EMH metering LZQJ-SGM User manual

EMH metering

GmbH & Co. KG

Neu-Galliner Weg 1 • 19258 Gallin

GERMANY

Tel. +49 38851 326-0

Fax +49 38851 326-1129

Web www.emh-metering.com

Tel. +49 38851 326-1930 (Technical Support)

Email [email protected]

Instruction Manual

LZQJ-SGM transformer connected meter

Digital 4-quadrant/combination meter

EN

Issue date: 19 November 2021; subject to technic al changes. LZQJ-SGM2-IM-E-1.04

Scope of delivery.................................................................................... 2

Important information.............................................................................. 2

Technical data......................................................................................... 5

Housing, display and control elements................................................... 7

Installation and start-up ........................................................................ 13

Functions and operation....................................................................... 20

Installation control register C.86.0........................................................ 31

Error register F.F................................................................................... 33

COMBI-MASTER 2.0................. 34

Communication module........................................................................ 35

Abbreviations........................................................................................ 36

EU Declaration of Conformity............................................................... 38

2

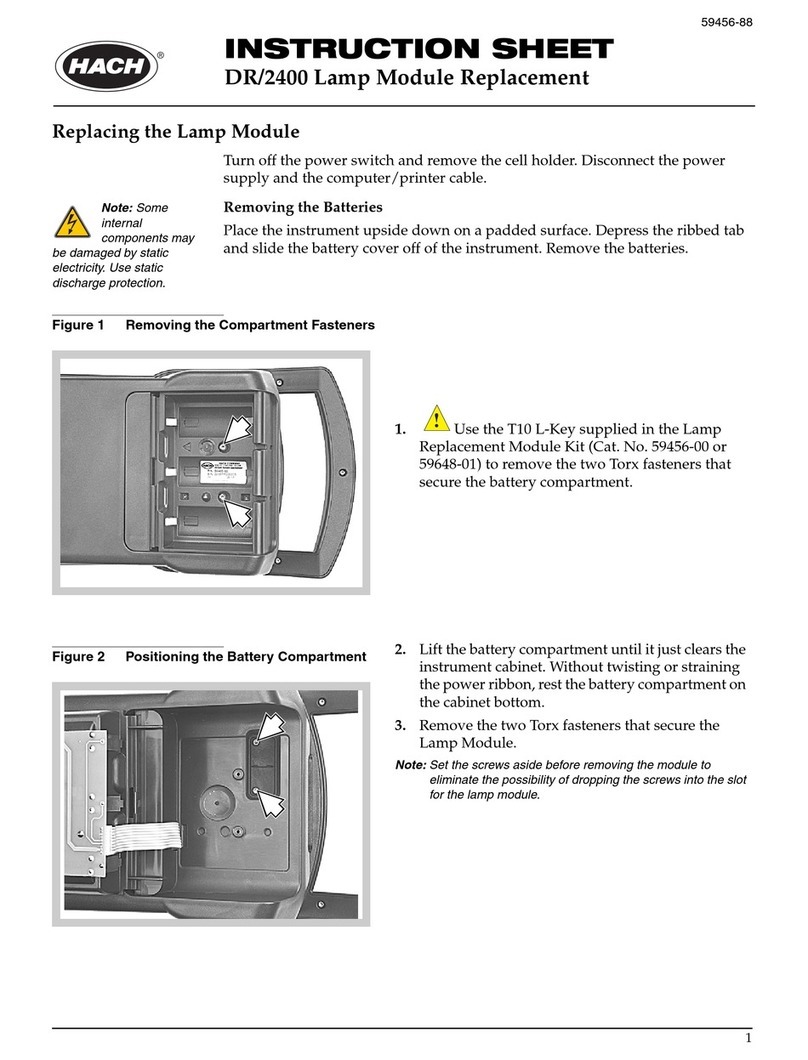

Scope of delivery

Please check that the contents of the packing box are complete before

starting the installation and start-up procedure.

y1 LZQJ-SGM device

y1 operating instructions

yConnection diagram

yAccessory (optional)

If the contents are incomplete or damaged, please contact your supplier.

Store, use and transport the device in such a way that it is protected

against moisture, dirt and damage.

Important information

These operating instructions are part of the documentation.

-

tures described herein may not be applicable to your particular device.

