Critical Assembly Requirements

1. Local code and jurisdictional requirements that are applicable to the water tank

installation must be adhered to.

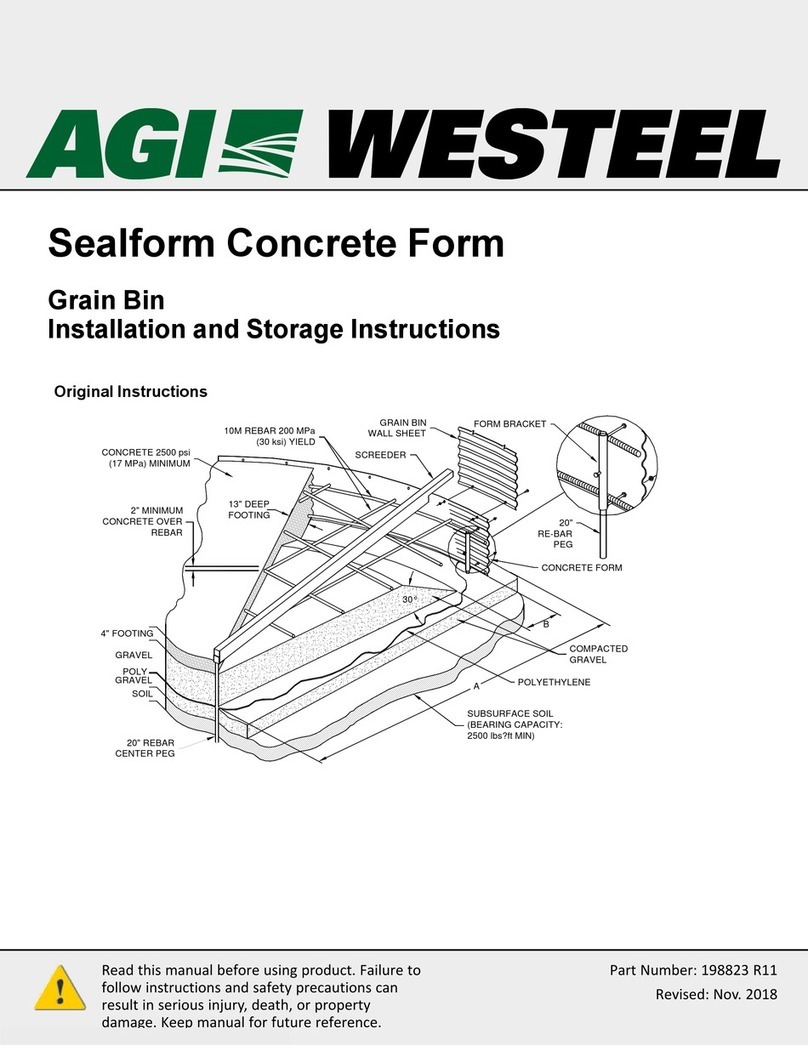

2. Foundations must be designed for the loads being imparted to them, and for local soil

conditions. Westeelfoundation guidelines are for a set of stated conditions and maynot

be applicable to local conditions.

3. A foundation must provide uniform and level support to the tank structure being

supported. Surface imperfections causing gapping must be remedied

4. Ensure that the proper hardware is utilized for all bolted connections. Refer to the

‘Hardware “Where Used” Chart’ in the Installation Manual. If a shortage occurs do not

substitute. Take the necessary steps to obtain the proper hardware. Ensure nuts are

tightened to the required torque values as provided in the Installation Manual.

