BGS technic 3260-1 User manual

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

BGS 3260-1

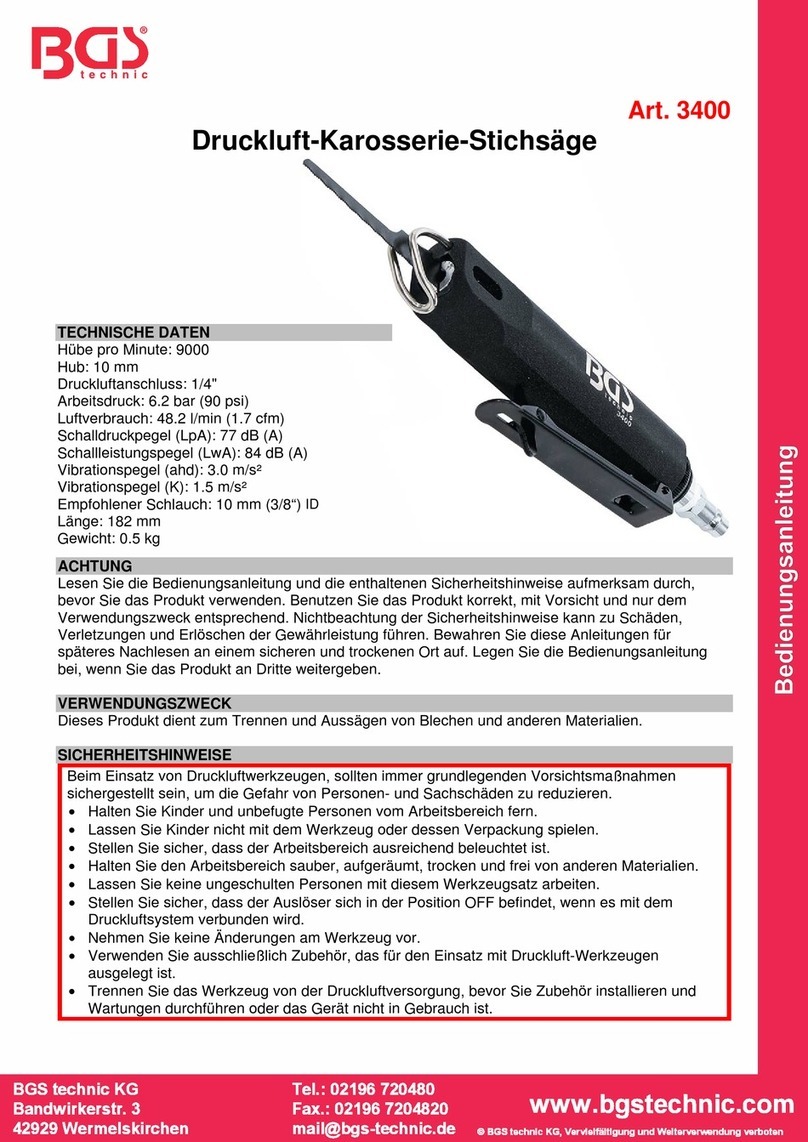

Air Body Saw

TECHNICAL DATA

Strokes per min.: max. 9000

Sawing depth: 10 mm

Working Pressure: 90 PSI (6.3 Bar)

Air Inlet: 1/4" (6.3 mm)

Recommended air hose: 3/8" (10 mm)

Length with blade: 270 mm

Air Consuption: 1.8 CFM (51.6 l/min)

Air exhaust: Front

Noise Level: LpA = 88.15 dB (A)

LwA = 99.15 dB (A)

Vibration Level: ahd = 15.06 m/s²

K = 1.99 m/s²

Weight: 0.65 Kg

CAUTION

Read and understand all rights and information in this manual.

Failure to comply with unconscious rights and information may include control and oversight.

Keep the operating instructions in a certain and controlled place for future reference.

SAFETY INSTRUCTIONS

•

Ensure that the tool is in the OFF position when it is connected to the compressed air

system.

•Always wear approved safety glasses when using compressed air tools. Wear a suitable

respirator when dust is whirled up.

•Only use accessories suitable for compressed air. Risk of injury.

•Disconnect the tool from the compressed air supply before installing accessories or

performing maintenance or before the device is not in use.

•Always use the tool with common sense. Do not wear loose clothing or jewelry that can be

caught by moving parts as it can cause injury. Only operate the tool at a safe distance from

yourself and others.