Please see the user manual for more comprehensive information about

the device. Please also observe all the documents included with other

components (such as the optical communication unit, for example).

Symbols used

DANGER Indicates immediate danger that can lead to severe

injuries or death unless avoided.

ATTENTION Indicates a situation that can cause damage to prop-

erty or the environment unless avoided.

This note indicates important information in the oper-

ating instructions.

3

Target audience

These instructions are intended for technicians who are responsible for

the installation, connection and servicing of the devices.

in accordance with the generally accepted technology standards and,

communication equipment and terminal devices.

After installation and start-up of the meter, make sure that the

operating instructions are available to the electricity customer.

Intended use

The meter is intended to be used solely for the measurement of electrical

energy in inside spaces, and it must not be operated outside the speci-

Make sure that the meter is suitable for the intended application.

Maintenance and warranty instructions

The device requires zero maintenance. It is not permitted to make any

repairs independently in the event of any damage (e.g. due to transport

or storage).

If the device is opened, the warranty and the Declaration of Conformity

will be rendered null and void. The same applies where a defect is

-

peratures and weather conditions), or by improper or careless use or

handling.

The seals may only be broken by authorised personnel.

4

Care and disposal information

DANGER

Risk of fatal injury in case of contact with live parts!

Before the housing of the meter is cleaned, all conductors that the

meter is connected to must be de-energised.

Use a dry cloth to clean the device housing. Do not use any chemical

cleaning agents!

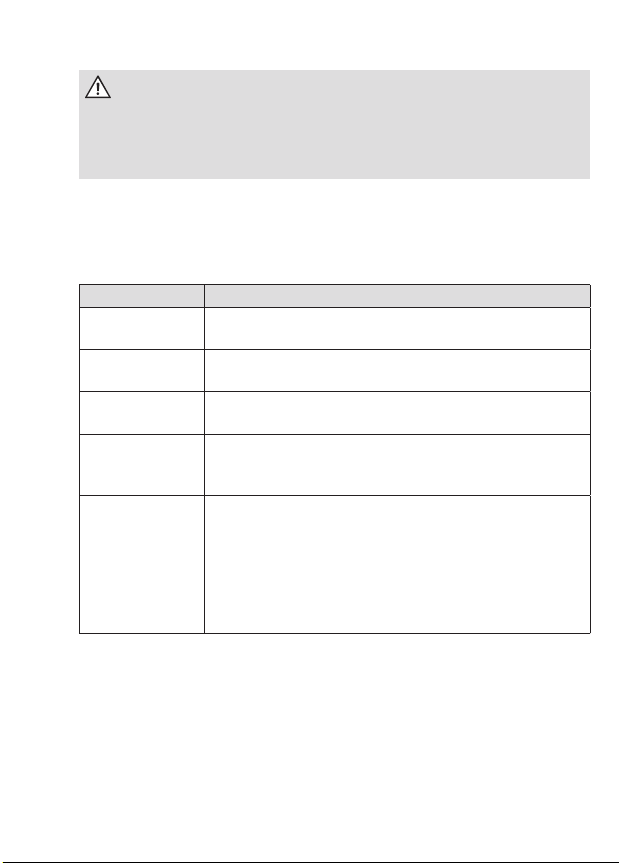

The following table names the components and how they are to be

treated at the end of their life cycle.

Components Waste collection and disposal

Printed circuit

boards

Electronic waste: Dispose of such waste in accord-

ance with the local regulations.

LEDs, LC

displays

Hazardous waste: Dispose of such waste in accord-

ance with the local regulations.

Metal parts Recyclable material: Sort such material and send it

for recycling.

Plastic parts Send sorted plastic parts to a recycling plant (re-

granulation) or, where applicable, to a waste inciner-

ation plant (thermal energy generation).

Batteries Take safety precautions against short circuits before

disposing of the batteries. Batteries can leak or

self-ignite. Dispose of the batteries in their original

packaging or insulate the terminals. Do not dispose

of batteries with the domestic waste. Instead, observe

the locally applicable waste and environmental

protection standards.

Basic safety instructions

Please adhere to the following basic safety instructions:

yRead all the enclosed instructions and information.

yObserve the warnings on the device and in the documents.

