9

3DISON AEP User Manual

Check if the filament is built up

normally in circle shape.

(This process goes on for

about 30 seconds)

Press OK button to stop loading.

Push the filament into the blue

cap on the extruder by pressing

the spring block until you feel

the motor pulling in it. Wait until

you see the filament coming out

from the extruder nozzle.

567

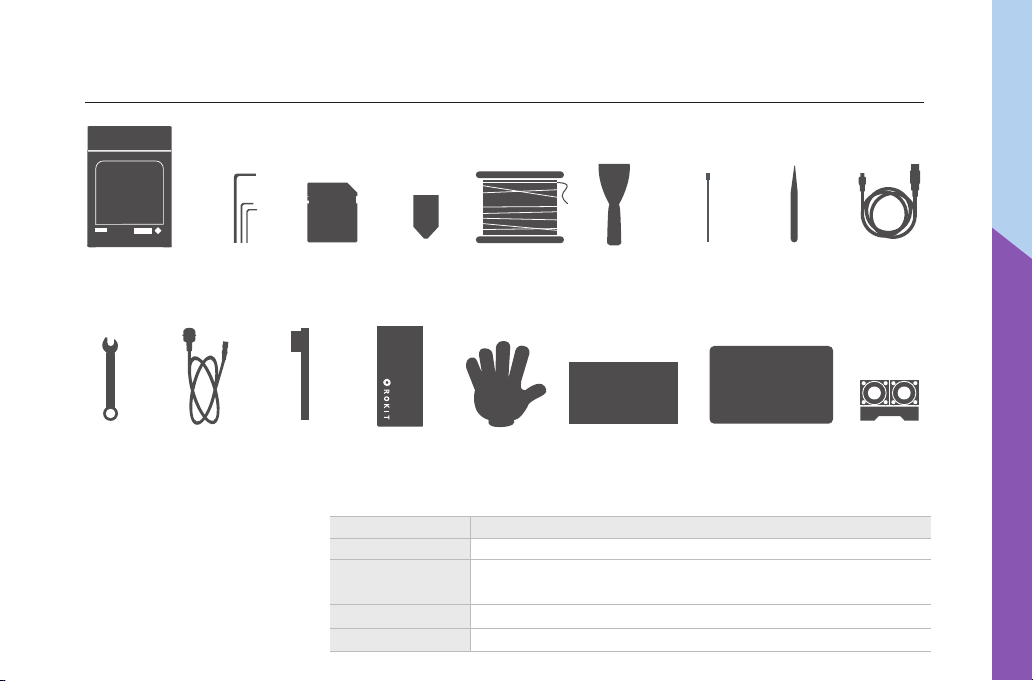

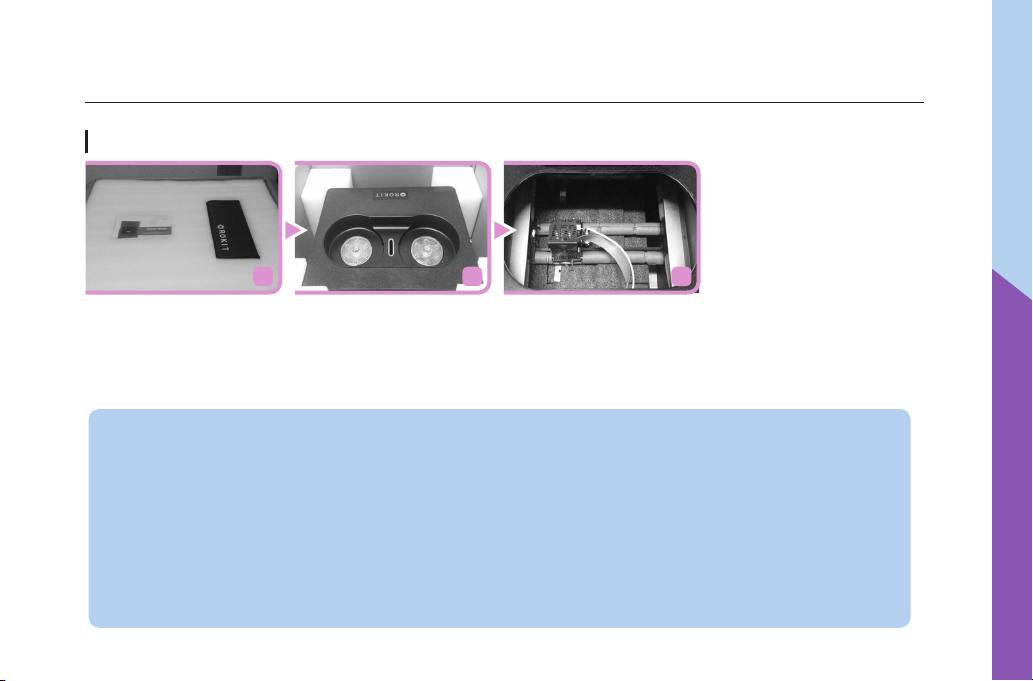

Loading Filament

Select Load Right or Load Left

depending on which side you

want to load the filament. Then

the extruder will start preheating.

(Left Hot-End : PLA, ABS, PC)

(Right Hot-End : ULTEMTM resin

grade 9085)

Go to the LCD panel and select

Utilities > Filament Loading.

When the extruder is completely

heated with alarm, put the

filament spool into the roof case

and insert filament into the hole

located in the middle of the roof

case.

Open the front door and check

if inserted filament is in, then

move extruder to the middle.

1 2 3 4

How to use 3DISON AEP

※

Please use separated

nozzle when using ULTEMTM

resin grade 9085.

(Right Hot-End)

※ ULTEMTM is a registered

trademark of SABIC or its

affiliates or subsidiaries.