Digital Monitoring Products 1124 PIR Installation Guide

2

1124 PIR Installation Guide Digital Monitoring Products

3

Selecting the Proper Transmission Location

(LED Survey Operation)

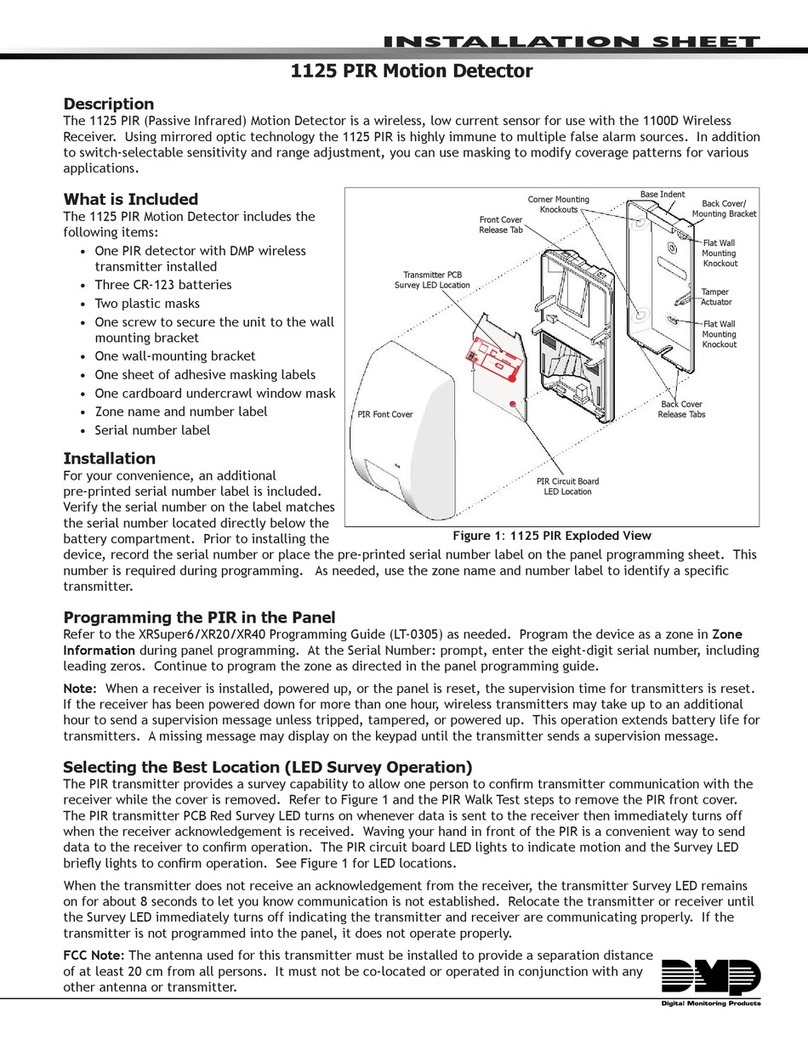

The PIR transmitter provides a survey capability to allow one

person to conrm transmitter communication with the

receiver while the cover is removed. Refer to Figure 2 to

remove the PIR cover. The PIR transmitter board Red Survey

LED turns on whenever data is sent to the receiver then

immediately turns off when the receiver acknowledgement

is received. Tripping the PIR tamper switch is a convenient

way to send data to the receiver to conrm operation. The

transmitter LED lights to indicate activity and to conrm

operation. See Figure 1 for LED locations.

When the transmitter does not receive an acknowledgement

from the receiver the LED remains on for about 8 seconds

to let you know communication is not established.

Communication is also faulty when the LED ashes multiple

times in quick succession. Relocate the transmitter or

receiver until the LED immediately turns off indicating

the transmitter and receiver are communicating properly.

Proper communication between the transmitter and receiver

is veried when for each press or release of the tamper switch, the LED

blinks immediately on and immediately off. Repeat this test to conrm ve

separate consecutive LED blinks. Any indication otherwise means proper

communication has not been established.

Mounting Location Considerations

Mount the unit:

• On a rigid vibration-free surface in a clean area

• So the expected intruder movement is across the detection pattern

elds, see Figures 4 and 5.

Do not locate the unit:

• Outdoors or in a place exposed to sudden temperature changes or

moisture

• In any area containing moving or vibrating objects

• In any ceiling tile containing an air vent

• Where it may be exposed to false alarm sources such as: direct sunlight,

heat sources (heater, radiators, etc.) in the eld of view or strong air drafts (fans, air conditioner, etc.)

Setting the Sensitivity Jumper

Use the jumper located on the sensor unit PCB to set the sensitivity, as shown

in Figure 3. Use the following to determine the appropriate jumper settings

for an application.

Pulse Width Sensitivity Adjustment

Position 1 (right two pins) is for normal operating conditions and operation. Set

the jumper on the two right pins of the 3-pin jumper closest to the number 1.

