Bien Air Lubricare HIM-1 User manual

Dental Handpiece Maintenance Unit

LUBRICARE

Operation Instructions

Thank you for purchasing LUBRICARE, a handpiece maintenance unit of Bien-Air Dental SA.

LUBRICARE lubricates and internally cleans dental handpieces easily and effectively.

For optimum safety and performance, read this manual thoroughly before using the unit and pay close

attention to the warnings and notes.

Keep this manual in a handy place for ready reference.

Operation 2017-12-27

1

Table of Contents

Page

PREVENT ACCIDENTS...........................................................................................2

ATTENTION............................................................................................................3

1. Warning and Prohibitions....................................................................................4

2. Technical Specifications .....................................................................................5

3. Parts Identification .............................................................................................8

4. Set Up............................................................................................................. 11

5. Operation ........................................................................................................16

6. Maintenance and Replacement Parts ..................................................................25

7. Maintenance and Inspection .............................................................................. 30

8. Troubleshooting...............................................................................................31

9. Service Contacts .............................................................................................. 32

10. Appendix – Electromagnetic Declaration............................................................33

Operation 2017-12-27 2

ATTENTION CUSTOMERS

Do not fail to receive clear instructions concerning the various ways to use this

equipment as described in this accompanying Operator’s Manual.

Fill out and sign the warranty and give a copy to the dealer from whom you purchased

the equipment.

ATTENTION DEALERS

Do not fail to give clear instructions concerning the various ways to use this equipment

as described in this accompanying Operator’s Manual.

After instructing the customer in the operation of the equipment, have the customer fill

out and sign the warranty. Then fill in your own section of the warranty and give a

copy to the customer. Do not fail to send the manufacturer’s copy to Bien-Air Dental

SA regional office.

PREVENT ACCIDENTS

Most operation and maintenance problems result from insufficient attention being paid to basic safety precautions

and not being able to foresee the possibilities of accidents. Problems and accidents are best avoided by foreseeing

the possibility of danger and operating the unit in accordance with the manufacturer’s recommendations. First

thoroughly read all precautions and instructions pertaining to safety and accident prevention; then, operate the

equipment with the utmost caution to prevent either damaging the equipment itself or causing bodily injury.

Note the meaning of the following symbols and expressions:

This warns the user of danger of death, serious bodily injury or total equipment

damage and failure or fire.

This identifies methods which must not be used or purposes which the

instrument is not suited for.

This alerts the user to the risk of light to medium injury or equipment damage.

This alerts the user of important points concerning operation.

The user (e.g., healthcare facility, clinic, hospital etc.) is responsible for the management, maintenance and use of

medical devices. Also this equipment must not be used by anyone except legally qualified dentist, doctor, or other

legally qualified professional.

Do not use this equipment for anything other than its specified dental treatment purpose.

Caution: Federal law restricts this device to sale by or on the order of a dentist (for U.S.A.).

Operation 2017-12-27

3

ATTENTION

Bien-Air Dental SA will not be responsible for accidents, instrument damage, or bodily injury resulting from:

1. Repairs made by personnel not authorized by Bien-Air Dental SA.

2. Any changes, modifications, or alterations of its products.

3. The use of products or instruments made by other manufacturers, except for those procured by Bien-Air

Dental SA.

4. Maintenance or repairs using parts or components other than those specified by Bien-Air Dental SA.

and other than in their original condition.

5. Operating the instrument in ways other than the operating procedures described in this manual or

resulting from the safety precautions and warnings in this manual not being observed.

6. Workplace conditions and environment or installation conditions which do not conform to those stated

in this manual such as improper electrical power supply.

7. Fires, earthquakes, floods, lightning, natural disasters, or acts of God.

Bien-Air Dental SA will supply replacement parts and be able to repair the product for a period of 10 years

after the manufacture of the product has been discontinued.

Operation 2017-12-27 4

1. Warnings and Prohibitions

No modification of this equipment is allowed. The customer is not allowed to repair this equipment

himself.

LUBRICARE cannot be used for air bearing handpieces (Astron series).

Electromagnetic wave interferences caused by cellular phones, transceivers, remote controls and similar

transmission devices could cause the equipment to operate randomly. All devices which transmit

electromagnetic waves located near the work area should be turned off.

