IMER 1188616 Datasheet

U.S.A. inc.

TD 10 Sawing machine

EL

R

MANUAL INSTRUCTION

and

PARTS LIST

Model - 1188616

Machine serial N°

Manual Part. number 3223601_R00 (2003/11)

Write in the serial n° of your machine here

2

IMER U.S.A. Inc.

TD 10

Special attention must be given to warnings with this symbol:

Thank-you for purchasing a TD 10 from an Imer U.S.A. dealer. Your decision is an intelligent one.

There is no other sawing machine in the world which delivers the benefits and features of the TD 10:

- Extremely rigid, mig welded bar steel frame.

- Electric motor 1.5 Hp.

.- Compact design for easy trasportation.

- Extremely rigid worktable for a precise cutting.

At IMER U.S.A. we continually search for ways to better serve our customers. Should you have an idea or thought to

share with us regarding this product we would appreciate hearing from you. Our motto is "Tools and Services for the

21st Century" .

We look forward to delivering the goods.

Thank you again for your purchase.

Mace T. Coleman, Jr.

President, Imer U.S.A, Inc.

IMERWEST

207 Lawrence Avenue

So. San Francisco, CA 94080

Tel 650 - 872 - 2200

Fax 650 - 873 - 6482

IMEREAST

221 Westhampton Place

Capitol Heights, MD 20743

Tel 301 - 336 - 3700

Fax 301 - 336 - 6681

14

1

2

3

45

6

7

8

9

10

11

12

13

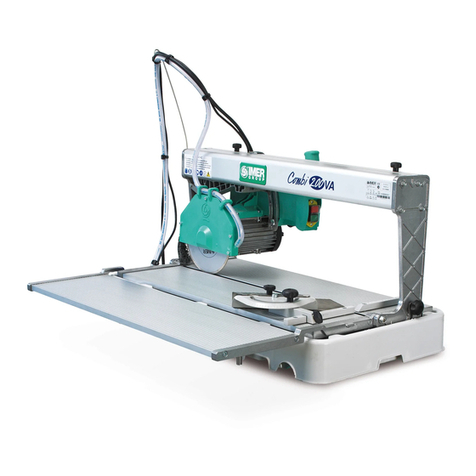

Fig. 1

1. Trestle element

2. Spray guard

3. Motor

4. Blade support

5. Water pump

6. Guide

7. Junction box

8. Worktable

9. Water tank

10. Blade guard

11. Support locking handle

12. Work piece

13. Blade

14. Frame

15. Disc cover

X

3

IMER U.S.A. Inc.

TD 10

Dear Customer,

Congratulations on your choice of purchase: this IMER saw, the

result of years of experience, is a fully reliable machine and is

equipped with the latest technical innovations.

- WORKING IN SAFETY

To work in complete safety, read the following

instructions carefully.

-ThisOPERATIONANDMAINTENANCEmanual mustbe kepton

site by the person in charge, e.g. the SITE FOREMAN, and must

always be available for consultation.

- The manual is to be considered part of the machine and must be

kept for future reference (EN 292/2) until the machine is disposed

of. If the manual is damaged or lost, a replacement may be

requested from the saw manufacturer.

- The manual contains important information regarding site

preparation, installation, machine use, maintenance procedures

and requests for spare parts. Nevertheless, the installer and the

operator must both have adequate experience and knowledge

of the machine prior to use.

- To guarantee complete safety of the operator, safe operation

and long life of equipment, follow the instructions in this manual

carefully, and observe all safety standards currently in force for

the prevention of accidents at work. Use personal protection

(safety footwear, suitable clothing, gloves, goggles, etc.).

- Safety glasses or a protective visor must be worn at all

times.

- Ear protection must be worn at all times.

- MAKE SURE THAT WARNING SIGNS ARE ALWAYS

LEGIBLE.

- It is strictly forbidden to carry out any form of

modification to the steel structure or working parts of the

machine.

- IMER INTERNATIONAL declines all responsibility for non-

compliance with laws and standards governing the use of this

equipment, in particular; improper use, defective power supply,

lack of maintenance, unauthorised modifications, and partial or

total failure to observe the instructions contained in this manual.

IMER INTERNATIONALis entitled to modify the characteristics of

the sawing machine and/or the contents of this manual without

necessarily updating previous machines and/or manuals.

