・Do not cut under inappropriate cutting condition.

・Do not use after the body is bumped and strongly

shocked.

・The tool is in the state of high temperature during cutting.

There is a danger of a burn, if it is touched soon after

cutting is done.

・Minimize the overhang of the tool for use.

・Use the machine tool with sufcient rigidity and

horsepower.

・Use a cover on a machine tool and a protector such as

glasses against shattering chips and broken tools due to

misuse.

・Do not use insoluble oil, because there is a danger of

causing re.

Do not use other insert clamping screw than the

accessory or genuine.

Be careful not to cut yourself when exchanging inserts.

・

・

Replace the screw periodically since they are

consumption parts.

Do not use the wrench whose tip is damaged and the

clamping screw whose hole is damaged.

・

・

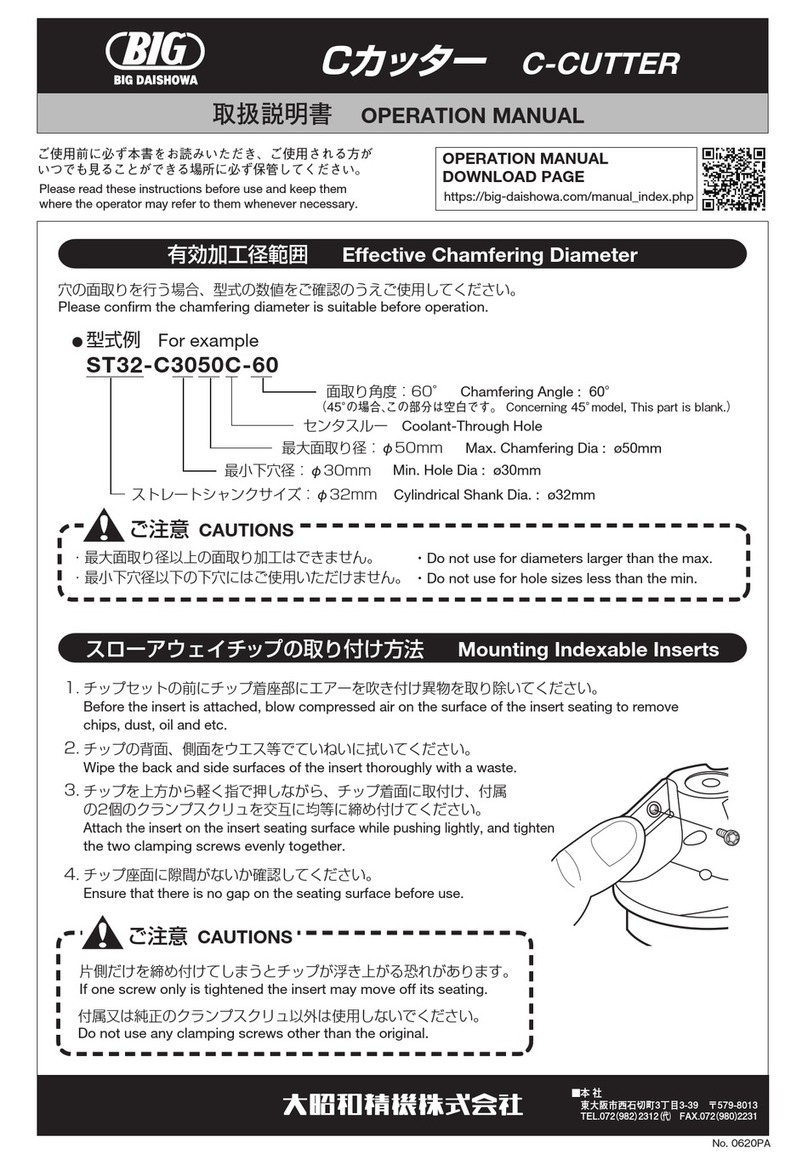

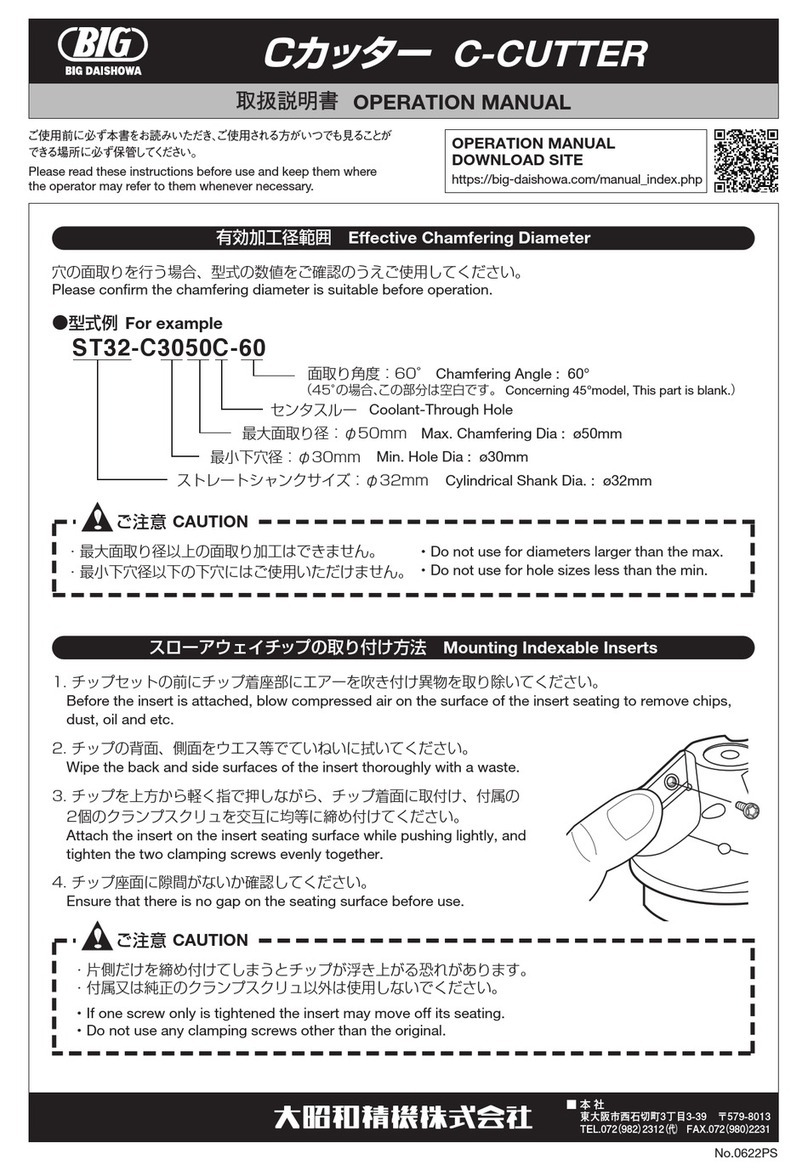

〈INSERT AND PARTS〉

CN0406 S2TS-6IP

CN0606 S2.5S-8IP

CN0906 S4S-15IP

Insert Insert clamping screw set

CN0406 0.5

CN0606 1.0

CN0906 3.5

Insert

Clamping torque (N・m)

・The insert clamping screw set includes 10 screws and

1 exclusive wrench.

Before attaching inserts, remove any alien particles on the insert seat with air blowing.

Wipe the side and back faces of inserts with a waste thoroughly.

Tighten the screw while lightly pressing of the insert.

Do not tighten a insert clamping screw with more

