Senju Sprinkler HF-RES User manual

Page:1 of 5

Document No.U028704 Date:Jan/11/2019

Residential Flush Horizontal Side-Wall Sprinkler

Model HF-RES

,

K=4.2

(

SIN / SS4423

)

(PTFE gasketed orifice seal design)

General Description

The Model HF-RES Residential Flush Horizontal Side-Wall Sprinklers are

automatic sprinklers of the compressed fusible solder type. They are

decorative, low profile, flush mount sprinklers. The Frame and Cover of the

sprinkler hide the Deflector and Valve Cap assemblies. (Reference Figure

1)

The Model HF-RES is designed for use in residential occupancies such as

homes, apartments, dormitories, and hotels. When aesthetics is the major

consideration, the Model HF-RES should be your first choice.

They are to be used in wet pipe residential sprinkler systems for one- and

two-family dwellings and manufactured homes per NFPA 13D; wet pipe

residential sprinkler systems for residential occupancies up to and including

four stories in height per NFPA 13R; or, wet pipe sprinkler systems for the

residential portions of any occupancy per NFPA 13.

The Model HF-RES has a 4.2 (60.5 LPM / bar1/2) K-factor which provides

very low design flow rates at reduced residual pressures, enabling smaller

pipe sizes and water supply requirements.

The flush design of the Model HF-RES features a separable escutcheon

providing 3/16 inch (4.7 ㎜) of total adjustment.

This adjustment reduces the accuracy to which the fixed pipe drops to the

sprinklers must be cut to help assure a perfect fit installation.

The Model HF-RES has been designed with heat sensitivity and water

distribution characteristics proven to help in the control of residential fires to

improve the chance for occupants to escape or be evacuated. However,

residential fire sprinkler systems are not a substitute for intelligent fire safety

awareness or fire safety construction required by building codes.

WARNINGS

The Model HF-RES Residential Flush Horizontal Side-Wall Sprinklers

described herein must be installed and maintained in compliance with this

document, as well as with the applicable standards of the National Fire

Protection Association, in addition to the standards of any authorities having

jurisdiction. Failure to do so may impair the integrity of these devices.

Because of the above cited stipulations and the varied nature of residential

type architecture, there will be some compartment designs which cannot be

fully sprinklered in accordance with the recommendations of NFPA 13, 13D,

or 13R, In the event of this condition, consult the authorities having

jurisdiction for guidance and approval.

It is the responsibility of the installing contractor to provide a copy of this

document to the owner or his representative, and in turn, it is the obligation

of the owner to provide a copy of this document to asucceeding owner.

The owner is responsible for maintaining their fire protection system and

devices in proper operating condition. The installing contractor or sprinkler

manufacturer should be contacted relative to any questions.