1. TECHNICAL DATA

Table 1 shows the saw s technical data, referring to figure 1.

2. DESIGN STANDARDS

TD10 sawsaredesignedandmanufacturedaccordingtothefollowing

standards:EN292-1-2;EN 12418;EN60204-1.

TABLE 1

TECHNICALDATA 1188616

Blade rpm rpm 3400

Blade diameter in. 10

Blade mounting hole in. 5/8

Motor rating Hp 1.5

Voltage V 115

Current A 14.4

Frequency Hz 60

Motor rpm rpm 3600

Cutting table dimension in. 12" x14"

Overall dimensions

(widthxlengthxheight) in. 23½" x 42½" x 23¼"

Overall dimensions for

transport

(widthxlengthxheight) in. 24" x43" x23½"

Water pump flowrate L/min 10

Water tank capacity L 42

Weight lb. 117

Weight for transport lb. 134

Blade rotationdirection(seen

fromblade clamping flange) CLOCKWISE

3. NOISE EMISSION LEVEL

Table2indicatesthenoiselevelproducedbythe sawingmachine,

measured at the operator s ear (LpA at 1 m - 98/37CE) and the

environmental noise emission level (power LWA) measured in

accordance with EN ISO 3744; UNI EN 12418.

4. CUTTING SPECIFICATIONS

This saw model has been specially designed for cutting stone,

ceramics, marble, granite, concrete and similar materials. Only

water-cooled diamond blades with continuous or segmented

edges (see paragraph 14) must be used. Under no

circumstances must dry cutting blades be used or materials

other than those specified above. IMER INTERNATIONAL

declines all responsibility for damage caused by improper use

of the above machine.

5. CUTTING CAPACITY

- max. cutting capacity with vertical blade = 3¼" in. in one

single pass.

- max. height of workpiece: 4¾" in. (in two passes).

- min. width of workpiece: 2" in.

- max. cutting length: 15" in. (with blade lowered), 19¾" in.

(for max cutting height in one single pass).

-Blade at 45°: with support at 45° on the work surface.

6. WARNING

- Do not load the saw with workpieces that exceed the specified

weight (max. 55 lb.)

- Ensure stability of machine: it must be installed on a solid

base with a maximum slope of 5° (fig. 2).

- Ensure the workpiece is stable before, during and after cutting:

in any case, workpieces must not overhang the worktable.

- Respect the environment; use suitable receptacles for

collection of cooling water contaminated with cutting dust.

7. SAFETY PRECAUTIONS

- IMER saws are designed for work on construction sites and

under conditions of natural light, hence the workplace must be

adequately lit.

- The machine must never be used in environments

subject to risks of explosion and/or underground sites

- IMER saws may only be used when fitted with all required

safety devices, which must be in perfect condition.

- Never use makeshift and/or faulty power cables.

- Make electrical connections on the construction site where

they will not be subject to damage. Never stand the saw on

power supply cables.

- Lay power cables in such a way as to prevent water

penetration. Only use connectors fitted with water-spray

protection (IP67, EEC).

- Repairs to electrical installations must only be carried out by

qualified technicians. Always ensure that the machine is

disconnected from the power supply and is completely immo-

bile during repairs and maintenance operations.

- The symbol shown on the label (see left)indicates

thewarning ENSUREALLPROTECTIONDEVICES

ARE INSTALLED AND IN PERFECT CONDITION

BEFORESWITCHINGONTHEMACHINE (fig.3).

8. ELECTRICAL SAFETY

IMER saws comply with EN 60204-1; and are fitted with:

- Protection device against automatic re-start after power failure.

- Short-circuit cutout device

- Motor overload cutout switch

Fig. 3

TABLE 2

SAWINGMACHINE TYPEOFMOTOR LpA

(dB) LWA

(dB)

TD10 ELECTRIC 82 92

4

IMER U.S.A. Inc.

TD 10

9. TRANSPORTATION

- WARNING!

Before moving the saw, lock head

support carriage movement by means of the relative knob

(Ref. 11, fig. 1).

The saw weights 117 lb and can be moved by means of the

side handles on the tank.

Always empty the tank before moving the machine.

