Bien Air CHIROPRO User manual

REF 2100318-0003/2019.12© Bien-Air Dental

Rx Only

CHIROPRO 3rd Gen

ENG INSTRUCTIONS FOR USE.

FRA INSTRUCTIONS D’UTILISATION.

DEU BEDIENUNGSANLEITUNG.

ESP INSTRUCCIONES DE USO.

ITA ISTRUZIONI PER L’USO.

PRT INSTRUÇÕES DE UTILIZAÇÃO.

RUS ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ.

中文 使用说明书 .

JPN 取扱説明書 .

REF 2100318-0003/2019.12 © Bien-Air Dental

Set Chiropro 3rd Gen REF 1700708-001

REF 1600995-001 REF 1303393-001 REF 1601008-001 REF 1601009-001 REF 1600631-001 REF 1500984-005 REF 1307727-010

REF 1301575-001 REF 1502329-002

Set Chiropro 3rd Gen CA REF 1700707-001

REF 1700708-001 REF 1600692-001

Set Chiropro 3rd Gen KM REF 1700737-001

REF 1600995-001 REF 1303393-001 REF 1601008-001 REF 1601009-001 REF 1600631-001 REF 1501635-010 REF 1307727-010

REF 1301575-001 REF 1502329-002

Set Chiropro 3rd Gen KM CA REF 1700736-001

REF 1700737-001 REF 1600786-001

Options

REF 1601008-001 REF 1600692-001 REF 1600598-001 REF 1600785-001 REF 1600786-001 REF 1600052-001 REF 1303393-001 REF 1601009-001

REF 1600631-001 REF 1301575-001 REF 1502329-002 REF 1307727-010 REF 1307312-010 REF 1500984-010 REF 1501738-010 REF 1501635-010

REF 1501621-010 REF 1307031-001

ENG

1

1 Symbols............................................................. 2

1.1 Description of symbols for Chiropro 3rd Gen units ...................2

1.2 Description of symbols for Chiropro 3rd Gen accessories .....2

2 Identification, Intended Use and Notation... 3

2.1 Identification..........................................................................................3

2.2 Intended use ..........................................................................................3

2.3 Notation and chapter links................................................................3

3 Warnings & Precautions of Use .................... 4

4 Description........................................................ 5

4.1 Chiropro 3rd Gen system overview ................................................5

4.2 Sets supplied.........................................................................................6

4.3 Options ....................................................................................................6

4.4 Technical data .......................................................................................6

4.5 Environmental protection and information for disposal..........7

4.6 Electromagnetic compatibility (technical description) .............7

4.6.1 Precautions of use ................................................................7

4.6.2 Electromagnetic compatibility warnings .......................7

4.6.3 Electromagnetic compatibility – emissions &

immunity .....................................................................................8

