Big Sprinkler 1000R User manual

15250 W. Sunshine Road | Yukon, OK 73099 | 1-855-805-7901

Thank you for purchasing the 1000R Wheeled Sprinkler Cart from BigSprinkler.comTM. This sprinkler cart

is an excellent and affordable option for irrigating a variety of areas such as a small or large lawn, gardens,

playgrounds, natural and artificial sports fields, horse arenas or round pens for dust control, and much

more. Our carts are fabricated with care and precision in our Yukon, Oklahoma facility with quality heavy

duty components.

The following manual is a guide for assembly, setup, and operation of your new BigSprinklerTM cart. Please

read and follow all instructions carefully.

We also offer accessories such as 3/4” garden hoses, larger pre-made hose kits with quick connects for

easy hook-up and booster pumps that will greatly enhance pressure and performance for your sprinkler cart.

1000R Wheeled Sprinkler Cart

Cart Assembly Instructions

Please read this manual carefully and follow all safety and assembly instructions below to ensure that your

cart is assembled correctly and operates properly upon start-up. If you have any questions please call 855-

805-7901.

Safety

Safety is the main priority and failure to follow these instructions may cause serious injury. BigSprinkler.com is not responsible for product failure,

property damage, or personal injury if these procedures and operation instructions are not followed.

•Beware of electric power lines

Irrigation water should never contact electric power lines or any other power source. Never let

any part of the sprinkler cart or any irrigation fittings or pipe come in contact with an electric

power source.

•Use caution up close to operating sprinkler heads

Pressurized water from the sprinkler head could cause serious damage to people or objects.

Never allow small children to play close to operating sprinkler heads!

!!

(2) Wheels – 8”

Rotor Sprinkler 1”

(#4 thru #18 Nozzles included)

Screw Driver

1/4”

(4) Flat Washers

5/16”

(2) Lock Nuts

3/8”

(2) Shoulder Bolts

3/8”

(2) Acorn Nuts

1/4”

Sprinkler Cart Axle

Sprinkler Cart Body

(2) Lock Washers

5/16”

Cart Assembly Instructions

STEP 2) MOUNTING WHEELS ONTO THE AXLE

Place the shoulder bolt through the middle on the front side of the wheel as shown in the image. Next,

continue to pass the threaded end through the hole at the end of the axle tab. To secure the wheel,

thread the 3/8” lock nut on the end of the bolt and tighten with a 9/16” wrench and the provided 1/4”

Hex Tool. Tighten until it stops. Repeat the same steps for the other wheel.

STEP 1) BODY & AXLE ASSEMBLY

First, assemble the axle to the main body. Place (1) flat washer on each of the threaded ends of the u-

bracket on the body. Next, align and insert the threaded ends of the u-bracket on the main body through

the 2 holes in the axle. Then, secure the axle to the body by placing (1) flat washer, (1) lock washer and (1)

1/4” acorn nut on each of the threaded ends. Tighten using a 9/16” wrench.

NOTE: Do not adjust the u-bracket mounted on the body. It is properly preset from the factory.

Front Side Back Side

123

4 5 6

U-Bracket

U-Bracket

Finished Body & Axle Assembly

STEP 4) Position sprinkler cart in area to be watered and attach cart to your hose. Your sprinkler cart is

now ready for operation. NOTE: Always run water through your garden hose to flush out before hooking it

up to your sprinkler cart. Doing so will prevent anything from clogging the sprinkler when running.

To make adjustments to the impact sprinkler please refer to the “Impact Sprinkler Adjustment” page.

Cart Assembly Instructions

STEP 3) INSTALLING THE IMPACT SPRINKLER HEAD

First, remove the thread protector cap to expose the taped threads, do not remove white thread tape.

Place the bottom of the sprinkler on top of the threads and slowly turn clockwise. NOTE: Make sure to begin

slowly so that the threads start correctly. If they are cross threaded, it will result with the threads being

damaged on both the cart and sprinkler.

Secure sprinkler head by tighteningwith a large enough crescent wrench or pipe wrench. CAUTION: Only

tighten sprinkler head by placing wrench on the lower base area of the sprinkler head to avoid damage to

the upper portion of the sprinkler.