5

yAlways be aware of safety issues and hazards when working on

the device.

yThe applicable occupational health and safety regulations for electri-

cal installations must be observed during assembly, installation and

removal of the device.

yMake sure that the installation and operating location of the device

yBefore assembly, check the devices for any externally visible damage.

y

line with its intended use.

yThe connection cables used to connect a meter must be selected to

match the maximum load of the meter and the installation environ-

ment in terms of type, cross section, voltage and temperature.

y

yObserve the maintenance and warranty instructions.

yIf the mains power fails and then returns, there is no need to do

anything to the meter.

Notes on correctness of measurements

For the notes on correctness of measurements applicable to

this meter in Germany, please see the enclosed document enti-

tled “Notes on correctness of measurements for LZQJ-SGM.”

Technical data

Voltage, current,

frequency, utilisation

category

See name plate

Overvoltage category

Rated peak withstand

voltage

OVC III (as per EN 62052-31)

4 kV (as per EN 62052-31)

Input

System voltage

100...240 V

6

Data interfaces

Optical

Electrical

Optical data interface D0 (38400 baud),

as per EN 62056-21

RS232 (115200 baud), as per

ANSI EIA/TIA-232-F (R1997)

RS485 (115200 baud), as per

ANSI/TIA/EIA-485-A-98 (R2003)

CL0 (19200 baud), as per DIN 66348-1

Output

Optocoupler MOSFET

max. 250 V AC/DC, max. 100 mA

Power consumption per

phase as per EN 62053-61

Base meter

Voltage circuit

Current path

Multifunction mode

approx. 95% power

consumption in

voltage circuit as per

EN 62052-31

<1.2 W / <1.9 VA

<0.04 VA

max. 2.1 W / 2.7 VA @ 3 x 58/100 V AC (RMS)

max. 2.4 W / 4.0 VA @ 3 x 240/415 V AC (RMS)

Temperature range −25 °C...+55 °C

Limit range for operation, storage and transport:

−40 °C...+70 °C

Altitude Operation up to 3,000 m

Humidity Maximum 95%, non-condensing, as per

EN 62052-11, EN 50470-1 and EN 60068-2-30

Protection class II

Degree of protection IP 54

Fire properties As per EN 62052-31

Environmental conditions Mechanical:

M1 according to the Measuring Instruments Directive

(2014/32/EU)

Electromagnetic:

E2 according to the Measuring Instruments Directive

(2014/32/EU)

Intended operating location:

Interior as per EN 50470-1

Weight Approx. 1.0 kg (transformer connected meter)

7

Housing, display and control elements

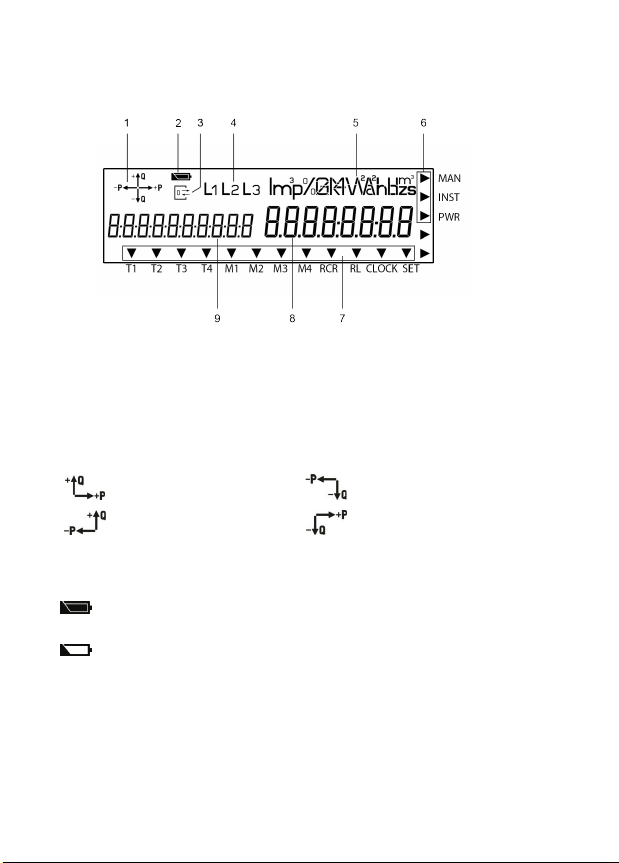

1 - Name plate

2 - Test LED for reactive power

3 - LC display

4 - Test LED for active power

5 - Optical call sensor (optional)

6 - Meter cover

7 - Sealing screw

8 - Optical data interface D0

9 - Call-up button

10 - Transformer plate (only for transformer connected meters)

11 - Reset button

12 -

13 - Module compartment

14 - Terminal cover

15 - Sealing screws

8

Optical call sensor: Used to call up the display lists on the

display. The sensor is operated with a

focussing torch.