5 Installation.....................................................10

5.1 Install the Chiropro 3rd Gen system ............................................ 11

5.2 On/off procedure............................................................................... 11

6 Interface overview......................................... 12

6.1 Chiropro 3rd Gen modes.................................................................. 12

6.2 Rotating knob functions overview................................................ 12

6.3 Sound alerts ....................................................................................... 13

7 Operation.........................................................14

7.1 Operation screen description ........................................................ 14

7.2 Perform an operation, steps P1 and P2 ..................................... 14

7.3 Perform an operation, steps P3, P4 and P5.............................. 14

8 Settings ........................................................... 16

8.1 MX-i LED 3rd Gen micromotor speed .......................................... 16

8.2 MX-i LED 3rd Gen micromotor torque ......................................... 16

8.3 MX-i LED 3rd Gen micromotor rotation direction..................... 16

8.4 Irrigation level.................................................................................... 17

8.5 Contra-angle ratio............................................................................. 17

9 Special modes................................................ 18

10 List of errors & Troubleshooting ...............20

10.1 Safety warning (operating)............................................................. 20

10.2 Device operating error..................................................................... 21

11 Maintenance ..................................................22

11.1 Servicing.............................................................................................. 22

11.2 Cleaning & disinfection.................................................................... 22

11.3 Important............................................................................................. 22

11.4 Replacement of fuses...................................................................... 23

12 General information and guarantee..........24

12.1 General information ......................................................................... 24

12.2 Terms of guarantee .......................................................................... 24

Table of contents

2

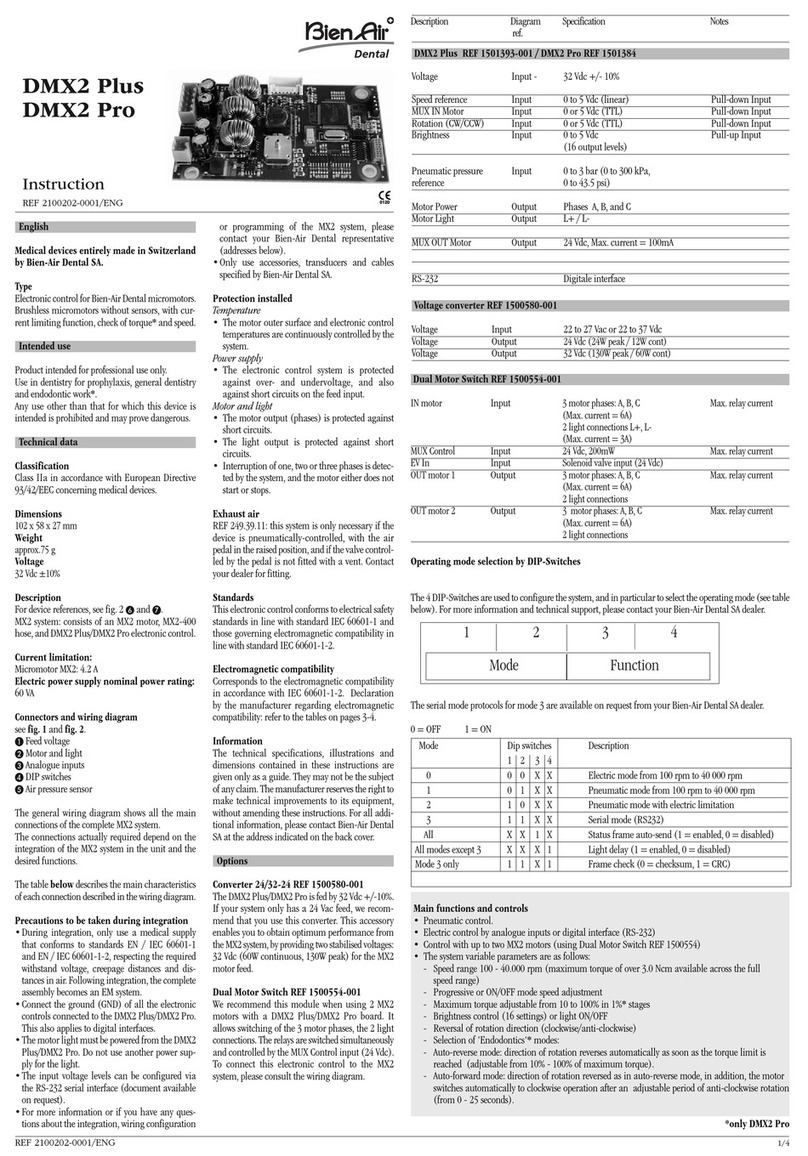

1.1 Description of symbols for Chiropro 3rd Gen units

1.2 Description of symbols for Chiropro 3rd Gen accessories

Symbol Description Symbol Description

CE Marking with number of the notified body. Recyclable materials.

Main switch - Power OFF. Separate collection of electric and electronic

equipment.

Main switch - Power ON. Manufacturer.

Fuse Ø 5 x 20 mm. Light.

Alternating current. Sound alerts.

RF emitting device (Interference may occur in the

vicinity of equipment marked with this symbol).

Warning: in accordance with federal law (USA), this

device is only available for sale upon recommen-

dation by an accredited practitioner.

CAUTION! Consult accompanying documents.

Provides an instruction that should be observed for

safety reasons.

CSA marking - Complies with U.S. and Canadian

standards.

Refer to the accompanying documents (www.bie-

nair.com/ifu). Serial number.

Reference number.

Symbol Description Symbol Description

CE Marking with number of the notified body. Thermo washer disinfectable.

Expiration date. Recyclable materials.

Do not reuse. Separate collection of electric and electronic

equipment.

Sterilized with Ethylene Oxyde. Sterilizable in autoclave up to the specified tem-

perature.

Electrical safety. Applied part type B. Manufacturer.

Reference number. Serial number.

Rx Only

SN

REF

STERILE

EO

135°C

REF

SN

1Symbols

ENG

3

2 Identification, Intended Use and Notation

2.1 Identification

Electronically controlled tabletop device for dentistry allowing

operation of a dental handpiece via an MX-i LED 3rd Gen

micromotor with variable speed control by a pedal.

A peristaltic pump conveys the physiological liquid via a

disposable irrigation line without being contaminated.

The device's LCD display indicates and allows to control operation

settings.

2.2 Intended use

The equipment is to be used by dentists and surgeons in dental

offices and hospitals. The system is designed to control a dental

MX-i LED 3rd Gen micromotor only which can drive a dental hand-

piece fitted with appropriate tools to cut hard and soft tissues in

the oral cavity and to place dental implants.

The system is intended for use in dentistry for implantology.

Any use other than that for which this product is intended is

unauthorized and may be dangerous.

The system meets all the current legal requirements for medical

devices.

The intended electromagnetic environment (per IEC 60601-1-2

ed. 4.0) is Professional healthcare facility environment.

2.3 Notation and chapter links

•A, B, C, etc.

Text preceded by a letter indicates a procedure to be carried

out step-by-step.

•

Indicates a procedure result.

•(1),(2),(3), etc.

Text preceded by a number indicates text used in

conjunction with an illustration.

•OK,Settings, etc.

Text in bold italic font style indicates, on-screen elements

such as buttons, menus, menu items, screen areas, values,

fields when they are named and screen names.

In order to simplify the notation, in this manual:

• «Clockwise» is referred to as «CW»;

• «Counterclockwise» is referred to as «CCW»;

• Forward micromotor rotation mode is referred to as «FWD»;

• Reverse micromotor rotation mode is referred to as «REV»;

• Rotational speed unit «revolutions per minute» is referred to

as «rpm»;

• Torque unit «newton centimetre» is referred to as «Ncm»;

• Micromotor control unit is referred to as «DMX».

4

3 Warnings & Precautions of Use

CAUTION

The power plug is used for disconnection in case of problems, it

must be easily accessible at all times.

CAUTION

Never connect a handpiece on a running MX-i LED 3rd Gen

micromotor.

CAUTION

Any modification of the medical device is strictly forbidden.

CAUTION

The device is not designed for use in an explosive atmosphere

(anaesthetic gas).

CAUTION

Do not attempt to open the device when it is connected to the

electric mains.

Risk of electrocution.

CAUTION

The parameters contained in the dental procedures are indicative

only. Bien-Air Dental SA cannot be held liable for them.

CAUTION

The device must not be touched by the patient.

CAUTION

Do not simultaneously touch the patient and the pump or contacts

of connectors.

CAUTION

Ensure that there is no water under the unit before switching it

on.

CAUTION

All connectors must be dry before use. Ensure the absence of

residual moisture due to cleaning.

WARNING

To avoid the risk of electric shock, this equipment must only be

connected to a supply mains with protective earth.

