Bierer HP72-DCXL User manual

Manufacturing & Service: Bierer & Associates Inc.

HP72-DCXL

HI POT DEVICE

Operating Instructions

2

Limitation of Warranty and Liability

Bierer & Associates Inc. warrants this product to be free from defects in workmanship and

material, under normal use and service conditions for a period of one year from date of

shipment.

Due to continuous product improvement and development, Bierer & Associates Inc.

reserves the right to modify product designs and specifications without notice.

It is impossible to eliminate all risks associated with the use of high voltage electrical

devices including this device. Risks of serious injury or death are inherent in working

around energized electrical systems. Such risks include but are not limited to variations

of electrical systems and equipment, manner of use or applications, weather and

environmental conditions, operator mentality, and other unknown factors that are

beyond the control of Bierer & Associates Inc.

Bierer & Associates Inc. do not express or imply to be an insurer of these risks, and by

purchasing or using this product you AGREE TO ACCEPT THESE RISKS. IN NO EVENT SHALL

Bierer & Associates Inc. BE LIABLE FOR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL

DAMAGES RESULTING FROM THE USE OR HANDLING OF THIS PRODUCT.

SAFETY MESSAGE DEFINITIONS per ANSI Z535

These instructions contain important safety messages to alert the user to

potentially hazardous situations, how to avoid the hazard, and the

consequences of failure to follow the instruction.

The safety alert symbol identifies a safety message. The signal word

following the symbol indicates:

DANGER A hazardous situation which, if not avoided, will result in

death or serious injury and equipment damage.

WARNING A hazardous situation which, if not avoided, could

result in death or serious injury and equipment damage.

CAUTION A hazardous situation which, if not avoided, could

result in minor or moderate injury and equipment damage.

NOTICE Important safety message relating to equipment damage

only.

3

PRODUCT SAFETY INFORMATION

WARNING

1. Meter assembly, interconnect cable assembly, and live line tool adapters

shall be considered non-insulating. Do not let live line tool fittings come

in contact with energized or grounded conductors. The live line tool

adapters, fittings, and handles supplied with meters shall not be used

on any other devices.

2. Use appropriate length live line tools for voltage being worked and

maintain minimum approach distances as outlined in OSHA 1910.269,

Table R-6.

3. All Phasing Meters and Voltage Detectors manufactured during and after

2007 will have a limit mark engraved on the high voltage probe(s) 2.5

inches from the tip to indicate to the user the physical limit that should

not be exceeded when approaching and contacting an electrical

conductor or other electrical test points. Zero Ohm insulated adapters

(81280IE) should be used if limit mark will be exceeded.

4. This equipment should be used only by qualified employees, trained in

and familiar with the safety-related work practices, safety rules and

other safety requirements associated with the use of this type of

equipment.

5. These instructions are not intended as a substitute for adequate training,

nor do they cover all details or situations which could be encountered

when operating this type of equipment.

6. Before operating this equipment, read, understand and follow all

instructions contained in this manual. Keep instructions with

equipment.

INSPECTION & MAINTENANCE BEFORE USE

WARNING

1. Prior to using any high voltage test equipment a careful inspection

should be made to ensure the unit is free from any contaminants such

as dirt, grease, etc. and that there are no apparent physical damages.

2. High voltage probe assemblies shall be wiped clean prior to each use

with a silicone impregnated cloth and kept clean and free of

contaminants. This will prevent tracking on the outside of the probe and

meter error.

