a. Base Part No. 10485 with 1/2"

(1 5 mm) NPTor

b. Base Part No. 10680 with 3/4"

(20 mm) NPT

To order the Cover Plate Assembly, re-

fer to: Part No. 09804.

NOTE:Specify temperature rating of

sprinklerandtemperatureratingandfin-

ishofcoverplateassembly(seeTable1

on page 58 d).

ACCESSORIES

Sprinkler Cabinet: Part No. 01731A

Capacity: six (6) sprinklers

Available since 1971.

Concealed Sprinkler Wrenches *:

A. Heavy Duty: Part No. 08336W/B

Available since 1993

B. Light Duty: Part No. 10366W/B**

Available since 1998

* A1/2"ratchetisrequired(notavailablefromVi-

king).

** Ideal for sprinkler cabinets.

5. AVAILABILITY AND SERVICE

Viking products are available through a

network of domestic, Canadian, and in-

ternational distributors. See the Yellow

Pagesofthetelephonedirectoryforalo-

cal distributor (listed under “Sprinklers-

Automatic-Fire”) or contact Viking.

Viking Technical Data may be found on

The Viking Corporation’s Web site at:

http://www.vikingcorp.com

The Web site may include a more recent

edition of this Technical Data page.

6. GUARANTEES

For details of warranty, refer to Viking’s

current price schedule or contact The

Viking Corporation directly.

7. INSTALLATION

WARNING: Viking sprinklersaremanu-

factured and tested to meet the rigid re-

quirements of the approving agency.

The sprinklers are designed to be in-

stalled in accordance with recognized

installation standards. Deviation from

the standards or any alteration to the

sprinkler or cover plate assembly after it

leaves the factory including, but not lim-

itedto: painting, plating, coating or mod-

ification, may render the sprinkler inop-

erative and will automatically nullify the

approval and any guarantee made by

The Viking Corporation.

A. Sprinklers must be installed in accor-

dance with the latest published stan-

dards of the National Fire Protection

Association, Factory Mutual, Loss Pre-

vention Council, Assemblee Pleniere,

Verband der Sachversicherer or other

similar organizations, and also with the

provisions of governmental codes, ordi-

nances, and standards whenever appli-

cable. Concealedsprinklers are decora-

tive sprinklers and may be considered

special purpose. Refer to the Authority

Having Jurisdiction prior to installation .

NOTE: Previous Model B-1 Cover Plate

Assembly Part Number 08310 may still be

used for ULC/UL installations .

B. Sprinklers must be handled with care.

Concealedsprinklers areprotected witha

plasticshell,whichshouldremaininplace

overthe sprinkler body during installation,

testing, and any time the sprinkler is han-

dled or shipped. The plastic protective

shellmustberemovedprior toplacing the

systeminservice. Seesection“I”belo w.

Prior to installation, sprinklers must be

stored in a cool, dry place in their origi-

nal shipping container. Never install

sprinklers that have been dropped,

damaged in any way, or exposed to

temperatures in excess of maximum

ambient temperature allowed. Such

sprinklers should be destroyed immedi-

ately .

C. Horizon®Mirage®Quick Response

ConcealedSprinklersmustbeinstalled

in neutral or negative pressure ple-

nums only.

D. U se care when locating sprinklers near

fixtures that can generate heat. Do not

installsprinklerswheretheywouldbeex-

posed to temperatures that exceed the

maximum recommended ambient tem-

peratureforthetemperatureratingused .

E. Horizon®Mirage ®Concealed Sprin-

klers are not intended for use in corro-

sive environments. Use only sprinklers

listed for corrosive environments when

subject to corrosive atmospheres.

F. Adequate heat must be provided when

Horizon ®Mirage®QuickResponse Ex-

tended Coverage Concealed Sprin-

klersare installedon wetpipe systems.

When installing sprinklers on dry sys-

tems, refer to appropriate installation

guides and the Authority Having

Jurisdiction.