ENG

5

4 Description

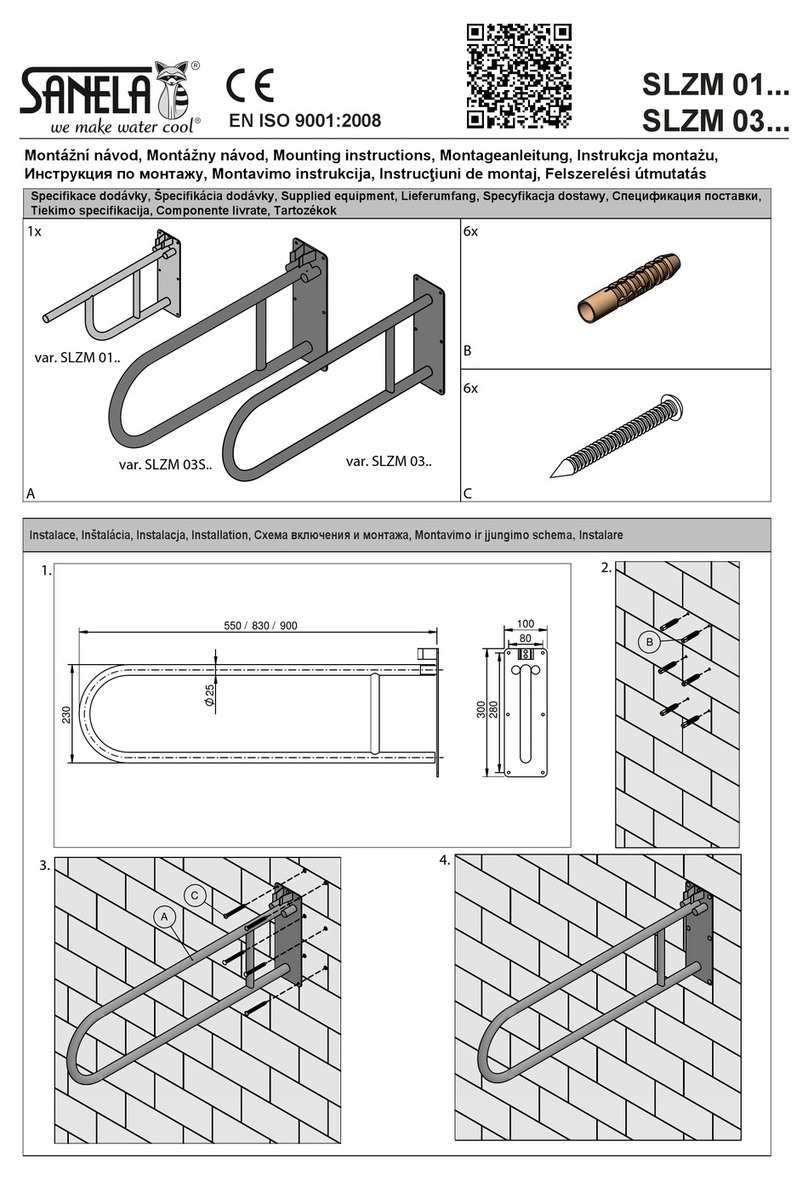

4.1 Chiropro 3rd Gen system overview

FIG. 1

(1) Peristaltic pump lid

(2) Pedal connector

(3) Marking

(4) Bracket support

(5) Main switch

(6) Fuse box

(7) Mains connector

(8) MX-i

LED

3rd Gen micromotor

(9) Button to start/stop irrigation

(10)

Foot control to reverse the rotation of the MX-i LED

3rd Gen

micromotor

(11) “Program” button to go to next operation step

(12) Motor start

(13) MX-i

LED

3rd Gen micromotor connector

(14) Control knob

(15) LCD control screen

8

24

356

7

3

13

1

9

11

12

10

1415

6

4.2 Sets supplied

Chiropro 3rd Gen set REF 1700708-001

Chiropro 3rd Gen CA set REF 1700707-001

Chiropro 3rd Gen KM set REF 1700737-001

Chiropro 3rd Gen KM CA set REF 1700736-001

4.3 Options

4.4 Technical data

Dimensions L x W x H

Chiropro 3rd Gen unit ..............................240 x 240 x 102 mm

Chiropro 3rd Gen unit (with bracket)...240 x 240 x 482 mm

Pedal ............................................................250 x 205 x 54 mm

Pedal (with handle)..................................250 x 205 x 144 mm

Motor cable (REF 1601009)...................L 2.0 m

Pedal cable.................................................L 2.9 m

The pedal is waterproof (IP X8 in accordance with IEC 60529).

