Bihong Q-JET User manual

广州碧宏印刷设备有限公司

地址:广州市番禺区石碁镇南浦村市莲路 32 号众信企业园 B栋

Guangzhou Bihong Printing Equipment Co., Ltd.

ADD: Building B, No. 32 Nanpu Village, Shilian Road, Shiqi Town, Panyu

District, Guangzhou City, China

0

Q-JET

Operation Manual

This Manual is including introduction, operating, maintenance and information about

electrical parts and pressure of the printer

1

Chapter 1 Safety!………………………………………………Page 2

Chapter 2 Company Profile ……………………………………Page 7

Chapter 3 Product Introduction ………………………………Page 8

Chapter 4 Operation Instruction ………………………………Page 12

Chapter 5 Electricity, Air Pressure and Ink

Channels ……………………………………………………Page23

Chapter 6 Service and

Maintenance …………………………………………………Page 28

Chapter 7 Common Problems

and Treatment ………………………………………Page 32

目录

2

Those signs are to make sure operators to use the machine safely, prevent injuries to human and damages

to machine. There are 3 levels as 'Note, Warning, Danger' due to different damages or urgency. Safety is

priority when operating this machine!

Note

Risk of injuries to someone and damages to parts if mis-operation.

Warning

Risk of huge injuries or death to someone if mis-operation

Danger

Risk of huge injuries or death to someone if no avoid of this urgent danger

Warning

1. The usage of this product is determined and responsible by the designer or constitutor, because

of the diversification of working conditions, and the necessity of analyzing and testing the

expected performance and safety of this system. If reconstruction, please refer to newest product

information and specification, and consider of potential malfunction.

2. This product must be mechanically installed, operated, and serviced by personnel who has

enough knowledge and experience.

3. Make sure to use and disassemble this product under mechanic/equipment safety.

Use or maintenance mechanic parts/equipment after confirming prevention of

incontrollable falling parts and moving.

Disassemble mechanic parts/equipment after safety precautions above are confirmed, main

power is cut off and specific attentional items are clear.

Reboot mechanic parts/equipment after confirming prevention of un-expectable movement

and malfunction

4. Consult our company beforehand if use this product under conditions or environment below,

meanwhile considering safety regulations.

Outdoor or direct sunlight or other conditions and environment not mentioned in this

manual.

Near nuclear, railway, aircraft, spaceship, ship, vehicle, military, medical, drink/food

equipment. Near burning unit, entertainment facilities, emergency cut-off circuit, Clutch for

punching machine, brake circuit, safety equipment and etc.

In the condition of greatly effecting human body and property, especially safety caution

needed.

When using interlock circuit, set double interlock and mechanically protect against

malfunction. Also periodically check these protection system if working properly.

Chapter 1 Safety!

3

Warning

This product is provided to manufacturing industry and peaceful places. For other

purposes, please advise to our company and change specifications and agreement.

■Limited Warranty/Applicable Conditions

This product is applied to “Limited Warranty”,“Applicable Conditions” below

Please use this product based on content below

『Limited Warranty』

1. Warranty is 1 year from start of using this product. (※1)

2. Replacement or Parts changing is under 1 year warranty only/if we are responsible

to those errors and damages.

3. Please refer to other warranty specifications.

※1 Print-head is not applicable to this warranty statement

『Applicable Conditions』

Must comply with local currency and trading laws and regulations when exporting this

product.

■Sign Description

Sign

Meaning of signs

Prohibited (Not allowed )

Details will show in the signs or indicated by drawing or in literal

Force to(Must do)

Details will show in the signs or indicated by drawing or in literal

■About Operator

1. This manual is for operator who has enough knowledge and experience, to operate, assemble

and maintenance the equipment

4

2. Please read and understand this manual carefully, to assemble, operate and maintenance the

equipment.

■Safety Attentions

Warning

■Don’t disassemble/rebuild/fix by oneself (including PCBs and Print-heads)

Could cause human injuries or machine damage

■Don’t use this product out of specification range

.Don’t use flammable or human-harmful gas or airflow

.Using this product out of the range could cause fire, malfunction, damage and etc.

.Please use it base on specifications confirmed.

