Service Manual

Ergometer 545 Description of the electronics

Description of the electronicsDescription of the electronics

Description of the electronics

10.03.1999 Panier Page 2 of 6 30-36-00-285

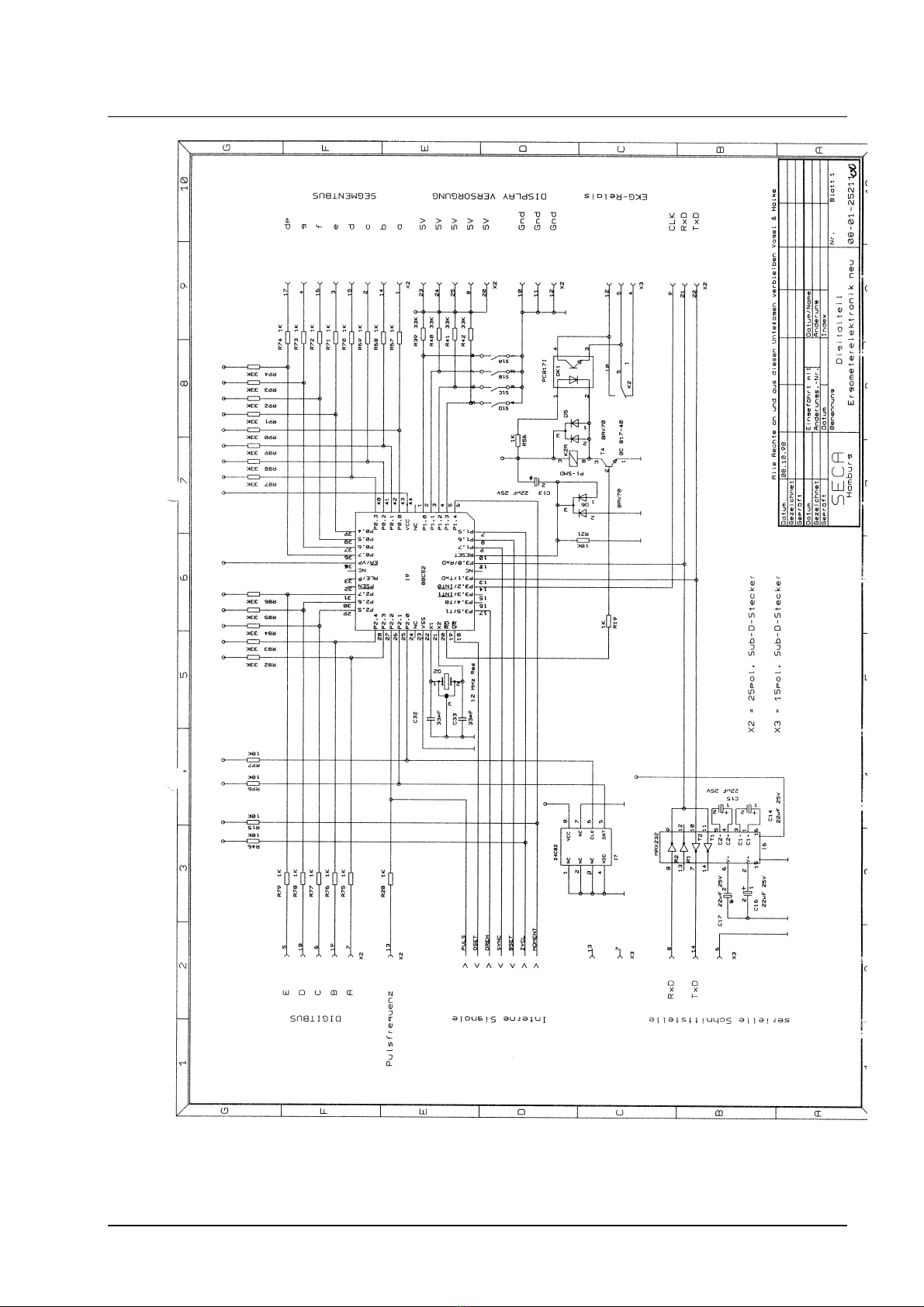

operates with open loop gain, and from there to the Schmitt trigger I5A.

The resulting square-wave pulse signal "PULSE" is passed firstly to the pulse LED on the

display and secondly to the µ-P I9 for pulse frequency determination. For triggering the pulse

frequency measurement from an ECG plotter input X3.15 is available.

b) The speed is determined with a photosensor mounted to the ergometer brake. As the output

voltage of this photosensor is high enough, one transistor stage T12 is sufficient to form the

square-wave pulse. The output voltage is passed as a "SPEED” signal to I9 which determines

the speed.

c) The current braking torque is determined by means of the DMS load cell EF3. Its output

voltage is amplified by I4 and I10A and is passed as an analog signal "MANA" to the AD

converter and as an analog value to the torque controller I3. The measuring amplifier I4 is

adjusted to the offset parameters of the measuring cell used by means of resistors with wired

contacts R53 and R54. Coarse adjustment can be performed without taking into account the

spring pretension that will be set later, since the processor will make a fine offset adjustment

via R100 during the operation.

d) The central part of the AD/DA converter is the ramp generator consisting of I10C and I2A.

The actual measuring ramp starts at 9.5V and ends at 2.5V. The upper voltage limit is set by

the potential divider R2 and R3, the lower limit by R2 and R3//R10. Switch-over of the

reference voltages is effected by T2. The moment of switch-over is determined by I2A. The

ramp time is determined on the one hand by the two reference voltages and on the other

hand by the integrating capacitor C55 ( C3 ) together with R29 and R12. For the given

component characteristics a time of 0.45 s is used. The time for the reset ramp (start at 2.5V

and end at 9.5V) is set to 14.5ms via R12. By means of I12B, which is connected as an

inverter/level converter, the processor determines the measuring ramp time for temperature

compensation ("CYCL"). The analog switch I12A synchronizes the ramp with the µP

measuring timer ( "SYNC" ).

The analog switch I12C generates the analog setpoint for the torque controller ( "BSOLL" ).

Control is performed by the µP using ( "BSET" ). The control voltage for the measuring

amplifier offset is produced in the same way via I12D and the control signal "OSET".

Description of the power section:

a) The Mosfet T7 provides the power supply for the brake. It is controlled by square-wave pulses

at a frequency of approx. 200Hz. The pulse duty factor for these pulses can be adjusted in the

range 0 to 1 via torque controller I3A. This causes the brake current to vary between 0 and

approx. 3A, which is certainly sufficient for the required braking torques. I1B is a sawtooth

voltage generator for generating the 200Hz control voltage. The sawtooth amplitude is

approx. 5V. The variable pulse duty factor for the control voltage for the brake solenoid is

generated by comparing this sawtooth voltage with the output voltage of torque controller I3A

( comparator I1A ). Torque controller I3A is an IT1 type with an integration time constant of

0.22s. Selecting this time constant allows the torque controller to almost completely adjust the

specified torque within a DA interval. R17 and C1 are used to optimize the controller

characteristics. T11 and T10 limit the maximum controller stroke to the amplitude of the

200Hz sawtooth to prevent the I-controller “overshooting” and producing detrimental delay

times in the control loop. I3B is an inverter for the torque setpoint ( "BSOLL" ). It has an

additional time constant C54, R59 and thus ensures smooth transitions if the torque setpoint

changes suddenly. Due to the analog controller the settling time for the required braking

torque can be almost freely controlled by the processor ( > approx. 1s ).