Operation 2017-12-27

5

2. Technical Specifications

Specifications

Name LUBRICARE

Model HIM-1

Type BA

Rating AC 100 to 240 V 50/60 Hz

Power Consumption 25 VA

Fuse 250 V 2 A Slow Blow and High breaking Type ⌀5 × 20 mm

Input Air Pressure 1.0 MPa max.

Air Pressure 0.3 to 0.5 MPa

Class Class I

Isolation from the Supply Mains Unplug the power cord from supply mains

Recommended Air Pressure 0.35 MPa

Air Flow Rate 40 to 60 NL/min

Weight Approx. 10 kg

Size (including regulator) Width 300 × Height 370 × Depth 300 mm

Product Description

Used to maintain optimum performance and prolong working life of dental handpieces.

Delivers oil and air automatically to handpiece.

Used after dental treatment and before autoclaving.

Operating Principle

Physical methods used to accomplish its intended use:

Air Pressure: 0.3 – 0.5 MPa

Air Flow Rate: 40 – 60 NL/min

Maintenance oil spray can

Mechanisms by which it works:

Maintenance spray can is operated by pressurized air. Sprayed air delivers oil and lubricates the inside of

the handpieces. Also, excess oil is removed from the handpieces.

Operation 2017-12-27 6

Intended User

a) Engaged person (peoples) in dental clinic

b) Language Understanding: English or languages offered in the instruction for use. Understanding of

attention and warning marks.

c) Experience: Not relevant

Operating Envionments

Dental clinic, hospital

Temperature: +10°C to +40°C

Humidity: 30% to 75 % (without condensation)

Atmospheric Pressure: 70 kPa to 106 kPa

Transport and Storage Environments

Temperature: -10°C to +50°C

Humidity: 30% to 75 % (without condensation)

Atmospheric Pressure: 50 kPa to 106 kPa

Disposal

The package should be recycled. Metal parts of the equipment are disposed as scrap metal. Synthetic

materials, electrical components, and printed circuit boards are disposed as electrical scrap. Material must

be disposed according to the relevant national legal regulations. Consult specialized disposal companies for

this purpose. Please inquire of the local city / community administrations concerning local disposal

companies.

Meaning of Symbols

Rating Label

Operation 2017-12-27

7

Symbols

CE marking

Conforms with the

European Directive,

93/42/EEC. and

2011/65/EU

Attention, consult

accompany documents

Serial number

E.g., G A XXXX

①②③

①Year of Manufacture

E.g., F: 2017, G: 2018, H: 2019...

②Month of Manufacture

E.g., A: Jan., B: Feb., C: March...

③Lot No.

0001, 0002, 0003...

Rated supply voltage

Rated input amperes Supply frequency

Alternating current C-tick Supplier Code

Number

Manufacturer

Indicating separate

collection waste of

electronic equipment

C-tick Mark

cTUVus certification

mark for the U.S. and

Canadian

Note Firing

(ISO 3864-B3.2)

General warning sign

Refer to instructions for

use

No open flame; Fire,

open ignition source and

smoking prohibited

Stand-by (If the main

switch is on, green

power lamp next this

mark lights up)

Main switch

on off

Operation 2017-12-27 8

Operation Panel

3. Parts Identification

Selector Switches Selector Lamps (green)

Power Lamp (green)

Spray Can Empty Lamps (orange) Finished Lamp (green)

Start, Stop and Set Switch

Power Cord Connection

Fuse Holder

Side Door

Tray Filter

Tray Main Switch

Air Regulator

Front Door

Operation 2017-12-27

9

Connection Nut

Chuck Nozzle

Nozzle Guide

Oil Case

Oil Pad

Operation 2017-12-27 10

Components

Main Unit

Accessories

Oil Absorption Pads (5) Oil Absorption Case (1) Power Cord (1)

(CE・230 V)

(US・120 V)

Tray Filter (1) Tray (1) Spray Can Stand (2)

TR Coupling (2) Air Tube (1)

Operation 2017-12-27

11

4. Set Up

* Direct inquires concerning types of couplings, sprays, and

spray can stands to your local dealer or Bien-Air Dental SA.

Explosion Hazard: Do not use near open flames or other

ignition sources.

Use only spray provided by Bien-Air Dental SA.

Health Hazard: The area must be well ventilated. Breathing

fumes could damage your health.

The equipment must be properly grounded.

Set the unit on a level and stable surface.

♦Leave at least 5 cm of free, open space around the unit.

(1) Air Connection

1. Connect the green air tube provided to the air regulator and

the main air supply.

Open the valve for the main air supply.