G. Sprinklers must be installed after the

piping is in place to preventme chanical

damage. Before installation, be sure to

have the appropriate sprinkler model

and style, with the correct orifice size,

temperature rating, and response char-

acteristics. Install the sprinklers accord-

ing to the following steps :

1. Installallpipingand cutthe sprinkler

drop nipple to position the 1/2" or

3/4" (depending on the sprinkler)

NPT outlet of the reducing coupling

at the desired elevation. The drop

nipple must be perpendicular to the

ceilingand centeredin a2" (50mm)

diameter opening in the ceiling.

2. With the sprinkler in the plastic pro-

tectiveshell,applyasmallamountof

pipe-joint compound or tape to the

external threads of the sprinkler

only, taking care not to allow a

build-up inside the sprinkler inlet .

3. Use only the special wrenches de-

signed for installing Horizon ®Mirage ®

Concealed Sprinklers. With the sprin-

kler in the plastic protective shell,

place the unit into the wrench .

4. Turn the unit clockwise to thread the

sprinkler into the 1/2" or 3/4" (de-

pending on the sprinkler used) NPT

outlet of the coupling. DO NOT use

the fusible link to start or thread the

sprinkler into a fitting.

H.Afterinstallation,theentiresystemmust

be tested in accordance with recog-

nizedinstallationstandards.Thetestis

appliedaftersprinklerinstallationtoen-

sure that no damage has occurred to

thesprinklerduringshippingandinstal-

lation, and to make sure the unit has

beenproperlytightened.Ifathreadleak

occurs, normally the unit must be re-

moved, new pipe-joint compound or

tape applied, and then reinstalled. This

is due to the fact that when the joint seal

leaks, the sealing compound or tape is

washed out of the joint .

I. After testing, repairing of all leaks, and

installation and painting of the ceiling,

the cover plate assembly may be at-

tached.

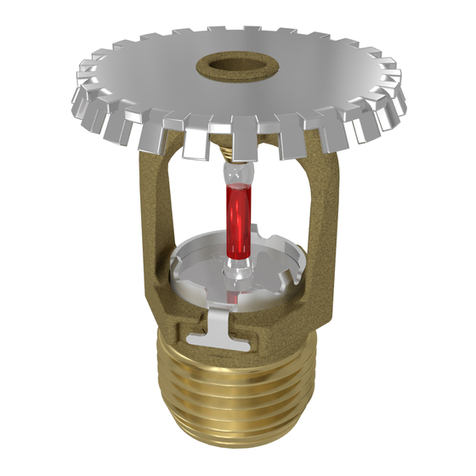

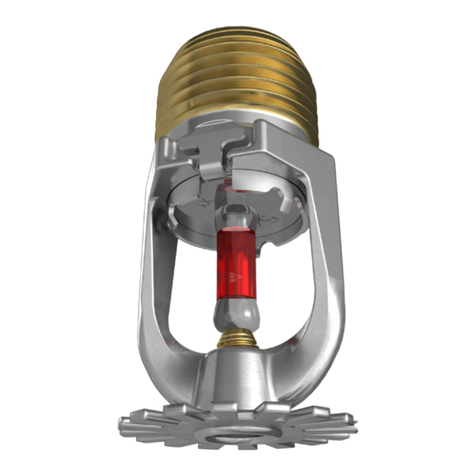

Sprinkler 58 b

1/2" NPT Sprinklers:

P/N 08498 (std. orifice)

P/N 10485 (large orifice)

3/4" NPT

Sprinkler:

P/N 10680

(large orifice)

Protective

Shell

May 25, 2000

TECHNICAL DATA

HORIZON®MIRAGE®

QUICK RESPONSE

EXTENDED COVERAGE

CONCEALED SPRINKLERS

Figure 1

Concealed Sprinkler Wrench** Part No.

08336W/B (shown) or Part No. 10366W/B

**A 1/2" ratchet is required (not available through Viking).