Weight

Chiropro 3rd Gen unit ..............................2.2 kg

Pedal ............................................................830 g

Bracket ........................................................115 g

Cable ............................................................105 g

Electrical data

Voltage.........................................................100 – 240 VAC

Frequency ..................................................50-60 Hz

Environmental conditions

Designation REF number

Chiropro 3rd Gen unit (1x) 1600995-001

MX-i

LED

3rd

Gen micromotor (1x) 1601008-001

3-button pedal (1x) 1600631-001

Cable MX-i LED 3rd Gen (2m) (1x) 1601009-001

Sterile protective sheet (2x) 1502329-002

Pack of 5 disposable sterile irrigation lines 1500984-005

Pack of 10 attachment collars for fastening

the sterile irrigation line to a cable 1307727-010

Bracket for fluid bottle (1x) 1303393-001

Handpiece support (1x) 1301575-001

3P cable system, US/Asia, length 2m (1x) 1300067-001

3P cable system, Europe, length 2.5 m (1x) 1300066-001

3P cable system, Switzerland, length 2 m (1x) 1300065-001

Designation REF number

Chiropro 3rd Gen set (1x) 1700708-001

Contra-angle handpiece CA 20:1 L Micro-

Series (light) (1x) 1600692-001

Designation REF number

Chiropro 3rd Gen unit (1x) 1600995-001

MX-i

LED

3rd

Gen micromotor (1x) 1601008-001

3-button pedal (1x) 1600631-001

Cable MX-i LED 3rd Gen (2m) (1x) 1601009-001

Sterile protective sheet (2x) 1502329-002

Kirschner/Meyer pack of 10 disposable ste-

rile lines 1501635-010

Pack of 10 attachment collars for fastening

the sterile irrigation line to a cable 1307727-010

Bracket for fluid bottle (1x) 1303393-001

Handpiece support (1x) 1301575-001

3P cable system, US/Asia, length 2m (1x) 1300067-001

3P cable system, Europe, length 2.5 m (1x) 1300066-001

3P cable system, Switzerland, length 2 m (1x) 1300065-001

Designation REF number

Chiropro 3rd Gen KM set (1x) 1700737-001

Contra-angle handpiece CA 20:1 L KM

Micro-Series (light) 1600786-001

Designation REF number

3-button pedal 1600631-001

MX-i LED 3rd Gen micromotor 1601008-001

Contra-angle handpiece CA 20:1 L KM

Micro-Series (light) 1600786-001

Contra-angle handpiece CA 20:1 L KM (light) 1600785-001

Contra-angle handpiece CA 20:1 L

Micro-Series (light) 1600692-001

Contra-angle handpiece CA 20:1 L (light) 1600598-001

Straight handpiece PM 1:1 Micro-Series 1600052-001

Sterile protective sheet 1502329-002

Pack of 10 disposable sterile lines 3.5 m 1501738-010

Kirschner/Meyer pack of 10 disposable ste-

rile lines 1501635-010

Kirschner/Meyer type detachable irrigation set

for CA 20:1 L KM and CA 20:1 L KM

Micro-Series, comprising 10 rings and 10 tubes

1501621-010

Pack of 10 disposable sterile lines 1500984-010

Bracket for fluid bottle 1303393-001

Handpiece support 1301575-001

Cable MX-i LED 3rd Gen (2m) 1601009-001

3P cable system, US/Asia, length 2m 1300067-001

3P cable system, Europe, length 2.5 m 1300066-001

3P cable system, Switzerland, length 2 m 1300065-001

Pack of 10 attachments collars for fastening

the sterile irrigation line to a cable 1307727-010

Pack of 10 fuses T4.0AH 250 VAC high brea-

king capacity 1307312-010

Knob 1307031-001

Environmental

conditions

Operating Transport and storage

(max. 15 weeks)

Temperature +5°C (41°F) to

+35°C (95°F)

-25°C (-13°F) to

+70°C (158°F)

ENG

7

CAUTION

Do not use Chiropro 3rd Gen outside the range of operating

temperature.

Classification

Class IIa in accordance with European Directive 93/42/EEC

concerning medical devices.

Electric insulation class

Class I per IEC 60601-1 (apparatus protected against electric shocks).

CAUTION

The device must be only used by the operator.

Applied parts (per IEC 60601-1):

MX-i LED 3rd Gen micromotor..............REF 1601008-001

Straight handpiece 1:1 ...........................REF 1600052-001

CA 20:1 L.....................................................REF 1600598-001

CA 20:1 L Micro-Series...........................REF 1600692-001

CA 20:1 L KM..............................................REF 1600785-001

CA 20:1 L KM Micro-Series....................REF 1600786-001

Irrigation lines...........................................REF 1500984-010

KM Irrigation lines....................................REF 1501635-010

Degree of ingress protection

IP 41 (protection against insertion of objects larger than 1 mm

and dripping water (vertically falling drops)).

Memory

Memory storage of 5 steps settings including adjustment of

speed, torque, rotation direction, irrigation, and contra-angle ratio

for each step.

Languages

English.

Bracket for physiological liquid flask

Stainless steel.

Peristaltic pump

Pump delivery...........................................From 30 to 150 ml/min.

(5 levels)

Hose for pump ..........................................External Ø 5.60 mm

.......................................................................Internal Ø 2.40 mm

Wall thickness ...........................................1.60 mm

Intended for use with: See instructions for use

MX-i LED 3rd Gen micromotor..............REF 2100245

Cable MX-i LED 3rd Gen ..........................REF 2100163

Contra-angle CA 20:1 L, light................REF 2100209

Contra-angle CA 20:1 L

Micro-Series, light....................................REF 2100209

Contra-angle CA 20:1 L KM, light.........REF 2100209

Contra-angle CA 20:1 L KM

Micro-Series, light....................................REF 2100209

Straight Handpiece 1:1...........................REF 2100046

CAUTION

The use of the system with other handpieces, motors

or cables has not been validated/certified (speed and torque

values are not guaranteed in this case).

List of errors & Troubleshooting

See chapter “10 List of errors & Troubleshooting” on page 20.

4.5 Environmental protection and

information for disposal

The disposal and/or recycling of materials must be performed in

accordance with the legislation in force.

Separate collection of electric and electronic equipment and

accessories in view of recycling.

Electrical and electronic equipment may contain dangerous

substances which constitute health and environmental hazards.

The user must return the device to its dealer or establish direct

contact with an approved body for treatment and recovery of this

type of equipment (European Directive 2002/96/EC).

4.6 Electromagnetic compatibility

(technical description)

4.6.1 Precautions of use

This electronic control is in compliance with electrical safety

standards in line with standard IEC 60601-1, edition 3.1, and

those governing electromagnetic compatibility in line with

standard IEC 60601-1-2, fourth edition.

CAUTION

The device must be used by a competent person, in particular in

compliance with the legal provisions in force regarding

occupational safety, health and accident prevention measures,

and the current instruction for use. According to these measures,

the user has the following obligations:

• to only use devices that are in perfect working order

• to make sure that the device is used solely for the purpose

for which it is intended

• avoid contact with liquids.

