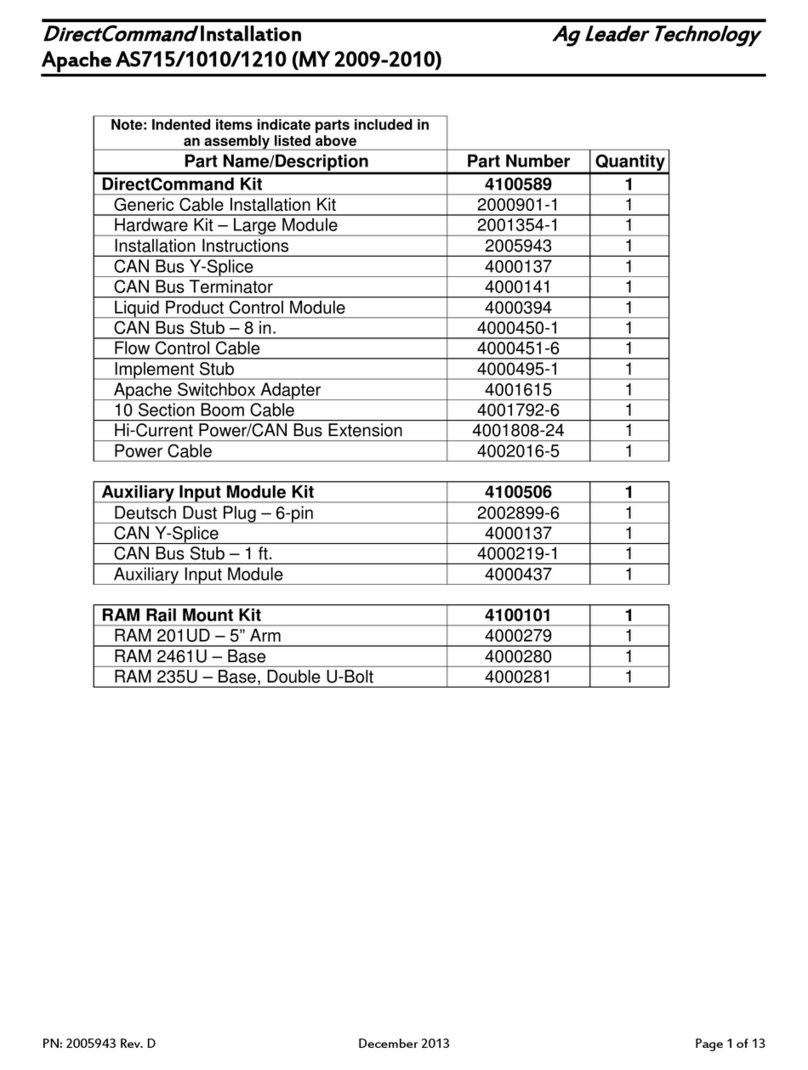

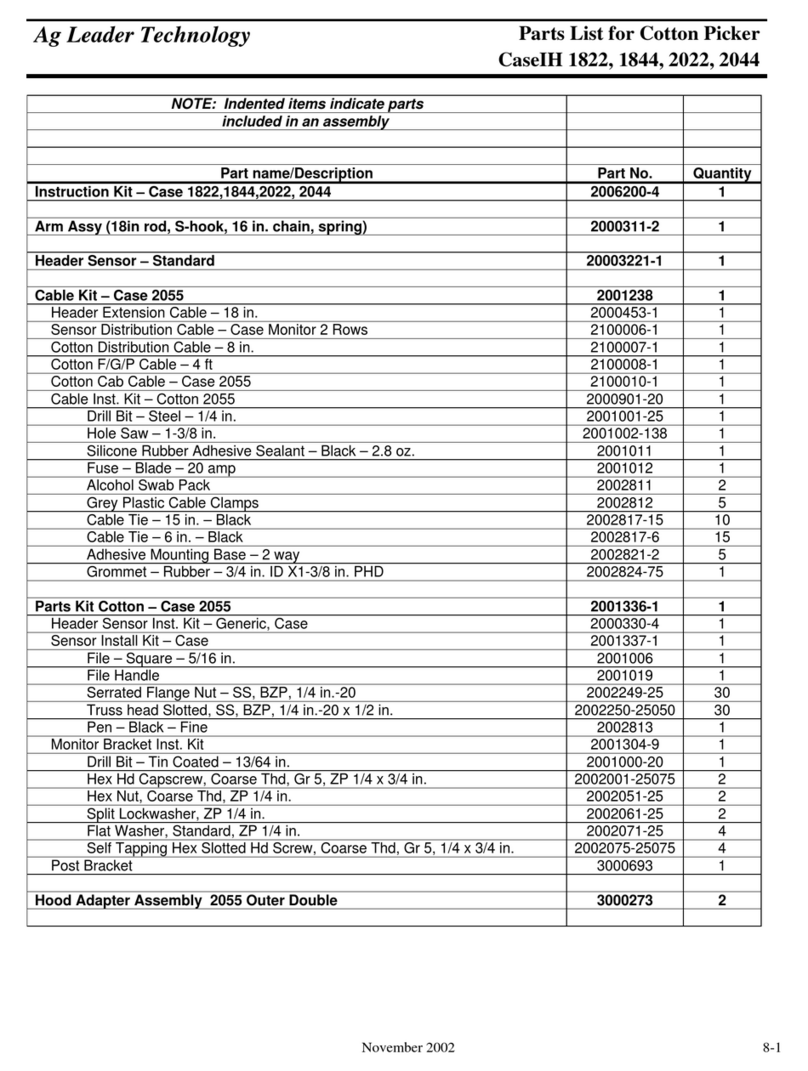

Ag Leader Technology Parts List for Cotton Picker

CaseIH 2055

November 2002 8-1

NOTE: Indented items indicate parts

included in an assembly

Part name/Description Part No. Quantity

Instruction Kit – Case 2055 2006200-1 1

Arm Assy (18in rod, S-hook, 16 in. chain, spring) 2000311-2 1

Header Sensor – Standard 20003221-1 1

Cable Kit – Case 2055 2001238 1

Header Extension Cable – 18 in. 2000453-1 1

Sensor Distribution Cable – Case Monitor 2 Rows 2100006-1 1

Cotton Distribution Cable – 8 in. 2100007-1 1

Cotton F/G/P Cable – 4 ft 2100008-1 1

Cotton Cab Cable – Case 2055 2100010-1 1

Cable Inst. Kit – Cotton 2055 2000901-20 1

Drill Bit – Steel – 1/4 in. 2001001-25 1

Hole Saw – 1-3/8 in. 2001002-138 1

Silicone Rubber Adhesive Sealant – Black – 2.8 oz. 2001011 1

Fuse – Blade – 20 amp 2001012 1

Alcohol Swab Pack 2002811 2

