1CONTENTS

1CONTENTS.................................................................................................................................................................................2

2CAUTION....................................................................................................................................................................................3

3NECESSARY REPAIRING TOOLS...........................................................................................................................................3

4LUBRICANTANDADHESIVEAPPLICATION......................................................................................................................4

5TIGHTENING TORQUE SPECIFICATIONS............................................................................................................................4

6REPAIR........................................................................................................................................................................................5

6-1 Hook section........................................................................................................................................................................5

6-1-1 Disassembling.............................................................................................................................................................5

6-1-2 Assembling..................................................................................................................................................................5

6-2 Shoe section.........................................................................................................................................................................6

6-2-1 Disassembling.............................................................................................................................................................6

6-2-2 Assembling..................................................................................................................................................................6

6-3 Blade clamp section.............................................................................................................................................................7

6-3-1 Disassembling.............................................................................................................................................................7

6-3-2 Assembling..................................................................................................................................................................9

6-4 Carbon brush section..........................................................................................................................................................13

6-4-1 Disassembling...........................................................................................................................................................13

6-4-2 Assembling................................................................................................................................................................13

6-5 Insulation cover section......................................................................................................................................................14

6-5-1 Disassembling...........................................................................................................................................................14

6-5-2 Assembling................................................................................................................................................................14

6-6 Switch/ Motor section........................................................................................................................................................15

6-6-1 Disassembling...........................................................................................................................................................15

6-6-2 Assembling................................................................................................................................................................18

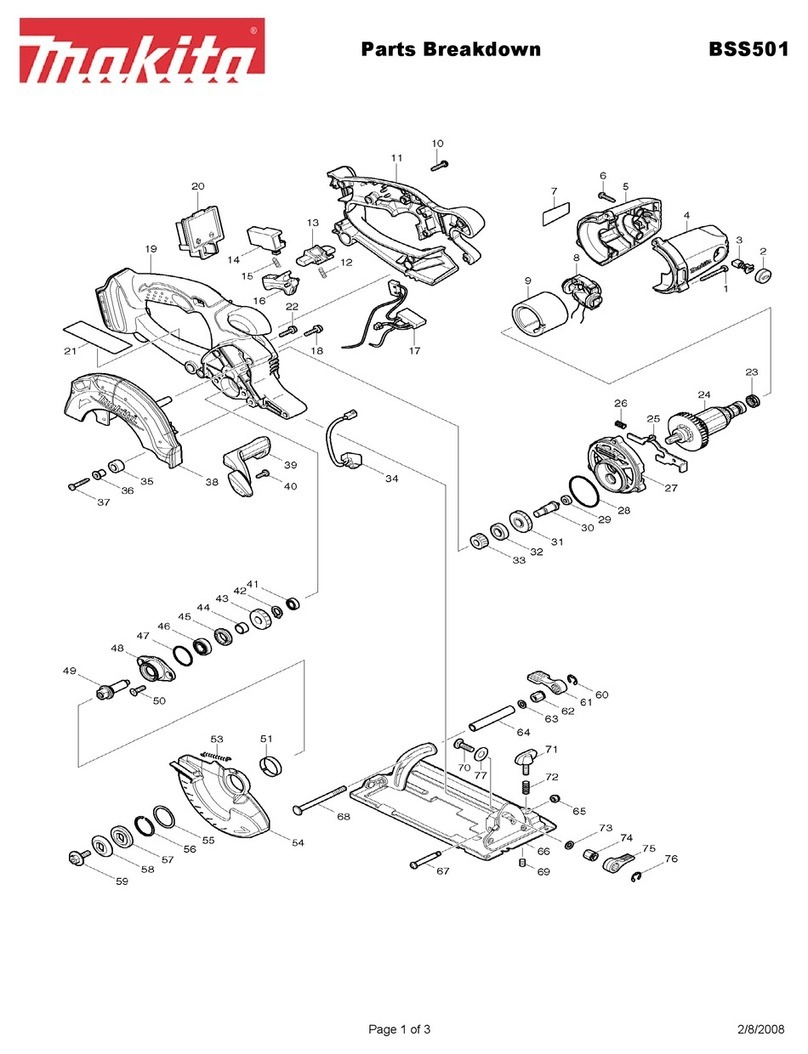

6-7 Armature/ Gear section......................................................................................................................................................21

6-7-1 Disassembling...........................................................................................................................................................21

6-7-2 Assembling................................................................................................................................................................24

6-8 Slider section......................................................................................................................................................................26

6-8-1 Disassembling...........................................................................................................................................................26

6-8-2 Assembling................................................................................................................................................................28

7CIRCUIT DIAGRAM................................................................................................................................................................30

8WIRING DIAGRAM.................................................................................................................................................................31

8-1 Field section.......................................................................................................................................................................31

8-2 Handle section....................................................................................................................................................................32