4.6.2 Electromagnetic compatibility

warnings

CAUTION

The Chiropro 3rd Gen complies with the EMC requirements

according to IEC 60601-1-2. Radio transmitting equipment,

cellular phones, etc., should not be used in the immediate vicinity

of the device, since this could affect its operation. The device is

not suitable for being used close to high-frequency surgical

equipment, magnetic resonance imaging (MRI) and other similar

devices where the intensity of electromagnetic disturbances is

high. In any case, ensure that no high frequency cables are routed

above or near the device. If in doubt, contact a qualified technician

or Bien-Air Dental SA.

Portable RF communications equipment (including peripherals

such as antenna cables and external antennas) should be used no

closer than 30 cm (12 inches) to any part of the Chiropro 3rd Gen,

including cables specified by the manufacturer. Otherwise,

degradation of the performance of this equipment could result.

CAUTION

The use of accessories, transducers and cables other than those

specified, with the exception of transducers and cables sold by

Bien-Air Dental SA as spare parts for internal components, may

result in increased emissions or decreased immunity.

Relative humidity

(including

condensation)

30% to 80% 10% to 100%

Atmospheric

pressure

700 hPa to

1060 hPa 500 hPa to 1060 hPa

Environmental

conditions

Operating Transport and storage

(max. 15 weeks)

8

4.6.3 Electromagnetic compatibility – emissions & immunity

Guidance and manufacturer’s declaration – Electromagnetic emissions

The Chiropro 3rd Gen is intended for use in the electromagnetic environment specified below. The customer or the user of the Chiropro 3rd

Gen must ensure that it is actually used in such an environment.

Guidance and manufacturer’s declaration – Electromagnetic immunity

The Chiropro 3rd Gen is intended for use in the electromagnetic environment specified below. The customer or the user of the Chiropro 3rd

Gen must ensure that it is actually used in such an environment.

Emissions test Compliance Electromagnetic environment - guidance

RF emissions CISPR 11 Group 1

The Chiropro 3rd Gen uses RF energy for its internal operation only. Therefore, its RF

emissions are very low and are not likely to cause any interference in nearby electronic

equipment.

RF emissions CISPR 11 Class B

The Chiropro 3rd Gen is suitable for use in any building, including residential buildings

and those directly connected to the public low-voltage power supply network that sup-

plies buildings used for residential purposes.

Harmonic emissions IEC

61000-3-2 Class A

Emissions due to voltage

fluctuations IEC 61000-3-3 Conforming

Immunity test IEC 60601 test level Compliance level Electromagnetic

environment - guidance

Electrostatic discharge

(ESD)

IEC 61000-4-2

±8 kV contact

±2 kV air

±4 kV air

±8 kV air

±15 kV air

±8 kV contact

±2 kV air

±4 kV air

±8 kV air

±15 kV air

Floors should be wood,

concrete or ceramic tile. If

floors are covered with

synthetic material, the

relative humidity should be

at least 30%.

Electrical fast transient/

burst

IEC 61000-4-4

±2 kV for power supply lines

±1 kV for other lines

±2 kV for power supply lines

N.A.

Mains power quality should

be that of a commercial or

hospital environment.

Surge

IEC 61000-4-5

±0.5 kV line to line

±1 kV line to line

±0.5 kV line to earth

±1 kV line to earth

±2 kV line to earth

±0.5 kV line to line

±1 kV line to line

±0.5 kV line to earth

±1 kV line to earth

±2 kV line to earth

Mains power quality should

be that of a commercial or

hospital environment.

Voltage dips, short inter-

ruptions and voltage varia-

tions on power supply

input lines

IEC 61000-4-11

0% UTfor 0.5 cycle, at 0°, 45°, 90°,

135°, 180°, 225°, 270° and 315°

0% UTfor 1 cycle and

70% UTfor 25/30 cycles at 0°

0% UTfor 250 cycles at 0°

0% UTfor 0.5 cycle, at 0°, 45°, 90°,

135°, 180°, 225°, 270° and 315°

0% UTfor 1 cycle and

70% UTfor 25/30 cycles at 0°

0% UTfor 250 cycles at 0°

Mains power quality should

be that of a commercial or

hospital environment. If the

user of the Chiropro 3rd

Gen requires continued

operation during mains

power interruptions, it is

recommended that the

Chiropro 3rd Gen be powe-

red from an uninterruptible

power supply or a battery.

Magnetic field due to mains

frequency (50/60 Hz)

IEC 61000-4-8

30 A/m 30 A/m

Magnetic fields generated

by the mains frequency

should be at levels charac-

teristic of a typical location

in a typical commercial or

hospital environment.

ENG

9

Conducted disturbances

induced by RF fields

IEC 61000-4-6

3 VRMS

0,15 MHz – 80 MHz

6 VRMS in ISM bands

0,15 MHz – 80 MHz

80% AM at 1 kHz

3 VRMS

0,15 MHz – 80 MHz

6 VRMS in ISM bands

0,15 MHz – 80 MHz

80% AM at 1 kHz

Field strengths from fixed

RF transmitters, as deter-

mined by an electromagne-

tic site surveyashould be

less than the compliance

level in each frequency

range.

Interference may occur in

the vicinity of equipment

marked with the following

symbol:

Radiated RF EM fields

IEC 61000-4-3

3 V/m

80 MHz – 2,7 GHz

80 % AM at 1 kHz

3 V/m

80 MHz – 2,7 GHz

80 % AM at 1 kHz

Proximity fields from RF

wireless communications

equipment

IEC 61000-4-3

Test freq. [MHz] Max. power [W] Immunity test level

[V/m]

Distance: 0.3 m

385 1.8 27

450 228

710, 745, 780 0.2 9

810, 870, 930 228

1720, 1845, 1970 2 28

2450 228

5240, 5500, 5785 0.2 9

NOTE: UTis the AC mains voltage prior to application of the test level.