Optical data

interface D0:

For communication between meter and

read-out device by means of an optical

more information on the optical data inter-

face in the user manual.

Module compartment:

A modem or interface module can be

installed here. Installation and removal

can be performed under voltage.

9

Name plate (example)

1 - Year of construction

2 - Test LED for reactive power

3 - Serial number

4 - Test LED for active power

5 - Product standard

6 - Optical call sensor

7 - Overvoltage category

8 - Accuracy class

9 - Operating temperature

10 - Space for ownership labelling

11 - Information about connection of the meter

12 - OBIS codes for the most important registers

13 -

14 - Safety and application information

15 - Voltage, current, frequency

16 - Type designation and type code

10

-

The cursor labelling below the display and the description of the OBIS

code numbers on the name plate are designed as standard and not

adapted to the meter version.

in question.

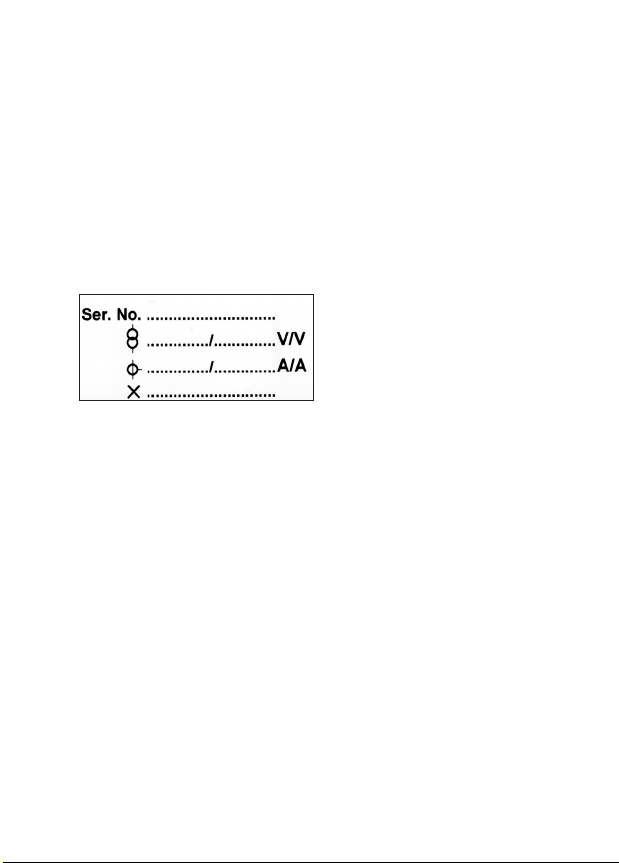

Transformer plate

Transformer connected meters (usually secondary meters) are

equipped with a transformer plate. It is located under the sealable

11

LC display

The LZQJ-SGM is equipped with a liquid crystal (LC) display as per

1. The operation display shows the energy direction that is currently

being measured by the meter (supply/draw of active power, inductive/

direction arrow indicates which quadrant is being used for the

measurement, e.g.:

1st quadrant +P/+Q 3rd quadrant −P/−Q

2nd quadrant −P/+Q 4th quadrant +P/−Q

2. The battery status indicator shows the residual capacity of

the internal power reserve of the real time clock.

= Power reserve run-down, internal battery is empty or not

available. In this instance, the real time clock cannot be

3. The communication display lights up permanently when the data

interface (optical or electrical) and the meter are communicating.

4. The phase display indicates when individual phase voltages are

12

5. The unit shown matches the type of energy being measured or the

measured value displayed.

6. The additional cursor eld displays the operating states for the

meter. The arrows indicate whether any manipulation or an installation

error was registered or if the power threshold was exceeded.

MAN The cursor is active where any manipulation of the terminal

INST The cursor is active if an entry has been registered in the

installation control register.

PWR

meter was exceeded.

