BIGREP ONE GENERATION 3 Release Note

TECHNICAL HANDBOOK

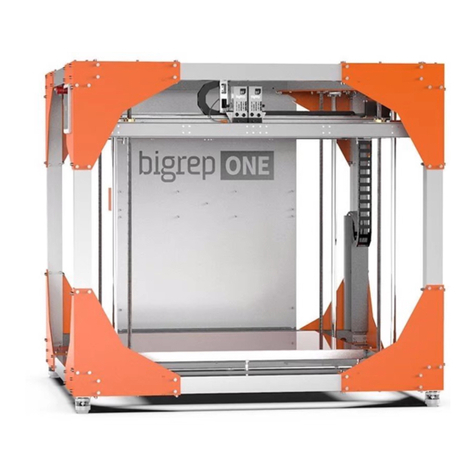

BIGREP ONE – LARGE SCALE 3D PRINTER

GENERATION 3 (01/2016)

2016/05/23

0. General Infos / Updates BigRep

General Infos

Whenever an update in the technical manual appears you can download this

updated subchapter in the reseller portal. Recent changes will be listed in the

changelog.

Please replace updated subchaptersin the printed manual.

Chapter No. Topic Last Update

I Mechanics I-A Overview 2016-04-07

I-B Table / Bed 2016-04-07

I-C End stops 2016-04-07

I-D Portal 2016-04-07

I-E Extruder 2016-04-07

I-F Spool cabinet 2016-04-07

I-G Machine base with brakes 2016-04-07

II Electric II-A Overview 2016-04-07

II-B Control Unit 2016-04-20

II-C Security stops 2016-04-07

II-D Extruder Wiring 2016-04-07

II-E PC 2016-04-07

III Soware III-A Overview 2016-04-07

III-B Firmware 2016-04-07

III-C Config 2016-04-07

III-D GUI 2016-04-07

III-E Pronterface 2016-04-07

III-F G-Codes / M-Codes 2016-04-07

IV Setup IV-A Overview 2016-04-07

IV-B Operating Environment / Requirements 2016-04-07

IV-C Unpacking 2016-04-07

IV-D Visual inspection 2016-04-07

IV-E Photo Documentation 2016-04-07

IV-F Electric Setup 2016-04-07

IV-G Assembling 2016-04-07

IV-H Basic Function Test 2016-04-07

IV-I Pre Autoleveling 2016-04-07

IV-J Auto Leveling 2016-04-07

IV-K Extruder 2016-04-07

IV-L Test Prints 2016-04-07

V Maintenance V-A Overview 2016-04-07

V-B Replacing Print Bed Tape 2016-04-07

V-C Replacing Nozzle 2016-04-07

V-D Replacing Extruder 2016-04-07

V-E Check stepper value axis 2016-05-07

V-F Lubricate 2016-04-07

V-G Belts 2016-04-07

V-H Leveling 2016-04-07

V-I Soware 2016-04-14

VI Appendix VI-A General Info 2016-04-07

VI-B Shipping/requirements/Unpacking 2016-04-07

VI-C Maintenance Config Overview 2016-04-20

VI-D Getting Started Simplify3D 2016-05-23

0. General Infos / Updates BigRep

Chapter Overview / Versiontracker

0. General Infos / Updates BigRep

Changelog / update history for technical manual

2016-05-23

New chapter structure all versions

VI-D New Subchapter ‘Starting Guide Simplify3D’ all versions

2016-04-20

II-B New jumper settings in config for ONE.3b only ONE.3b

VI-C Maintenance Config Overview: new config all versions

VI-C New stepper values in config for ONE.3b only ONE.3b

VI-C New jumper settings in config for ONE.3b only ONE.3b

I. Mechanics BigRep

I Mechanics

I-A Overview

* 2016-04-07

Red marked screws must be provided with toothed washer to guarantee proper

grounding

BedFrame

Portal

I-A 1/3

I. Mechanics BigRep

x

y

z

I

B

C

D

E

A

AControl panel (Fig. 3-2)

incl. touch screen

B Z-guide shas (4 pcs)

C Z-lead spindels (4 pcs)

DFilament guide

E Print Bed

G Mobile machine base (4 pcs)

I Extruder (2 pcs)

G

I-A 2/3

I. Mechanics BigRep

M

D

O

N

P

SR

T

MFilament spool holder

NControl cabinet

O Main switch with door

lock

PEmergency stop button

RTouchscreen

SReset

TUSB port

I-A 3/3

I. Mechanics BigRep

I-B Table / Bed

* 2016-04-07

Overview

›BigRep ONE comes with a heated (aluminum) printing bed, incl. polyamide

printing tape which can be replaced.

›The heated bed and polyimide tape ensures that the first layers stick to the

bed.

›The attachment of the bed is directly mounted to the frame.

›The bed is heated by two heating mats, glued to the rear side of the table.

›The bed is float mounted to assure expansion while heated.

›The height of the bed can be adjusted – but this is only necessary once

during the setup and should not be done by the customer.

›The adjustment of the bed is important to ensure correct leveling proce-

dure.

›The bed can be heated up to 85°, 60° is regular printing temperature.

I-B 1/1

I. Mechanics BigRep

I-C End stops

* 2016-04-07

Overview

End stops are the datum of each axes and make sure that the printer knows where

it is.

In general you need at least 3 end stops, 1 for each axis to define the homing

position.

BigRep end stops (see figure next page)

BigRep ONE comes with 6 optical end stops, two for each axis. The three addi-

tional end stops make sure that the printer always knows the maximum position

of each axis, even when the operator used the wrong build volume during slicing.

X- and Y-end stops are both fixed and not allowed to change.