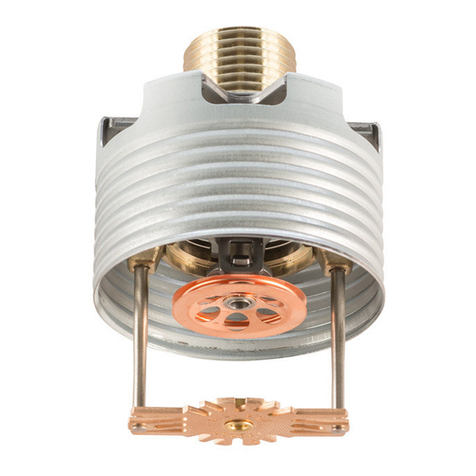

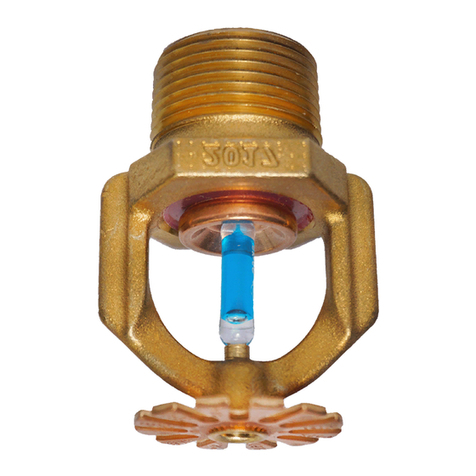

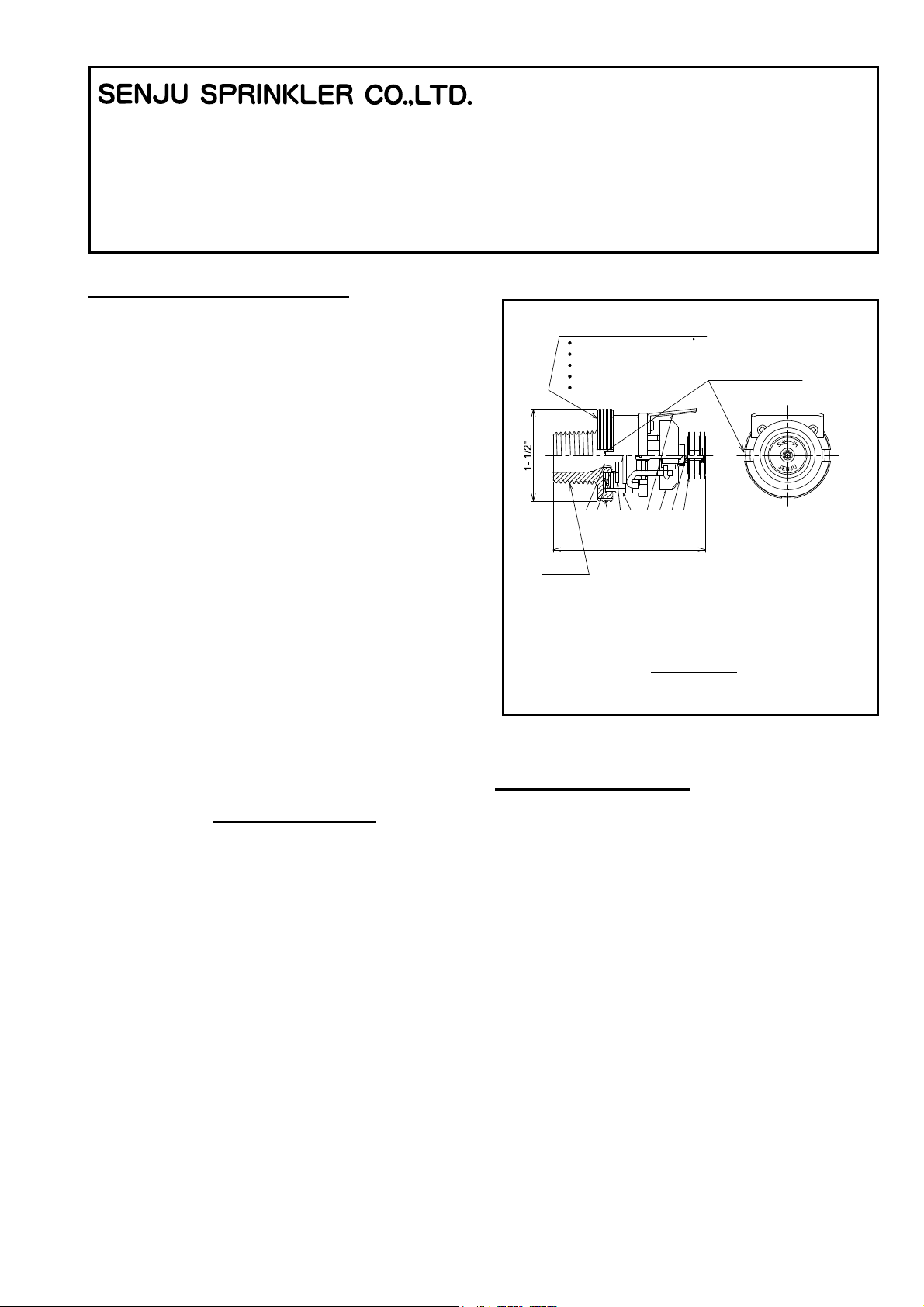

FIGURE 1

MODEL HF-RES K=4.2 RESIDENTIAL FLUSH HORIZONTAL

SIDE-WALLSPRINKLER

Technical Data

Approvals:

ULand ULC Listed.

Sprinkler Identification Number:

SIN SS4423

Maximum Working Pressure:

175 psi (12.1 bar)

Discharge Coefficient:

K = 4.2 GPM / psi1/2 (60.5 LPM / bar1/2)

Temperature Rating:

162 ℉/ 72 ℃

HorizontalAdjustment:

3/16 inch (4.7 ㎜)

Finishes:

Sprinkler and Escutcheon:

White Painted, Black Painted, Dark Brown Painted,

Chrome Plated.

Physical Characteristics:

Dezincification resistant copper alloy body and PTFE gasketed orifice

seal design.

Yearof Manufacture

Temperature Rating (162 F)

Listing Mark

Country Origin

I.D Number (SIN)

Marking

Four Wrench Slots

5-Cover (Copper)

7-Fusible Metal

2-Frame (Bronze)

1-Body (Copper Alloy)

6

6-Heat Collector (Copper)

8-Sub Deflector (Copper Alloy)

4-Gasket (PTFE)

3-Deflector (Copper Alloy)

COMPONENTS (MATERIALS) :

74

NPT 1/2

2- 7/16"

2

138

5

9-Valve Cap (Copper Alloy)