7. The standard cursor eld displays the operating states for the

internal device clock.

T1 - T4

M1 - M4

RL

is active.

CLOCK The cursor is active when the internal device clock actu-

SET The corresponding cursor is active when the meter is in

the Set mode.

8. The value area displays the measured values.

9. The code area

the OBIS key. The display can show all six value groups.

13

Installation and start-up

The meters in series LZQJ-SGM

are suitable for wall mounting as per

DIN 43857-2.

When connecting the meter, always

observe the corresponding connec-

tion diagram, which is located on the

meter’s name plate and in the delivery

documents. Please also observe

the notes on the installation control

register.

DANGER

Risk of fatal injury due to arcing and electric shock!

The voltage taps in the meter are not fuse-protected, and are connect-

ed directly to the measuring voltage potential.

yExternal devices that are operated using the meter’s voltage taps

the applicable technical regulations.

yThe transformer connected meter must be fuse-protected in a voltage

DANGER

Risk of fatal injury due to arcing and electric shock!

The inputs and outputs for the additional terminals are not fuse-pro-

tected in the meter.

y

the applicable technical regulations.

y-

tions on the meter name plate in accordance with the applicable

technical regulations.

y

14

DANGER

Risk of fatal injury in case of contact with live parts!

During installation or when replacing the meter, the wires connected to

the meter must be de-energised.

yThe installer bears responsibility for coordinating the rated values

and parameters of the supply-side overcurrent protection devices

with the maximum rated currents of the meter.

yRemove the corresponding pre-fuses, on the mains side and on the

creation side in case of a two-sided feed. Store them in a secure

location to ensure that no one else can insert the pre-fuses again

without being noticed.

yIf you use selective automatic circuit breakers for system discon-

nection, secure them to prevent them from being switched on again

without being noticed.

yBefore the installation of a meter, make sure that the consequences

of disconnecting the electrical system will not result in immediate

danger to the life or health of persons or cause any economic

damage.

yTo avoid any immediate hazards or damage, take appropriate

measures to prevent malfunctions before disconnection of the

system.

y

connection of the meter.

ATTENTION

Application of excessive torque will damage the connection

terminals!

The appropriate torque is dependent on the type of connection line

involved and its maximum current.

yTighten the connection terminals to the corresponding torque as

per EN 60999-1.

15

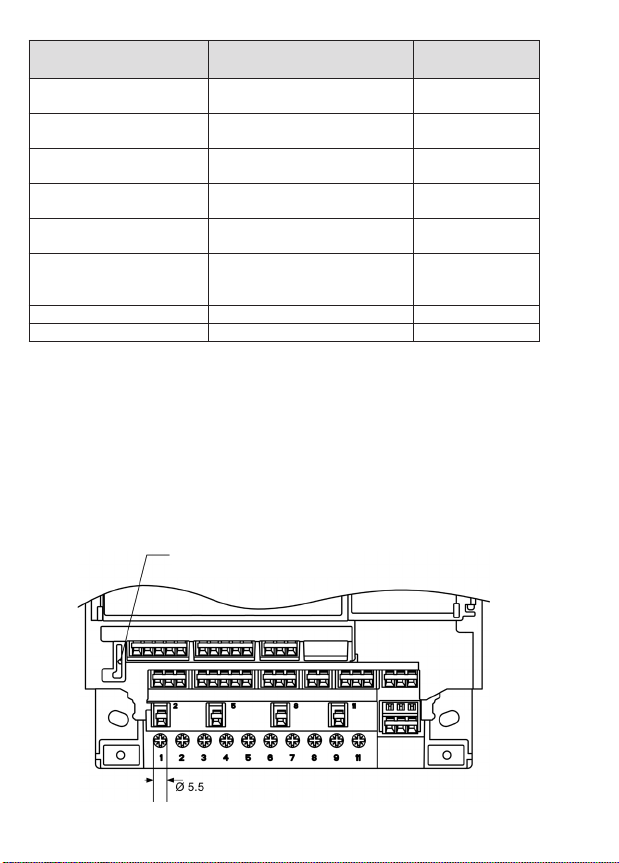

Transformer

connected meter

Current and voltage

terminals

Additional

terminals

Terminal dimensions

W x H or d (mm) 5.3 x 5.5 2.6 x 2.2

Minimum connection cross

sections (mm²) 2.5 1.0

Maximum connection

cross sections (mm²)* 10 2.5

Minimum torques

(Nm) 1.2 —

Maximum torques

(Nm) 1.7 —

Screw type

Cross slot combination screw

type PZ1

(as per ISO 4757)

Spring-loaded

terminal

Thread size M4 —

Stripping length (mm) 10.0 5.0

* Rated connection capacity based on EN 60999-1

Terminal block

the meter.