♦The main air supply must be clean and oil-free.

♦Make sure the tube is securely connected.

2. Set the air regulator dial between 0.3 and 0.5 MPa.

Pull the dial up to unlock it. Push it back down after

setting the pressure.

* Recommended Air Pressure is 0.35 MPa.

♦Less than 0.3 MPa will result in poor performance.

♦More than 0.5 MPa could result in damage.

Depending on the type of handpiece and coupling, there could

be a release of oil mist. In this case, lower the pressure to 0.3

MPa.

Air Regulator

Air Tube

Connector

A

ir

R

egulator Dial

Operation 2017-12-27 12

(2) Power Cord

Connect one end of the power cord to the main unit and plug

the other end into a standard receptacle.

Use the right cord!! Since power supply ratings differ

depending on the country, two power supply cords are

provided. Use the one suited for your local power supply;

using the wrong cord could cause a fire.

Make sure the ground is properly connected.

Do not place objects around the power input plug at any

time so that the equipment can be cut off from the supply

mains when necessary.

Do not place this equipment where the main switch cannot

be operated.

(3) Coupling

Fit the coupling onto the nozzle and tighten up its nut.

♦Make sure the nut is properly tightened. Otherwise oil and

air will escape and the maintenance will not be properly

performed.

(4) Oil Pad

Put an oil pad in its case and install the case.

Nut

Power Cord

Cord Connecto

r

Oil Pad

Oil Case

Operation 2017-12-27

13

(5) Tray

Put a filter in the tray and slide it into place.

♦Slide the tray all the way in; otherwise,

a film of oil will be deposited on the unit.

(6) Spray Cans

1. Open the side door.

Press the spot indicated in the photo to open the door.

2. Set the stands for the cans in place as shown in the photo.

Tray Filte

r

Tray

Side Doo

r

Press

Operation 2017-12-27 14

3. Can A is for the chuck maintenance and handpiece nozzles

1 and 2. Can B is for nozzles 3 and 4.

4. Push the lock levers down to a horizontal position to secure

the cans.

Oil will leak or spray out if the cans are not properly installed.

♦Make sure the lock levers are all the way down.

Otherwise, the oil will not come out. (The empty lamp will

start blinking.)

♦Pull and push the cans to make sure they are secure and do

not wobble.