Essential performance per IEC 60601-1: The essential performance is to maintain the visual luminous intensity of the LED and the

motor speed. The maximum speed deviation is ±5%.

a. Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and mobile field radios, amateur radios, AM and FM radio

broadcasts and TV broadcasts cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an elec-

tromagnetic site survey should be considered. If the measured field strength in the location in which the Chiropro 3rd Gen is used exceeds the RF compliance

level mentioned above, the Chiropro 3rd Gen should be observed to verify that it is operating normally. If abnormal operation is observed, additional measures

may be necessary, such as reorienting or relocating the Chiropro 3rd Gen.

Immunity test IEC 60601 test level Compliance level Electromagnetic

environment - guidance

10

FIG. 1 FIG. 2 FIG. 3 FIG. 4

1 2

1

1

2

FIG. 5 FIG. 6 FIG. 7 FIG. 8

12

AAAA-MM-JJ

1 2 3

FIG. 9 FIG. 10 FIG. 11

5 Installation

ENG

11

5.1 Install the Chiropro 3rd Gen system

FIG. 1

A. Place the Chiropro 3rd Gen on a flat surface capable of bearing

its weight.

CAUTION

It may be positioned on a table, on a trolley or any other surface

but in no circumstances on the floor.

FIG. 2

B.

The fuse box may be opened with a screwdriver.

100 - 240 VAC = fuse T4.0AH 250 VAC REF 1307312-010.

To replace a fuse, see chapter“11.4 Replacement of fuses” on

page 23.

C.

Connect the power cable (1) to the connector (2).

Note 1

CAUTION

The power plug is used for disconnection in case of problems, it

must be easily accessible at all times.

FIG. 3

D.

Connect the pedal cable to the input provided on the rear panel,

guiding the connector and plug by means of the index pin on the

connector.

CAUTION

Do not lift the pedal holding the connection cable.

To disconnect the pedal cable pull the cable socket connector (1).

Do not pull the cable (2) without disconnecting the cable socket

before.

FIG. 4

E.

Connect the MX-i LED

3

rd Gen

micromotor cable to the motor

output, guiding the connector and plug by means of the index pin on

the connector.

FIG. 5

F.

Align and attach the bracket to the housing provided on the rear

of the console and suspend the flask or bottle.

FIG. 6

G.

Check the packaging integrity, as well as the expiry date of the

irrigation line on the label (1).

CAUTION

The medical device must be used only with lines supplied by

Bien-Air Dental to ensure trouble-free operation. These lines are

sterile and for single use. Re-use may result in microbiological

contamination of the patient.

H.

Remove the single-use sterile irrigation line (2) from its pouch.

FIG. 7

I.

Connect the flexible hose of the irrigation line to the spray tube of

the handpiece or contra-angle.

FIG. 8

J.

Install the peristaltic cassette (1) in the peristaltic pump (2).

Check that the cassette is clipped correctly.

FIG. 9

K.

Close the pump lid (3). If there is resistance to closing, open the

lid again and check the correct positioning of the cassette. When the

lid is correctly closed, the user should hear a click sound.

CAUTION

Do not run the pump while the lid is open.

CAUTION

Do not run the pump without irrigation line.

CAUTION

Risk of pinching!

FIG. 10

L.

Perforate the cap of the physiological liquid flask with the pointed

end of the irrigation line after removing the protective cap.

CAUTION

There is no detection of empty physiological liquid flask! Always

check the content of the flask before operating.

FIG. 11

M.

Attach the irrigation line on the motor cable using the 3

attachment collars REF 1307727-010.

5.2 On/off procedure

The device can be switched on and off in complete safety using

the main switch on the Chiropro 3rd Gen.

CAUTION

Do not switch off the device while the motor is running.

NOTES

1The equipment is powered by the mains power supply (100 -

240 VAC / 150W / 50-60Hz).

12

6 Interface overview

FIG. 1 FIG. 2

6.1 Chiropro 3rd Gen modes

The Chiropro 3rd Gen allows to visualize and control operation

parameters by the means of the LCD display.

A unique screen allows to use the following modes:

FIG. 1

• Operation mode (to perform an operation in 3 steps)

See chapter “7 Operation” on page 14 for details.

FIG. 2

• Settings mode (to set up operation parameters)

See chapter “8 Settings” on page 16 for details.

FIG. 3

• Special modes (to test system and reset settings)

See chapter “9 Special modes” on page 18 for details.

FIG. 4

A. Long press on the rotating knob (1) to switch between

Operation and Settings modes.

Note 1

See chapter “6.2 Rotating knob functions overview” on page 12 for

details.

See chapter “9 Special modes” on page 18 for entering special

modes.

6.2 Rotating knob functions overview

Note 2

Knob action Description

CW rotation Increase current value, go to the element

on the right

CCW rotation Decrease current value, go to the element

on the left

One short press

(Operation mode)

Go to the next programmed step,

acknowledge error messages

One short press

(Settings mode)

Enter selected setting, validate and store

the current setting value, exit the current

setting, acknowledge error messages

One long press Switch between Operation and Settings

modes

Double short

press

Enter special modes (only when gear

ratio is selected in settings mode)

ENG

13

6.3 Sound alerts

Sound alert Description

One short beep

Activating irrigation, going to next step,

and switching rotation direction to

FORWARD

Two short beeps Deactivating irrigation,and switching

rotation direction to REVERSE

Two long beeps Switching from low speed to high speed

programmed step

Alternate short

beeps Warning notifications

Alternate medium

beeps Micromotor REVERSE running indicator

Alternate long

beeps System failure notification

FIG. 3 FIG. 4

1

NOTES

1The Operation mode is the default startup mode.

2Any knob or pedal action will be ignored when the motor is

running.