•Observe the manufacturer's instructions for the compressed air system when installing

regulators, filters and other accessories.

•Keep children and other unauthorized persons away from the work area.

•Do not let children play with the tool or its packaging.

AIR SOURCE

Clean and dry air and a correct air pressure is recommended as air supply for this air tool.

Maximum of 90 PSI at the air tool is recommended for most air tools of this class. Check specifications

section for recommended pressure. (Depending on length of air hose and other circumstances, air

pressure at compressor may need to be increased to 100 PSI to ensure 90 PSI at the tool. Water in the air

hose and compressor tank contributes to reduced performance and damage of the air tool. Drain the air

tank and filters before each use and as necessary to keep the air supply dry. Hose length over 25” causes

loss in line pressure. Increase hose ID or increase compressor pressure to compensate the pressure loss.

Use an in-line pressure regulator with gauge if air inlet pressure is critical.

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

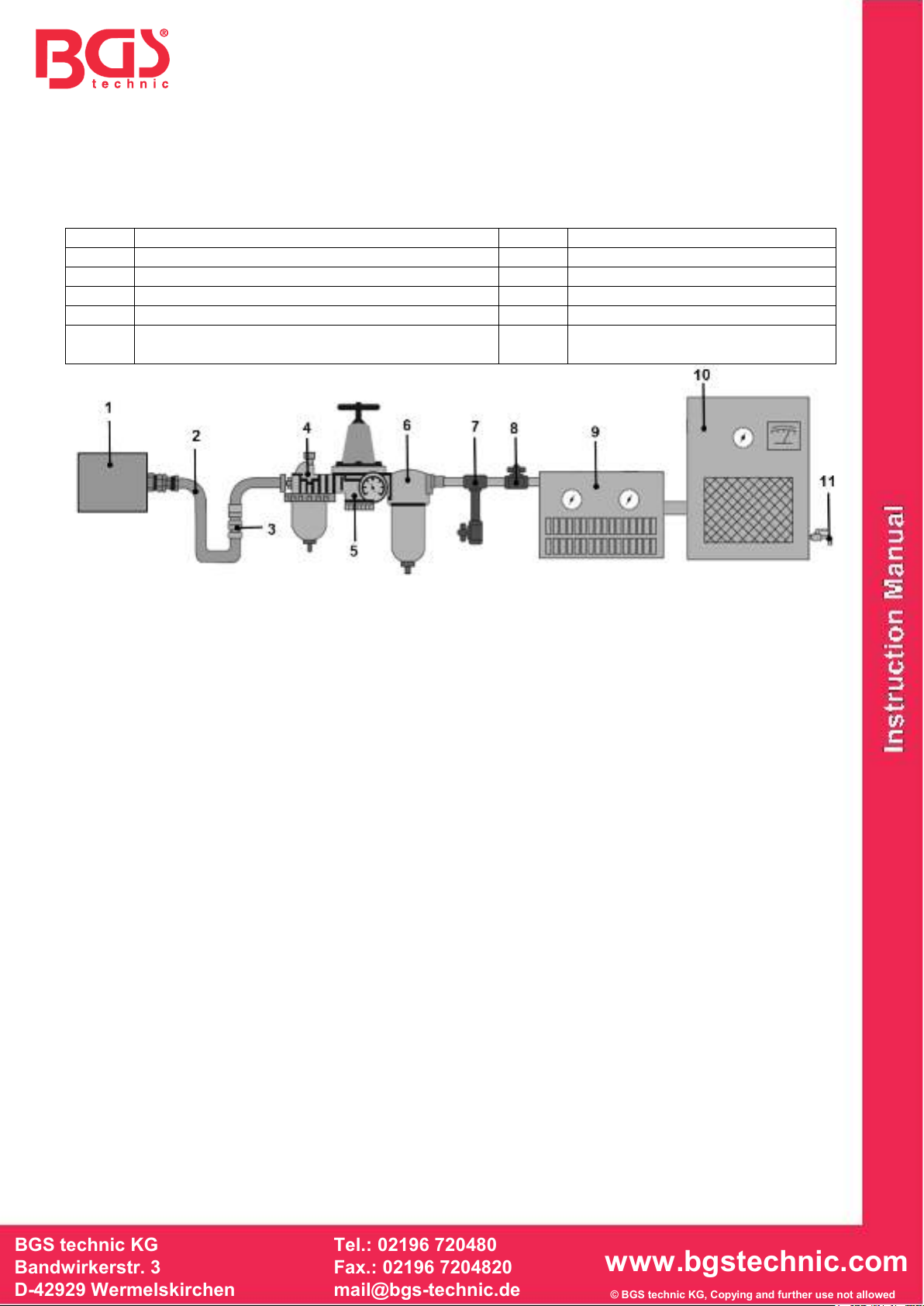

RECOMMENDED AIR SUPPLY

No.