■Don’t use it in inflammable and explosive condition

Could cause fire and explosion

This product is not constructed with anti-explosion system

■Don’t use it in electrostatic field

Could cause system errors

■In the case of using in interlock circuit

.Please set multiple interlock circuit constituted by other systems(mechanically protection

function)

.Periodically check the protection system if working properly

Could cause accident by malfunction

■In service or maintenance

.Main power off

.Air pressure released

Could cause human injuries

Warning

■Don’t touch wire connectors and terminals when power is on

Could get a electrical shock, malfunction, switch damage and etc

■After service or maintenance, check appropriate function and leakage.

When there is malfunction or leakage, stop running it

When there is leakage or sensor damage, must turn off power and air pressure

Don’t supply air pressure when there is leakage

5

Mis-operating without safety sense is not allowed

■Operation Attentions

●Operation Matters

* Assembly and installation

.Please follow rules to tighten screws

If over tight, could break the screws or tools. If not tight enough, screws and parts to be

tight could loose and move

.Do not touch surface of print-head by hand during installation, or it could reduce print

quality

.Leveling

If not leveled, will cause bad print and Print-head damage

.Do not drop, hit, crash

It could damage the accuracy of assembly, and make parts malfunction.

.Make sure tubes and fittings are firmly connected when installing tubes in the machine

If not, could cause air or ink leakage

.Use an air-gun to blow out dust or dirt before assemble the tubes

Or it could cause parts damage or malfunction

* Operation Condition

.Do not use it near water place.

Or it could cause error, malfunction. Please use isolation room or chamber.

.Do not use it near corrosive gases or liquid.

It could cause parts/equipment damage, print-head damage, malfunction

.Do not use it near electricity surge place.

It could cause damage circuit element or relative parts by electricity-surge equipment

such as electromagnetic elevator, electromagnetic oven, motors etc. Please also separate

the cables from electricity surge of power supply and do not use electricity-surge load.

.There is no specific tolerance of thunder-strike in CE certification, please set up protection

unit from lightening for the equipment. Excessive interference will change settings even if

this is a CE certificated product.

.Please install it in a non-quake, non-crash place.

Or it could cause errors and malfunction

.Please avoid of any wiring debris falling into the equipment

6

Or it could cause errors and malfunction

.Do not use it in widely-fluctuate temperature place.

Over the normal temperature, it could effect badly the ink and inner parts of the

equipment.

.Do not use it in direct sunlight

Shelter from direct sunlight, or could cause errors and malfunction

.Make sure temperature of ink and working condition, and humidity is within the specific

range when using the equipment

Temperature is at the range of 20~30 °C, humidity is at a range of 60%~70%RH

If the temperature is too low or too high, print heads could be damaged because the ink

characteristics change. If the humidity is too low, ink will dry up at the surface of nozzle of

print head.

.Pleas do not use it in a place containing hot resource and radiation.

Or it could cause bad movement

7

Bihong○

TM Printing Machinery Co, Ltd ( Pingyang Shunlong Packaging Machinery Co, Ltd )was

founded in 2008, owns the brand machine, cutting machine, bag-making machine and other

related equipment.

BIHONG○

TM and Guangzhou Bihong Printing Equipment Co. Ltd was established in 2016. We

have our own professional R&D team, specialized in researching, producing and selling high

quality automatic screen printing machine, digital printing

For now, most enterprises face with the recruitment difficulty, especially the work of screen

printing type is more difficult to recruit, the product profit shirking. Our company adheres to

the "improve the production efficiency, reduce production costs, reduce the number of

labor"as our own duty, and is committed to providing customers with high quality digital

printing machine and automatic oval t-shirt printing machine. Our equipments are now

widely used in printing material of t-shirt, PVC/PET/PC/PE, paper, cloth, leather, sticker,

non-woven fabric, textile and so on.

We enjoy much reputation abroad due to our strong ability, professional staff and perfect

after-sales service. Recently, with our continuous efforts, innovations and rigorously quality

control, we have received increasing orders from all over the world.