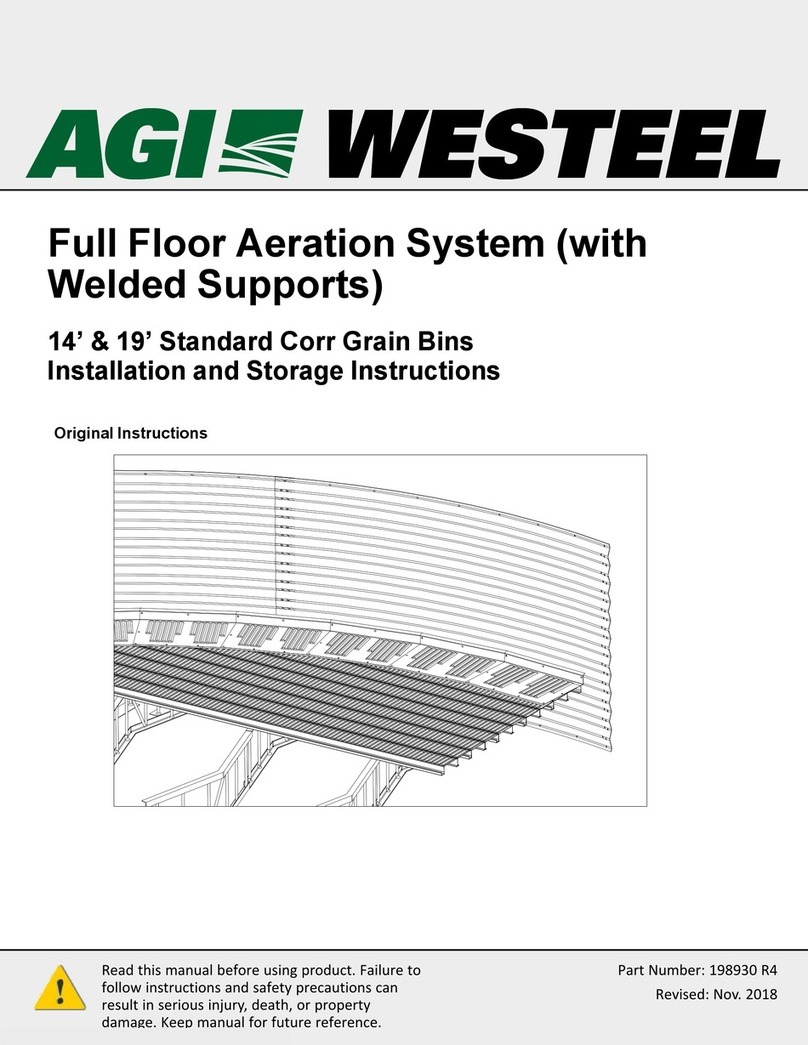

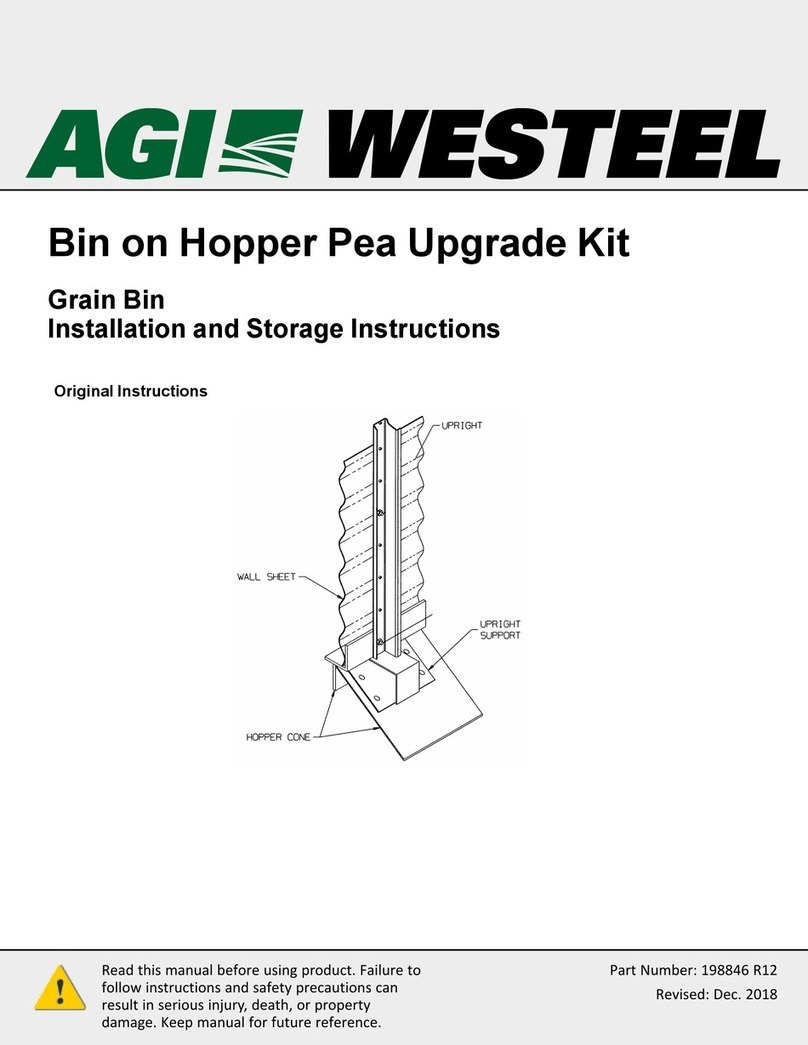

5. Refer to the appropriate Installation Manual to ensure a safe, proper structure, in

particular but not exclusively for the wall sheet and upright layouts. Do not deviate

from the layouts provided.

6. When installing roof stiffening rings, and if it is necessary to shorten the stiffening ring

tubes, shorten them as little as possible. Initially the nuts on the expanders should be

centeredandasclosetogetheraspossible. Whentightening,sharetheamountoftake-

up between expanders such that the nuts remain centered, and the amount of

engagement between all expanders on the same ring is equalized.

7. Before anchoring the tank to the foundation, ensure that the tank is round. The

maximum variation from perfect roundness is 3/4" on the radius (see details in "wall

sheet " section of manual). Locate anchor bolts towards the outside of the anchor bolt

holes(awayfromtank)topermittheincrementalexpansionthatcanoccurwiththeinitial

filling.

Product Storage

Rust on Galvanized Parts

1. White rust forms when moisture is allowed to collect on galvanized surfaces that have

yet to develop the durable zinc oxide layer. This zinc oxide layer naturally occurs as the

surface interacts with carbon dioxide, and is characterized over time by the dull grey

appearance that weathered galvanized surfaces get.

2. Parts that are not well ventilated or well drained can collect water between surfaces

and develop white rust.

3. White rust is not a structural concern if its development is stopped in the early

stages. A light film or powdery residue can occur after a period of heavy rainfall or a

short time of improper storage. If white rust has started to develop, separate parts

and wipe off any moisture. Next, using a clean cloth, apply a thin layer of petroleum

jelly or food-grade oil to the entire part.

4. If moisture is left on parts, this white rust can become more aggressive and turn into

red rust. Red rust can cause degradation in the material and become a structural

concern. Any parts that have red rust should be replaced immediately.

Page 6