Grey Plastic Cable Clamps 2002812 5

Cable Tie – 15 in. – Black 2002817-15 10

Cable Tie – 6 in. – Black 2002817-6 15

Adhesive Mounting Base – 2 way 2002821-2 5

Grommet – Rubber – 3/4 in. ID X1-3/8 in. PHD 2002824-75 1

Parts Kit Cotton – Case 2055 2001336-1 1

Header Sensor Inst. Kit – Generic, Case 2000330-4 1

Transfer Punch – 11/32 in. 2001003-34

File – Square – 5/16 in. 2001006 1

File Handle 2001019 1

Monitor Bracket Inst. Kit 2001304-9 1

Drill Bit – Tin Coated – 13/64 in. 2001000-20 1

Hex Hd Capscrew, Coarse Thd, Gr 5, ZP 1/4 x 3/4 in. 2002001-25075 2

Hex Nut, Coarse Thd, ZP 1/4 in. 2002051-25 2

Split Lockwasher, ZP 1/4 in. 2002061-25 2

Flat Washer, Standard, ZP 1/4 in. 2002071-25 4

Self Tapping Hex Slotted Hd Screw, Coarse Thd, Gr 5, 1/4 x 3/4 in. 2002075-25075 4

Fastener Kit – (1/2 in, 35 pcs) 2001337-1 1

Pen – Black – Permanent – Fine 2002813 1

Post Bracket 3000693 1

Hood Adapter Assembly 2055 Outer Double 3000273 2