View from the front (maximum terminal assignment,

specications in mm)

Button for manipulation recognition

of the terminal cover

16

View from below (maximum terminal assignment,

specications in mm)

DANGER

Risk of fatal injury from high voltage when power transformers

disconnected!

In transformer connected meters, the high voltage generated on

a disconnected power transformer can cause fatal injuries and result

in electric arcs on the terminal block.

yBefore disconnecting the current paths, short-circuit the secondary

circuits of the power transformer at its testing terminals.

DANGER

Danger to life due to excess voltages on the terminals of the

current paths!

The voltages on the terminals of the current paths must not be higher

than the rated voltages of the voltage circuits and not be higher than

yUse the meter only with suitable current transformers to avoid

exceeding the voltage limits. If necessary, the secondary side of

the transformers must be earthed.

17

DANGER

Risk of fatal injury from high voltage when voltage transformers

are used!

yObserve all the safety instructions in the documents for the voltage

transformers in use.

yIf necessary, the secondary side of the voltage transformers must

be earthed.

Connection to current and voltage terminals

Proceed as follows when connecting the LZQJ-SGM:

1. Ensure that all lines are free from voltage.

2. Shorten the conductors to the necessary length if necessary.

3. Strip 9 to 10 mm of each conductor.

4.

a ferrule.

5. Open the screw-type terminal.

6. Insert the conductor into the screw-type terminal up to its

insulation.

7. Tighten the screw of the screw-type terminal while observing

the cable insulation is not put inside the terminal.

8. Repeat the process until all conductors are connected.

Connection to spring-loaded terminals

Proceed as follows to connect external devices to the spring-loaded

terminals:

1. Shorten the conductors to the necessary length.

2. Strip 4 to 5 mm of the conductor.

3.

that all individual wires are fully inside the terminal.

18

4. Push the lever of the spring-loaded terminal

down with the screwdriver until the terminal

opens.

5. Insert the line into the open terminal up to its

insulation. Ensure that the cable insulation is

not put inside the terminal.

6. Remove the screwdriver to allow the

terminal to close.

7. Repeat the process until all conductors are connected.

Information on connecting interfaces

Example:

19

the user manual.

In addition to the connection diagram for current and voltage, the type

plate contains information on the interfaces, such as the maximum

voltage of the outputs, for example.

The interfaces are marked with numbers, which can be found above the

matching terminals in the terminal block area. Framed terminal numbers

indicate the respective earth (GND) of the interface.

The electrical data interfaces RS232, RS485 and CL0 are implemented

by means of spring-loaded terminals.

The assignment is as follows:

RS232

Tx Rx RS GND

23 24 27

RS485

A(-) B(+) RS GND

23 24 27

CL0

+NC -

23 24

Securing the terminal cover

To prevent any unauthorised access to the connection terminals, the

terminal cover is attached with 2 sealing screws (slot and PZ2 drive),

which you can secure with seals.

20

ATTENTION

Application of excessive torque will damage the device!

yTighten the sealing screws on the terminal cover with a maximum

torque of 0.5 Nm.

Functions and operation

For a detailed description on operating the LZQJ-SGM by means of a

PC connected to the meter, please see the chapter on the COMBI-

MASTER 2.0 in the user manual. The following sections describe only

the procedure using the buttons on the device itself.

Calling up display lists

The display lists below can be displayed on the meter display. The dis-

play is operated by means of the call-up and reset button. As an alterna-

tive to the call-up button, it is possible to use the optical call sensor.

The display lists contain the following:

yOperation display (alternating display)

yDisplay test

yCall list (Std-dAtA display all register contents in the list)

yP.01

yAdjustment list (SEt edit adjustable variables)

yInformation list (InFO-dAtA display instantaneous values)

MASTER 2.0 tool.

Other manuals for LZQJ-SGM

1

Table of contents

Other EMH metering Measuring Instrument manuals