7ENGLISH

8. Keep handles and grasping surfaces dry,

clean and free from oil and grease. Slippery

handles and grasping surfaces do not allow for

safe handling and control of the tool in unexpected

situations.

9. When using the tool, do not wear cloth work

gloves which may be entangled. The entangle-

ment of cloth work gloves in the moving parts may

resultinpersonalinjury.

Service

1. Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

2. Follow instruction for lubricating and chang-

ing accessories.

Cut-o machine safety warnings

1. Position yourself and bystanders away from

the plane of the rotating wheel. The guard helps

toprotecttheoperatorfrombrokenwheelfrag-

ments and accidental contact with wheel.

2. Use only bonded reinforced cut-o wheels for

your power tool.Justbecauseanaccessorycan

beattachedtoyourpowertool,itdoesnotassure

safe operation.

3. The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool. Accessories running faster than

theirratedspeedcanbreakandyapart.

4. Wheels must be used only for recommended

applications. For example: do not grind with

the side of a cut-o wheel.Abrasivecut-o

wheels are intended for peripheral grinding, side

forces applied to these wheels may cause them to

shatter.

5. Always use undamaged wheel anges that are

of correct diameter for your selected wheel.

Properwheelangessupportthewheelthus

reducingthepossibilityofwheelbreakage.

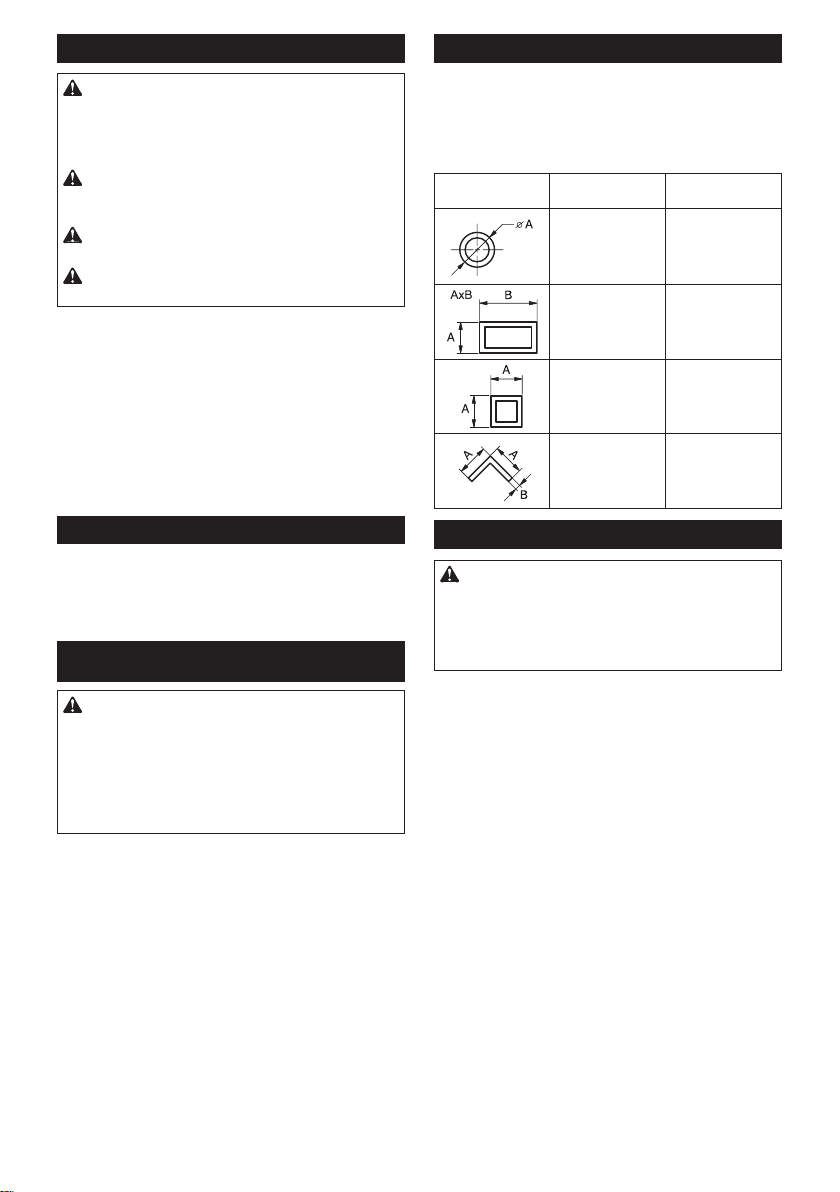

6. The outside diameter and the thickness of your

accessory must be within the capacity rating

of your power tool. Incorrectly sized accessories

cannotbeadequatelyguardedorcontrolled.

7. The arbour size of wheels and anges must

properly t the spindle of the power tool.

Wheelsandangeswitharbourholesthatdonot

match the mounting hardware of the power tool

willrunoutofbalance,vibrateexcessivelyand

may cause loss of control.

8. Do not use damaged wheels. Before each use,

inspect the wheels for chips and cracks. If the

power tool or wheel is dropped, inspect for

damage or install an undamaged wheel. After

inspecting and installing the wheel, position

yourself and bystanders away from the plane

of the rotating wheel and run the power tool

at maximum no load speed for one minute.

Damagedwheelswillnormallybreakapartduring

this test time.

9. Wear personal protective equipment.

Depending on application, use face shield,

safety goggles or safety glasses. As appro-

priate, wear dust mask, hearing protectors,

gloves and shop apron capable of stopping

small abrasive or workpiece fragments. The

eyeprotectionmustbecapableofstoppingying

debrisgeneratedbyvariousoperations.Thedust

maskorrespiratormustbecapableofltrating

particlesgeneratedbyyouroperation.Prolonged

exposure to high intensity noise may cause hear-

ing loss.

10. Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragmentsofworkpieceorofabrokenwheelmay

yawayandcauseinjurybeyondimmediatearea

of operation.

11. Position the cord clear of the spinning acces-

sory.Ifyoulosecontrol,thecordmaybecutor

snaggedandyourhandorarmmaybepulledinto

the spinning wheel.

12. Regularly clean the power tool’s air vents. The

motor’s fan can draw the dust inside the housing

and excessive accumulation of powdered metal

may cause electrical hazards.

13. Do not operate the power tool near ammable

materials. Do not operate the power tool while

placed on a combustible surface such as

wood. Sparks could ignite these materials.

14. Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

Kickback and related warnings

Kickbackisasuddenreactiontoapinchedorsnagged

rotating wheel. Pinching or snagging causes rapid

stalling of the rotating wheel which in turn causes the

uncontrolledcuttingunittobeforcedupwardstoward

the operator.

Forexample,ifanabrasivewheelissnaggedor

pinchedbytheworkpiece,theedgeofthewheelthat

is entering into the pinch point can dig into the surface

ofthematerialcausingthewheeltoclimboutorkick

out.Abrasivewheelsmayalsobreakunderthese

conditions.

Kickbackistheresultofpowertoolmisuseand/or

incorrectoperatingproceduresorconditionsandcanbe

avoidedbytakingproperprecautionsasgivenbelow.

1. Maintain a rm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. The operator can control

upwardkickbackforces,ifproperprecautionsare

taken.

2. Do not position your body in line with the

rotating wheel.Ifkickbackoccurs,itwillpropel

the cutting unit upwards toward the operator.

3. Do not attach a saw chain, woodcarving blade,

segmented diamond wheel with a peripheral

gap greater than 10 mm or toothed saw blade.

Suchbladescreatefrequentkickbackandlossof

control.