Position AUTO (left two pins) is used for harsh environment locations with

air drafts. Set the jumper on the two left pins of the 3-pin jumper below the

word AUTO.

Unit Testing

There are three ways to activate the walk and alarm transmission tests to

check PIR range and verify signals. Before performing any of the tests,

ensure the 1124 PIR is currently programmed in the Command Processor™

panel. Refer to Figures 2 and 3 as needed.

1. Using a magnet placed close to the sensor cover opposite the lock screw.

OR

2. Remove the cover and press the internal test button. OR

3. External push button connected to the two terminals marked EXT. TEST. When testing is complete disconnect

the external push button wires and replace the sensor cover.

Figure 4: Detection Pattern

Ceiling

10 ft. high

(3m)

46 ft. (14 m)

2.6 ft.

(0.8 m)

Effective

Detection

Diameter

Floor

65 ft. (20 m)

PIR Pattern

0 (0)

32.8 21.6 10.8 0 10.8 21.6 32.8 ft.

(10) (6.6) (3.3) (0) (3.3) (6.6) (10) (m)

Top View

Side View

ft. (m)

65.6 ft. (20m)

8 (2.4)

10 (3)

12 (3.6)

Figure 5: Lens Pattern

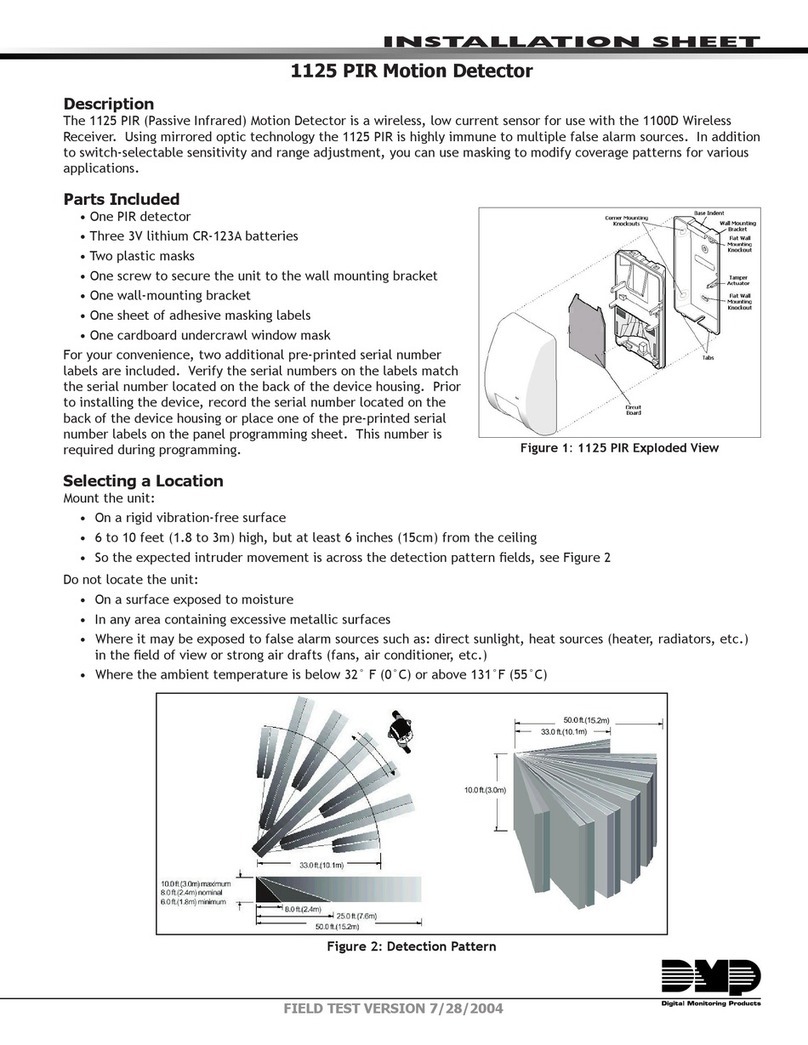

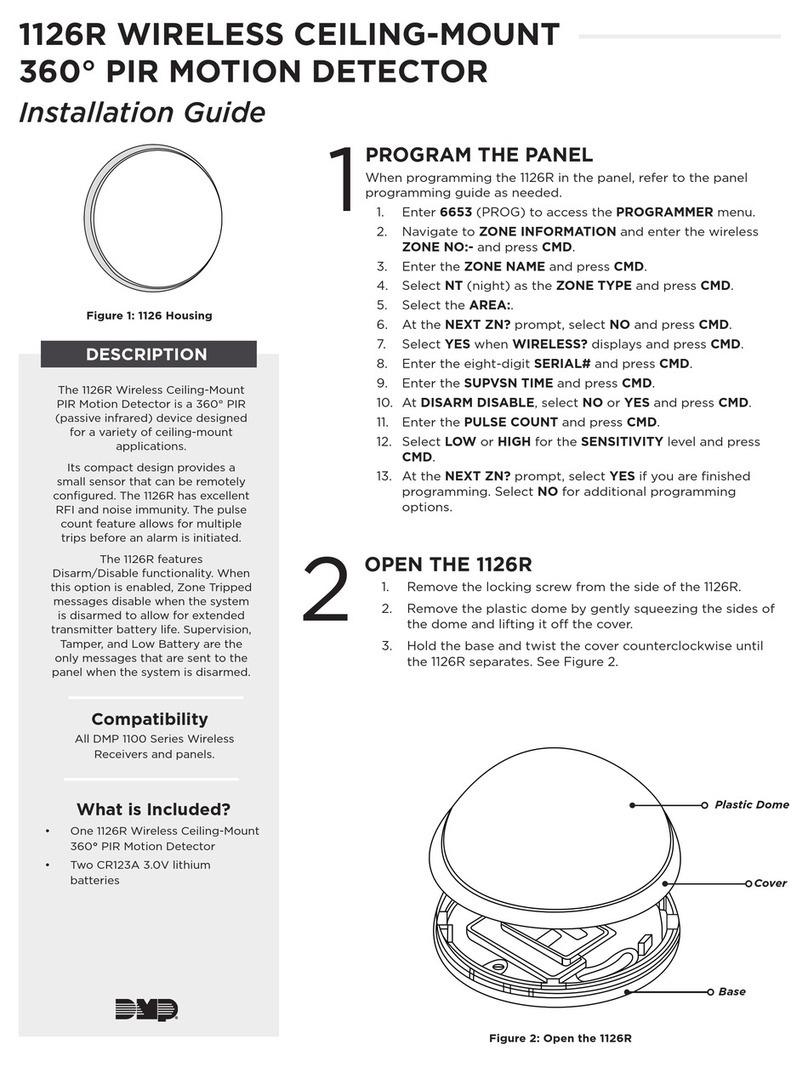

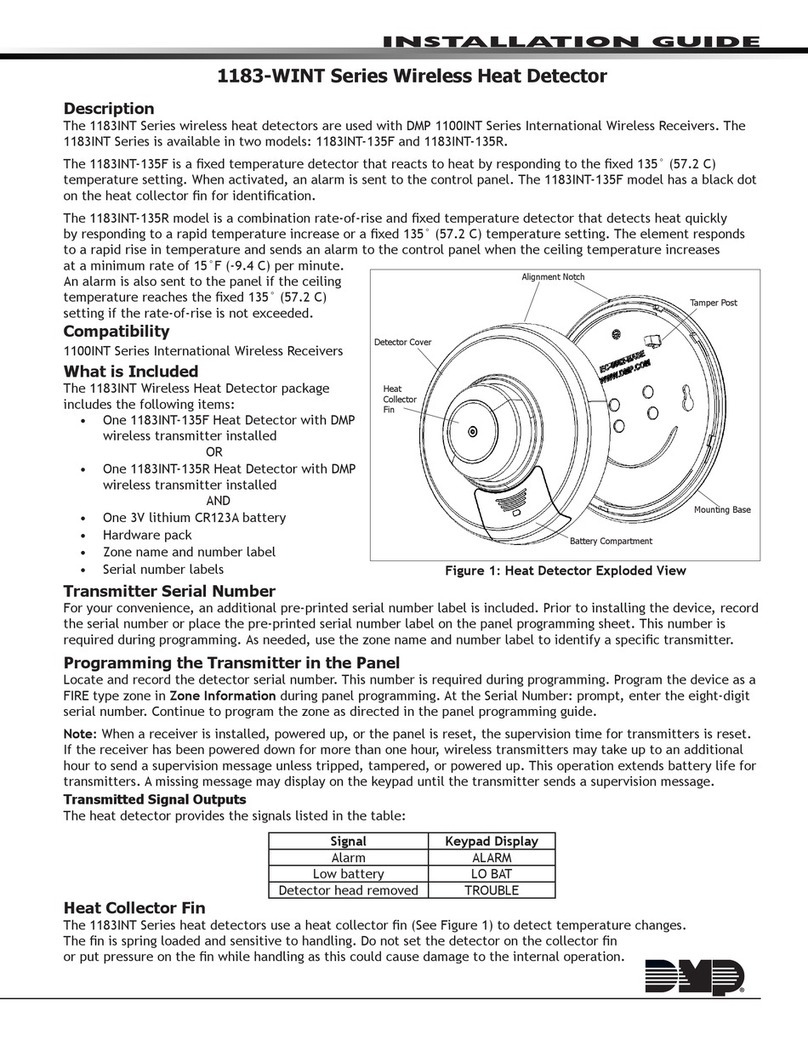

Figure 3: 1124 PIR Circuit Layout

Battery

Compartment

Pulse Width

Sensitivity

Adjustment

Alarm Test LED

Magnet Reed Switch

for Testing

Pushbutton for

Alarm Testing

1124 External

Test Option

Tamper

Transmitter LED

Transmitter

PCB

Serial

Number

Label

Location