10. INSTALLATION

The machine must be placed on a smooth surface that is at least

as large as the tank, with the saw on the relative stand (Ref. 11,

fig. 1).The correct side for the operator is as shown in Fig.1

position X.

- Ensure that the stand is positioned on the relative

inserts on the tank base and thus secured.

- Always remove the plug from the mains power before

moving the machine.

11. ELECTRICAL CONNECTION

Connect the mains power cable to the plug on the electrical

panel.

- Ensure that the electric line has a suitable

differential overload switch(RCD)(GFCI-USA).

THERMAL CUTOUT PROTECTION:

- The electric motor is protected against overload by

a thermal cutout; in the event of overheating this device

shuts down the motor.

Cool the motor and restart by means of the RCCB

switch and the main switch on the handle .

The machine is protected against short circuits by a

magnetic protection inside the RCCB.

-Ensure that the mains voltage corresponds to that specified

for the machine: 115/60Hz. The electrical power cable must be

suitably sized to avoid voltage drops. Cable drums must not be

used.

Cables used on construction sites must be fitted with suitable

external sheathing that is resistant to wear, crushing and

extreme weather conditions (for example H07RN-F).

- All power supply installations must comply with

CEI 64-8 standards (harmonised document CENELEC

HD384).

12. MACHINE START-UP

Before connecting the machine to the power supply:

1 - Ensure that the tank contains sufficient cooling water.

2-Connect the power supply cable to the electric panel plug.

3-Turn on the concrete mixer using the switch located on the

electric control panel (ref. 7, fig. 1) comprising two buttons: the

green one switches on the machine, while the red one switches

it off. The switch has minimum voltage protection: after a power

failure or accidental power loss, push the green start button to

start the machine up again.

4 - Check that the direction of blade rotation corresponds to that

indicated by the arrow on the blade guard.

Open the valve and ensure sufficient flow of cooling water to

the diamond blade.

5 - Never dry cut material or cut when cooling water levels

are low.

6 - If all is in order, proceed with cutting.

13. EMERGENCY STOP

- In case of an emergency, stop the machine by

pressing the red stop button (extended), then disconnect

the plug from the power supply socket.

- The motor is protected against automatic re-start

after interruptions due to power failure. To resume

operation, when power is re-connected, press the green

switch on the overload cutout device.

14. BLADE INSTALLATION

Always remove the plug from the mains power.

- Note that the blade must have an external diameter of

10"in., a central hole diameter of 5/8"in. and max. thickness

of 1\8in.

The diamond blade is made of material that may be damaged

when subject to high temperatures, and therefore must be

cooled during the work phases.

To replace the blade, proceed as follows:

1.Block axial movement of the cutting head by means of the

handwheels (ref.11 fig. 1).

2.Stop the blade rotation fitting the shaft blocking pin (ref. 1 fig.

5) in the hole of the belt cover (ref. 2 fig. 5) rotating the blade

till the pin has entered the hole in the shaft.

Verify that the blade doesn t turn, otherwise repeat the

operation again.

3. Disassemble the front guard.

4. Loosen the locknut by rotating clockwise (left thread),

using a 19 mm wrench.

5. Move the cutting head forward slightly and incline to

remove the blade from its seat.

6. Ensure that there are no foreign objects between the

fixing flange and diamond blade. During disassembly, avoid

use of tools that could dent or deform the flange.

7. Insert the new blade proceeding in reverse order of the

operation described at point 4. Take special care to ensure

correct direction of rotation of the diamond blade.

8. Tighten the blade locknut fully down by rotating

anticlockwise (left thread), to a torque of 40 Nm.

9.Take the shaft blocking pin off the belt cover.

10.Verify the blade turn freely.

11.Connect the plug again.

- Check that the blade to be used is

suitable for the material to be cut.

- Do not use blades for wood! (fig. 6).

15. USE

- Leave a space of 5 ft. around the machine to operate

in full safety.

-Donot allowotherpersonstoapproachthemachineduringcutting.

- Never use the machine in fire-risk areas. Sparks can cause fire or

explosions.

- Make sure that the machine is switched off before positioning or

handling.

- Always ensure that the blade is free of any contact before start-

up.

- Ensure correct installation of all protective devices.

Before starting work, fill the water tank. Top up during operation

whenever necessary: N.B. the pump suction hose must

always remain immersed in water.