9

Page:2 of 5

Document No.U028704 Date:Jan/11/2019

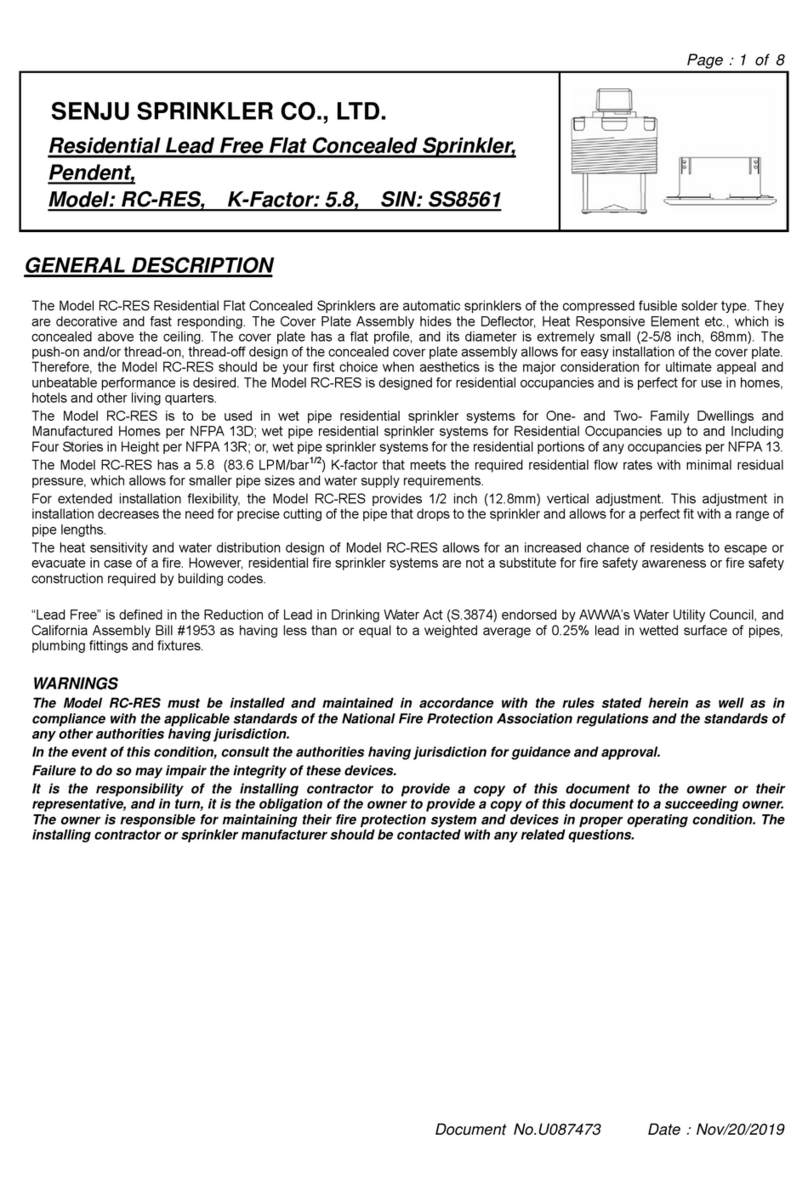

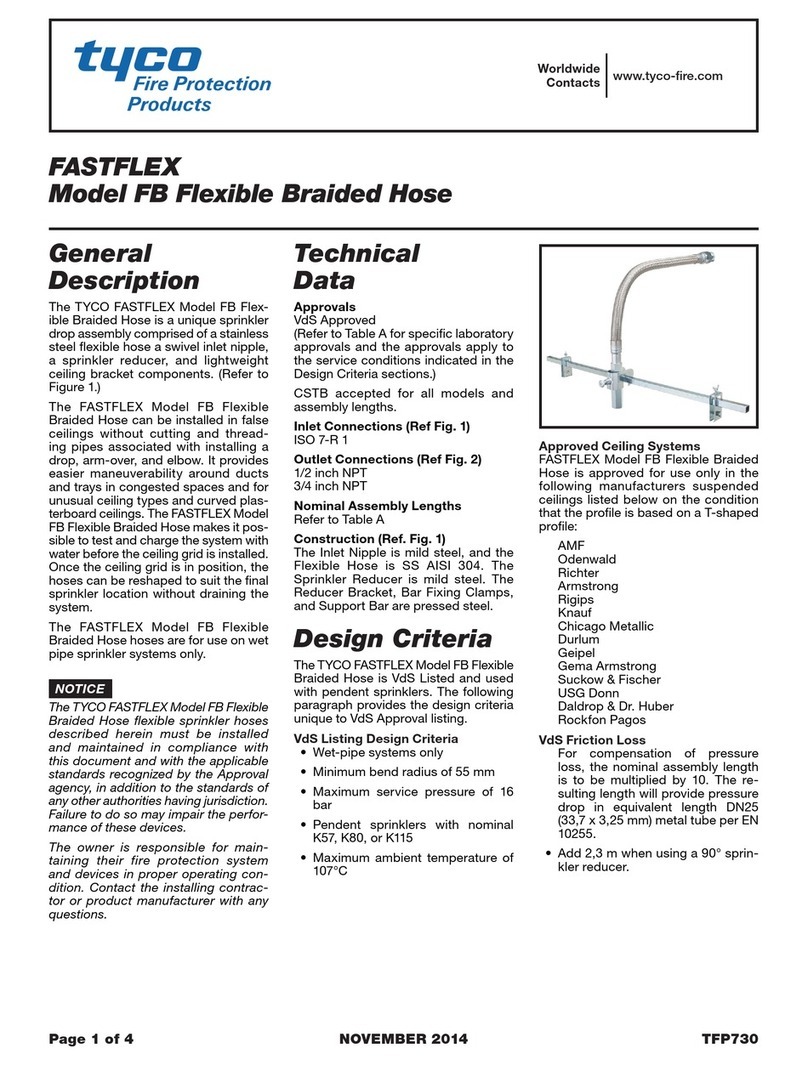

Operation

The Sprinkler assembly contains a small fusible solder element. When

exposed to sufficient heat from a fire, the solder melts and enables the

internal components of the sprinkler to be released. At this point the

sprinkler activates with the deflector moving into its operated position

(Reference Figure 2), permitting water to flow.

