTALLATION OR OPERATION OF YOUR

BEVLES HOT HOLDING CABINET, REVIEW THIS MANUALAND THEN CALL THE BEVLES FACTORY

CUSTOMERSERVICESUPPORTHOTLINE:

NOTE:

WARNING: Always unplug the cabinet before

dismantling or cleaning

CAUTION:At least two people should do the

lifting to avoid possible injury

CAUTION: Use care when handling the airflow (side) panels. Any

damage or bending maymake re-installation difficult

WARNING: Avoid splashing water or any other liquid into the top mounted heating module to

prevent possible damageto electrical components.

BEVLES800/441-1601

5. CLEANING

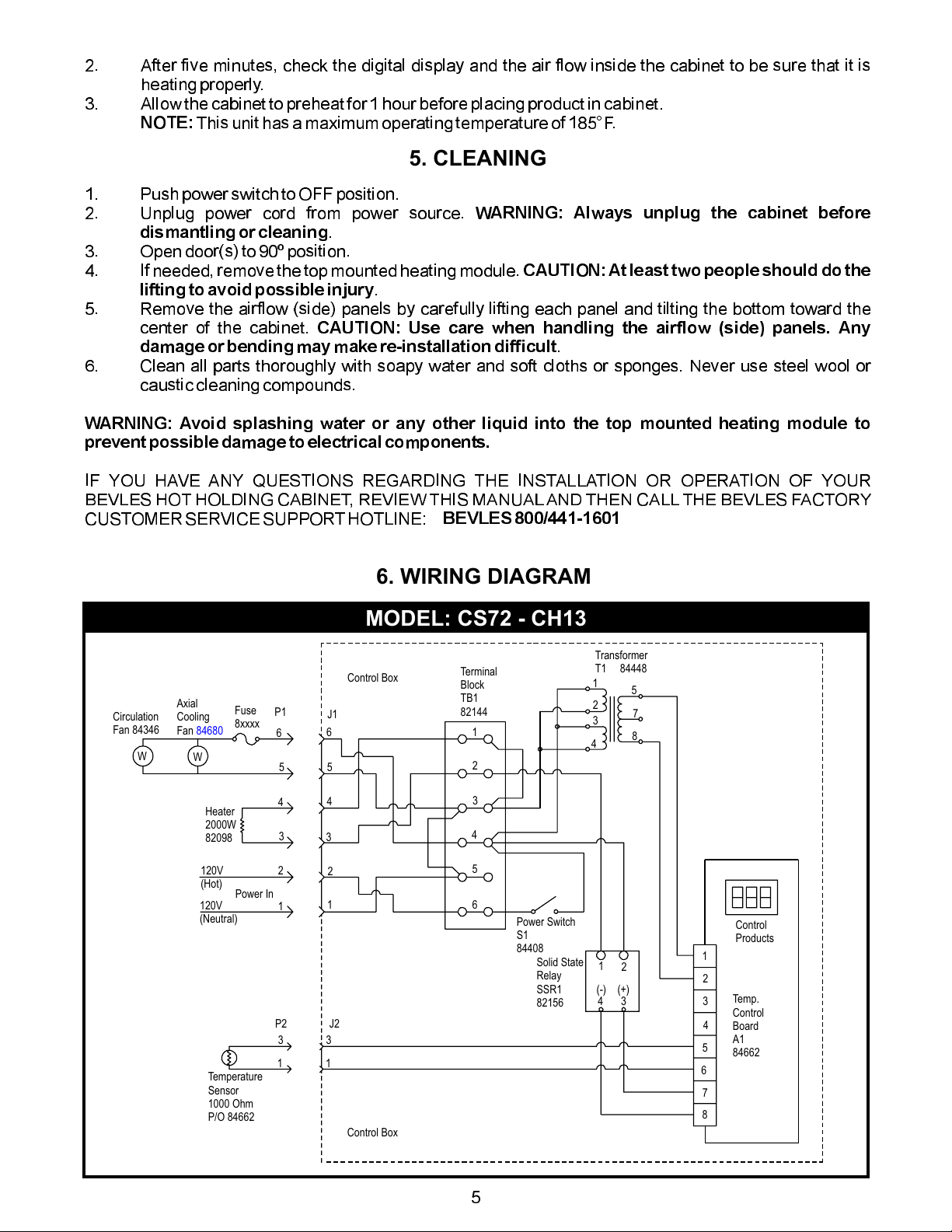

6. WIRING DIAGRAM

MODEL: CS72 - CH13

J1

6

5

4

3

2

1

Control Box

Control Box

J2

3

1

Terminal

Block

TB1

82144

Transformer

T1 84448

1

2

3

4

5

6

Power Switch

S1

84408

Solid State

Relay

SSR1

82156

12

34

(-) (+)

1

2

3

4

5

7

8

Control

Products

Temp.

Control

Board

A1

84662

1

2

3

4

5

6

7

8

Circulation

Fan 84346

Axial

Cooling

Fan 84680

Fuse

8xxxx

P1

6

5

4

3

Heater

2000W

82098

120V

(Hot)

120V

(Neutral)

2

1

Power In

WW

P2

3

1

Temperature

Sensor

1000 Ohm

P/O 84662

This manual suits for next models

1

Table of contents

Other BevLes Industrial Equipment manuals