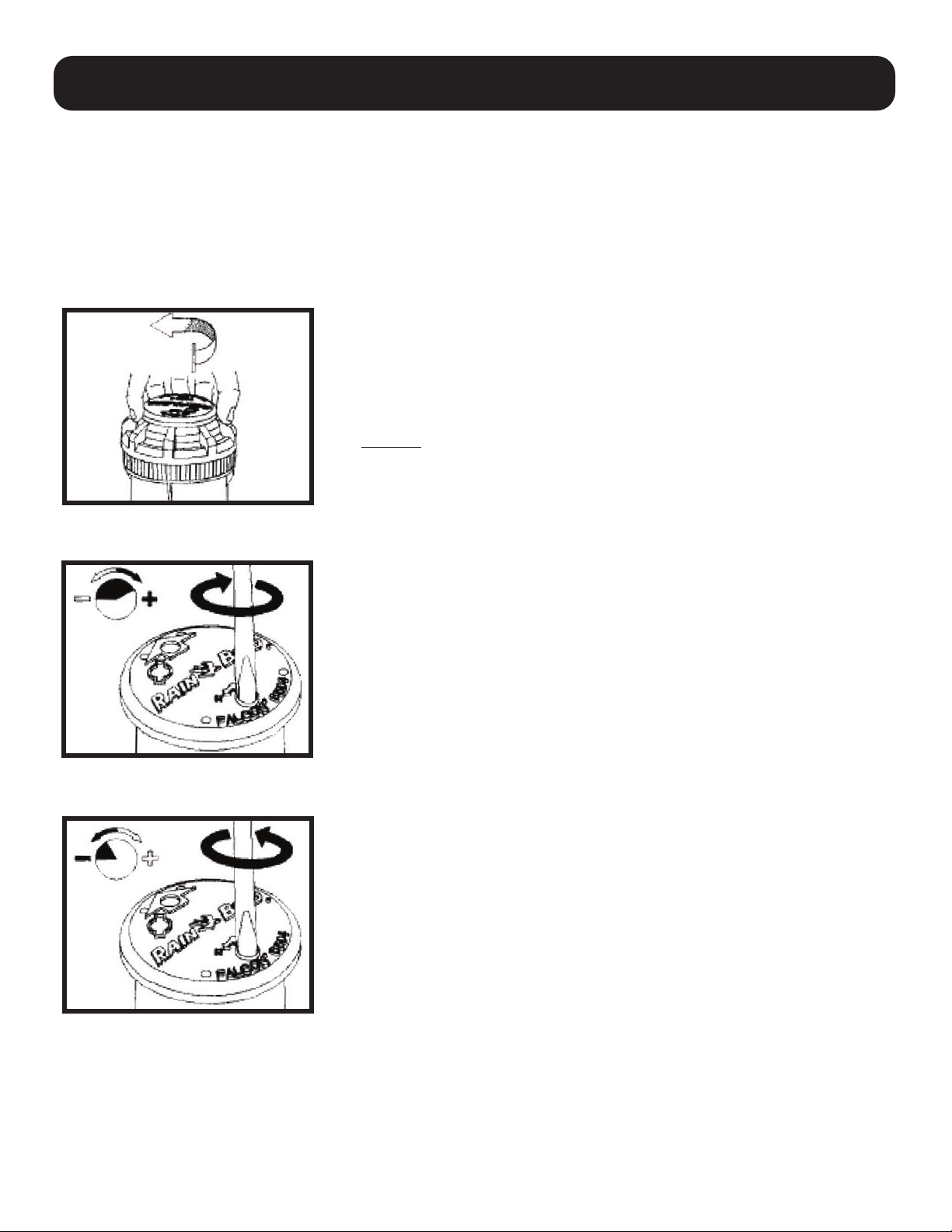

Arc Adjustment

The arc is adjustable from 400- 3600(PC units only). All part-circle

Falcon 6504 rotos are factory preset to approximately 180 degrees.

It can be adjusted from the right trip. The left trip is fixed.

Align Fixed Left Trip (A)

1. Pull up turret and turn the left trip point (counterclockwise).

Caution: If the rotor does not turn easily, first turn it right,

(clockwise) to the right trip point.

2. Next, turn the turret until the arrow points in the

direction you want to set the left edge trip.

To Increase the Arc (B)

1. While holding the nozzle turret at the fixed left stop, insert tool or

screwdriver into the adjustment socket.

2. Turn the screwdriver counterclockwise (+) to increase

the arc.

3. Each full turn of the counterclockwise turn of the

screwdriver will add 45 degrees of arc.

4. When the maximum arc of 360 degrees has been set, you will feel

some resistance in the adjustment screw. Do not adjust the rotor

beyond the maximum arc.