We will continue to develop our skills and designs to meet the demands of our clients all

over the world

Copy rights reserved by Bihong○

TM , any infringement will be investigated and affixed

legal liability. There may be some errors in the manual, it is welcome to point out and

correct them. To make better manual to make better service.

Chapter 2 Company Profile

8

1. Overview

Q-Jet is specially built by Bihong○

TM , for combining oval machines. This hybrid system

can print very accurate, with less screens but more colorful digital printing images,

while oval machine is doing traditional screen printing such as water-base, binder,

plastisol, flock, foam, flicker, cube, jelly, cracker, metal etc. It is a combination, can

fulfill garment and cut-piece print, of advantages of traditional printing technology and

modern digital printing technology.

Q-Jet is installed by Dimatix SG1024 industrial print-heads (made in USA), 4-color

printing, with high speed and resolution.

2. Structure

A. Overview Description

a. 3-Color ALARM, to give alarm when there is an attention or problem

Light color

status

Alarm for

Note

b. LCD Display

c. Electrical Cabinet

d. Operating Platform

f. Pallet

g. Head Carriage

a.3-Color ALARM

Chapter 3 Product Introduction

e. Front Door

9

Green

Blinking

Printing

Yellow

On

Ready

Red

Blinking

Error Alarm

Need to check or inquire of supplier

b. LCD display, for the computer controlling system

c. Electrical Cabinet, main control circuit and ink and air channels

d. Operating Platform, operating and controlling the equipment

e. Front Door (Back Door), do not open the doors when operating the equipment

f. Pallet, the main platform for printing for loading fabrics

g. Head carriage, a core component for digital printing

B. Operating Platform

a. P. pressure gauge, displays Positive Pressure.

b. N. pressure gauge, displays and controls Negative Pressure

c. Emergency Stop button, stops danger movement but not powers off.

d. Start button, turns the power on.

e. Mouse, controls the computer

f. Keyboard, controls the computer

g. Touch Screen, a control interface of the equipment

e. Mouse

f. Keyboard

g. Touch Screen

a. P. pressure gauge

b. N. pressure gauge

c. Emergency Stop

d. Start Button

10

C. Head Carriage

a. Head Board, Control and drive print heads

b. Ink Cartridges, Core Parts for Printing to supply ink

c. Ink Recirculation Cartridges, same like ink cartridge but lower For ink

recirculation

d. Ink Supply Distributor, Core Parts for printing to supply ink

e. Right Safety Bar, to avoid hitting the heads in case of getting obstacles inside

f. Left Safety Bar, to avoid hitting the heads in case of getting obstacles inside。

g. Print Heads, Most Core Print Components

h. N. pressure box, stabilize Negative Pressure and store waste ink if bubbles come

in

a. Head Board

b. Ink Cartridges

c. Ink Recirculation Cartridges

d. Ink Supply Distributor

e. Right Safety Bar

f. Left Safety Bar

g. Print Heads

h. N. pressure Box

11

D. Capping and Cleaning Component

a. Capping Station, Capping the nozzles when the machine is turned off, to avoid

air comes in to dry up and make clogging. And please note, these caps need to

be cleaned every day

b. Cleaning Station, when cleaning , the wipers will wipe off the ink drops on the

nozzles. And please note, these wipers need to be cleaned every day

Capping Station

Cleaning Station

12

1 Touch Interface

1.1 Homepage (Main Interface)

1Set number of printed to clean heads automatically

2Production Count, reset to zero

3Set correct fabric thickness to keep correct print height

4Show status including pumps, online/offline, n.pre. cartridge, more details in Para.4

this chapter.

5Show current height

6Clean heads when there are clogging or white lines. Please refer to [Chp4-1.3

Settings] to set more

7Clean and cap the nozzles before powers off automatically

8Production mode active/de-active with oval machine.

9Pause printing

10 Provide information about our company

11 Press to change CHN/ENG language

12 Set parameters and adjustment for equipment in settings interface

13 Operation related to Printing

2

1

3

7

6

10

9

8

4

11

12

13

5

Chapter 4 Operation Instruction

13

1.2 Printing Interface

1Press to print selected image in PrinterManager (computer interface)

2Print Nozzles Check pattern

3Pause/Resume current print job

4Abort current print job

1.3 Settings

A. Pneumatic and Ink system

1Set purge time to clean heads

2Purge and wipe to clean heads

②

③

④

①

1②

②

③

④

⑥

⑤

⑦

⑧

⑨

⑩

14

3Not Full:Waste ink is not full in the N. pres. cartridge (normal)

Full:The N. Pres. Cartridge is full of waste ink, this is abnormal. Must use N.