FIGURE 2

Design Criteria

The Model HF-RES Residential Flush Horizontal Side-Wall Sprinklers must

only be installed and utilized in accordance with the following described

criteria, which are provided by the manufacturer.

TABLE A

NFPA 13DAND NFPA 13R HYDRAULIC DESIGN CRITERIA

for Model SS4423

Ordinary Temperature Rating:162℉(72℃)

Maximum

Coverage

Area(a)

Ft.×Ft.

(m×m)

Flow

GPM

(L/min)

Pressure

PSI

(bar)

Top of

Sub

Deflector

to

Ceiling

Installation

Type

Minimum

Spacing

Ft.

(m)

12×12

(3.7×3.7) 13

(49.2) 9.6

(0.66)

14×14

(4.3×4.3) 16

(60.6) 14.5

(1.00)

16×16

(4.9×4.9) 20

(75.7) 22.7

(1.56)

4 to 6

Inches Flush 8

(2.4)

(a) For coverage area dimensions less than or between those indicated, it is

necessary to use the minimum required flow for the next highest coverage area

for which hydraulic design criteria are stated.

(b) Requirement is based on minimum flow in GPM from each sprinkler. The

associated residual pressures are calculated using the nominal K-factor. Refer to

Hydraulic Design Criteria Section for details.

(c) For systems with ceiling types smooth flat horizontal, or beamed, or sloped, in

accordance with the 2013 Edition of NFPA13D, 13R or 13 as applicable.

NOTES

Residential Fire Sprinkler Systems should only be designed and installed by

those component and completely familiar with automatic sprinkler system

design, installation procedures, and techniques.

Several criteria may apply to the installation and usage of each sprinkler.

Consequently, it is recommended that the sprinkler system designer review

and develop a working understanding of the complete list of criteria prior to

initiating the design of the sprinkler system.

Questions concerning sprinkler installation and usage criteria, which are not

coverage by the following instructions, should be submitted to Contact

Company. Include sketches and technical details as appropriate.

In some instances, the requirements of this document may concern

specifications which are more stringent and which take precedence over

those specified in NFPA 13, NFPA 13D, NFPA 13R, or by the authority having

jurisdiction.

The spray from the sprinkler is distributed outward and downward from the

sprinkler deflector in a semicircle. Consequently, the sprinklers must be

located such that there will not be any blind spaces shielded from spray by

partitions, room dividers, overhangs or other parts of the dwelling structure.

The number of sprinklers within each compartment (as defined by NFPA 13,

13D, or 13R) must be kept as few as possible. Do NOT use more sprinklers

than necessary to cover a particular space.

Use only the escutcheon provided with the Model

HF-RES

.

The sprinkler must be secured in position by firmly fastening the sprinkler

system piping to the structure. If the sprinkler is not properly secured in

position, reaction forces resulting from sprinkler operation could alter its

orientation and its water distribution pattern.

The sprinkler escutcheon cannot be used to hold the sprinkler in position.

Obstruction to Water Distribution

Locations of sprinklers are to be in accordance with the

obstruction rues of NFPA 13 for Residential Sprinklers.

Precautionary Warnings for Corrosive Environments

Model HF-RES should not be installed where they may be subjected to a

corrosive environment including the following:

1

)

Chlorine ion and Chloride environment.

Stress corrosion cracking may be caused by exposure to environments

with Chlorine ion and Chloride. Exposure to this environment may result

in sprinklers operating under non-fire conditions or not operating when

exposed to an actual fire.

2

)

Sprinkler system piping with Copper.

Sprinkler systems should be constructed in compliance with the

applicable standards and the requirements for the copper piping when

copper piping is used in the sprinkler system. (Reference standards

NFPA 13, ASTM B813, ASTM B828, and CDA (Copper Development

Association) – Solder Joint)

All residual flux must be removed from the interior and exterior of copper

piping by thoroughly flushing before installation of the Sprinkler Heads.

Otherwise, residues of flux may cause corrosion and leakage in the

sprinkler system.

General Service Conditions

The Model HF-RES must only be utilized in wet pipe sprinkler systems.

Hydraulic Design Criteria

The minimum required sprinkler flow rates for systems designed to

NFPA 13D or NFPA 13R are given in Table A as a function of

temperature rating and the maximum allowable coverage areas. The

sprinkler flow rate is the minimum required discharge from the most

hydraulically demanding sprinkler from each of the total number of

“design sprinklers” as specified in NFPA13D or NFPA 13R.

Normal Condition

Operation

W

ater Discharge

Page:3 of 5

Document No.U028704 Date:Jan/11/2019

For systems designed to NFPA 13, the number of design sprinklers is to

be the four most hydraulically demanding sprinklers. The minimum

required discharge from each of the four sprinklers is to be the greater of

the followings:

・ The flow rates given in Table Afor NFPA 13D and 13R as a function of

temperature rating and maximum allowable coverage area.

・ A minimum discharge 0.1gpm/sq.ft. [4.07(L/min)/sq.m] over the

“design area” comprised of the four most hydraulically demanding

sprinklers for the actual coverage areas being protected by the four

sprinklers.

Operational Sensitivity Criteria

For proper operational sensitivity, the model HF-RES must be installed

under smooth, flat, horizontal ceilings as outlined in the applicable

installation standard recognized by the approval agency (e.g. UL

recognizes NFPA 13, 13Dand 13R)

The distance from the Top of the sub-deflector to the ceiling has to be

within 4-6 inches.