14

FIG. 1 FIG. 2

6

4

8

3 5 7

2

1

1

7 Operation

7.1 Operation screen description

FIG. 1

The Operation screen differs whether the micromotor is stopped

or running and depending on the active step.

It allows to perform an operation in 3, 4 or 5 predefined steps P1,

P2, P3, P4, P5 (which can respectively be used to program

settings for the bone preparation, drilling, threading and implant

insertion phases), and displays the following information:

(1) Step P1 (inactive step, in black)

(2) Step P2 (inactive step, in black)

(3) Step P3 (active step, in green)

P4 and P5 steps are disabled by default, see “ Number of steps” on

page 18 for enabling them.

(4) Speedometer

Note 1

(5) Torquemeter

Note 2

(6) Contra-angle ratio

Note 3

(7) Bar graph for torque

Note 4

(8) Operation settings symbols

See chapter “8 Settings” on page 16 for details on adjusting settings.

7.2 Perform an operation, steps P1 and P2

FIG. 2

A.

Operate by pressing the footpedal to adjust the MX-i LED

3rd Gen

micromotor speed.

Inactive steps symbols turn off when the motor is running.

Speedometer displays real-time speed value in black.

Note 5 - 6 - 7

FIG. 3

B.

If necessary, release the footpedal to perform the following actions:

Speedometer (1) displays the set micromotor maximum

reachable speed in cyan.

• Turn the knob CW or CCW to respectively increase or

decrease the micromotor maximum reachable speed (quick

setting mode).

The speedometer is cyan and displays the set micromotor

maximum reachable speed (1).

Note 8

• Long press on the knob to change operation settings.

The Settings mode is displayed.

See chapter “8 Settings” on page 16 for details.

• Long press on the orange button to activate the 5 Ncm

torque boost.

Note 9

C.

Short press on the footpedal’s orange button or on the knob to go

to the next step.

The next step symbol turns green and the step’s last used

settings are restored.

Note 7 - 10

7.3 Perform an operation, steps P3, P4 and P5

FIG. 4

A. In steps P3 (1), P4 and P5, operate by pressing the footpedal to

adjust the MX-i LED 3rd Gen micromotor speed.

All inactive steps symbols turn off when the motor is running.

Speedometer (2) displays real-time value.

Torquemeter (3) displays real-time value.

The torque bar (5) displays ratio between the real-time torque

value (represented by cyan dots when the micromotor is

running) and the maximum reached torque (represented by

green dot).

Note 5 - 6 - 7

B.

If necessary, release the footpedal to perform the following

actions:

Torquemeter (3) displays maximum reached value together

with the symbol (4).

Torque bar (5) dots that were displayed in cyan turn black,

except for the maximum value dot which turns green.

ENG

15

NOTES

1Real-time speed value is displayed in black when the MX-i

LED 3rd Gen micromotor is running. Maximum reachable speed

value stored is displayed in cyan when the MX-i LED 3rd Gen mi-

cromotor is not running, in steps P1 and P2.

2Torquemeter is only displayed when micromotor speed is be-

low 100 RPM in steps P1 and P2.

3

The contra-angle ratio is cyan-colored for direct-drive and

green-colored for reduction gears.

4Torque bar graph is only displayed when micromotor speed is

below 100 RPM.

5Each step settings are restored from the corresponding step

last used settings, excluding quick settings made directly in the

Operation mode.

6In REVERSE mode, the rotation direction symbol blinks

and there is a sound alert (alternate medium beeps). The Torque

value is automatically increased in REVERSE mode when torque-

meter is displayed. The torque value can be increased from 0 to

10 Ncm, see chapter see “ Reverse torque boost value” on page 18

to adjust it.

7Actions on footpedal’s buttons have no effect when the micro-

motor is running.

8Changing the torque in steps P1 or P2 can only be performed

through the Settings mode.

9The torque boost can only be activated when the torquemeter

is displayed in Operation mode, in low speed steps (<100 RPM).

10 For safety reasons, the speed setting icon turns red and

blinks together with the speedometer for 2 seconds when switch-

ing from low speed to high speed (≥100 RPM) step.

11 Changing the speed in steps P3, P4 and P5 can only be per-

formed through the settings mode.

• Turn the knob CW or CCW to respectively increase or

decrease the micromotor maximum reachable torque (quick

setting mode).

The torquemeter (3) turns cyan and displays the set

micromotor maximum reachable torque.

Note 11

• Long press on the knob to change operation settings.

See chapter “8 Settings” on page 16 for details.

• Long press on the orange button to activate the 5 Ncm

torque boost.

Note 9

C.

Short press on the footpedal’s orange button or on the knob to go

to the next step.

The next step symbol turns green and the step’s last used

settings are restored.

Note 7 - 10

FIG. 3 FIG. 4

1

21 3

5

4

16

8 Settings

FIG. 1 FIG. 2

1

1

FIG. 1

The Settings mode allows changing all parameters of each step.

It is accessed by long pressing the knob from the Operation mode

and leaved by also long pressing the knob or by running the

motor.

All changes made in this mode are automatically saved for the

corresponding step.

Note 1

A.

From the Settings mode menu, navigate through the operation

parameters by

turning the knob CW or CCW.

The selected parameter symbol (1) is encased in a cyan square

and an arrow points on it.

B.

If necessary, short press on the footpedal’s orange button to go to

the next step without going back to the Operation mode.

The Settings mode is still displayed, the next step symbol

turns green and the step’s last used settings are restored.

C.

Short press on the knob to change the selected parameter

setting (setting sub-mode).

The selected setting sub-mode is displayed.

8.1 MX-i LED 3rd Gen micromotor speed

A. From the Settings mode menu, select the symbol and

short press on the knob to change maximum reachable speed.

FIG. 2

B.

Turn the knob CW or CCW to respectively increase or decrease

micromotor maximum reachable speed.