Description

No.

Description

1

Air Tool

6

De-Watering / Filter Unit

2

Air Hose

7

De-Watering Valve

3

Quick Coupler

8

Shut-Off Valve

4

Oiler (only required for air tools with motor)

9

Dryer / Filter Unit

5 Pressure Regulator 10

Compressor / 11 De-Watering

Valve

SERVICE

•Only operate the product on compressed air systems that have the correct air pressure and

sufficient air volume (L / min) for this tool.

•Before using the compressed air device, put 4 to 5 drops of compressed air device oil into the

compressed air connection. The performance of the device depends on the size of the air

compressor and the compressed air supply volume.

•The speed can be set via an air supply controller (not included in the scope of delivery).

•The technical data of the tool refer to a working pressure of 6.3 bar.

•Always be careful when using the Air Body Saw. In case of negligent operation, internal

components of the device can be damaged and the work performance can be restricted.

•Press the actuation lever (trigger) to operate the tool.

•Release the operating lever to stop the tool.

•Do not remove any information labels from the device and replace damaged labels.

•Keep hands, loose clothing and long hair away from the moving part of the tool.

APPLICATION

Note: Take the time to carefully select a work area.

Let the tool work independently without exerting extreme pressure! Excessive pressure reduces the

speed of the saw and thus the cutting performance. Furthermore, the engine is subjected to an

unnecessarily high load. Start the tool in front of the workpiece, then place it evenly on the workpiece

and move it in the desired direction to make the cut. After the cut, detach the tool from the workpiece

and then stop the motor.

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

CHANGING SAW BLADE

CAUTION:

Disconnected air tool from air supply before replacing the blade or other maintenance work.

1. After opening the protective cap, loosen the adjusting screw of the saw blade by turning it with

the Allen key counter-clockwise (Fig. C).

2. Remove the old saw blade by pulling it out of the saw with your hand.

3. Insert a new saw blade completely into the saw.

4. Tighten the set screw by turning it clockwise (Fig. D).

5. Close the protective cap again.

SAWING

•Adjust the speed by turning the inner screw (Fig. A) clockwise or counterclockwise with a flat-

blade screwdriver (Fig. B) until the desired air flow is achieved.

•Press the trigger against the saw body and deactivate the safety lock with your finger.

•Stop the saw by releasing the trigger. The security lock engages automatically.

Air Regulator

Blade Mounting

ALWAYS disconnect air supply before changing saw blades! Loosen blade set screw by turning

counter-clockwise with the included allen wrench.

Fully insert new blade into saw. Tighten set screw by turning clockwise. ALWAYS make sure the

set screw is tight on BOTH sides.

Fig. A

Fig. B

Fig. C

Fig. D

BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

LUBRICATION & MAINTENACE

•Oil the tool before each use with 4 to 5 drops air tool oil, placed in the air inlet is sufficient.

•Use proper air pressure and CFM rating listed for this tool.

•Drain water from hoses and compressor tank.

•Water in the air supply system damaged the tool and loss of power.

•Clean or replace air filters at prescribed intervals from.

TROUBLESHOOTING (Insufficient power)

Probable Cause

Solution

Dirty or clogged air passages

Flush and lubricate tool, drain air tank and supply line

Insufficient air supply

Increase line pressure, make sure compressor matches

tool's air pressure and consumption needs

Air leakage

Use teflon tape at all fittings and joints.

Check tool for worn or damaged o-rings & seals.

Worn/damaged wear & tear parts

Replace as necessary

Tool matching

Be sure you are using a tool suited for the sanding

requirements of the job at hand.

ENVIRONMENTAL PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools,

accessories and packaging must be sorted, taken to a recycling point and

disposed of in an environmentally friendly manner.

DISPOSAL

Dispose of this product at the end of its service life in accordance with your

region's disposal regulations. Ask your local waste agency about recycling

measures.