The Model HF-RES must NOT be used above or below open-gridded

type suspended ceilings; beneath soffits or beams exceeding 3 inches in

height or joists, or ducts having a height of more than 3 inches located

within the sprinkler coverage areas.

Beams having a height of more than 3 inches may be located with their

centerlines along the boundaries separating adjacent sprinkler coverage

areas.

Sprinkler Spacing Criteria

The minimum spacing between sprinklers is 8 feet. The maximum

spacing between sprinklers cannot exceed the length of the coverage

are being hydraulically calculated.

Heat Source Criteria

Refer to NFPA 13D or NFPA 13R for the requirements relating to

preventing the possible release of a Model HF-RES heat responsive

element, due to exposure to heat sources other than an actual fire.

Installation

The Model HF-RES must be installed in accordance with the following

instructions:

NOTES

Do not use sprinklers which have been subjected to potential mechanical

damage. Do not use sprinklers which show deformation or cracking in either

the sprinkler or protection cap.

The Protective Cap must remain on the sprinkler during installation and until

the ceiling installation is completed. The Protective Cap must be removed to

place the sprinkler in service.

A leak tight 1/2-inch NPT sprinkler joint should be obtained with a torque of

7 to 14 ft.lbs. (9.5 to 19.0 Nm). A maximum of 21 ft.lbs. (28.5 Nm) of torque is

to be used to install sprinklers. Higher levels of torque may distort the

sprinkler inlet with consequent leakage or impairment of the sprinkler.

Do not attempt to compensate for insufficient adjustment in an Escutcheon

Plate by under- or over-tightening the sprinkler. Readjust the position of the

sprinkler fitting to suit.

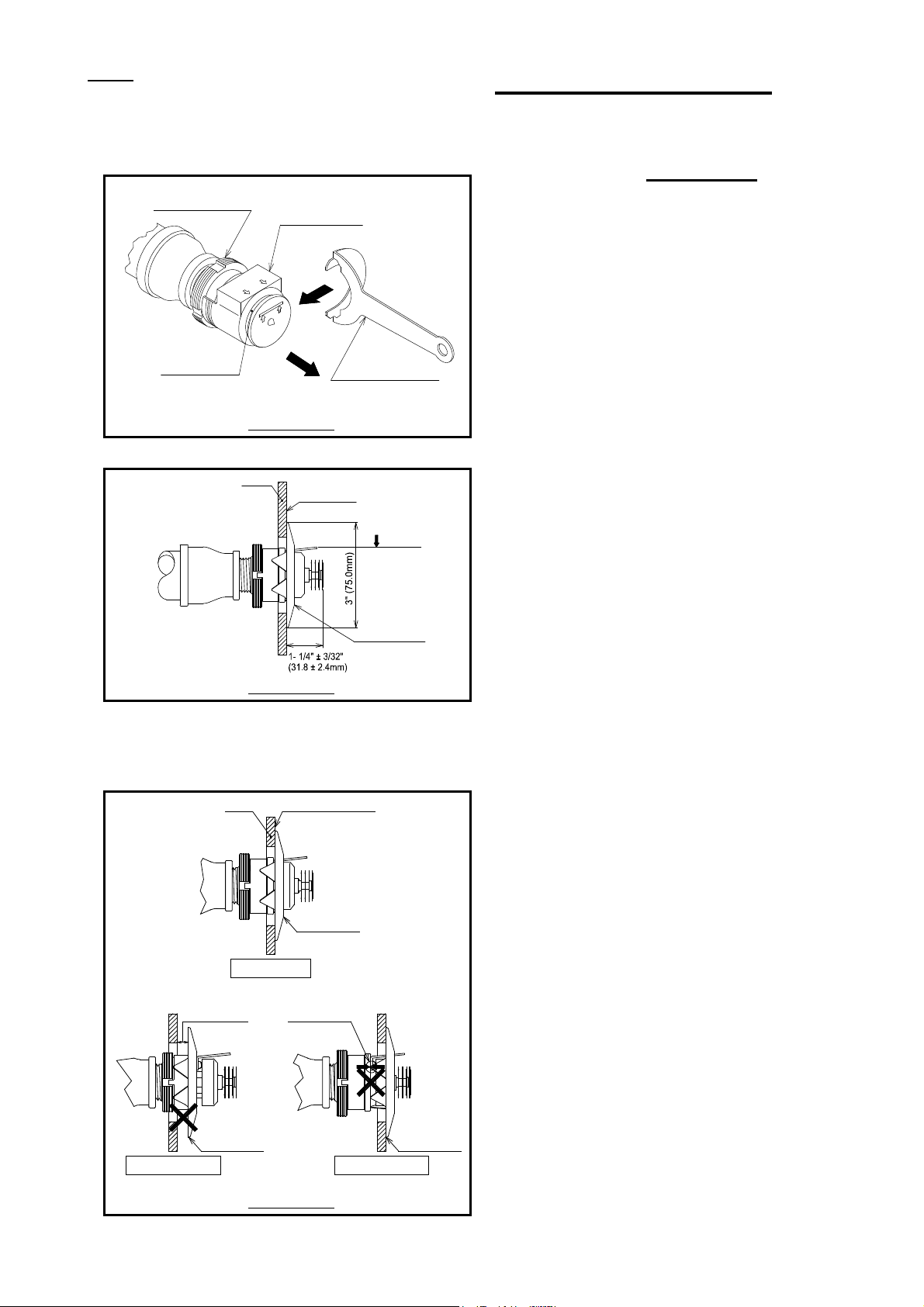

Installing procedure

Step 1.