5. Close the side door.

Lock Leve

r

Operation 2013-07-08

15

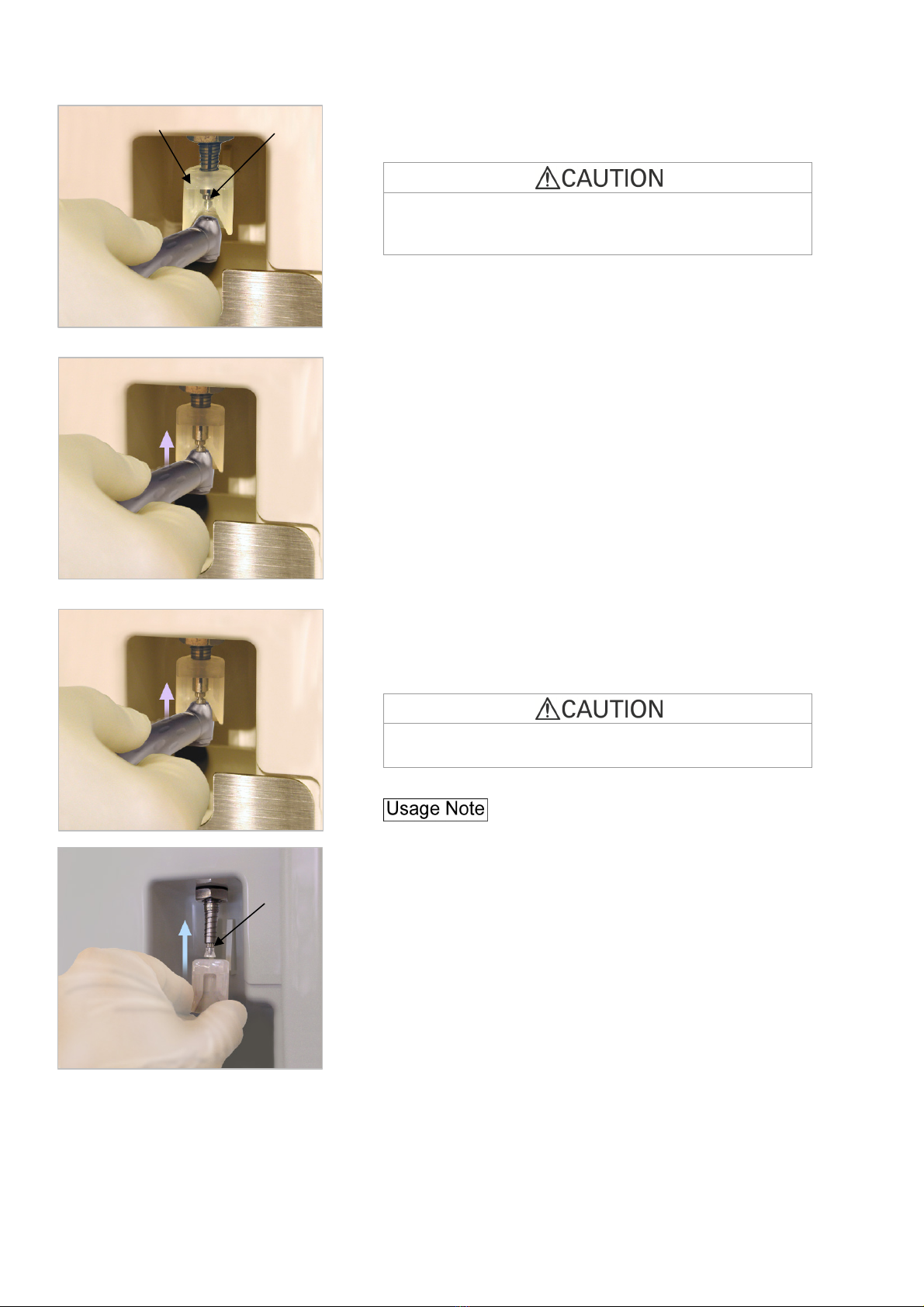

(7) Spray Can Removal

1. Pull the lock lever straight up to lower the stand.

2. Take the can out.

If the can’s nozzle is stuck in place, simply pull it down

slightly and take it out.

Operation 2017-12-27 16

5. Operation

Handpiece Autoclave Sterilization

To prevent the spread of grave, life-threatening diseases like HIV and hepatitis B, autoclave handpieces after

performing regular maintenance using LUBRICARE.

<Take Off>

<Clean>

(1) Take the handpiece off its tube.

(Remove the burr as well.)

(2) Clean the head with a brush and running water.

(3) Wipe the handpiece with gauze dampened with Ethanol

for Disinfection (Ethanol 70 to 80 vol%).

LUBRICARE Procedure

< Clean and Lubricate >

Perform chuck maintenance for Morita ball bearing

handpieces.

Perform the maintenance procedure.

<Clean>

Remove excess oil by wiping with Ethanol for Disinfection

(Ethanol 70 to 80 vol%).

<Autoclave> Autoclave in a sterilization pouch.

♦Some oil may remain inside the handpiece even after autoclaving. Refer to the user instructions for each

handpiece for proper storage. (Storing the handpiece in an upright position is recommended.)

Operation 2017-12-27

17

* If LUBRICARE hasn’t been used for a while, make sure it

operates properly and safely before using it.

Avoid the risks of electrical shock, equipment damage and

fire during an electrical storm: Turn LUBRICARE off

and do not touch it or its cord.

Wear surgical gloves to operate and clean LUBRICARE.

<Set Up>

• Carefully clean off the outside of the handpiece before

performing maintenance.

• Remove the burr.

Chuck Cleaning and Lubrication

Turn the main switch on.

(Green power lamp lights up.)

Open the front door.

Front doo

r

Power Lamp

Operation 2017-12-27 18

Line up the front end of the head with the nozzle guide and set

the chuck in place.

Make sure the head is flat against the nozzle guide. If it is

tilted, the nozzle might be bent or oil might spray out into your

eyes.

Lift the handpiece up slightly to begin cleaning and

lubricating the chuck.

Hold it in place for about 5 seconds.

A beep sounds when the procedure is finished.

* A series of beeps signals an error. In this case, try again.

Oil will spray out of the nozzle if the handpiece is removed too

soon (before the beep).

♦Chuck cleaning and lubrication is only for Bien-Air

handpieces.

♦If the nozzle guide comes off, line up the tab on it with the

groove and slide it back on.

Nozzle Guide Chuck Nozzle

Groove

Hold

Table of contents

Other Bien Air Medical Equipment manuals