SW-Stahl und Werkzeugvertriebs GmbH Tel. +49 (0) 2191 / 46438-0

F56essartSresukreveL ax +49 (0) 2191 / 46438-40

ed.lhatsws@ofni:liaM-EdiehcsmeR79824-D

Info

BGS technic KG

Bandwirkerstr. 3

42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

www.bgstechnic.com

© BGS technic KG, Vervielfältigung und Weiterverwendung verboten

Teile / Parts Art. 3260-1

Nr.

No. Bezeichnung Decription Stk.

Pcs. Nr.

No.

Bezeichnung Decription Stk.

Pcs.

1

Ventilkegel

Valve Plug

1

28

Zylinder

Cylinder

1

2

O-Ring

O-Ring

1

29

Dichtung

Gasket

1

3

O-Ring

O-Ring

1

30

Hinterer Schutz

Rear Bumper

2

4

Luftregler

Air Regulator

1

31

Kolbenschaft

Piston Stem

1

5

Ventilfeder

Valve Spring

1

32

Gehäuse

Housing

1

6

Ventilschaft

Valve Stem

1

33

Kunststoffgriff

Plastic Grip

1

7

O-Ring

O-Ring

1

34

Schraubensatz

Set Screw

2

6

O-Ring

O-Ring

1

35

Schraubensatz

Set Screw

2

9

Ventilbuchse

Valve Bushing

1

36

Sicherheitsabdeckung

Protector, Cover

1

10

Drucklufteingang

Air Inlet

1

37

Schraubensatz

Set Screw

2

11

Schraubkappe

Cap Screw

4

38

Buchse

Bushing

2

12

Federscheibe

Spring Washer

4

39

Führungsbolzen

Guide Pin

1

13

Hebelstift

Lever Pin

1

40

Federstift

Spring Pin

1

17

Auslöser

Throttle Lever

1

41

Feder

Spring

1

18

Ventilgehäuse

Valve Housing

1

42

Untere Abdeckung

Nether Cover Plate

1

19

Dichtung

Gasket

1

43

Schraubensatz

Set Screw

2

20

Dichtung

Gasket

1

44

Schraubensatz

Set Screw

2

21

Schraube

Screw

1

45

Sägeblattaufnahme

Blade Chuck

1

22

Scheibe

Washer

1

46

2 mm Innen-6-kant

2 mm Hex. Wrench

1

23

Umkehrventil

Conv. Valve

1

47

4 mm Innen-6-kant

4 mm Hex. Wrench

1

24

Ventilhülse

Valve Sleeve

1

48

Führungsrahmen

Work Guide

1

25

Ventilgehäuse

Valve Body

1

49

Sägeblatt

Saw Blade

1

26

Buchse

Bushing

1

50

Label

Label

1

27

Dichtung

Gasket

1

SW-Stahl und Werkzeugvertriebs GmbH Tel. +49 (0) 2191 / 46438-0

F56essartSresukreveL ax +49 (0) 2191 / 46438-40

ed.lhatsws@ofni:liaM-EdiehcsmeR79824-D

CE-Erklärung

BGS technic KG

Bandwirkerstr. 3

42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

www.bgstechnic.com

EU-KONFORMITÄTSERKLÄRUNG

EC DECLARATION OF CONFORMITY

DÉCLARATION „CE“ DE CONFORMITE

DECLARATION DE CONFORMIDAD UE

Wir erklären in alleiniger Verantwortung, dass die Bauart des Produktes:

We declare that the following designated product:

Nous déclarons sous propre responsabilité que ce produit:

Declaramos bajo nuestra sola responsabilidad que este producto:

folgenden einschlägigen Bestimmungen entspricht:

complies with the requirements of the:

est en conformité avec les réglementations ci-dessous:

esta conforme a las normas:

Angewandte Normen:

,GHQWL¿FDWLRQRIUHJXODWLRQVVWDQGDUGV

Norme appliquée:

Normas aplicadas:

ppa.

Frank Schottke, Prokurist

BGS technic KG, Bandwirkerstrasse 3, D-42929 Wermelskirchen

Wermelskirchen, den

Druckluft-Karosserie-Stichsäge (BGS Art.: 3260-1)

Air Body Jigsaw

Scie sauteuse de carrosserie à air comprimé

Sierra de chapa neumática

Machinery Directive 2006/42/EC

EN ISO 12100:2010

EN ISO 11148-12:2012

Certificate No.: HMIC-2020/3/5 / HY-176A

Test Report No.: 20180307-1

23.05.2020

Table of contents

Other BGS technic Saw manuals