The height of the Zmin end stop has to be adjusted during the setup to define the

correct ratio between end stop and height of the printbed.

→ To adjust the correct height for Zmin end stop please have a look at →V-H Lev-

eling

I-C 1/2

I. Mechanics BigRep

132

4

1

3

2

4

1 Xmin Homeposition X-axis

2a Xmax End position X-axis

2b Ymin Homeposition Y-axis

3 Zmin Homeposition Z-axis

adjustable

4 Zmax End position Z-axis

2a

2b

I-C 2/2

I. Mechanics BigRep

I-D Portal

* 2016-04-07

Overview

BigRep has three moving Axis, X, Y and Z. If you are standing in front of the printer

the movement of the axis is as following:

›X-Axis: moves the extruder in X direction from le to right.

›Y-Axis: moves the X-Axis Y direction from front to back

›Z-Axis: moves the X-Axis and Y-Axis (portal) up and down

Mechanical Description

X-Axis and Y-Axis are driven by one stepper motor (Nanotec) each + belt and pul-

ley.

Z-Axis is driven by one stepper motor (Nanotech) + belt and several pulleys

Maintenance

Please have a look at section V - Maintence of the technical manual for further in-

formations.

All motors and pulleys can be replaced if needed.

X- and Y-Axis are using self-lubricated carriages and have to be lubricated with

industrial grease about once a year. We recommend mineral oil-based lubricants.

All belts have to be lubricated with silicon spray about once a year.

It is important to check the tension of the belts, which should be around 20Hz.

Note

As Silicon and Grease react with each other, please make sure that you never put

silicon spray at the X- or Y-Axis.

I-D 1/

I. Mechanics BigRep

I-E Extruder

* 2016-04-07

Overview

The extruders are the main unit for 3D printing with the BigRep ONE. The extruder

contains the hot end (n) where the filament is heated and then squeezed through

the nozzle (o).

The BigRep ONE is equipped with two extruders which can be changed individ-

ually. Given the two extruders, the two nozzles can be used simultaneously for

separate printing projects (with the same or diering diameters), e.g. to print ad-

ditional support material for supporting structures alongside the main object.

If you want to use other nozzle diameters than the ones installed, the extruders

need to be retrofitted. You can either replace the entire extruder or only the hot

end. In both cases the extruder must first be removed from the machine.

aFilament guide with sponge kPin hole

bLever filament drive lScrews to remove front cover

cIdler wheel mMain filament drive wheel

dFilament cooling fan nHot end with nozzle

eHot end cooling fan oNozzle

fKnob for extruder attachment screw pFilament cooling duct

gMain cooling fan qAccess hole for screw to

remove hot end

hElectrical connectors

a

e

f

c

g

h

f

k

b

l

d

I-E 1/6

I. Mechanics BigRep

.

Front RightLeft Back

Filament cleaning sponge (filament must be fed

through this when loading new filament)

2x Screws to

remove

Front Cover

Lever to release idler

wheel spring. Push to

the right to load /

unload filament

Knob for extruder

attachment screw

Main cooling

fan (always on)

Hot-end cooling

fan (always on)

Filament cooling fan

(turned on/off by

software during print) Nozzle heater

(HOT, do not touch!)

2x Electrical

connectors

(different sizes)

Hole + Slot

(aligns to printer when

installing extruder)

BigRep Logo

(lights up when

extruder is

connected)

Idler wheel spring

adjustment

Access hole for screw

to remove hot-end

Extruder Features

I-E 2/6

I. Mechanics BigRep

X-Stage

Mounting the extruder

Step 1:

Extruder slides straight

back onto X-Stage mount

Step 2:

First engagement is with the attachment screw. User

begins screwing it in by hand to pull extruder back

Step 3:

Pins line up with extruder hole / slot

Step 4:

User hand tightens attachment screw to

secure extruder Step 5:

User makes 2x electrical

connections on back of extruder

I-E 3/6

I. Mechanics BigRep

X-Stage

Adjustment to set height of nozzle

T1 extruder shown in “down /

lowered / active / printing” position

T0 extruder shown in “up /

lifted / standby” position

Adjustment knob to adjust height of extruder &

printing nozzle. Note: This adjustment must be

done when extruder is in the “down” position

Locking nut, used to lock the rotation of the

adjustment knob after the nozzle height is set

I-E 4/6

I. Mechanics BigRep

User Accessible Components

Shown with front cover removed

Main filament

drive wheel

Idler wheel

Turn this direction to

increase idler wheel

spring pressure

I-E 5/6

I. Mechanics BigRep

Auto Leveling

BigRep ONE comes with an auto leveling X-Axis to Bed

The laser sensor is mounted to the X-Axis le from the extruder

The sensor measures the distance between X-Axis and Bed

Before you start a print, the sensor measures (with 3 points) the distance be-

tween Axis and Bed + automatically levels correct z-height during a print in case

the planarity is not 100% correct in total

The laser cannot balance minimums and maximums within the bed.

I-E 6/6

I. Mechanics BigRep

I-F Spool cabinet

* 2016-04-07

adjustable roller

adjustable sponge

I-F 1/1

I. Mechanics BigRep

I-G Machine base with brakes

* 2016-04-07

To change the height and for horizontal alignment adjust the idler wheel at the

machine base as shown and check the frame’s horizontal alignment with a spirit

level.

I-G 1/1

II. Electric BigRep

II Electric

II-A Overview

* 2016-04-07

Printer configuration: 200-240V, needed: at least 200V & 16 Amp

Preassembled Schuko Plug can be replaced

II-A 1/1

Table of contents

Other BIGREP 3D Printer manuals