Pres. Pump to pump out the waste ink.

4N. Pres. Pump:For pumping out the waste ink in the N. Pres. Cartridge (it works

only when pressing)

Note:In case of air leakage, the tube below is normally disconnected. Connect it

by the quick couplers before pumping.

5Ink Channel Selection:Selection working ink channels, normally CMYK all

selected.

6Stop Recirculation:Stop recirculation pump separately in maintenance if needed

7Stop Supplying:Stop supplying ink if needed

8Force Recirculation:Keep recirculation pump running all the time

9Force to supply ink:Force to keep supplying pump on all the time

10 Purge all:Purge all will purge all colors, purge single color if press K/C/M/Y

separately

15

B. Manual Interface

1Off line mode, move head carriage/crossbar to 4 directions manually.

2Move head carriage (Z) up or down. Back to Homepage at normal height

3Move Capping Station up or down, with lights on up/down limit

4Move Maintenance tray up or down, with lights on up/down limit

5Turn off power of the boards separately

6Show current Z-position

7Adjust the speed of manual Y (crossbar) movement

8Adjust the speed of manual X (head carriage) movement

C. I/O Monitoring

Check all current I/O status, to help solve problems.

2②

1②

3②

4②

8②

5②

7②

6②

16

D. Alarm Record

Recording Alarm information

E. Advanced Setup

For advanced engineer limited mode, please contact us for further information

F. Homepage

Back to homepage (main interface)

1.4 Status

1Show Offline mode status, can’t print in this mode

2Show Full/Not Full in Negative Press Cartridge

3Ink supply timeout, press indicated color if supplying needed

4Recirculation timeout, press indicated color if recirculation needed.

2

1

3

4

17

2 Printer Manager (PM)

A. Homepage

1Functional settings

2Preview Image. Please note, color and direction showed are not correct.

3Define work fold and show preview of prt files.

4Print list. Add print-able prt files to the list and select it then press

to print

5Error List. List error messages and codes.

6Main Menu. To adjust set parameter backup, calibration and voltage, etc

7Show image information

8The printer's current status display, and printing can be done only when it is ready.

Functional settings

Icon

Function

Details

Note

Add new job

Add new print job, ripped by PP

Delete

Delete selected print job in the list

Print

Print selected job

Pause/Resume

Pause/Resume Printing job

Abort

Abort printing job

4

7

3

2

6

8

5

1

18

Nozzles Check

Check nozzles, clean it if needed

Clean

Clean heads if needed

Spray

Spray ink to jet out little surface

clogging

Move to left or

right

Move the head carriage manually

Forward/Backw

ard

Move the head carriage manually

X home

Move head carriage to X home

position (note 1)

Y home

Move head carriage to Y home

position (note 1)

Printer settings

set print mode, feathering, language

and so on

Set X origin

Print starts at this point on X direction

Set Y origin

Print starts at this point on Y direction

Step

Step adjustment with different pass

modes

Select Pass

Select correct pass with RIPPED

file(note 2)

Select speed

Select different speed with different

print quality (not3)

Bi-direction

Check box with bi-direction print,

uncheck with right-direction print(not

3)

Y back home

Check box, head carriage auto-move

back to home position

Note 1:the home position means head carriage in standby position

Note 2:pass mode selection, 4 pass means 720(600)x800dpi, 6pass means

720(600)x1200dpi

Not e 3:check bi-direction value in the calibration menu when use

bi-direction print. Adjust the value when there are double lines or printed

image is fuzzy.

19

B. Printer settings

1. Printer settings

1.1 Printer Settings(Note 4)

a. Auto Skip White:The white edge of the image will be skipped without

printing or scanning

b. Y continue print :

if check box, print starts from current Y position. Uncheck

is default

c. Feather Type:different feather type options.

d. Feather:Choose the degree of feathering according to the need, weak,

medium, strong and none. The higher the degree of feathering, the lower the

printing efficiency.

e. Multiple Ink: you can increase the amount of printing ink, while printing the

number of Pass also need to be increased by the same multiple.