The sprinkler must be installed only in the sidewall position with their

centerline of waterway perpendicular to the back wall and parallel to the

ceiling. The word “TOP” on the sub-deflector has to face towards the

ceiling with the front edge of the sub-deflector parallel to the ceiling.

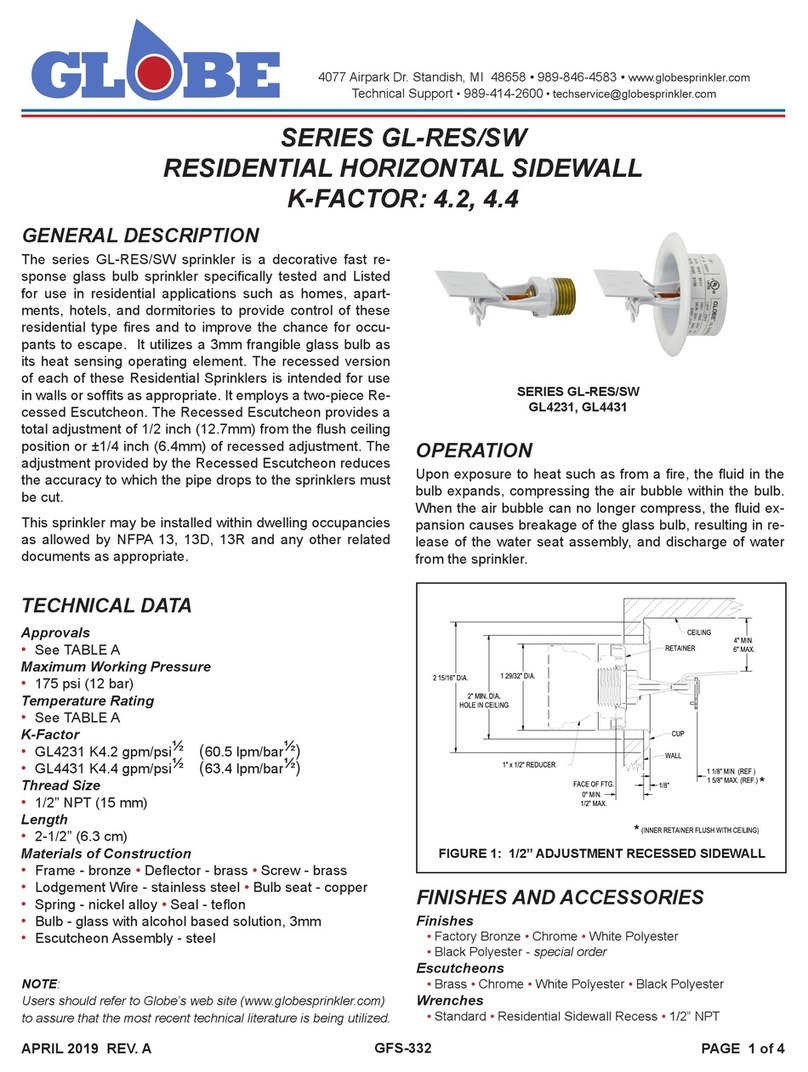

Step 2.

Install the sprinkler fitting so that the distance from the face of the fitting

to the mounting surface will be nominally 53/64 inch (21.0mm) as shown

in Figure 3.

FIGURE 3

Step 3.

With pipe thread sealant applied to the pipe threads, hand tightens the

Sprinkler into the sprinkler fitting.

Step 4.

Wrench tighten the Sprinkler using only the Sprinkler Socket or Wrench

& Socket Combination (Ref. Figure 4). Put the Sprinkler Socket over the

sprinkler without the sub-deflector hit till the socket touches the body of

the sprinkler. Turn the socket till the wrench recess of the Socket can be

applied to the sprinkler wrenching area (Ref. Figure 4).

Special care must be exercised to avoid damage to the sprinkler while

you remove the socket wrench from the sprinkler as well.

FIGURE 4

Step 5.

Use the “tolerance limit of back-wall level” indicator on the Protective

Cap to check for proper installation depth (Ref. Figure 3) Relocate the

sprinkler fitting as necessary. If desired the Protective Cap may also be

used to locate the center of the clearance hole by gently pushing the

back wall material against the center point of the Cap.