To Decrease the Arc (C)

1. While holding the turret at the fixed left stop, insert tool or

screwdriver into the arc adjustement socket.

2. Turn the srewdriver clockwise (-) to decrease the arc.

3. Each full clockwise turn of the screwdriver will remove 45

degres of arc.

4. When the minimum arc of 40 degrees has been set, you will feel

some resistance in the adjustment screw. Do not adjust the rotor

below the minimum arc.

(if ordered with part circle sprinkler)

A

B

C

Arc Adjustment

NOTE: The internal spring has been removed in order for the Rotor head to

operate with lower pressures. This will not change the sprinklers performance.

Arc Adjustment Slot

Arc adjustment slot—Only on part circle models

Pull Up Slot—Insert

rotor tool here and

turn 90 degrees

to pull stem up and

change nozzle size.

Nozzle Retainer Screw which also acts

as the radius adjustment to diffuse the

spray pattern and decrease sprinkler

throw.

CAUTION: Always use black plastic hold

up tool when changing nozzles. Hold

up tool will snap into the riser stem to

hold it in an extended position while

performing nozzle changes.

Nozzle Installation (D & E)

1. Insert the Pull up Tool into the pull-up slot, turn 90 degrees and lift up stem.

Clip the black plastic hold up tool onto the riser to support the riser in this

extended position.

2. Loosen the nozzle retainer screw until it no longer

obstructs the nozzle opening in the nozzle housing.

3. To remove the nozzle, insert the flat-head of the rotor tool supplied into the

lower right side of the nozzle to pry it loose.

4. To re-install a nozzle, insert the color coded nozzle firmly into the

opening until it is flush with the nozzle turret.

5. Tighten the nozzle retainer screw (which also acts as the radius

adjustment to decrease sprinkler throw) clockwise to secure

the nozzle. The screw threads must engage the nozzle surface

to ensure proper seating of the nozzle and hold it in place during

operation.