1.2 Media

a. X Width:Set the printer's X-direction working width, which is the software

limit protection.

b.Y Height:

Set the printer's Y-direction working paper height, which is the limit

protection of software.

1.3 clean Settings

Table of contents

Other Bihong Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Eaton

Eaton Airflex DBB Assembly instructions

Kooltronic

Kooltronic KNHE24 Operator's manual

WEISS ROBOTICS

WEISS ROBOTICS GRIPLINK manual

Stuart Turner

Stuart Turner FLANGE SIDE ENTRY installation instructions

Emerson

Emerson Yarway Installation, operation and maintenance instructions

Hawk

Hawk 2082-MF instruction manual

Zimmer

Zimmer MATCH LWR50L-27 Series Installation and operating instructions

Bradley

Bradley Lenox Lockers Installation

Cassese

Cassese 910 JR owner's manual

Mitsubishi Electric

Mitsubishi Electric MDU-BN instruction manual

Husky

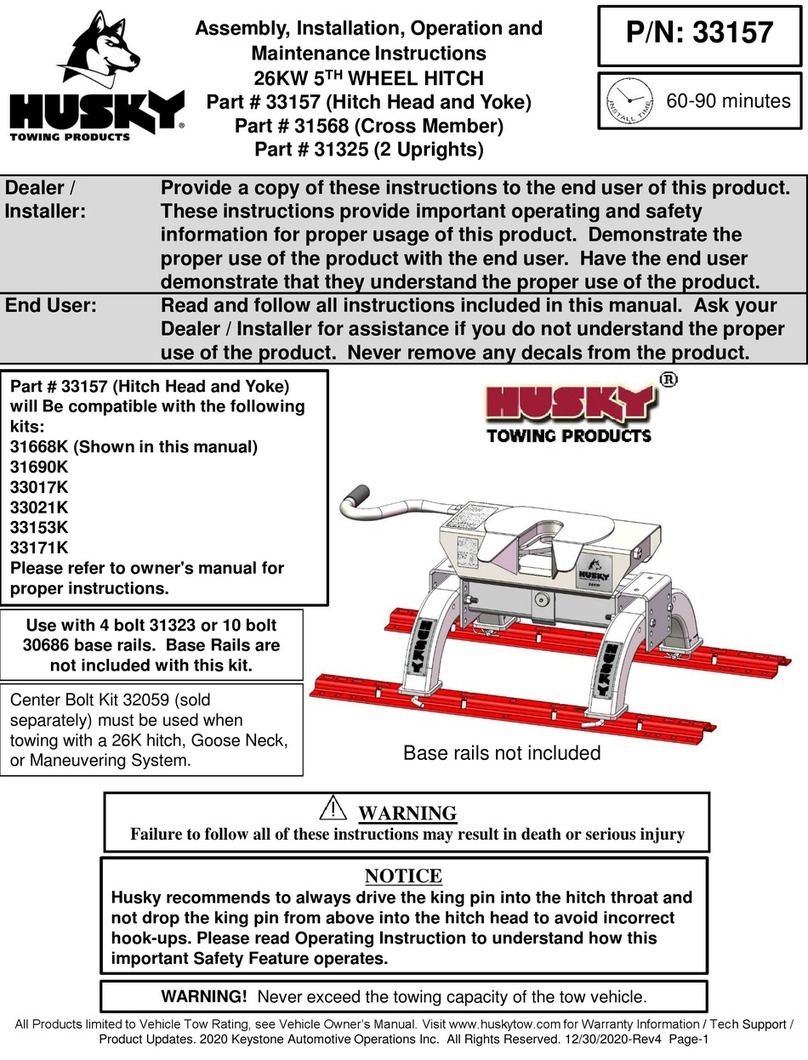

Husky 33157 Assembly, Installation, Operation and Maintenance Instructions

Virutex

Virutex EB140PLC Premilling Annex Operating Instructions