53/64"

MOUNTING SURFACE

CENTER MARK

Min. 1/8" (3mm)

MAKE ASPACE HERE

2- 3/8" (60mm)

WALL HOLE

DIAMETER

DO NOT

OVER-TIGHTEN

BODY

REDUCER

REDUCER

CORRECT

INCORRECT

TOLERANCE LIMIT OF

BACK-WALL LEVEL

WALL

WALL SURFACE WALL

Wrench

Socket

Protective Cap

Page:4 of 5

Document No.U028704 Date:Jan/11/2019

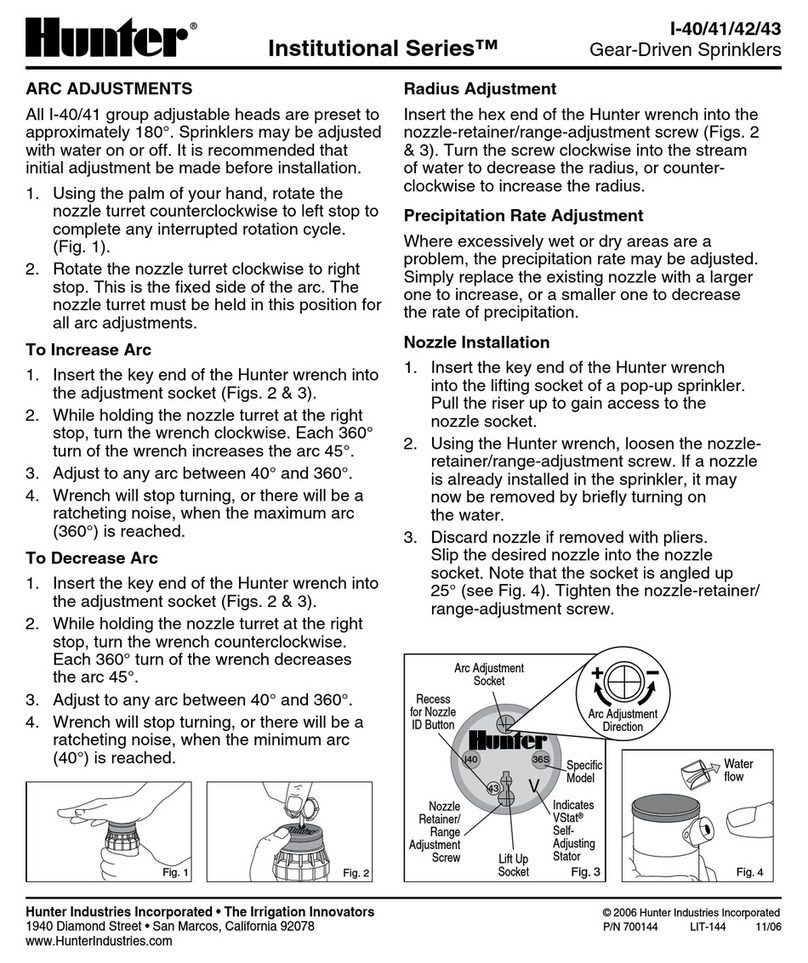

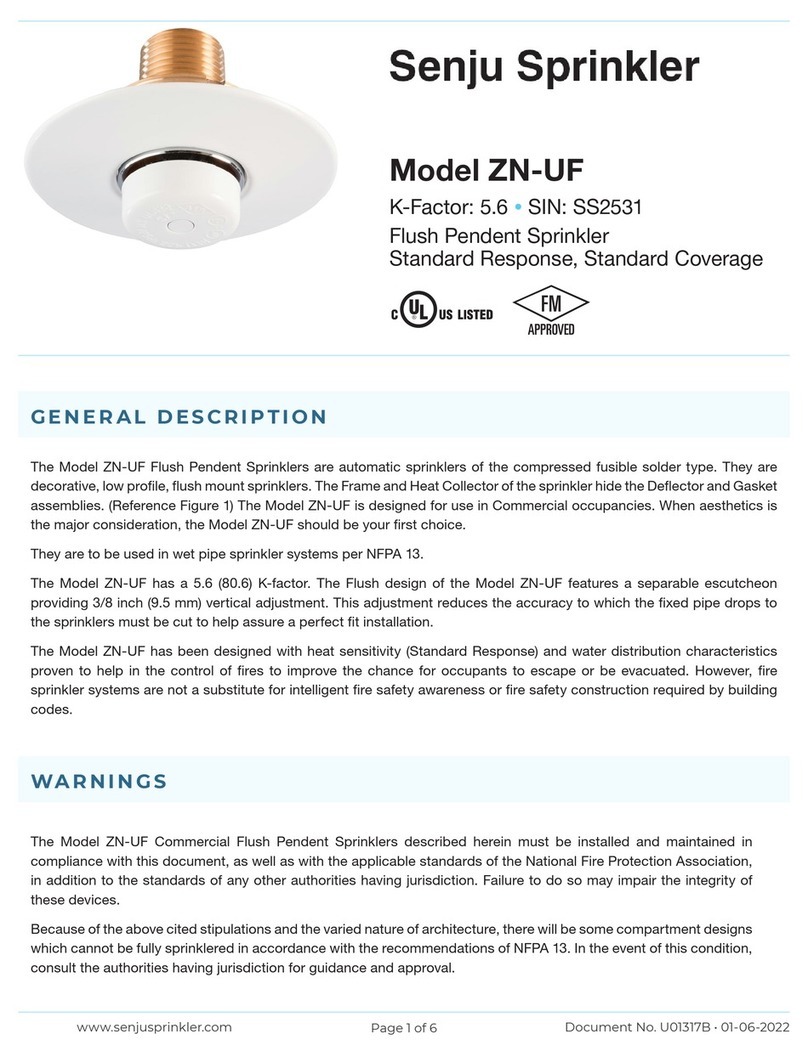

Step 6.