The speedometer (1) displays the set maximum reachable

speed.

C.

Short press on the knob to exit speed setting.

New maximum reachable speed is saved and the Settings

mode menu is displayed again, FIG. 1.

8.2 MX-i LED 3rd Gen micromotor torque

A. From the Settings mode menu, select the symbol and

short press on the knob to change maximum reachable torque.

FIG. 3

B.

Turn the knob CW or CCW to respectively increase or decrease

micromotor maximum reachable torque.

The torquemeter (1) displays the set maximum reachable

torque.

C.

Short press on the knob to exit torque setting.

New maximum reachable torque is saved and the Settings

mode menu is displayed again, FIG. 1.

8.3 MX-i LED 3rd Gen micromotor rotation

direction

A. From the Settings mode menu, select the symbol and

short press on the knob to change rotation direction.

Note 1

B.

Turn the knob CW or CCW to alternatively toggle between

FORWARD

and REVERSE micromotor rotation.

C.

Short press on the knob to exit rotation direction setting.

Rotation direction is saved and the Settings mode menu is

displayed again.

Note 2

ENG

17

8.4 Irrigation level

A. From the Settings mode menu, select the symbol and

short press on the knob to change irrigation level.

Note 1

FIG. 4

B.

Turn the knob CW or CCW to set up the irrigation level (1).

6 levels of adjustment are possible:

irrigation OFF, 30ml/min, 60ml/min, 90ml/min, 120ml/min,

150ml/min.

Note 3

C.

Short press on the knob to exit irrigation level setting.

Irrigation level is saved and the Settings mode menu is

displayed again.

8.5 Contra-angle ratio

A. From the Settings mode menu, select the symbol and

short press on the knob to change the contra-angle ratio.

B.

Turn the knob CW or CCW to change the contra-angle ratio.

Note 4

C.

Short press on the knob to exit the contra-angle ratio setting.

The contra-angle ratio is saved and the Settings mode menu is

displayed again.

FIG. 3 FIG. 4

1

1

NOTES

1The rotation direction and the irrigation level symbols differ

depending on the actual settings.

2The Torque value is automatically increased in REVERSE

mode when torquemeter is displayed. The torque value can be in-

creased from 0 to 10 Ncm, see chapter “ Reverse torque boost val-

ue” on page 18 to adjust it.

3When setting the irrigation level to OFF, all dots (1) are dis-

played in black. Irrigation level is off when the irrigation is com-

pletely turned off by means of the footpedal’s blue button,

regardless of the active step. In this case, the OFF symbol is dis-

played in Operation mode. The irrigation is considered as a quick

setting and therefore is turned ON when starting again from step

P1.

4The contra-angle ratio is cyan-colored for direct-drive and

green-colored for reduction gears.

18

9 Special modes

FIG. 1 FIG. 2

1

21 3

The special modes allow to, in the following order:

• Display software version;

•TestLCDdisplay;

• Define number of steps (3, 4 or 5);

• Define reverse torque boost value;

• Restore factory settings.

Note 1

A. From the Operation mode, long press on the rotating knob to

enter Settings modes.

The Settings mode is displayed.

FIG. 1

B.

Turn the knob CW or CCW to select the contra-angle ratio symbol

(1).

The contra-angle ratio symbol is encased in a cyan square and

an arrow points on it.

Software version

FIG. 2

C.

Double short press on the knob to enter special modes.

The contra-angle ratio symbol (3) turns blue to differentiate it

from the ratio change cyan symbol.

The software version is displayed as following:

(1) Major version

(2) Minor version

LCD display test

FIG. 3

D.

Short press on the knob to test LCD display.

All dots are displayed in black, except for the contra-angle

ratio symbol (1).

Number of steps

E.

Short press on the knob to define the number of steps.

The step number screen is displayed.

F.

Turn the knob CW or CCW to alternatively display the

3

,

4

or

5

text.

G.

Short press on the knob to define the number of steps.

Reverse torque boost value

Reverse torque boost allows an automatic increase of torque

value when in REVERSE mode, in order to ease bur rotation when

stuck.

H.

Short press on the knob to define reverse torque boost value.

The reverse torque boost screen is displayed.

I.

Turn the knob CW or CCW to alternatively display the

0, 5

or

10

text.

J.

Short press on the knob to define no boost value when

0

is

displayed, or short press on the knob to respectively define 5 Ncm or

10 Ncm boost value when

5

or

10

is displayed.

Settings reset

FIG. 4

K.

Short press on the knob to display factory settings reset screen.

The factory settings reset screen is displayed.

L.

Turn the knob CW or CCW to alternatively display the

reset yes

or

reset no

text (1).

Note 3

M.

Short press on the knob to restore factory settings when the

reset yes

text is displayed, or short press to go back to the Settings

mode when the

reset no

text is displayed.

Reset can take up to 2 seconds. Meanwhile, the symbol is

displayed, and the yes text is turned off. When reset is done,

the Settings mode is displayed again.

Table of contents

Languages:

Other Bien Air Medical Equipment manuals

Popular Medical Equipment manuals by other brands

bort medical

bort medical StabiloBasic Lady Sport Instructions for use

onCare

onCare Harmony Low Bed user manual

Hospira

Hospira Plum XL System Operating Manual

Seca

Seca 545 Series Service manual

Boston Scientific

Boston Scientific Vercise Neural Navigator 4.0 installation guide

Defibtech

Defibtech DDU-2300 operating guide

Orthofix

Orthofix Spinal-Stim instruction manual

Veridian Healthcare

Veridian Healthcare 11-50D instruction manual

Schill

Schill Multisonic MN 80170 Instructions for use

Shimmer

Shimmer 3 Getting started

Fluke Biomedical

Fluke Biomedical ProSim 8 Series Getting started manual

Abbott

Abbott FreeStyle Libre2 quick start guide