D

E

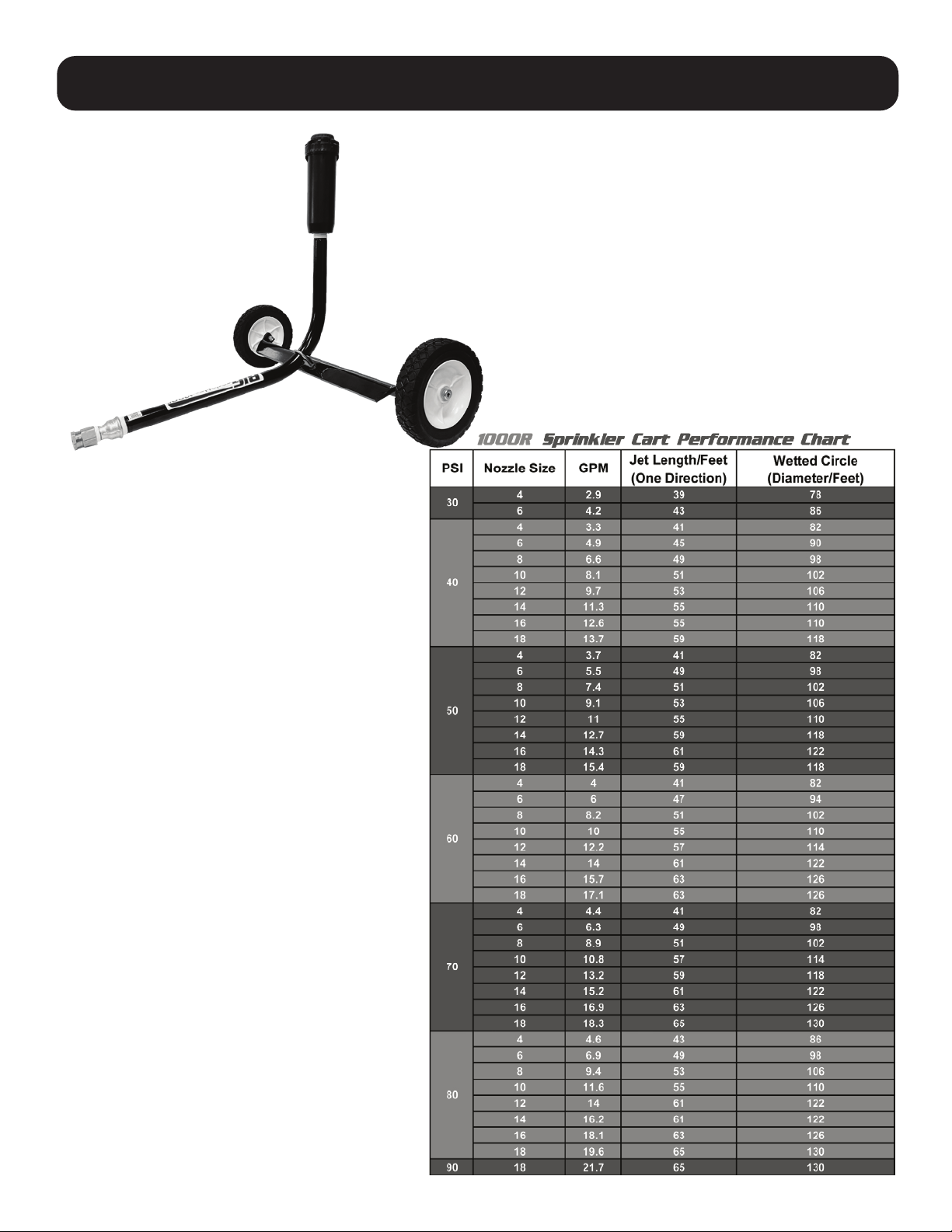

Falcon Rotor Sprinkler Head Settings

Notice: These

specifications are to be

used as a guide only and

have been calculated at

zero wind conditions.

Performances can

vary due to pressure,

terrain, wind, and field

conditions.

1000R Sprinkler Cart Chart

LIMITED WARRANTY AND REMEDY:

WARRANTY

BigSprinkler.comTM warrants to the original purchaser only of the products described in the face hereof

as of the date of the original invoice, that the product is merchantable and free from defects in

material and workmanship.

Warranty shall be provided by the original manufacturer of products sold on BigSprinkler.comTM for the

length of time specified by the manufacturer of the given product.

Sprinkler stands - 1 year

Sprinkler heads - 1 year

REMEDY

If BigSprinkler.comTM determines that the above warranty was breached with respect to any part or

component provided by the manufacturer of the product (and if all conditions set forth below have

been satisfied) then, BigSprinkler.comTM will (at BigSprinkler.comTM ’s option) provide purchaser a refund

of the purchase price less the freight costs to or from the customer, or provide a replacement product

of the same kind.

All remedies provided herein are for goods only, no labor or freight allowance for return goods is

implied.

This warranty extends only to the original purchaser of products purchased from BigSprinkler.comTM.

CONDITIONS TO ENFORCEABILITY AND CLAIMS:

1. Product has been maintained and operated within the guidelines outlined in the manufacturer’s

product guide and maintenance manual.

2. Product warranty shall be considered void if any component or function of the equipment has

been altered in any form other than what has been provided or intended by the original product

manufacturer.

3. Any return must be submitted on form provided by BigSprinkler.comTM in writing immediately and

in no event longer than 20 days from occurrence. You can reach our sales department through the

“contact us” form on our website should such an event occur.

4. Purchaser must return all goods within 30 days of BigSprinkler.comTM ’s authorization date, that

have been determined by BigSprinkler.comTM to be defective to the Purchaser with Purchaser being

responsible for freight.

LIMITATIONS:

BigSprinkler.comTM or it’s affiliates shall not be liable for any incidental or consequential damages

(including but not limited to, damages for injury to the person, property or lost turf, crops or profits)

by reason of any defect in the products sold or its manufacture, design, or function.

Warranty

Table of contents

Popular Irrigation System manuals by other brands

Senju Sprinkler

Senju Sprinkler HF-RES quick start guide

Tyco Fire Protection Products

Tyco Fire Protection Products CC2 manual

wesmartify

wesmartify essentials Smart Garden operating instructions

Tyco

Tyco EC-11 Series manual

Parkside

Parkside PTBS 30 A1 operating instructions

SNOWJOE

SNOWJOE AquaJoe AJ-IS10WB instructions

Rain

Rain SuperPro S075 S Setting instructions

Reliable

Reliable DH56 Dry installation instructions

Viking

Viking VK290 Technical data

Underhill

Underhill Mirage M-125 Operating and maintenance instructions

Tyco Fire Product

Tyco Fire Product CENTRAL ESFR-17 instruction manual

Fiskars

Fiskars 1027028 Original instructions