After the back wall has been completed with the 2-3/8inch (60mm)

diameter clearance hole, use the Protective Cap Removal Tool (Ref.

Figure 5) to remove the Protective Cap and then push on the

Escutcheon until its flange just comes in contact with the back wall (Ref.

Figure 6 & Figure 7).

FIGURE 5

FIGURE 6

Do not continue to push on the Escutcheon such that it lifts a wall out of its

normal position. If the Escutcheon cannot be engaged with the Sprinkler, or the

Escutcheon cannot be engaged sufficiently to contact the back wall, relocate the

sprinkler fitting as necessary.

FIGURE 7

Care and Maintenance

The Model HF-RES must be maintained and serviced in accordance with

the following instructions:

NOTES

Wet pipe sprinkler systems must be maintained at a minimum temperature

of40

℉

/ 4

℃

to prevent freezing and bursting of the pipe and/or sprinklers.

Automatic sprinklers are not to be tested with a heat source. Operation of the

heat responsive element can result.

Absence of an Escutcheon Plate may delay the time to sprinkler operation in

a fire situation.

Before closing a fire protection system main control valve for maintenance

work on the fire protection system, which it controls, permission to shut

down the affected fire protection system must be obtained from the proper

authorities and all personnel who may be affected by this action must be

notified.

Do NOT enclose sprinklers within drapes, curtains, or valances.

DoNOT hang anything fromthesprinklers.

Do NOT cleanse the sprinklers with soap and water, detergents, ammonia,

cleaning fluids, or other chemicals. Remove dust, lint, cobwebs, cocoons,

insects, and larvae by gently brushing with a feather duster or gently

vacuuming with a soft bristle (i.e., dusting) brush attachment.

Exercise suitable safety precautions in the use and storage of highly

flammable materials. The rapid rate of fire development and spread of which

can be caused by such materials can reduce the ability of the sprinkler

system to aid in the control of a fire in which they are involved.

Sprinklers, which are found to be leaking or exhibiting visible signs of

corrosion, must be replaced.

Automatic Sprinklers must be kept in a cool and dry place. Automatic

sprinklers must never be painted, plated, coated, or otherwise altered after

leaving the factory. Modified or over heated sprinklers must be replaced.

Care must be exercised to avoid damage to the sprinklers-before, during,

and after installation. Sprinklers damaged by dropping, striking, wrench

twist / slippage, or the like, must be replaced.

The model HF-RES must only be replaced with Horizontal Side-Wall

sprinklers which are listed for residential fire protection service and which

have the same nominal K-factor, the same coverage area, and the same or

lower flow ratings (as indicated under “Hydraulic Design Criteria”).

When remodeling, such as by adding false beams or light fixtures or

changing the location of compartment walls, first verity that the new

construction will not violate the installation requirements stated under

WARNINGS. Alter the new construction and/or the sprinkler system to suit

the requirements of this document.

The owner is responsible for the inspection, testing, and maintenance of

their fire protection system and devices in compliance with this document,

the applicable standards of the National Fire Protection Association (e.g.,

NFPA 25), and the standards of any other authorities having jurisdiction.

The installing contractor or sprinkler manufacturer should be contacted

relative to any questions.

It is recommended that automatic sprinkler systems be inspected, tested,

and maintained by a qualified Inspection Service in accordance with NFPA

25.

ESCUTCHEON

ESCUTCHEON

ESCUTCHEON

THERE MUST

NOT BE SPACE

AND FRAME

NOT ENGAGED

MOUNTING SURFACE

CORRECT

ESCUTCHEON

INCORRECT INCORRECT

WALL

Cap Removal Tool

Groove of cap

Step2

Pull out

Step1

HF-RES Sprinkler Protective Cap

ESCUTCHEON

MOUNTING

SURFACE

WALL

TOP OF

DEFLECTOR

Page:5 of 5

Document No.U028704 Date:Jan/11/2019

Order Procedure

Please Specify:

Sprinkler Head:

SS4423, Model HF-RES K=4.2, Residential Flush Horizontal

Side-Wall Sprinkler

Finishes:

White Painted, Black Painted, Dark Brown Painted,

Chrome Plated.

Escutcheon:

Escutcheon for HF-RES Flush Horizontal Side-Wall.

(O. D. 3inch/75mm)

Finishes:

White Painted, Black Painted, Dark Brown Painted,

Chrome Plated.

Accessories:

・Socket for Model HF-RES

・Wrench & Socket for Model HF-RES

・Protective Cap Removal Tool for Model HF-RES

This manual suits for next models

1

Table of contents

Other Senju Sprinkler Irrigation System manuals

Senju Sprinkler

Senju Sprinkler ZN-UF User manual

Senju Sprinkler

Senju Sprinkler RC-QR User manual

Senju Sprinkler

Senju Sprinkler HF-RES User manual

Senju Sprinkler

Senju Sprinkler CN-RES User manual

Senju Sprinkler

Senju Sprinkler CN-QR User manual

Senju Sprinkler

Senju Sprinkler ZN-QR User manual

Senju Sprinkler

Senju Sprinkler RC-QR-EC User manual

Senju Sprinkler

Senju Sprinkler FR-RES User manual

Senju Sprinkler

Senju Sprinkler RC-RES User manual

Senju Sprinkler

Senju Sprinkler SS8464 User manual