clamping torque than those in the gure shown right.

Otherwise, an insert, may come to be broken.

Ensure that there is no space between the insert and the

insert seat.

●

●

●

●

●

Refer to the catalogue for the standard cutting condition.

For centering, always use soluble oil.

For chamfering, dry cutting (including air blowing) is

basically recommended. However, in case that severe

built-up edge occurs for cutting aluminum, use soluble oil.

When large centering is needed, lower cutting condition

and/or add step feed.

If large chamfer is needed, increase No. of cuts (# of

pecking for chamfering a bore),

or decrease a cutting speed.

●

●

●

●

●

If edges with large burrs left are chamfered, an insert

comes to be chipped. Burrs should be removed as much

as possible e.g. by changing a cutting tool earlier.

Retain as short projection length of the tool as possible.

Hand feed is not recommended.

Do not exceed a cutting condition in the catalogue or the

maximum rotational speed of 20,000min-1.

The nose radius of the insert forms slightly convex shape

at the bottom of the centering hole.

●

●

●

●

●

※Centering can not be done by multiple cutting edge cutters.

HOW TO ATTACH INSERTS

ABOUT CUTTING CONDITION

CAUTION

CAUTION

OPERATION MANUAL

C-CENTERING CUTTER

Please read these instructions before use and keep them where

the operator may refer to them whenever necessary.

OPERATION MANUAL

DOWNLOAD SITE

https://big-daishowa.com/manual_index.php