- Insert the plug in the power socket.

- WARNING!

For safety purposes the removal of

protective guards from the machine is strictly prohibited

- WARNING! Always switch off the machine before

carrying out blade adjustment.

15.1 VERTICAL BLADE MOVEMENT

To raise or lower the blade, slacken the support locking handle

turning it anti-clockwise (Ref. 11, fig. 1). The blade support (Ref. 4,

fig.1) remains free to rotate, so it can be secured in the desired

position, fully tightening the handle (ref. 11, fig. 1).

- Ensure that the locking handle is tightened fully before

starting work.

15.2 BLADE POSITIONING FOR 45° CUTS

To make a cut at 45°, the 45° support on the carriage is necessary.

Oncetheworkpieceiscorrectlypositioned,cuttingcanbegin,starting

the electric motor.

Fig. 6

5

IMER U.S.A. Inc.

TD 10

15.3 CUTTING

- Check that the blade is aligned with the cutting line.

- Place the workpiece on the worktable (ref. 8, fig. 1), resting firmly

against the stop. Start the motor.

Wait until the water reaches the blade. Begin cutting.

- Horizontal cutting movement is carried out by pulling the carriage

towards the blade.

- As cutting thickness increases, the blade is subjected

to greater stress. To avoid overloading the motor, the

operator should continually check blade feed speed. The

speed will also depend on the characteristics of the

material being cut (hardness, toughness etc.).

15.3.1 CUTS WITH BLADE LOWERED FROM ABOVE

Bring the blade support to its highest position and lock. Position the

workpiece. Start themachine, unlockthe blade support andbegin

vertical cutting until the blade reaches its lowest point. Lock the

support once more and proceed with horizontal cutting

15.3.2 BLADE CHANGE

To change the blade refer to section 14.

16. MAINTENANCE

- WARNING! Servicing must always be carried out by

qualified technicians and only after the motor has been

switched off.

- Always keep the guards in proper working order

and free from damage.

- As there is the continuous risk of inadvertent

damage to the electric cables, these must be checked

regularly each time before the machine is used.

Never leave the machine out in the open. Make sure that it is

stored in a sheltered area away from extreme weather

conditions.

Below is a list of the cleaning operations that must be carried out

at the end of every shift.

Recommended product for cleaning and lubricating the

mechanical parts of the saw: WD40

16.1 TANK CLEANING ON WORK COMPLETION

- Empty the tank by removing the plug. Remove cutting residue

using a jet of water.

16.2 WORK SURFACE CLEANING

Always keep work surfaces clean. Residual dirt can impair cutting

precision.

16.3 GUIDE RAIL CLEANING

It is good practice to remove all traces of dirt from the guides.

16.4 CLEANING AND MAINTENANCE OF COOLING

CIRCUIT

- If water does not reach the blade stop the machine immediately

to avoid blade damage.

- After switching off the machine ensure that the water level is

sufficient.

At regular intervals (or when the flow rate of the blade cooling

water is reduced) clean the cooling water supply circuit. To do

this, disassemble the delivery nozzle located inside the blade

guard and clean in water.

Periodically clean the cooling water delivery line between the

pump and valve, and blade guard using water.

16.5 TENSIONING THE DRIVE BELT (fig. 3)

- Switch off the electric motor and remove the plug from the

power supply.

- Unscrew the 4 screws that secure the movable belt guard (ref. 1).

- Loosen the 4 (ref. 2) screws that clamp the electric motor to

the blade support.

- Tension the belt using the nut (ref. 3): apply a force of about

F=14 lb. to the centre of the free section of the belt, the arrow

should be about f=1/4" in. (fig. 4).

- Tighten the screws on the electric motor, checking the alignment

of the motor pulley and the blade pulley

- Refit the guard and lock it using the 4 screws.

- To avoid shortening the life of the belt, the bearings

and the blade shaft, do not overtension the belt. Finally,

check the two pulleys are aligned.

16.6 DRIVE BELT REPLACEMENT

Repeat the operations described in section 16.5, replacing the

belt before tensioning it

17. REPAIRS

- Do not start the saw during repair work.

Only use genuine IMER spare parts and do not modify them.

- If the guards are removed to carry out repairs, they

must be refitted properly when the repair work is finished.

Table of contents

Other IMER Saw manuals