3. Always confirm internal battery voltage before and after each use.

4. Unit shall be tested before and after each use on a known voltage source.

Failure to do so could result in false negative indications

4

DESIGN and FUNCTION

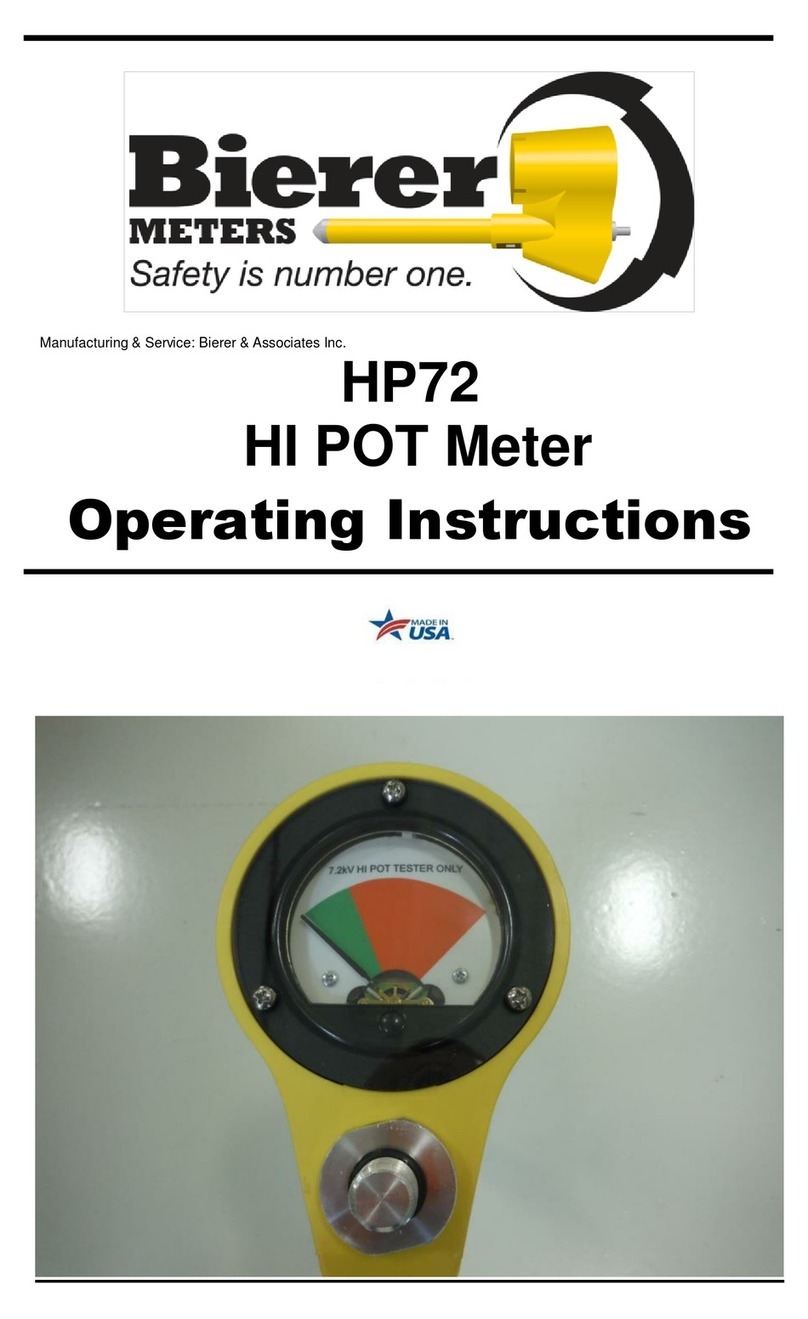

The HI POT DEVICE is designed to HI POT de-energized 15kV class cables. The tools

transforms 18 volts from the battery to approximately 8,000 volts DC. When the

battery is installed and the safety switch is in the closed position, the unit is in

voltage detection mode. Unit should be in this position when installing the device

as it will sound a warning alarm if you approach an energized source. When the

safety switch is open and the toggle switch is switched ON (forward), the unit is

in the Hi-Pot mode and the high voltage DC is being applied.

BATTERY REPLACEMENT

There is an 18V battery on the base of the unit. On the front of the battery is a

built in battery test button. If the battery test results in 2 or less lights, it is

recommended to remove the battery by pressing both buttons on the sides, and

sliding the battery out of the device to be charged. Once the battery is fully

charged, you can resume any testing required.

METER SET-UP and TESTING

WARNING

See “Product Safety Information”, page 3.

See “Inspection & Maintenance”, page 3.

1. Ensure the safety switch is in the closed position. This ensures the high

voltage doesn’t become active when installing the battery.

2. Install the 18V rechargeable battery.

3. To test the meter, attach the ground clamp to the probe tip. Then flip

the safety and power switch to the open and ON position. If the meter

and tester are working properly, the needle will move the 100% full

scale position. This indicates a full short on the line. Once complete you

can flip the safety switch closed, which will automatically switch the

toggle OFF, at which point the high voltage is removed. The unit is ready

for operation.

5

URD CABLE DC LEAKAGE TESTER “Hi-Potting”

WARNING –see “Meter Set-Up & Testing”, page 4.

Testing De-Energized URD cable

1. Attach Meter to appropriate length live line tools for the voltage being

worked.

2. Attach a bushing adapter to the end of the meter probe.

3. Attach alligator clip to any ground, being sure to observe all safety

methods while doing so.

4. Isolate both ends of the cable to be tested, use a feed-through bushing

on the near end.

5. Approach the other side of the feedthrough bushing slowly with the

meter. An audible sound will indicate voltage is still on the line. If

voltage is present, remove the tool and follow appropriate procedures

to isolate the cable to be tested.

6. If no horn sounds, you can push the meter all the way onto the

feedthrough bushing.

7. Flip the red safety cover up and then the power switch up to activate

the high voltage test.

8. A good cable may show a rise as far as the 100% mark but will then go

back down to near 0%.

9. A bad cable will either show a steady high percentage on the scale or

the meter will continuously bounce up and down.

10. After completion of the test, flip the red safety switch down, there may

be a horn sound momentarily as the unit is discharging the DC voltage

off the cable.

11. Remove all equipment and return the tested cable to its normal

configuration.

NOTE 1: The section of cable under test must be isolated on both ends and

cannot be connected to/or through equipment or lighting arrestors.

NOTE 2: The maximum reading during the hi-potting test is 100% which

represents a “bolted” fault. Readings near zero represent a good cable with

little or no cable leakage. Readings in between near zero and 100% could be

high leakage or bad cable.

6

NOTES______________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

7

PARTS & ACCESSORIES

PART NO.

DESCRIPTION

3402

Quick Change to Grip All Adapter

3403

Quick Change to Universal Adapter

8128EALB

15 –25kV Elbow Adapter

8128TBALB

15 - 25kV Bushing Adapter

Technical & Service

Bierer & Associates Inc.

Manufacturing & Repair

10730 Farrow Rd.

Blythewood, SC 29016

Tel: (803) 786-4839

Fax:(803)786-5457

bierermeters.com

8

Table of contents

Other Bierer Measuring Instrument manuals